Features and benefits P 2 /10

stops the electric current when accidental over load on

the machine, and protects motor from burning.

And when the machine will be freed from the load,

restart the motor automatically. At this time, the soft

starter functions for suppression of starting shock.

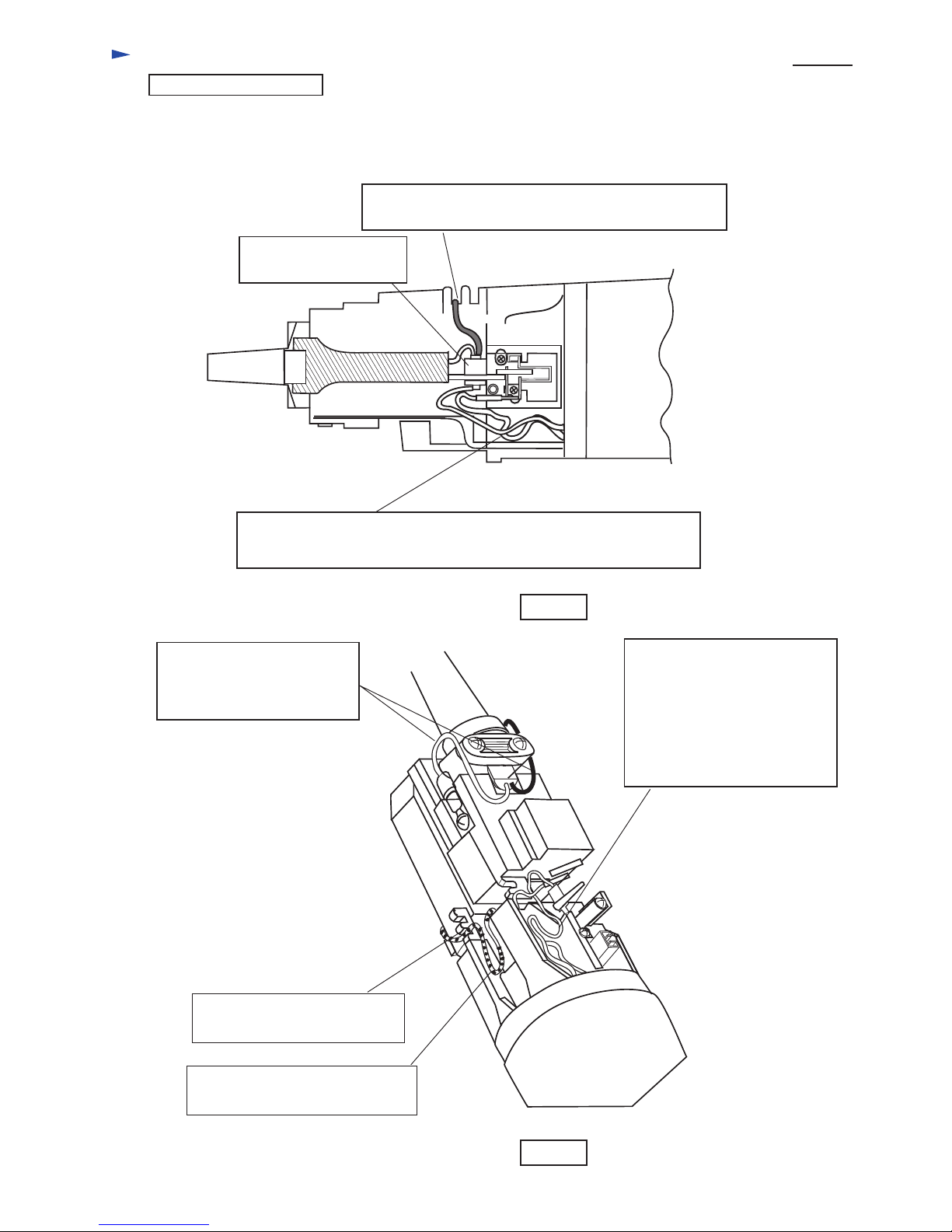

Electronic limiter for 9562C/CV, 9565C/CV Electronic controller for

9562C/CV, 9565C/CV

for keeping constant rpm.

even under loaded condition,

and for suppressing starting shock.

