5

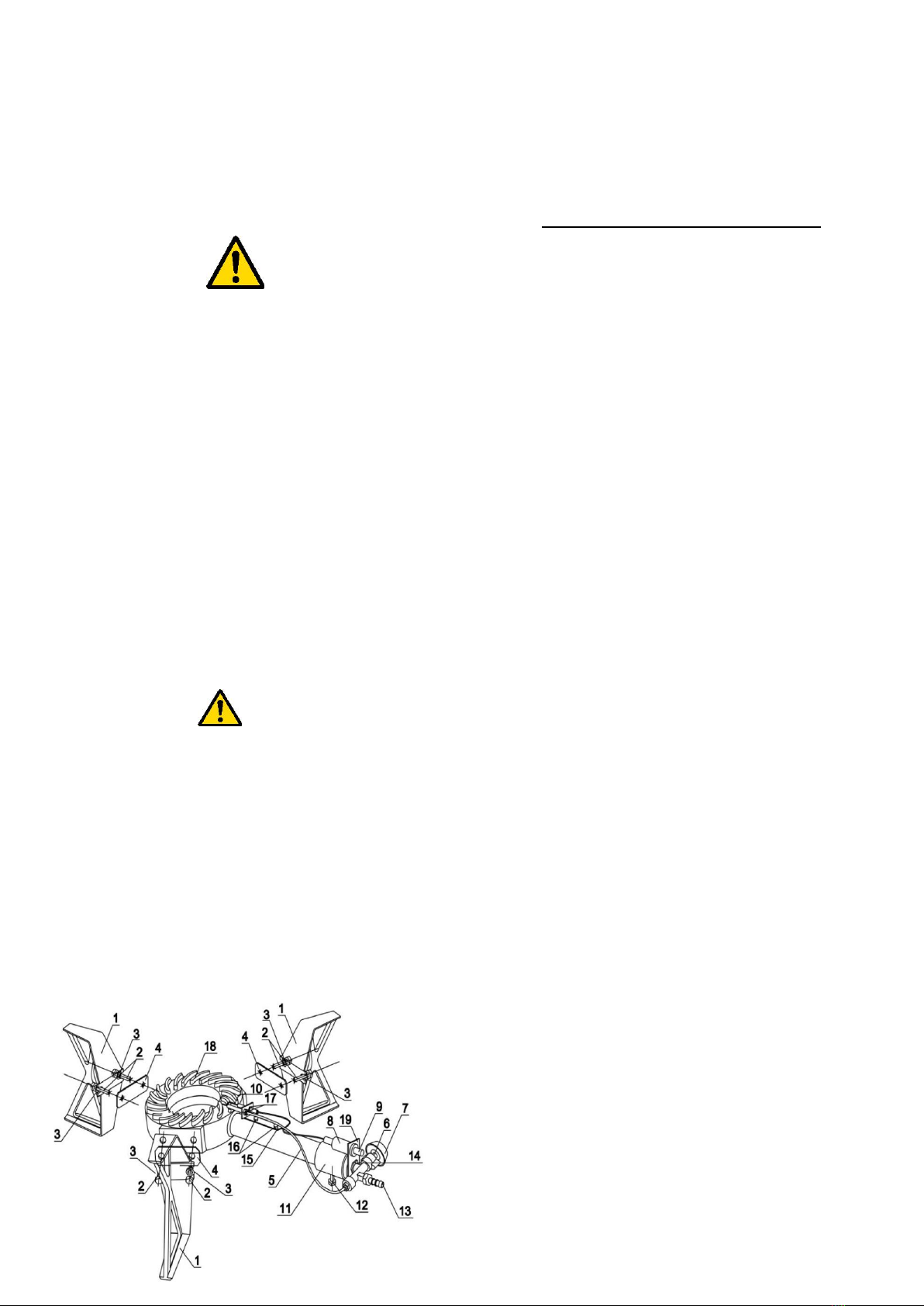

1. Slightly release the lock screw (item 1).

2. Slightly move the tie (item 2) and set up the primary air

flow in such a way to achieve blue flame optimally (yellow

or red flame indicates wrong settings)

3. Slightly tighten the lock screw (item 1) .

4. After every gas cylinder replacement, the primary air

flow must be regulated again.

