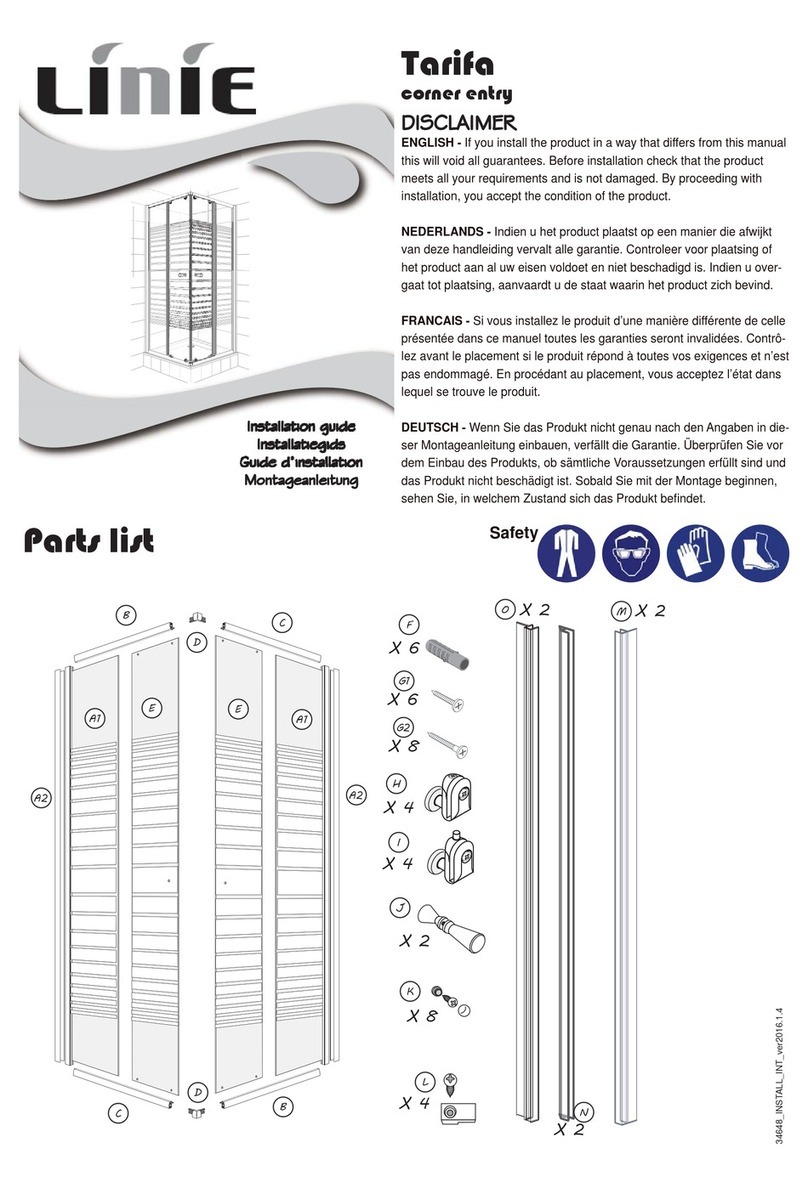

English

6

2

2

-

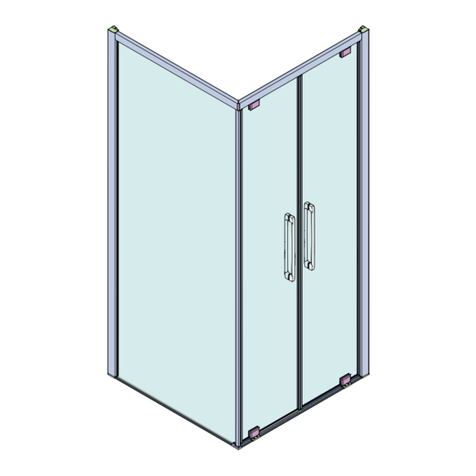

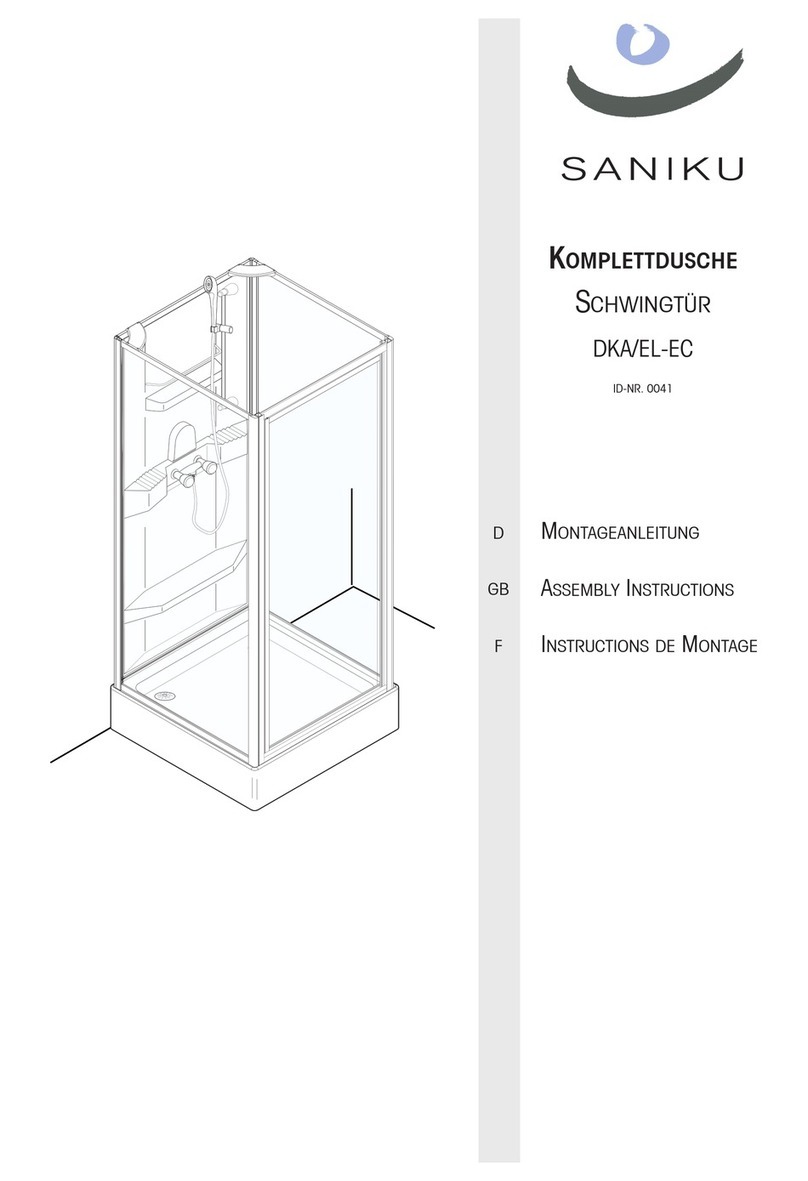

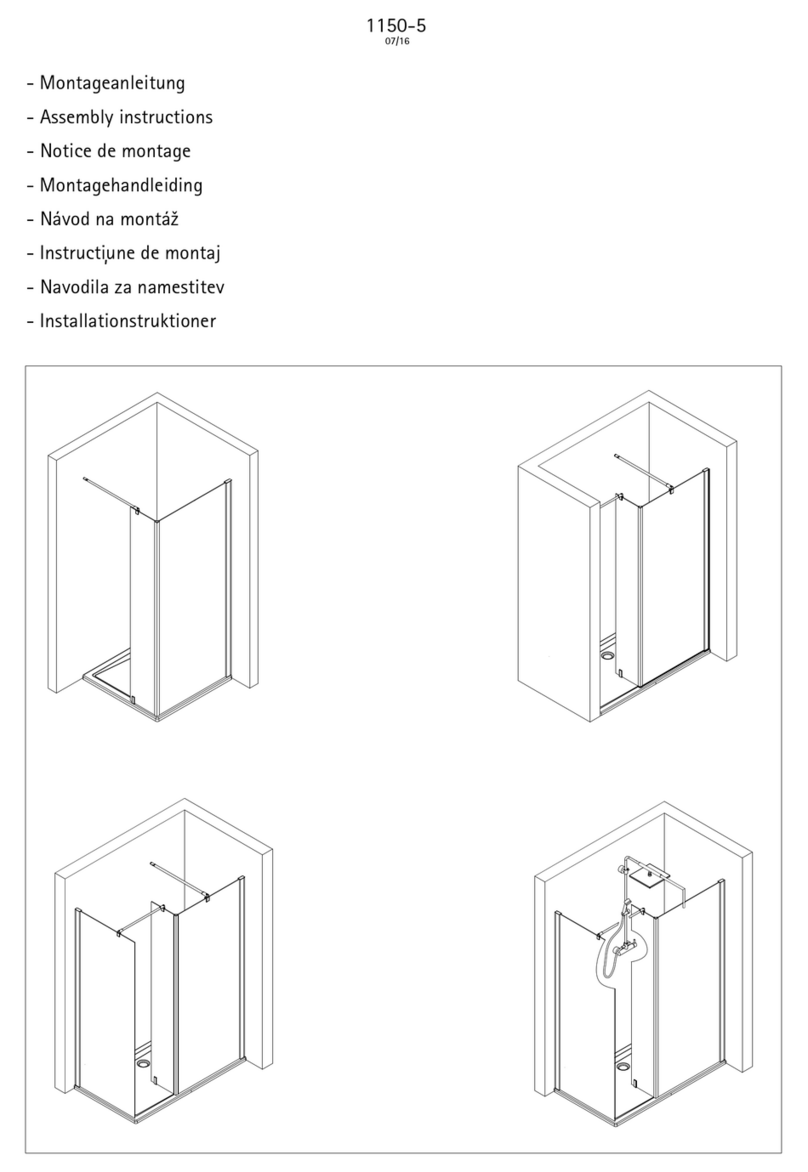

-WALL POST POSITIONING AND INSTALLATION

6

6

The rail ideal position should be on the base

threshold centerline, as illustrated.

+45º

Note:The bottom of the

wall posts must be filed

to adjust for installation

on a single-hull unit.

Wall bracket

front view.

Lift the frame assembly and position

it on the base. Center the frame

from left to right, as illustrated in the

figure.

Note: By positioning the frame over the

base, the wall posts can be pushed further

back inside the panel posts.

