5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-5024 Rev.9 P. 1 / 2

INSTRUCTION MANUAL

Mini-M™

CURRENT LOOP SUPPLY

(with square root extractor; non-isolated) MODEL M2DL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■PACKAGE INCLUDES:

Signal conditioner (body + base socket).............................(1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■NONINCENDIVE APPROVAL OPTION

• This equipment is suitable for use in Class I, Div. 2,

Groups A, B, C and D or Non-Hazardous Locations only.

• WARNING! Before You Remove the Unit from Its Base

Socket or Mount It, Turn Off the Power Supply and Input

Signal for Safety.

• WARNING! – Explosion Hazard –

Substitution of Components May Impair Suitability for

Class I, Div. 2.

• WARNING! – Explosion Hazard –

Do Not Disconnect Equipment Unless Power Has Been

Switched Off or The Area is Known To Be Non-Hazardous.

• The equipment was evaluated for use in the ambient tem-

perature and relative humidity as mentioned in ‘ENVI-

RONMENT’ section.

• The input and output wiring must be in accordance with

Class I, Div. 2 wiring methods and in accordance with the

authority having jurisdiction for use in these hazardous

locations.

■CONFORMITY WITH EU DIRECTIVES OR UL

• The equipment must be mounted inside a panel.

• The actual installation environments such as panel con-

figurations, connected devices, connected wires, may affect

the protection level of this unit when it is integrated in

a panel system. The user may have to review the CE re-

quirements in regard to the whole system and employ ad-

ditional protective measures* to ensure the CE conformity.

* For example, installation of noise filters and clamp fil-

ters for the power source, input and output connected

to the unit, etc.

• Install lightning surge protectors for those wires connect-

ed to remote locations.

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

85 – 264V AC rating: 85 – 264V, 47 – 66 Hz, approx. 3 – 5VA

24V DC rating: 24V ±10%, approx. 3W

11 – 27V DC rating: 11 – 27V, approx. 3W

110V DC rating: 85 – 150V, approx. 3W

■GENERAL PRECAUTIONS

• Before you remove the unit from its base socket or mount

it, turn off the power supply and input signal for safety.

■ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

• Be sure that the ventilation slits are not covered with ca-

bles, etc.

