2 ©2012MadCowRocketry™ AGM-33PIKE™Assembly AGM-33PIKE™Assembly ©2012MadCowRocketry™ 3

Please make sure you read all directions and understand how to assemble your model

beforeyoustartconstruction.Itisalsoagoodideatotestteachpartbeforeassembly.

Fiberglass parts still contain small amounts of mold release and other materials on the

surfacethatwillinhibitadhesivesand/orpaint.Itisimportanttocleaneachpartprior

to assembly with a solution of 1 part rubbing alcohol, 3 parts water and a drop of dish

washingsoap.IMPORTANT:donotsandanypartsuntilafteryouhavecleanedthem-

youwillembedthematerialsyouaretryingtocleanmakingitdifculttoclean.

TheG10partswillhaveholdingtabsleftoverfromtheCNCmachine.Thesesmalltabs

will need to be sanded off before assembly. Before assembling any part with epoxy,

roughupthesurfacetobeepoxiedusingcoursesandpaper.ThescratchesintheG10

surface will give the epoxy something to grab onto.

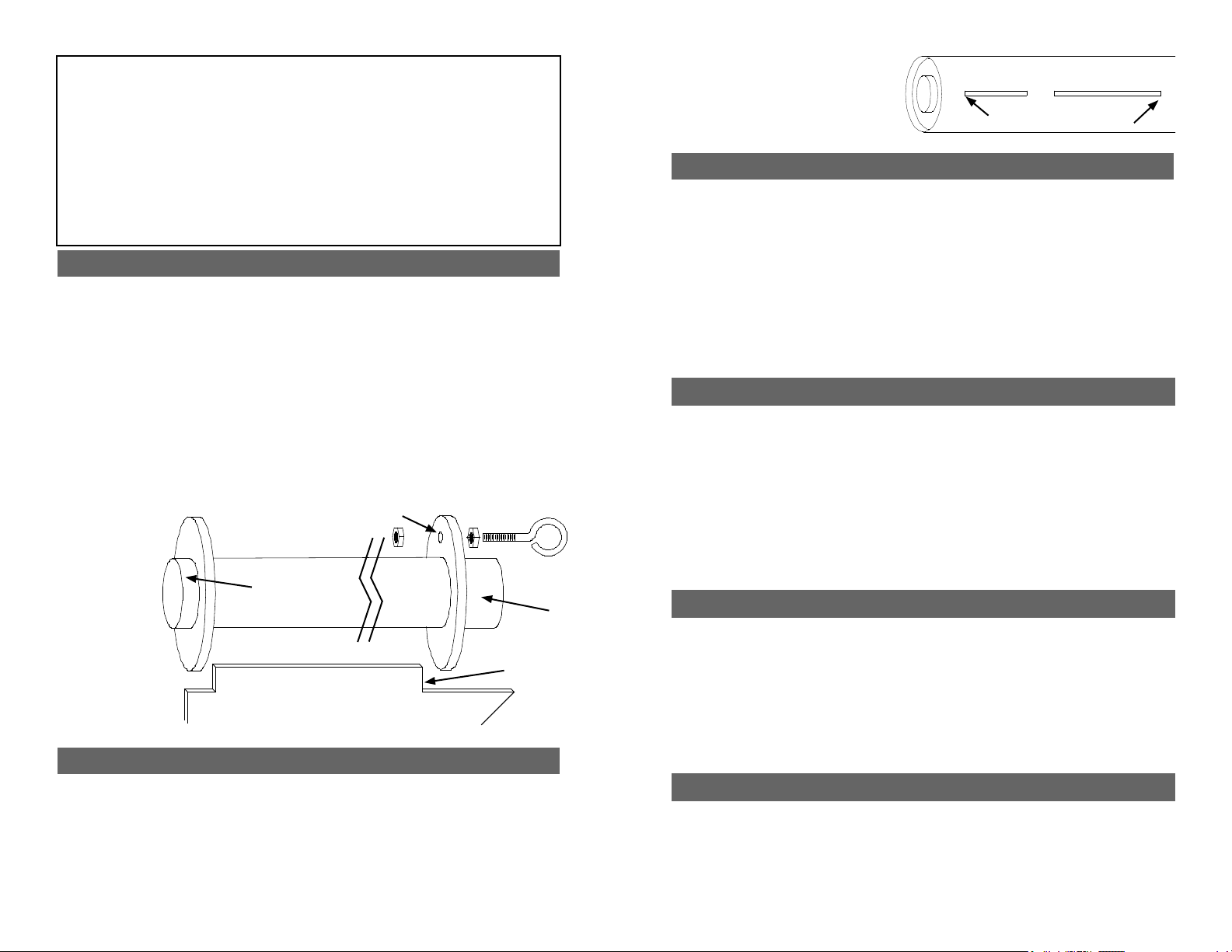

Step1–MotorMountAssembly

Testtthecenteringringsoverthemotormounttubeandsandifnecessary.Alsotest

tthecenteringringsinthebodytubeandsandifnecessary.Takeoneofthecentering

ringsanddrilla1/4”holefortheeyebolt.IMPORTANT:makesuretheholeiscentered

between the inner and outer edge of the ring so the nut on the eyebolt will not interfere

withthebodytubeormotortubelater.Theringwiththe1/4”holeforaneyeboltwillbe

the forward ring. Mount the eyebolt using the two nuts as shown in the forward ring hole.