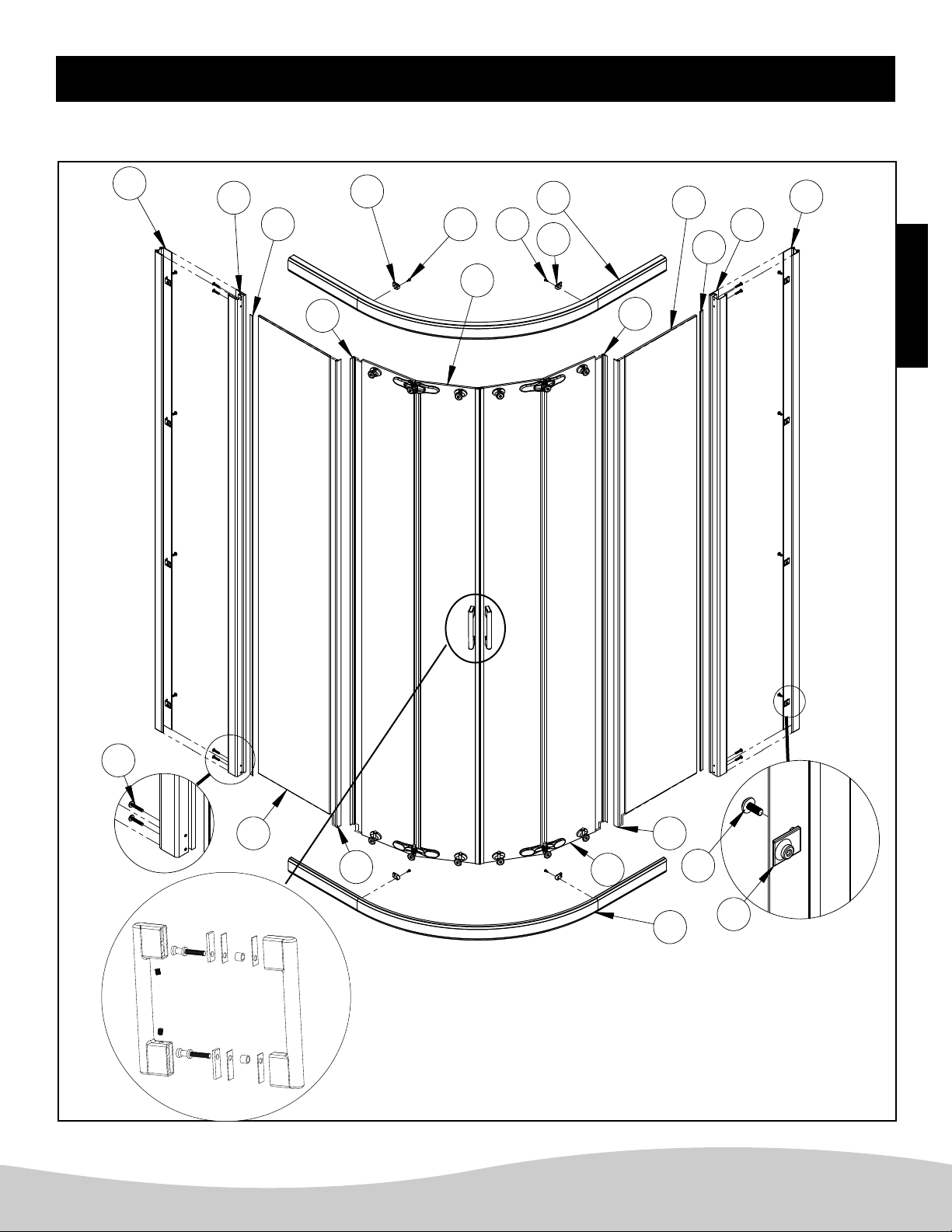

1

1Using a pencil, makes sure that the

wall posts are plumb, and mark a

line with a pencil inside the wall post to

mark its position on the wall, as illustrated

in the figure.

While a person holds the shower frame in

position, the other should makes sure that

wall posts are in contact with the wall. If

