7

ASSEMBLY

STEP2

3POINTHOOKUP

IMPORTANT:

A3pointcategory1hitchisrequired.

Thelowerarmsofthe3pointhitchmustbestabilized

topreventsidetosidemovement.Mosttractorshave

swayblocksoradjustablechainsforthispurpose.

SlowlybackupthetractortotheBoxScraperanduse

thetractor’s3pointhydrauliccontrol.

Returntothetractorandslowlyoperatethetractor’s3

-point hydraulic control up and down to check for

clearancebetweentires,framedrawbar,etc.

Move or removethe draw bar if it interfereswith the

BoxScraper.

Manually adjust one of the two lower lift arms up or

downtoleveltheBoxScraperfromlefttoright.

Manually adjustthelengthofthetop-link tolevel the

BoxScraperfromfronttorear.

Ensurethatthelowerliftarmsareblockedtoprevent

excessivemovement.

DANGER

TOPREVENTINJURIES:

Hooking up equipment to the tractor is dangerous

and can result in serious injury or death. Do not

allow anyone to stand between the tractor and the

Box Scraper while backing up to the equipment. Do

not operate hydraulic 3-point lift controls while

someone is directly behind tractor or near the

scraper.

WARNING

TOPREVENTINJURIES:

Parkthevehicleonaflatsurfaceinawellventilated

area.

DisengagetheP.T.O.

Applyparkingbrake.

Stoptheengineandremovetheignitionkey.

Wait until all moving parts have stopped before

leavingthedriver’sseat.

