The subject models are cordless angle grinders powered by 18V Li-ion battery,

and equipped with highly enhanced Brushless DC motor compared to the current

models DGA402/ DGA452.

A built-in controller changes the cutting speed automatically according to load condition,

enabling users to obtain high speed rotation on light duty application/ high torque on

heavy duty application.

Models No.

Description

PRODUCT

TECHNICAL INFORMATION

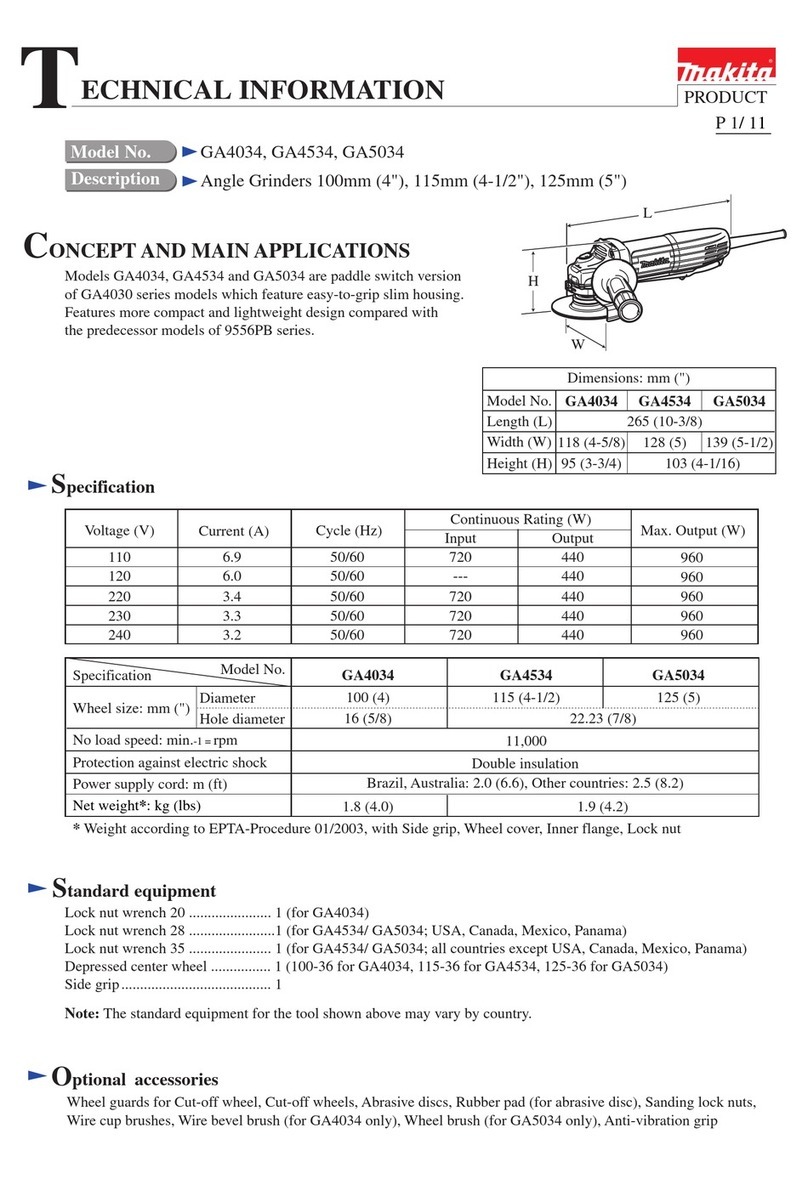

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

P 1/ 14

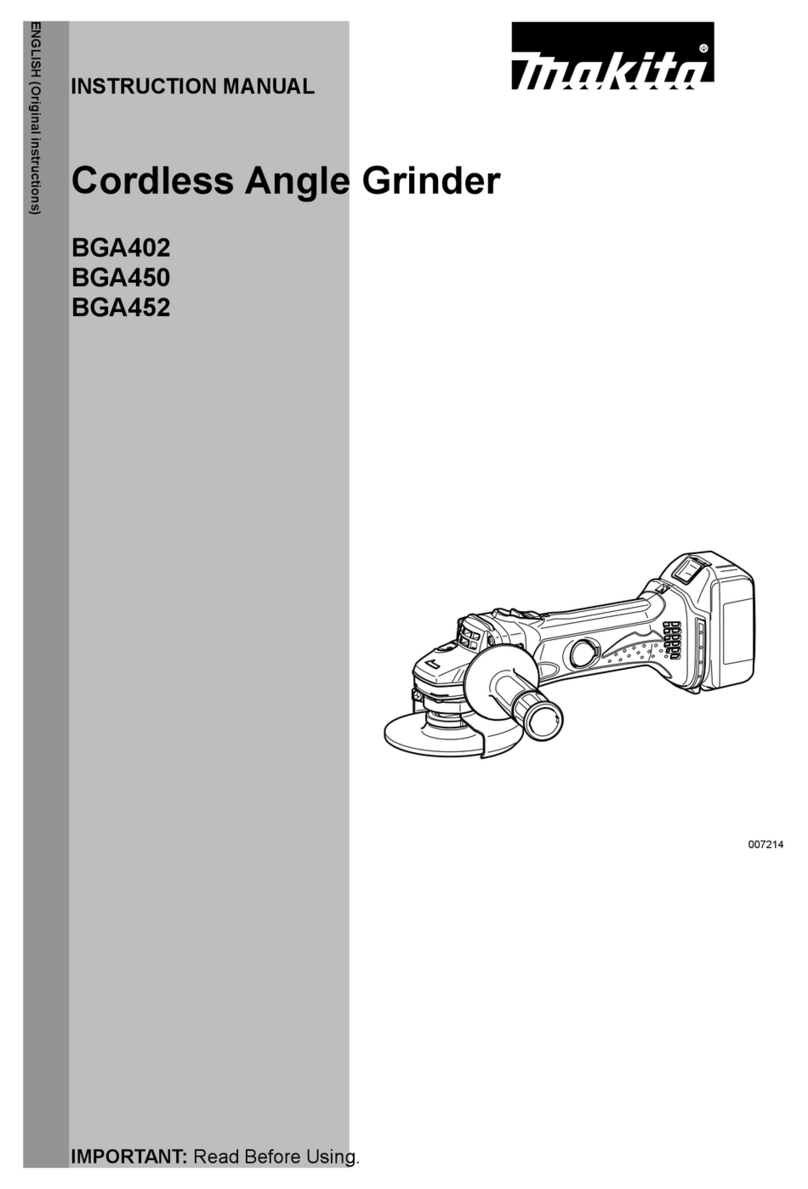

Dimensions: mm (")

DGA404

All

Width (W) DGA454

Length (L)*1 362 (14-1/4)

117 (4-5/8)

130 (5-1/8)

DGA504

DGA404

Height (H)

140 (5-1/2)

140 (5-1/2)

DGA454,

DGA504 145 (5-3/4)

Note: The standard equipment may vary by country or model variation.

DGA404, DGA454, DGA504

18V Cordless Angle Grinders L

H

W

Specification Model DGA404

18

Weight according to

EPTA-Procedure 01/2003: kg(lbs)*22.5 (5.5) 2.5 (5.6)2.4 (5.3)

Battery

1.5, 2.0, 3.0, 4.0, 5.0Capacity: Ah

Voltage: V

Li-ionCell

Energy capacity: W 27, 36, 54, 72, 90

Charging time (approx.): min. 15, 18, 22, 36, 45 with DC18RC

Wheel size: mm (") Hole diameter

6 (1/4)Max. thickness

Diameter 100 (4)

16 (5/8) 22.23 (7/8)

8,500

No

Yes

Yes