required, wall posts can be removed or

inserted. Remove the shower unit from

the base and remove the wall posts from

the panel posts.

2

2

Repeat for both sides

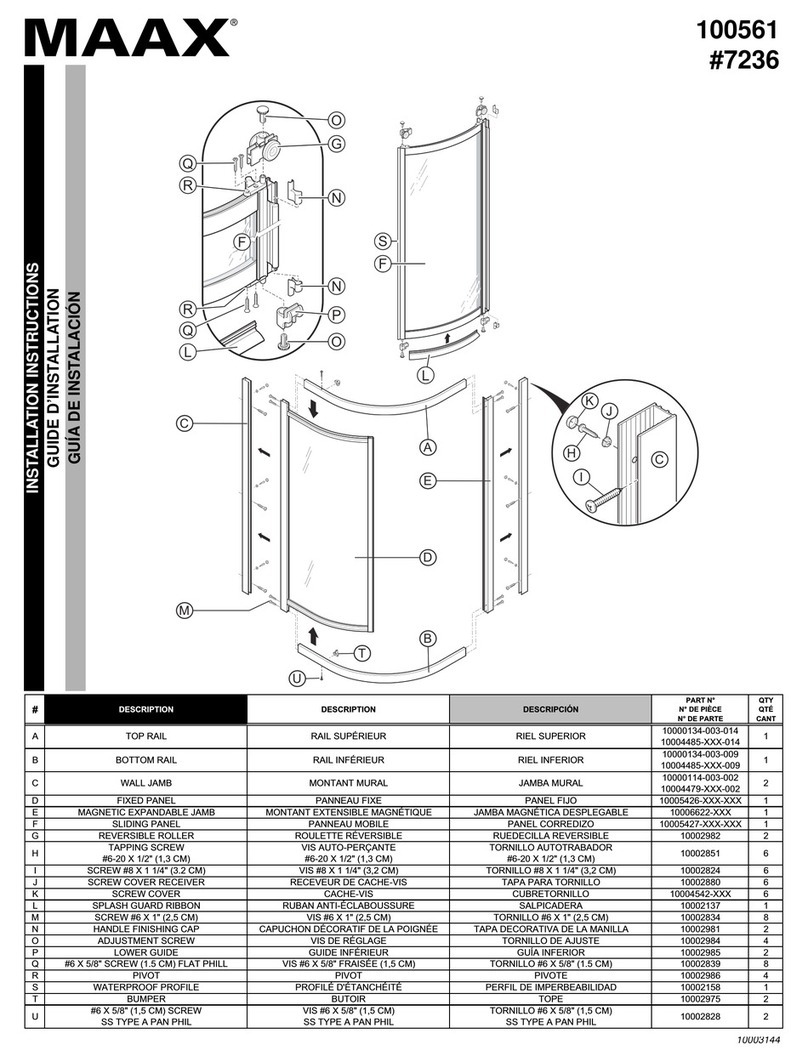

Reinstall the wall posts on the wall

at the marked location. The wall

post lower edges must align with the

pencil marks, as illustrated on the figure.