Tough Cord guard

excellent in flexibility

to protect power supply cord

from disconnection.

Speed control dial for

9562CV and 9565CV

for getting optimum rotating

speed to suit various work piece.

2

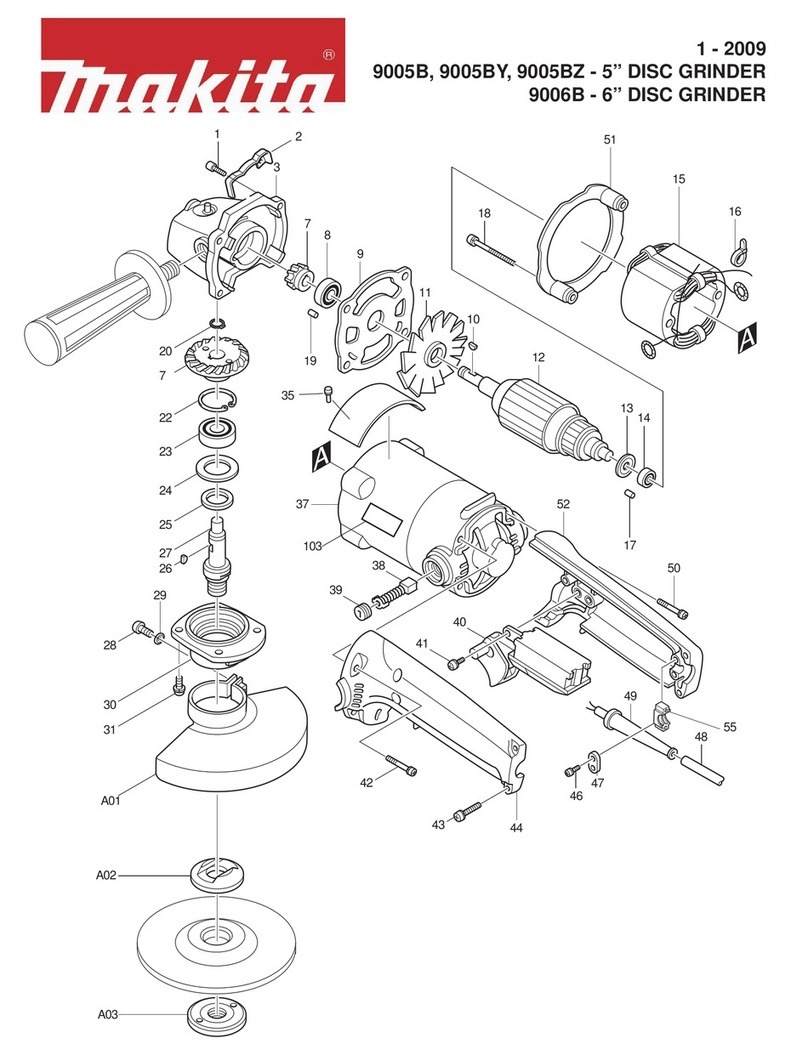

High sealed gear housing

to prevent leaking of grease

Adjustable wheel

cover's position

Wheel cover's position can be

adjusted without any tool.

High power and tough motor

9565C/CV: 1,400W

9562C/CV: 1,100W

9565 : 900W

9562 : 800W

High power from slim and compact body

thanks to new S60 type motor and electronic

control system.(only Model 9565C/CV and 9562C/CV)

Jig zag, and powdered varnish coating on

armature and field ensure effective protection

from sharp grinding dust.

