General 5

© Lutz-Jesco GmbH 2018

Subject to technical changes.

180108

BA-12604-02-V02

Multi-function valve PENTABLOC Operating instructions

2 General

2.1 General warnings

The following warnings are intended to help you to eliminate the dangers

that can arise while handling the product. Risk prevention measures al-

ways apply regardless of any specific action.

Safety instructions warning against risks arising from specific activities

or situations can be found in the respective sub-chapters.

WARNING

Danger from unsuitable materials

The materials of the dosing pump and hydraulic parts of the system

must be suitable for the dosing medium that is used. Should this not be

the case, the dosing media may leak.

ðMake sure that the materials you are using are suitable for the

dosing medium.

ðMake sure that the lubricants, adhesives, sealants, etc. that you

use are suitable for the dosing medium.

ðWear appropriate personal protective equipment, especially for

the protection of eyes and skin.

CAUTION

Danger when changing the dosing medium!

Changing the dosing media can provoke unexpected reactions, dam-

age to property and injury.

ðClean the dosing pump and the system parts in contact with the

media thoroughly before changing the dosing medium.

2.2 Hazards due to non-compliance with the safety

instructions

Failure to follow the safety instructions may endanger not only persons,

but also the environment and the device.

The specific consequences can be:

ndanger for individuals through dangerous dosing media,

ndanger to the environment caused leaking from the system.

2.3 Personal protective equipment

Based on the degree of risk posed by the dosing medium and the type of

work you are carrying out, you must use corresponding protective equip-

ment. Read the Accident Prevention Regulations and the Safety Data

Sheets to the dosing media find out what protective equipment you need.

You will require the minimum of the following personal protective equip-

ment:

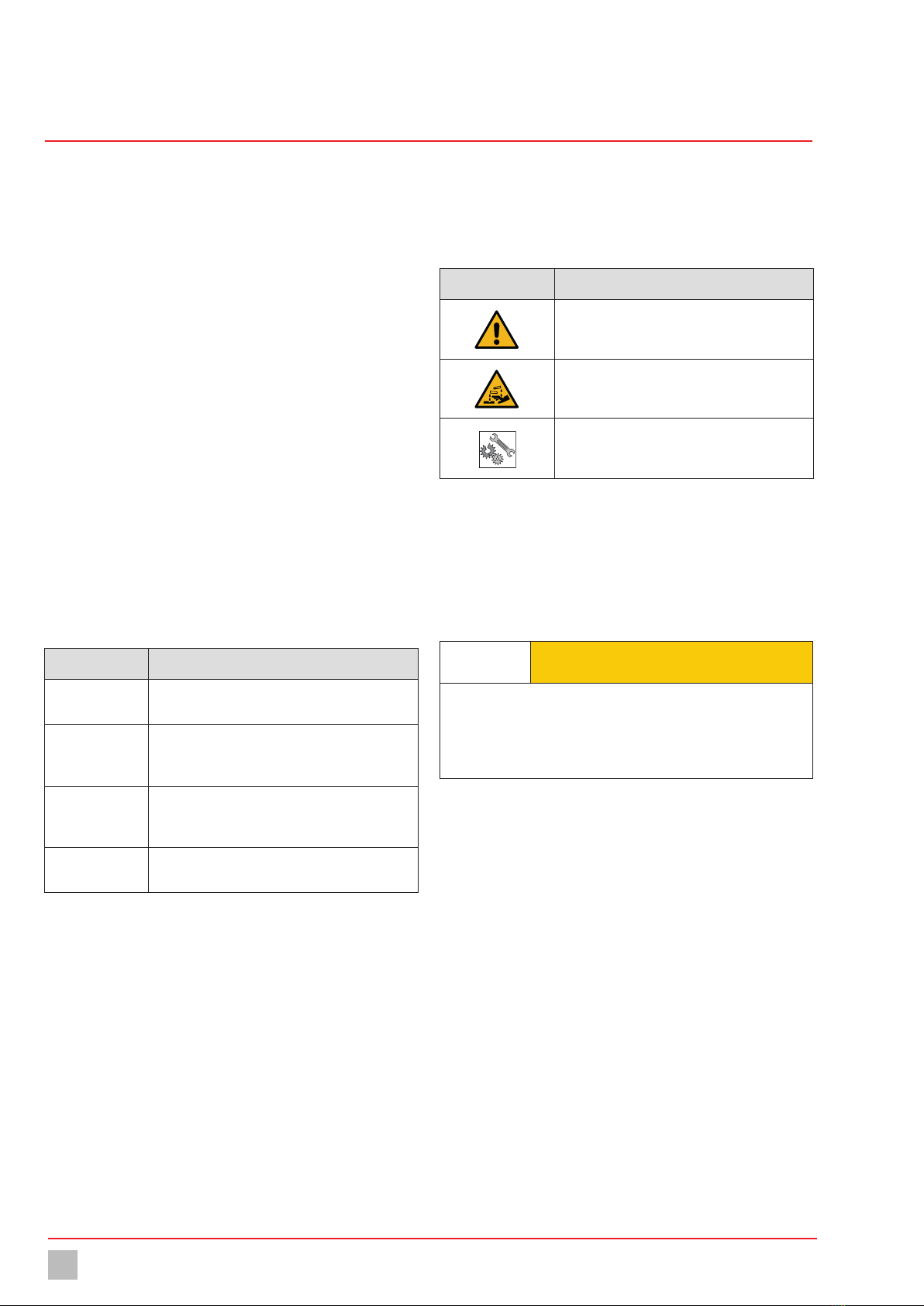

Personal protective equipment required

Protective goggles

Protective clothing

Protective gloves

Table 3: Personal protective equipment required

Wear the following personal protective equipment when performing the

following tasks:

nInstallation,

nShut-down,

nMaintenance work.