Properly performed regulation should provide:

quick and proper burner ignition, re-ignition and mild

flame transfer, non-explosion flame dispersion at all flame

orifices within 5 second at the utmost, slight flame lit-off is

permissible, however after 1 minute the flame should be

stable, non-extinguishing and not getting back into the

nozzle when the thermal power of the burner is changed

along the entire range of anticipated power regulation and

while the hand wheel of the gas cock is turned from

maximum to minimum position with normal speed (the

normal speed , i.e. turning the gas cock hand wheel from

maximum to minimum power lasting approximately 1 s)

WARNING! After each usage the device must always be

cleaned. Prior to cleaning, one must make sure that gas

stool has cooled down - high risk of scalding. Gas flow

must be closed by closing the cocks. In case when the

device is to be rotated during cleaning, it is necessary to

disconnect the gas supplying hose.

(A). Prior to starting the maintenance, device must be

switched off and gas supplying hose disconnected.

(B). Make sure that the device has cooled down.

(C). In order to prevent the damages to the device

surface, it must be cleaned regularly.

(D). Remains of fat or food inside the device may bring

about fire.

(E). The device is to be cleaned with a wet cloth.

(F). Use the neutral cleaning agents only. Never use the

abrasive agents, agents containing caustic substances,

bleaches or acids to clean the gas stool. Using acidic or

alkaline substances must be avoided ( lemon juice,

vinegar, etc) .

(G). Do not clean the device with steam washers.

(H). Once the device has been cleaned, it must be dried.

3. PERIODICAL INSPECTIONS

After the guarantee period has expired, the device must

be inspected at least once a year. Periodical inspections

must be performed by the persons qualified for repairs

and maintenance of gas devices. The minimum inspection

range shall include the control for proper operation, gas

valve maintenance and the tightness tests. Outside the

guarantee period periodical inspections are not included

into the costs of purchasing the device.