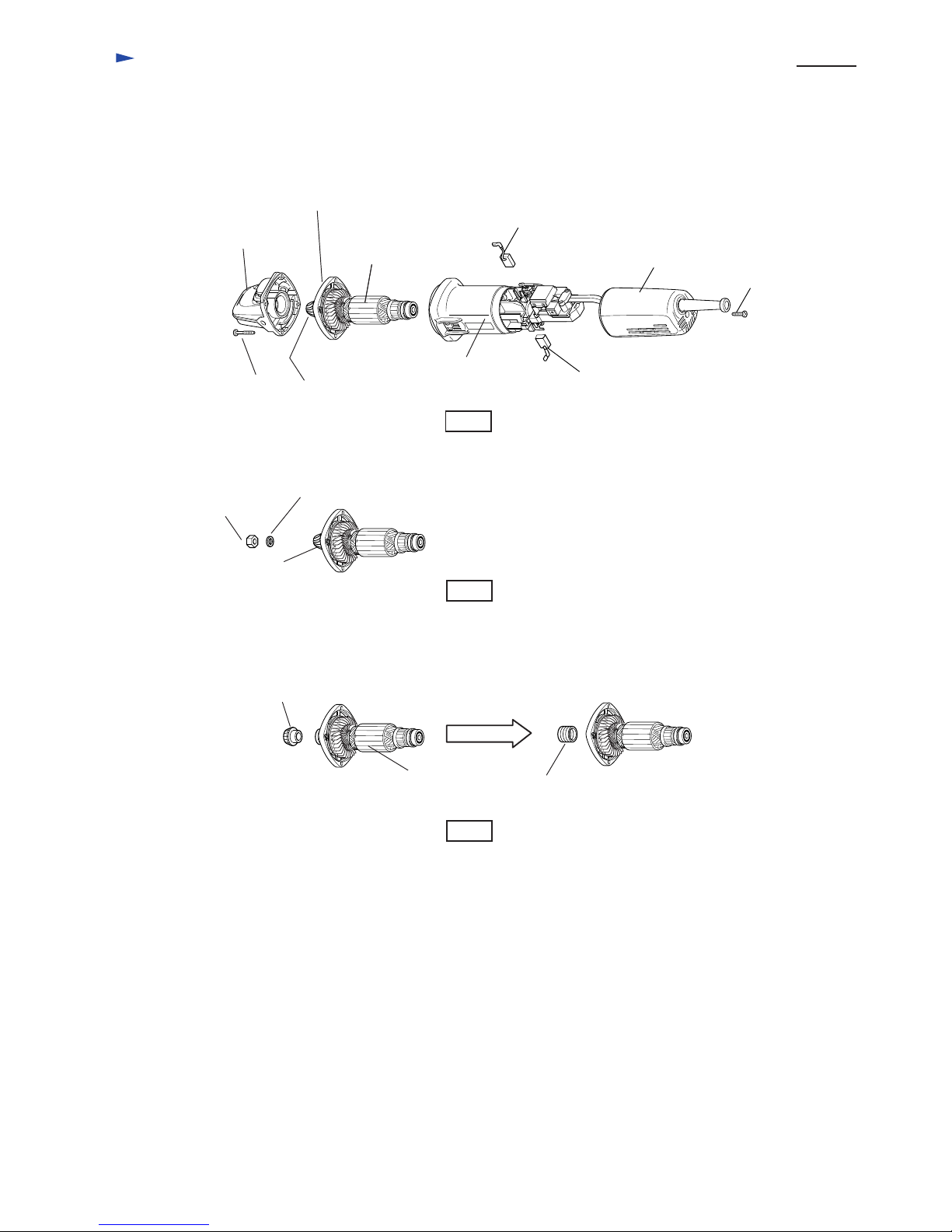

"Super Join System - SJS"

Lock spring joining spiral bevel gear

and armature shaft provides following

benefits.

* Smooth and comfortable grinding work.

* Suppression of shock by accidental

wheel lock during work.

* Prevention of damage on gear coming

from accidental wheel lock.