2.4 Personnel qualification

2.4.1 Specialist staff

Thanks to their professional training, knowledge, experience and knowl-

edge of the relevant specifications, specialist staff are able to perform the

job allocated to them and recognise and/or eliminate any possible dan-

gers by themselves.

2.4.2 Personnel tasks

In the table below you can check what qualifications are the pre-condi-

tion for the respective tasks. Only people with appropriate qualifications

are allowed to perform these tasks!

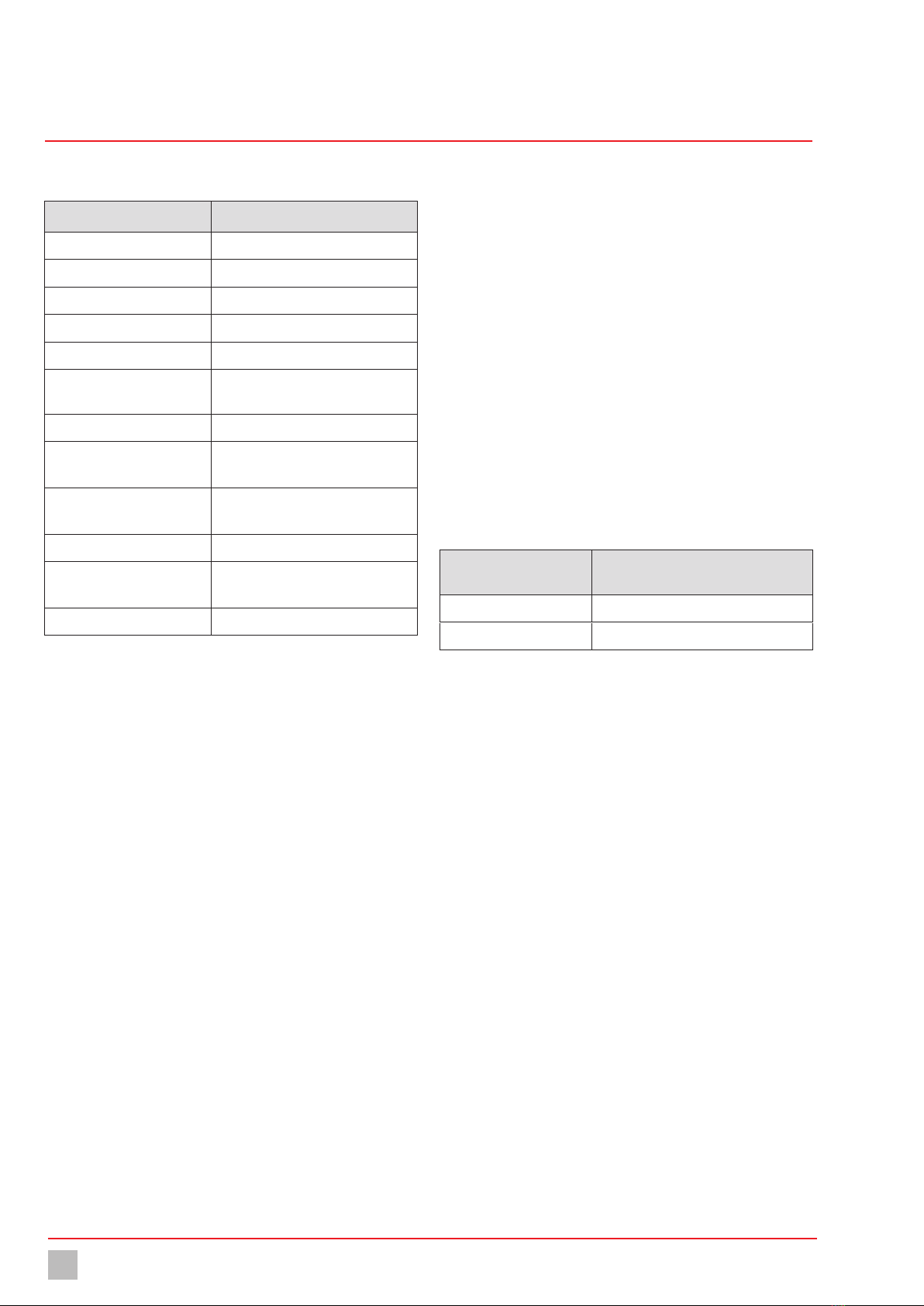

Qualification Activities

Specialist staff nInstallation

nOperating

nMaintenance

Table 4: Personnel qualification