■WIRING

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

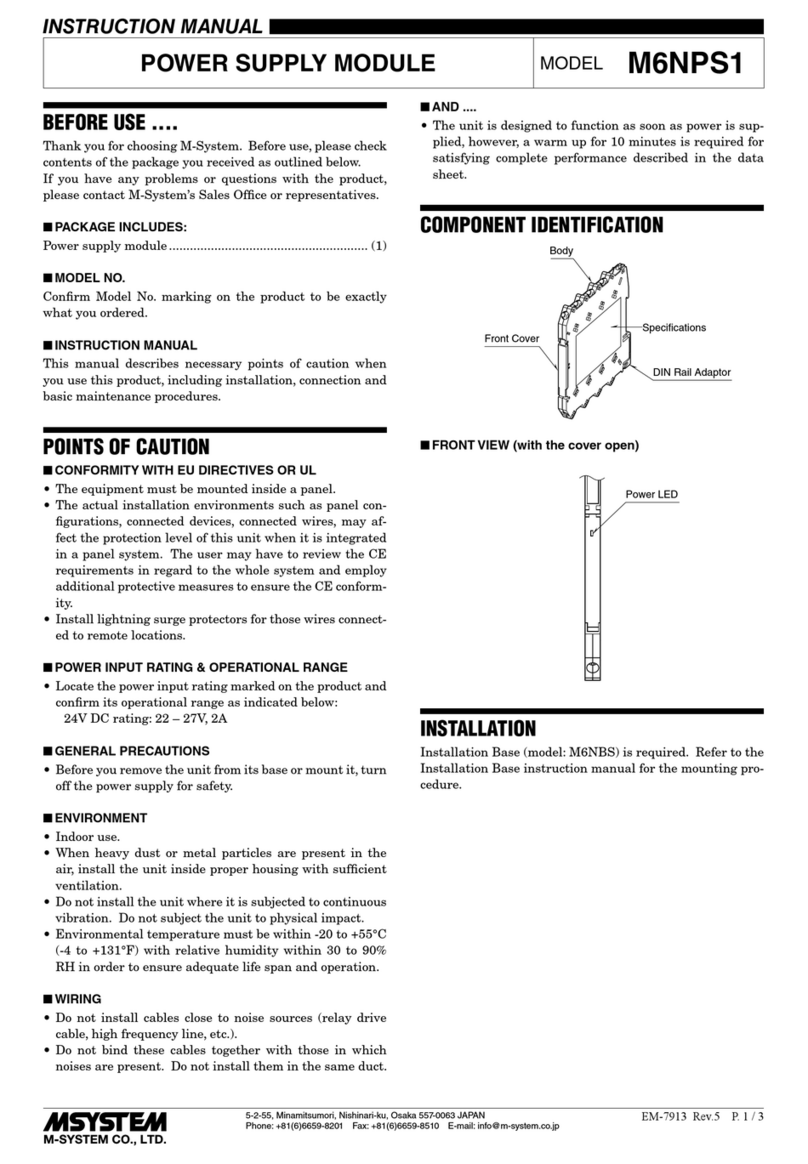

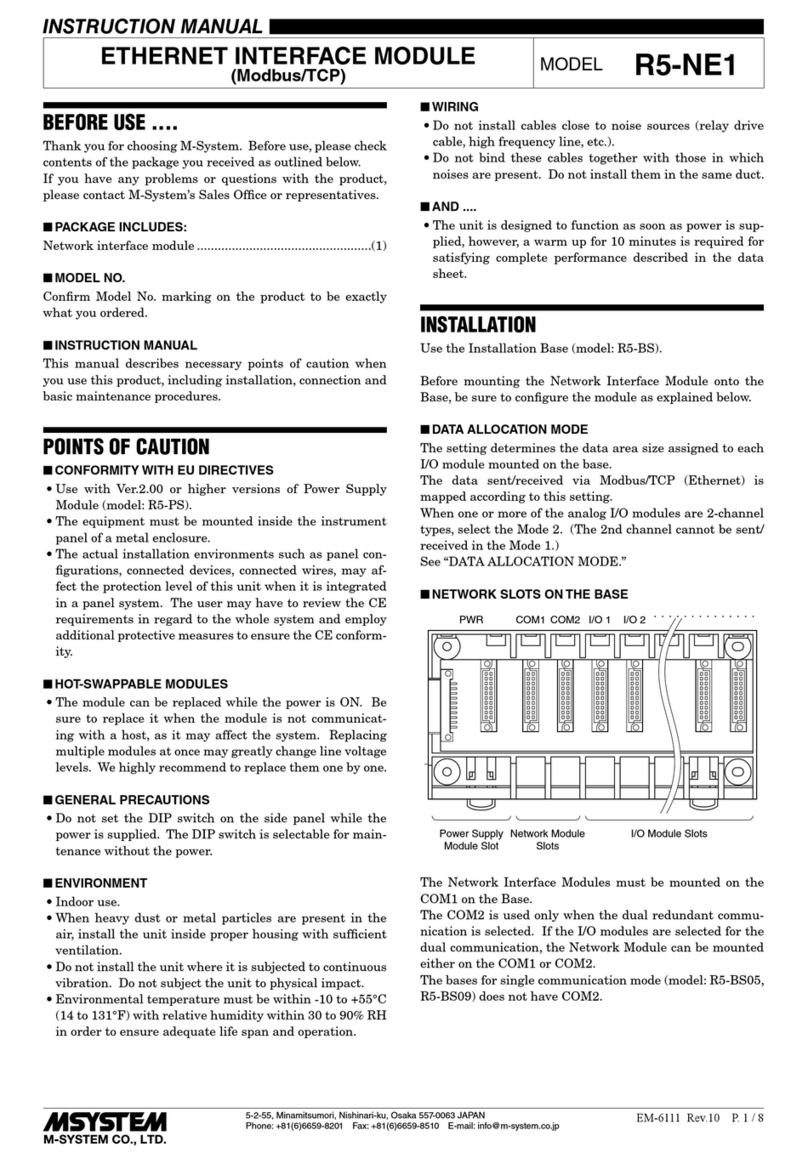

COMPONENT IDENTIFICATION

Model

SPAN

ZERO

Zero Adj.

Span Adj.

Body Base Socket

Connection

Diagram

Specifications

Fixing Screw

INSTALLATION

Loosen the fixing screw at the front of the unit in order to

separate the body from the base socket.

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

■DIN RAIL MOUNTING

Set the base socket so that

its DIN rail adaptor is at

the bottom. Position the

upper hook at the rear side

of base socket on the DIN

rail and push in the lower.

When removing the socket,

push down the DIN rail

adaptor utilizing a minus

screwdriver and pull.

■WALL MOUNTING

Refer to “EXTERNAL DIMENSIONS.”