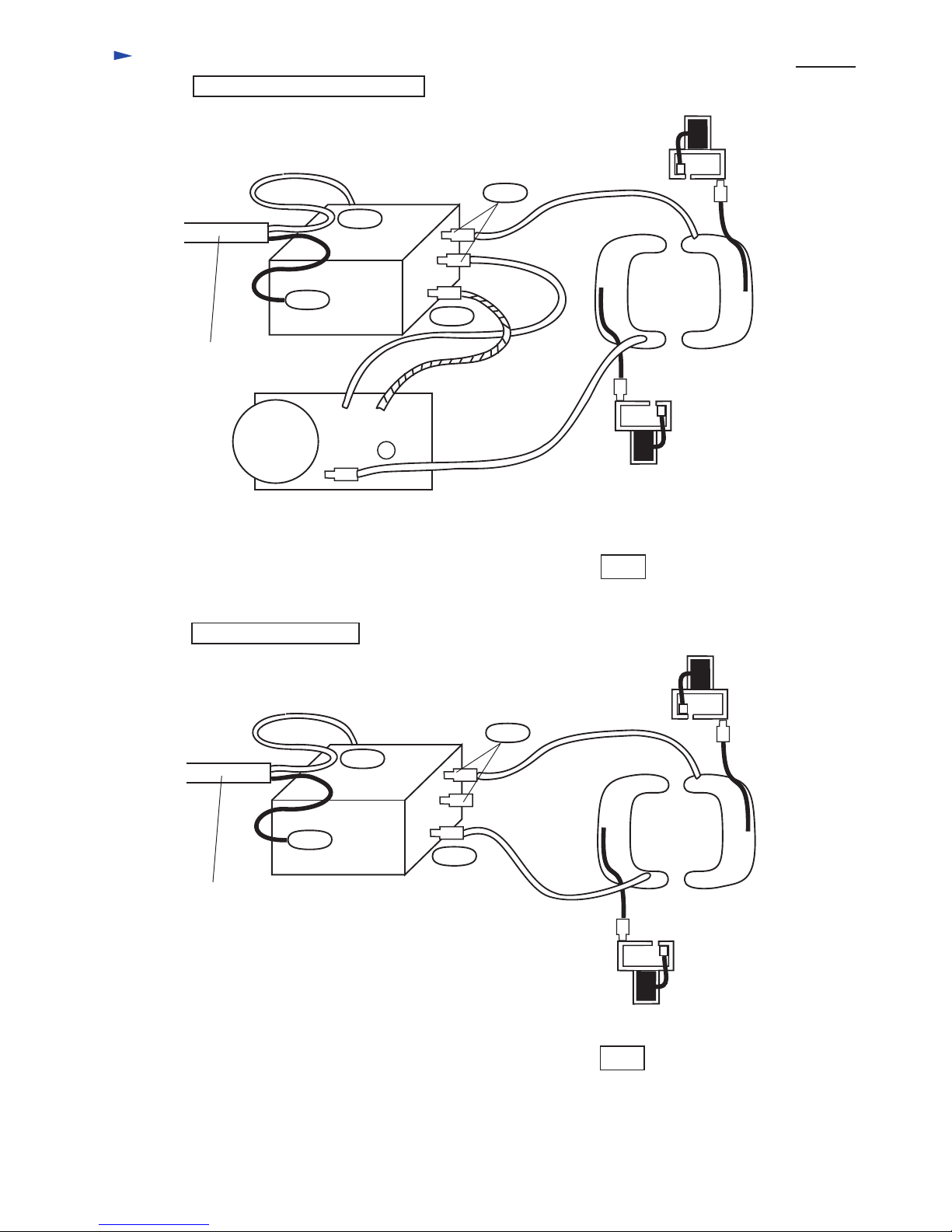

Protection from dust

Dust proof bearing Labyrinth structure Dust proof washer

Fan side of armature

Commutator side of armature

Wheel side of spindle X

X

**

**

: The spindle portion is protected from not only dust but also intruding water firmly.

Double Labyrinth