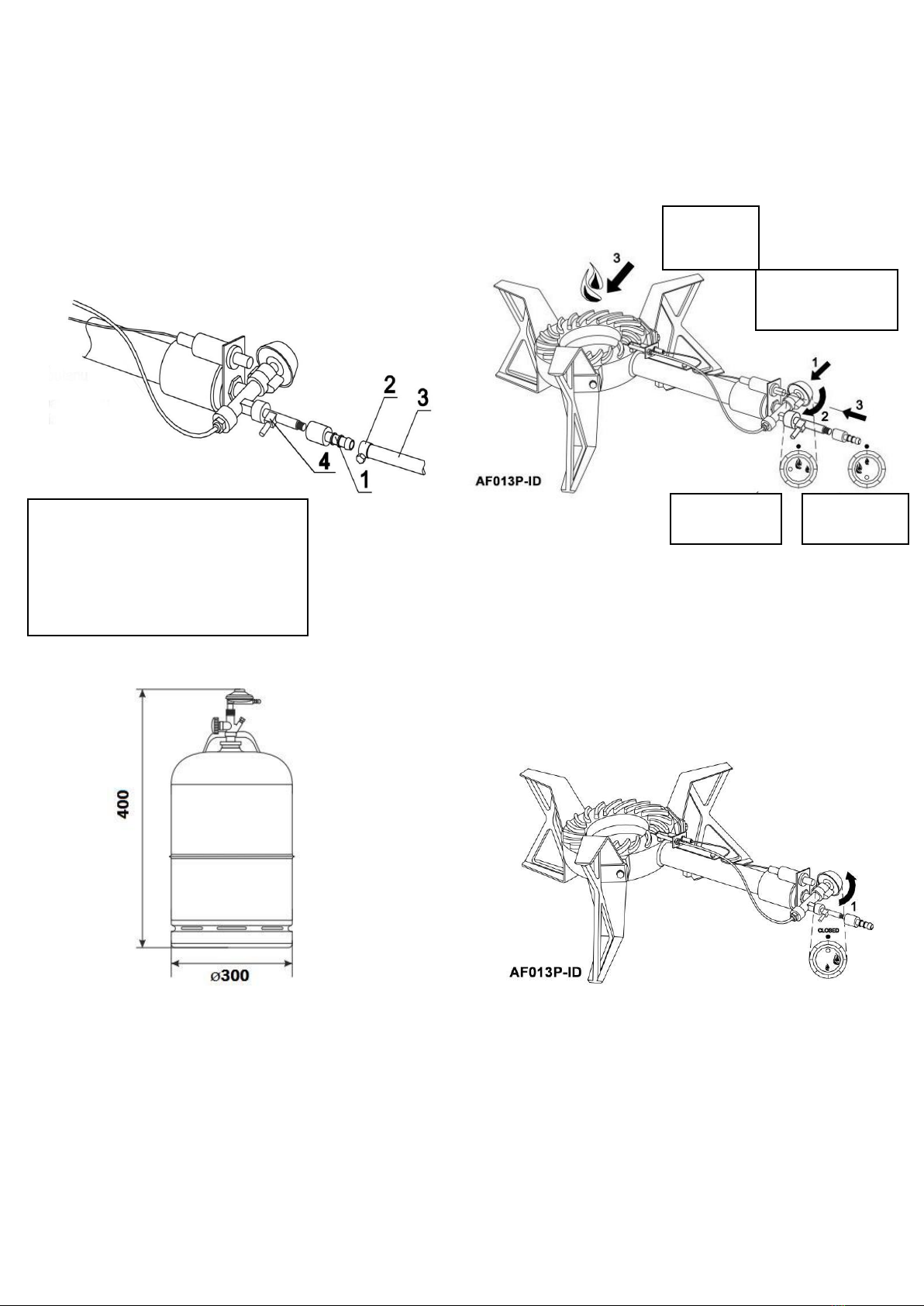

Properly prepared burner with the regulator to be

connected to the gas cylinder.