Applysomeepoxytothenutstoensuretheywillnotcomelooselater.IMPORTANT:

Make sure the eyebolt and nut are aligned properly so the motor assembly can

slide into the body tube.

Spread some epoxy on the outside of one end of the motor tube and slide the ring

(without the hole) until there is approximately 1/2” of motor tube exposed. Make sure

youcleanthemotortubeofanyepoxysoasnottointerferewiththentangslater.After

the aft ring is dry, make a mark 1” from the other end of the motor tube. Spread some

epoxy on the motor tube and slide the forward ring until it aligns with the mark. VERY

IMPORTANT:

make sure

there is not

any epoxy on

the motor tube

that would

interfere with

the n tangs

later on.

Attachoneend

of the shock

cord to the

eyebolt using an

overhand knot.

Step4–RailButtonAttachment

Mark the CP point along the rail button line you made in the previous step. Make sure

youmeasuretheCPpointfromthetipofthenoseconeandNOTtheendofthebody

tube.Drilla5/64”holeontherailbuttonlinefortheforwardandaftrailbuttons.Theaft

hole should be 1” from the aft end of the body tube and the forward hole should be at the

CPpoint.Applyasmallamountofepoxyintheholesandattachtherailbuttonsusing

the supplied #6 wood screws. Make sure the screw is loose enough for the rail button

to spin freely - this ensures the button is not compressed to the point it will hang on the

rail guide. IMPORTANT: The screw from the forward rail button should be behind

the forward centering ring. If it isn’t, make sure the forward rail button screw

protruding through the body tube doesn’t snag the chute. Epoxy over the screw

to provide a smooth surface. The screw can also be cut shorter.

Step2–InsertMotorTubeAssemblyintoBodyTube

Wrap the shock chord into a small bundle and stuff it inside the motor tube for this next

step.Testtthemotortubeassemblyintothebodytubetoensureasnugt.Sandthe

centeringringsifnecessary.Whenyouaresatisedwiththet,spreadsomeepoxyon

the inside of the body tube and slide the forward centering ring of the motor assembly

into the body tube. Make sure you have the motor assembly facing the right way!

Spread some more epoxy on the inside edge of the body tube before sliding the rear

centering ring into the body tube. Continue sliding the assembly inside the body tube

untiltheaftendofthemotortubeisevenwiththeaftendofthebodytube.It’sagood

ideatotesttanineachslothere

before the epoxy sets. Hold the body

tube with the motor tube assembly down

until the epoxy sets. Make sure the

weightofthemotorassemblydoesn’t

cause it to slide out of alignment.

Step3–FinAssembly

Using a door jam or small section of angle stock, pencil a line halfway between two of the

nsthatextendsfromthefronttothebackofthebodytube.Thislinewillbeusedlater

toaligntherailbuttons.Testteachofthensintotheprecutnslots.Thenshould

seatrmlyagainstthemotortube-sandeachnifnecessary.Whenyouaresatised

withthet,applysomeepoxytotheendofthentangthatwillcontactthemotortube.

Also,spreadathinlayerofepoxyoneachsideofthentang.Slidethenintoplace

andcheckthealignment.Continuerecheckingthenalignmentuntilyouaresurethe

epoxyhasset.Cleananyexcessepoxyfromaroundthenjoint.Youcanclampsome

woodplankstotheforwardandaftnstokeepthemalignedwitheachotherwhilethe

gluesets.Repeatfortheremainingns.Next,applyepoxylletstobothsidesofeach

nbyapplyingathinbeadofepoxyatthen-bodytubejoing.Carefullysmooththe

epoxylletswithyourngerbeforetheepoxysets.Alloweachllettosetbeforerotating

theairframeforthenextllet.

Step5–BalanceandNoseConeAssembly

Mount the remaining eyebolt using the nuts and washer in the nose cone bulkplate.

Applysomeepoxytothenutsoitwillnotcomelooselater.Testtthebulkplateinthe

baseofthenoseconeandsandifnecessary.Atthispoint,packthechuteandassemble

therocket.Insertthelargestmotorthatyouintendtoy(orsimulatetheweightwithan

appropriate substitute) and ensure that the CG is at least 1 body diameter in front of the

estimatedCPpointspeciedontherstpage.TheCPshouldbemeasuredfromthetip

ofthenosecone.IftheCGistoofarback,addweightinsidethenoseconeandsecure

withepoxy.WhenyouaresatisiedwiththeCG,epoxythebulkplateintothebaseofthe

noseconeleavingatleasta1/4”liptoapplyallet.Next,applyalletofepoxyaround

the bulkplate and nose cone shoulder joint.

Step6–FlyingYourModel

Attachtheendoftheshockcordandtheparachutetothenoseconeeyebolt.You

can also attach the chute protector to the shock cord just below the nose cone. When

packing your chute, wrap the chute protector around the chute with the opening in the

chuteprotectorfacingforward.Alwaysmakesureyourchuteiswellprotectedasthehot

ejection motor gasses will melt the nylon chute.

1/2” Exposed

1” Exposed

Forward Ring Hole

Fin

FinTang

Ensureringsareclearofthenslots