Yes

Yes

Yes

No load speed: min.ֿ ¹= rpm

Slide

Switch type

Electronic

control

Overload warning lamp

Electronic current limiter

Soft start

Anti-restart function

Battery fuel gauge

Soft grip

*2 With 3.0Ah battery

*1 With BL1830/ BL1840/ BL1850

Note: BL1815 is not compatible.

DGA504DGA454

115 (4-1/2) 125 (5)

Lock nut wrench ............................................ 1

Side grip ......................................................... 1

Depressed center grinding wheel ................... 1 (100mm for DGA404, 115mm for DGA454, 125mm for DGA504)

Battery cover .................................................. 1 (except -Z- model)

Plastic carrying case ....................................... 1 (except -Z- model)

Charger DC18RC ........................................... 1 (except -Z- model)

Li-ion battery BL1830 or BL1840 ................. 2 (except -Z- model)

Depressed center wheels

Rubber pads

Abrasive discs

Wire brushes

Diamond wheels

Abrasive cut off wheels

Toolless wheel covers

Sanding lock nuts

Fast charger DC18RC

Fast charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Four port multi charger DC18SF

Li-ion battery BL1815N

Li-ion battery BL1820

Li-ion battery BL1830

Li-ion battery BL1840

Li-ion battery BL1850

OFFICIAL USE

for ASC & Sales Shop