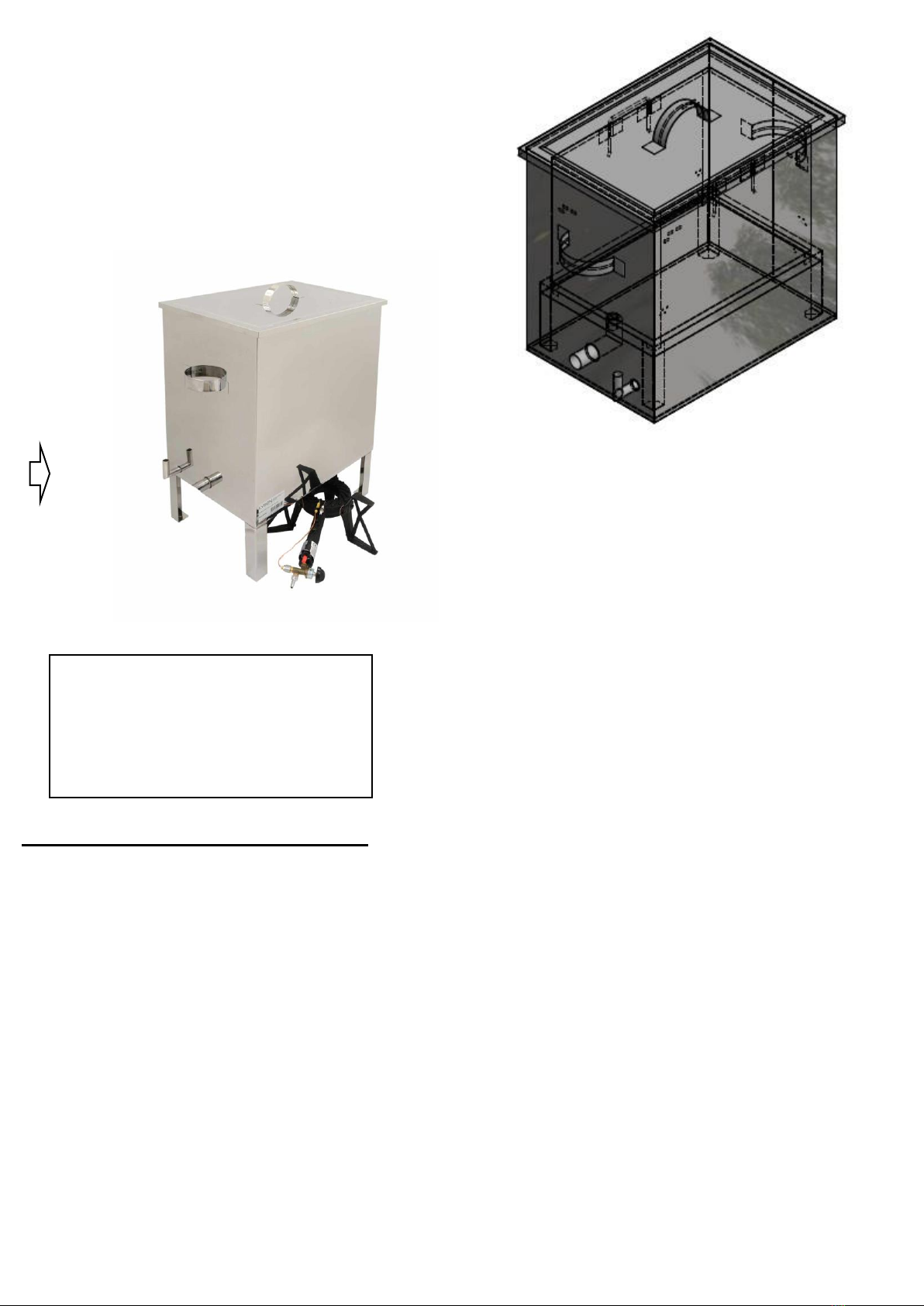

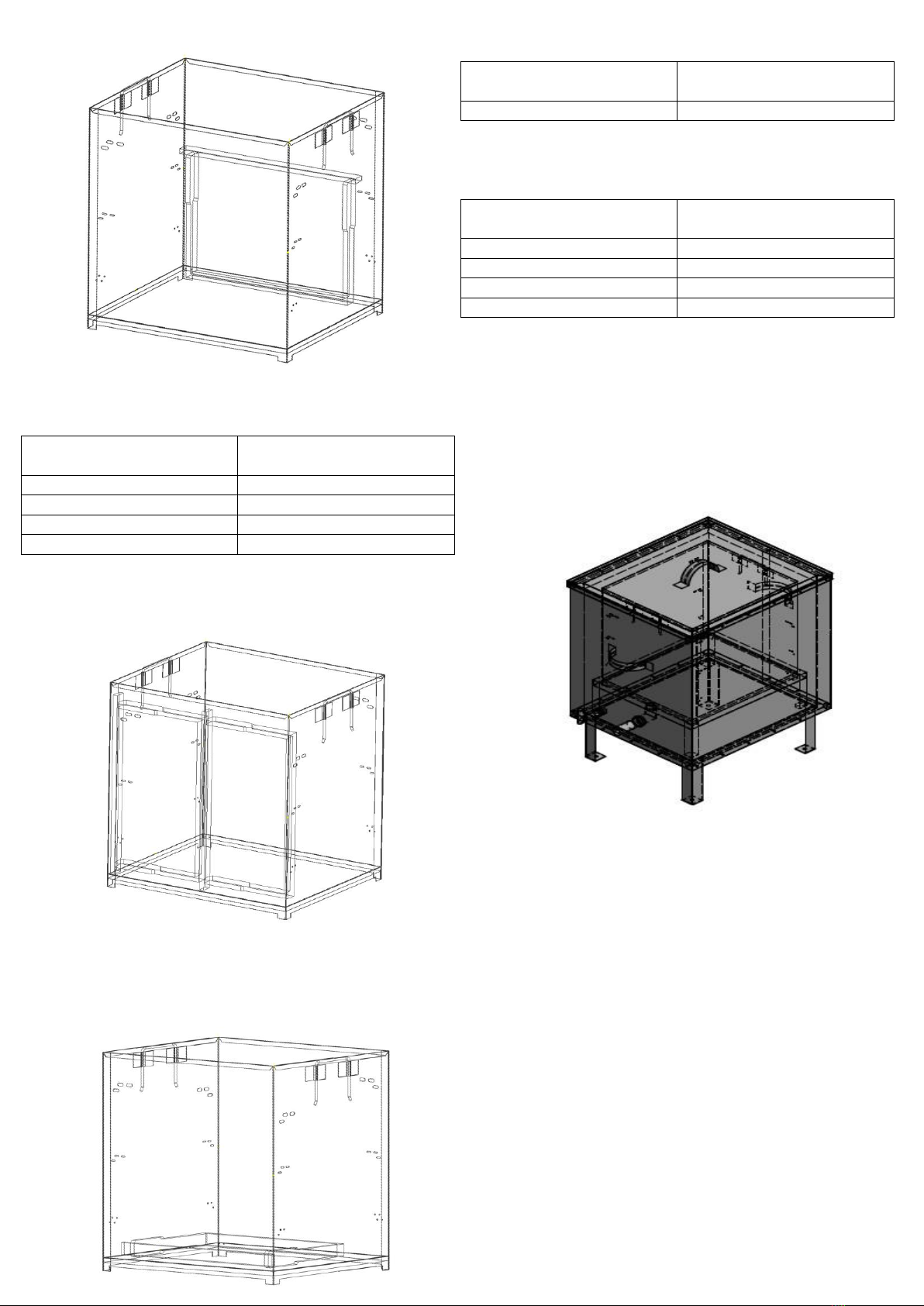

4. OPERATION DESCRIPTION OF A WAX

EXTRACTOR WITH A GAS BURNER

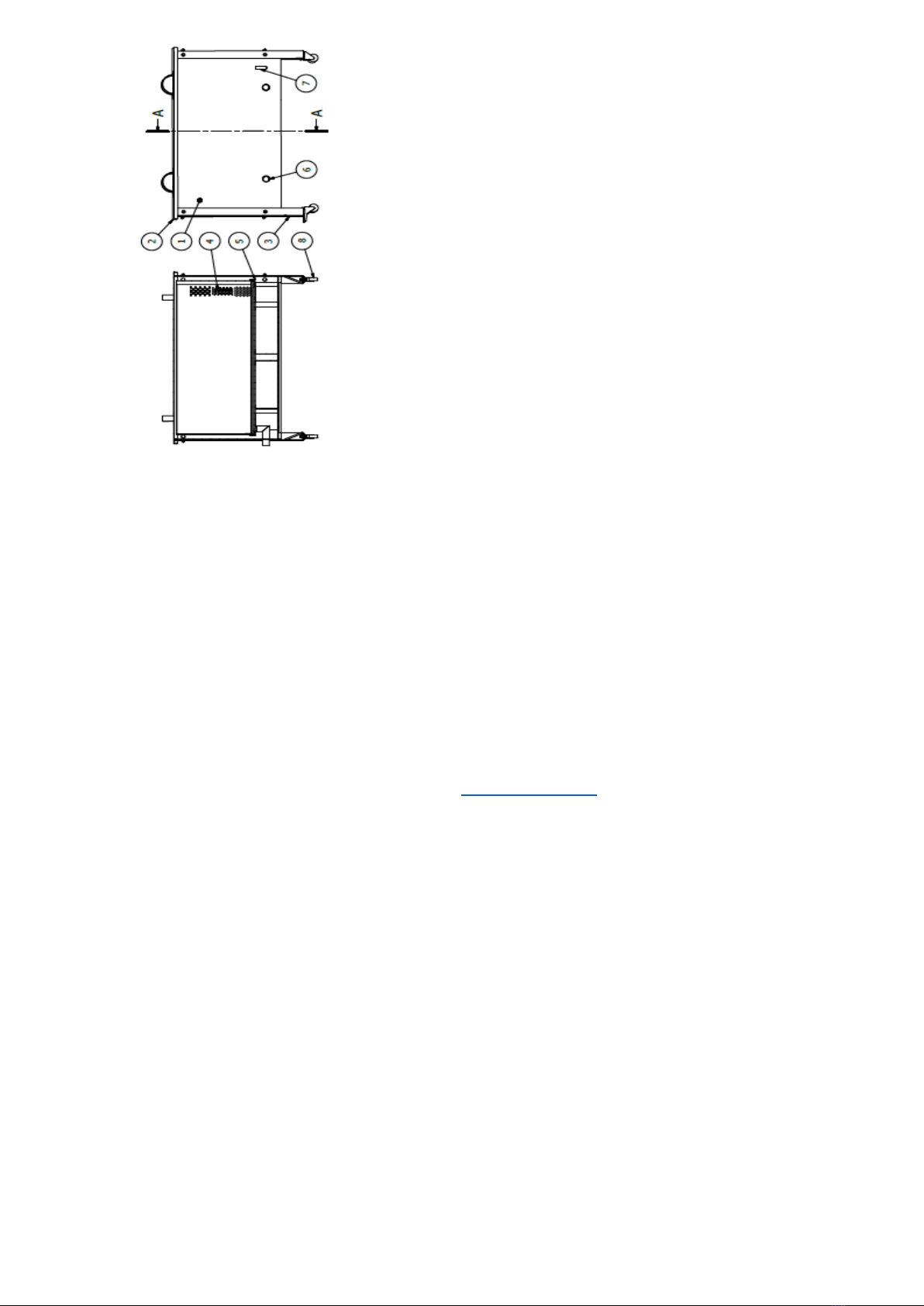

1. Fill the tank with water until the level of the

discharge pipe, as in the figure (Fig. 1). Water losses

must be completed (take special precautions not to get

burnt).

2. Fill the basket with frames or dried honey. .

3. Cover the device with a lid.

4. Place the burner under the device in such a way to

make the flame heat the entire surface of the device

bottom.

5. Wait until steam is formulated and melted wax

flows out.

6. After the batch has been melted, check the water

level and make up for the potential losses.

7. Add the frames or dried honey in the basket.

8. Steps 6 and 7 to be repeated until extraction has

been terminated

9. Once the process has ended, the burner must

be switched off and the gas cylinder closed.