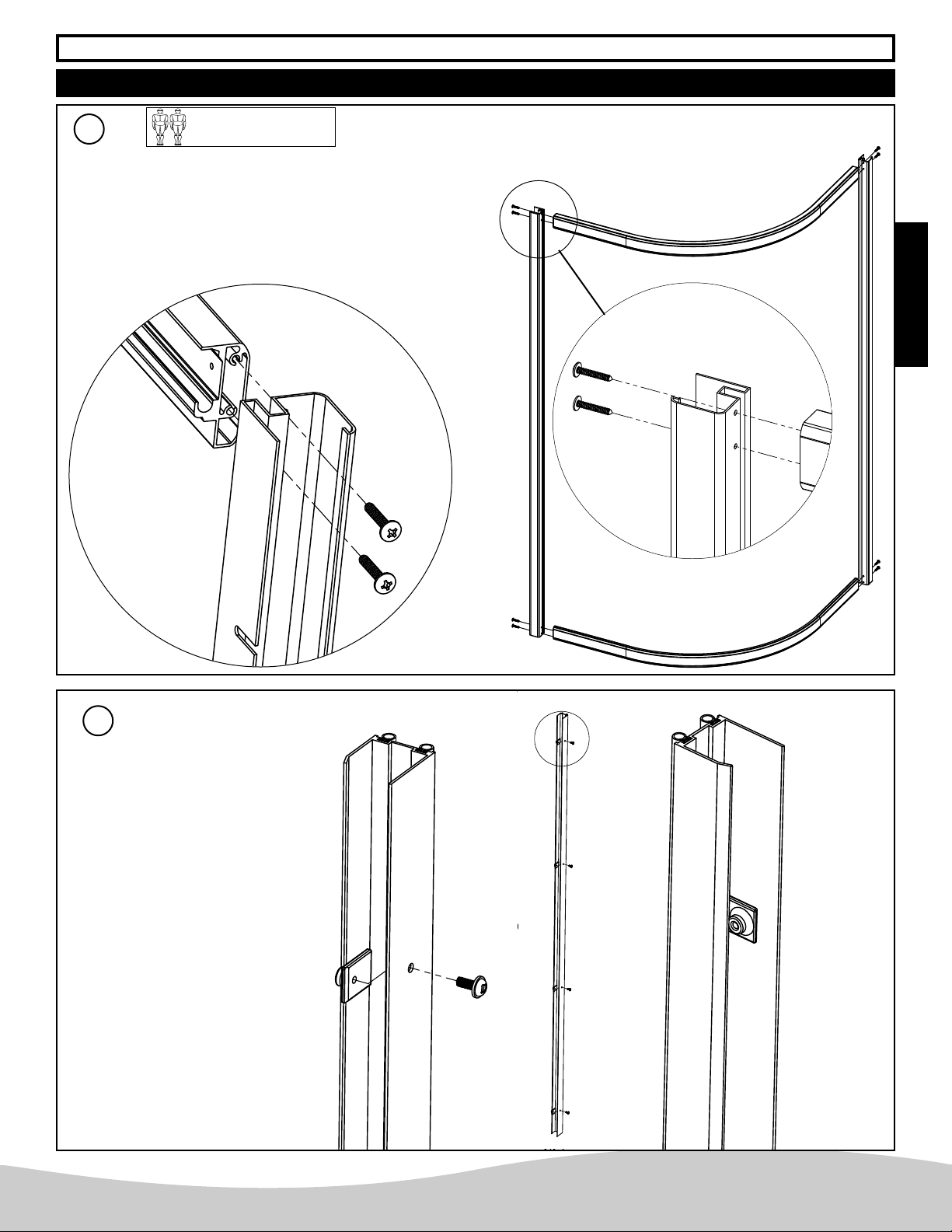

3

3

Using a pencil, mark all attachment

hole locations, as illustrated in

the figure.

4

4Remove the wall posts and drill

holes at each attachment location,

as illustrated in the figure.

For installation on ceramics tiles, use a

1/4"masonry bit.

5

5

Using a center punch, punch the ceramics

surface at the location of the attachment

points. Drill, then insert plugs.

For installation on an acrylic enclosure,

use a 1/8"bit. Plugs are not required.

Reinstall the wall posts and attach them to

the wall with #8 x 1", screws, as illustrated

in the figure. Wall posts are equipped with

for better horizontal adjustment.