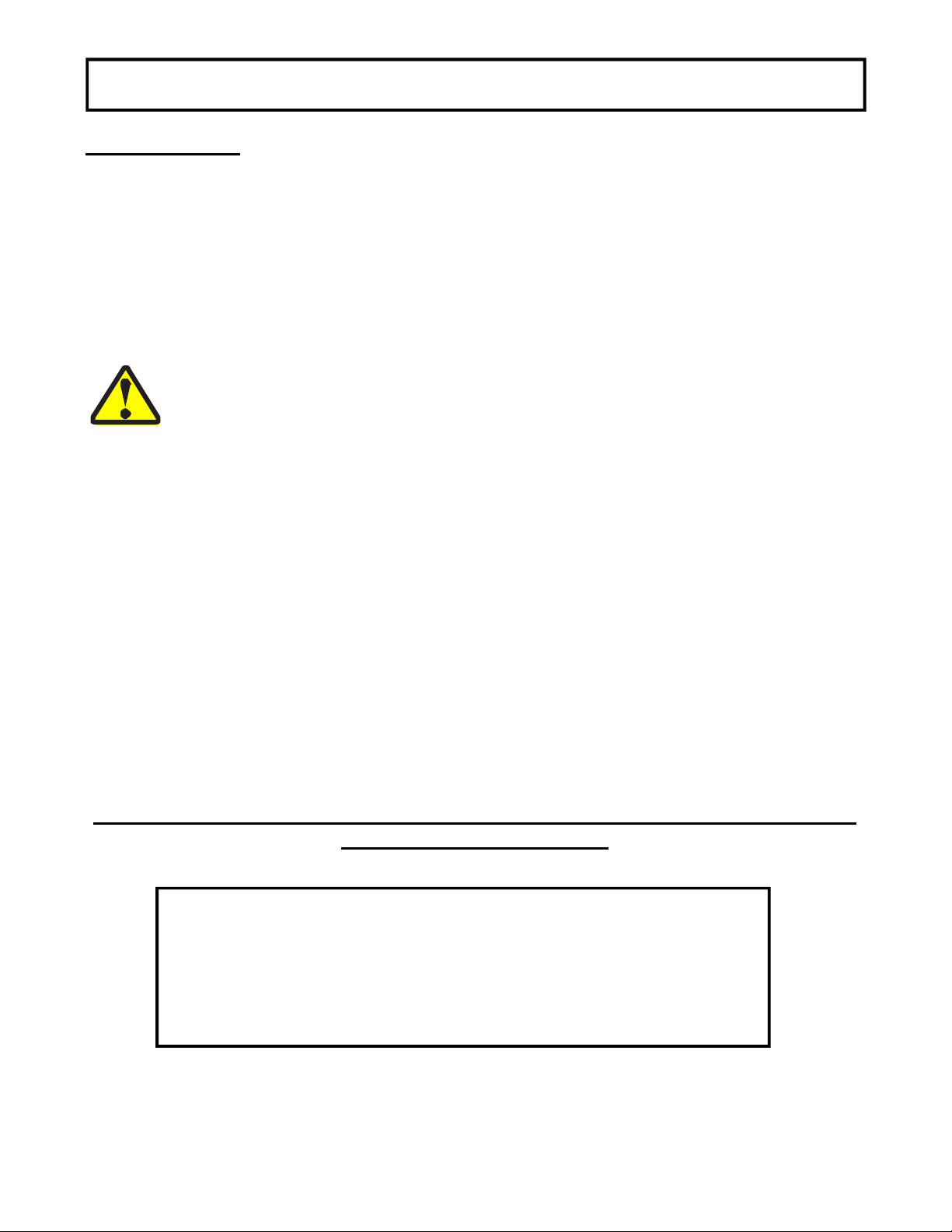

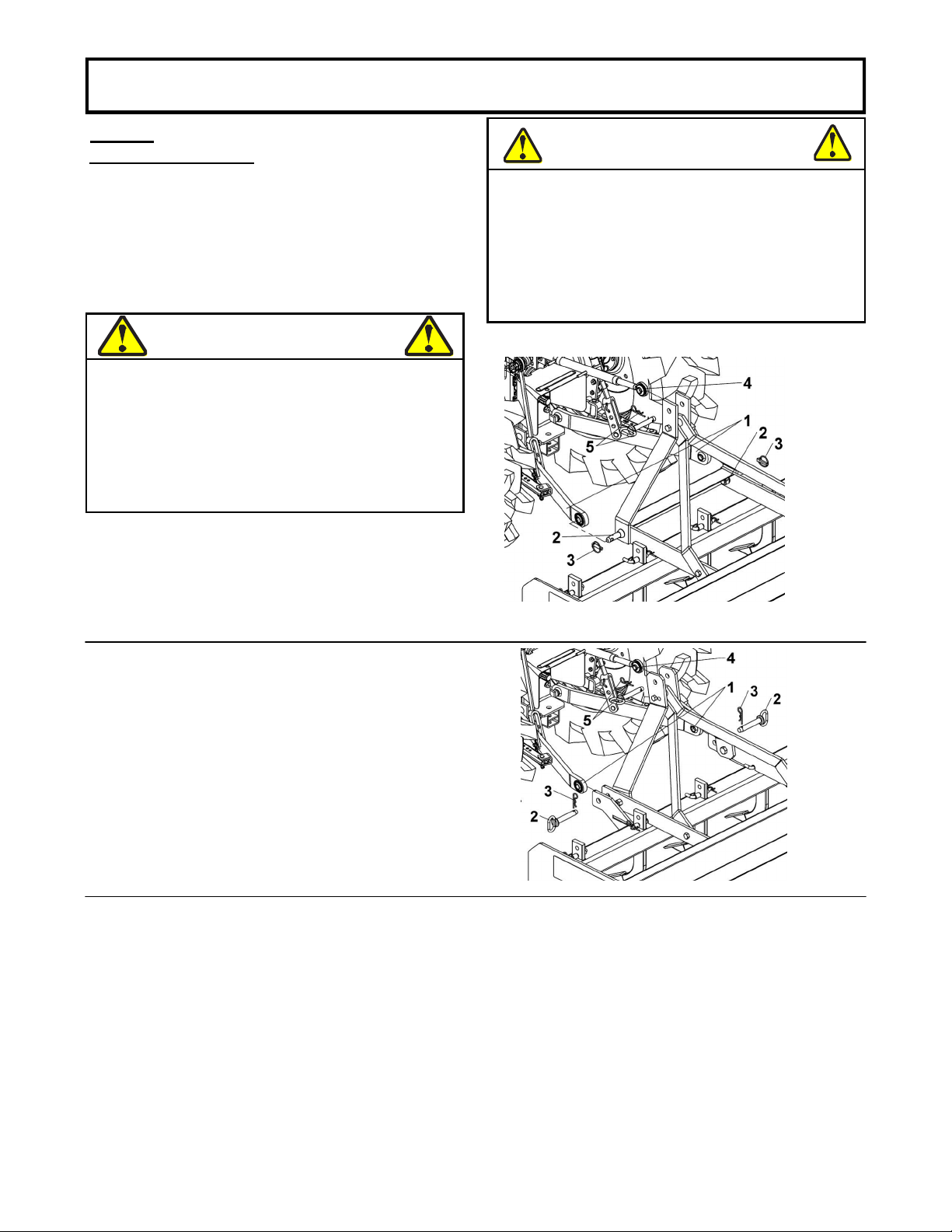

FORSDMODEL

Attachtractor’slowerarms(item1) onthepins(item

2)andsecurewithlynchpins(item3)

Connect top center link (item 4) to the upper hitch

usingapinandhairpin(item5)asshowninfigure3a.

