2

1. General safety instructions, intended

use

Before first use read the manual carefully and follow

the instructions contained therein. The

manufacturer is not liable for damage caused by

equipment used inappropriately or by incorrect

handling.

Intended use

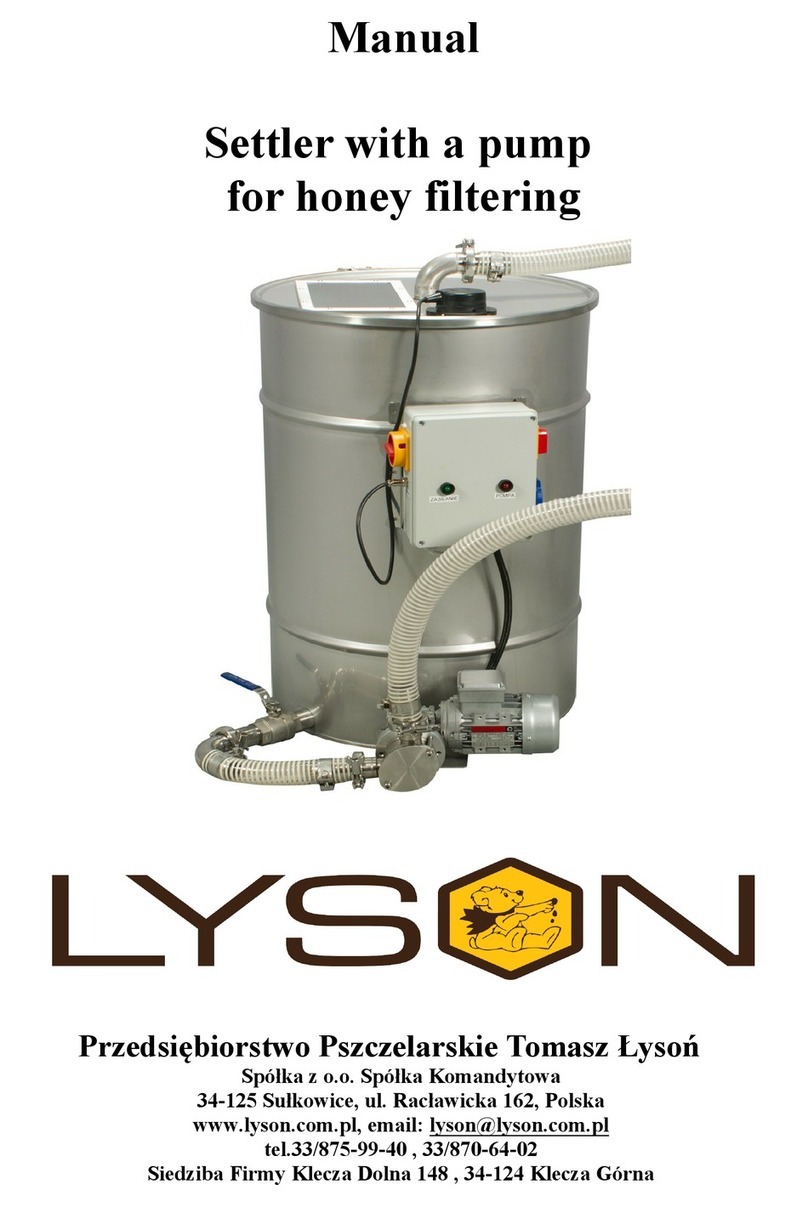

The device is designed to automatically

fill honey into the jars, and pump or

cream honey

1.1. Electrical safety

a) Make sure that the nominal voltage of the device and

power source are compatible and the socket is

grounded.

b) The electrical supply system must be fitted with a

residual-current circuit breaker with rated tripping

current not higher than 30mA. Performance of the

circuit breaker should be checked periodically.

c) Periodically check the condition of the power cord.

Replace the power cord if damaged. Replacing the

power cord can only be performed by the manufacturer

or by qualified personnel.

d) Do not use the device if the power cord is damaged!

1.2. Operation safety

a) a) The device is not intended for use by persons

(including children) with limited physical, sensory or

mental abilities, or by inexperienced users, unless under

supervision or with instructions given by an accountable

party.

This device is not a toy, and shouldn’t be used as one.

Children should not to play with it.

b) In the event of damage to the device, to avoid any

health and safety risks, repairs should be carried out

only by qualified personnel.

c) Do not use the device near any flammable

materials.

d) Never carry out any maintenance or

repairs during operation or if the device is

plugged in!

e) In case of any danger, use the safety switch

immediately.

f) The device can be restarted after the hazard has

been eliminated.

g) For indoor use only. The device is not suitable for

outdoor use.

h) Protect the motor and the control unit from

moisture (also during storage).

i) Do not pull the power cord.

j) Keep the power cord away from heat sources and

sharp edges to ensure its good condition.

NOTE!

HONEY INTENDED FOR BOTTLING SHOULD BE

WARMED UP TO 30°C.

POUR HONEY INTO THE PUMPING UNIT

BEFORE USING THE DISPENSER.

Required honey temperatures:

liquid, freshly extracted:20 - 25°C

heather, cream or with water content of <16%: 25-

35°C

maximum honey temperature: 40°C

Not adhering to the recommendations concerning the

temperature of honey may cause damage to the machine,

for which the manufacturer is not responsible. The product

damaged due to improper use is not subject to warranty.

Instructions:

1. Connect the hose to the dispenser pumping unit

with a clamp, take care to seat the seal correctly.

2. Pour about 1 kg of honey (i.e. a 0.95 kg jar) into the

other end of the tube.

3. Hold the hose up until the honey flows into the

pump. The hose is transparent so you can

see when the honey is flowing into the pump.

4. Select the creaming mode.

5. When the honey has flowed into the pump,

press the „START” button

6. Remember to put a container or a jar for

honey under the pump’s (dispenser) nozzle.

7. When the honey poured earlier into the pipe is

pumped, stop the pump by pressing the button

„START” again.

8. Once the above steps have been completed, insert

the hose into the honey barrel and start bottling or

pumping.

9. Make sure there is no air left in the hose

10. The machine is ready for operation.