Fig.3a

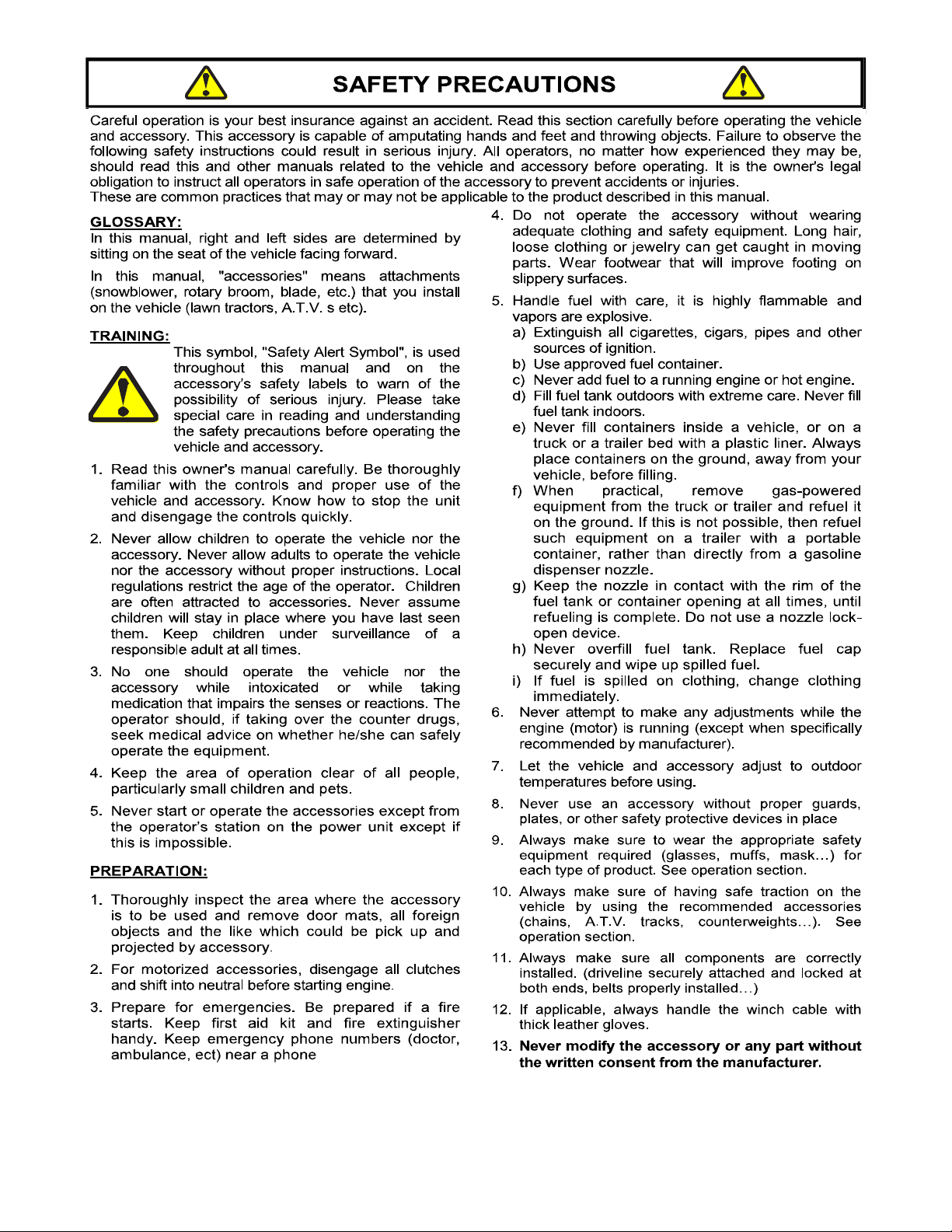

FORHDMODEL

Attach tractor’s lower arms (item 1) to frame of

assembled box scraper with two pins (item 2) and

securewithlynchpins(item3)

Connect top center link (item 4) to the upper hitch

usingapinandhairpin(item5)asshowninfigure3b.

Fig.3b