P 2 / 9

Repair

[2] LUBRICATION

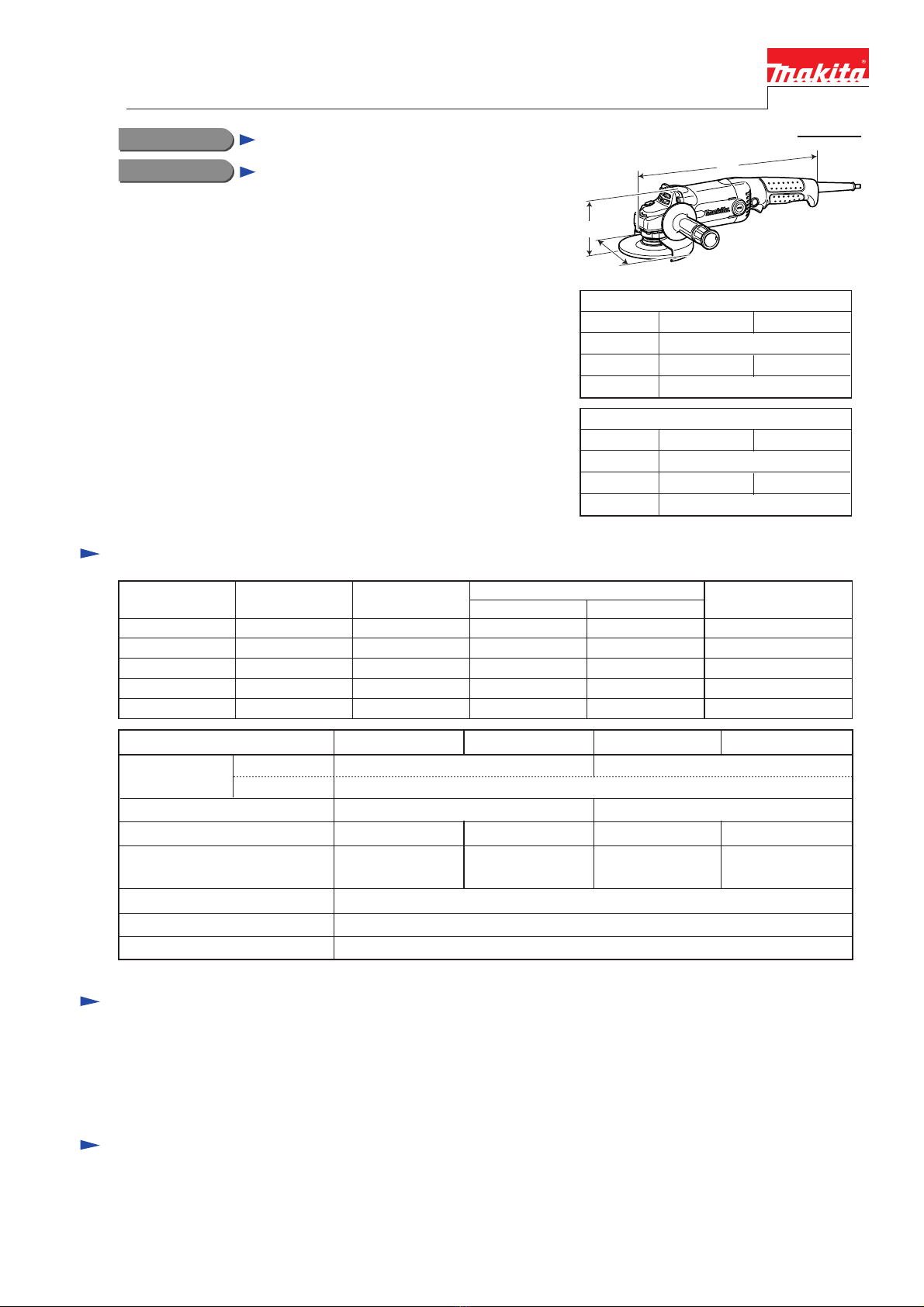

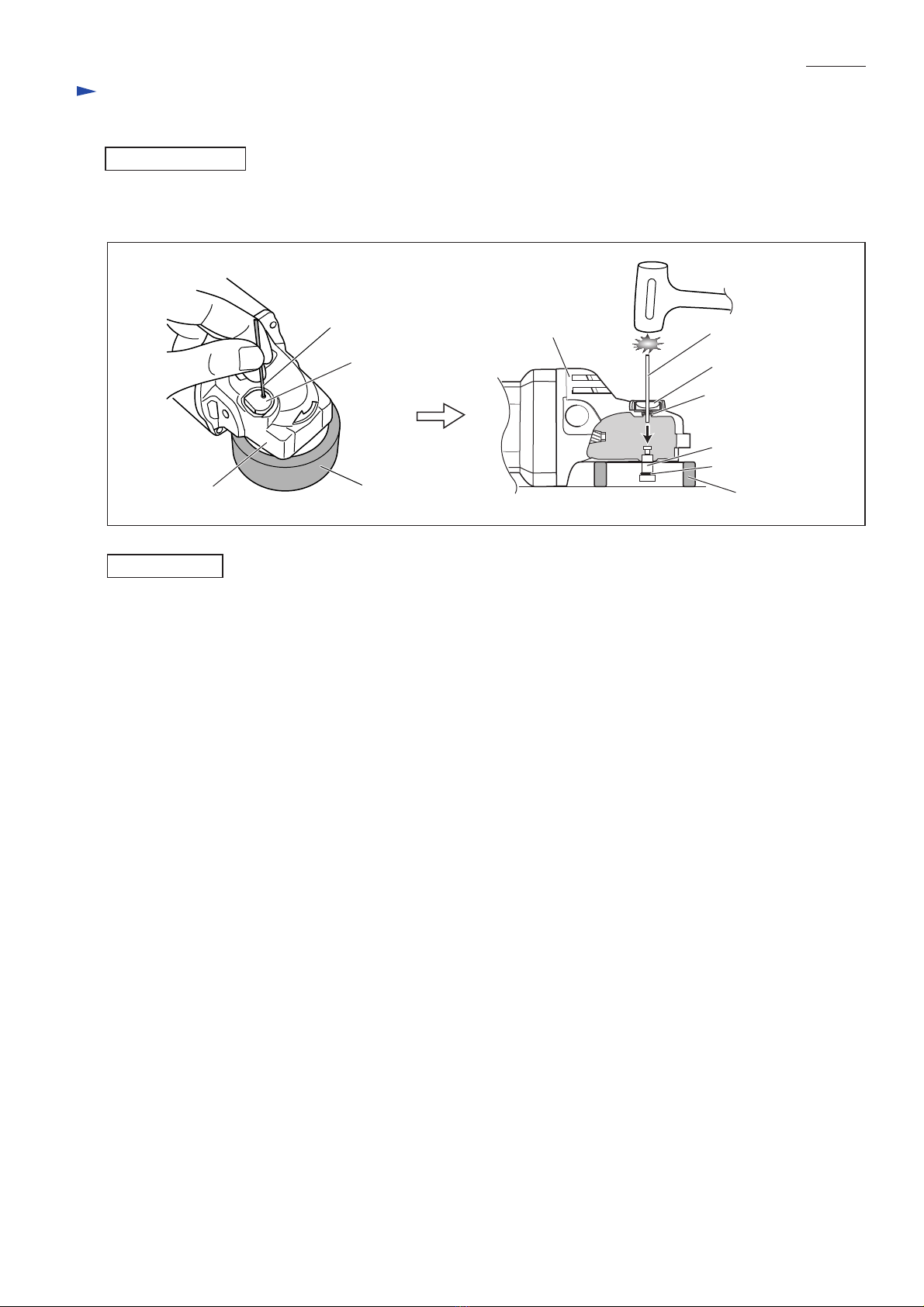

Lubricate the parts below in order to protect parts and product from unusual abrasion.

All models: Put approx. 15g of Makita grease SG No.0 in the gear room of Gear housing.

GA5020/ GA6020: Apply Makita Grease SG No.0 to the portions designated with the mark of . (Fig. 1)

[3] DISASSEMBLY/ASSEMBLY

[1] NECESSARY REPAIRING TOOLS

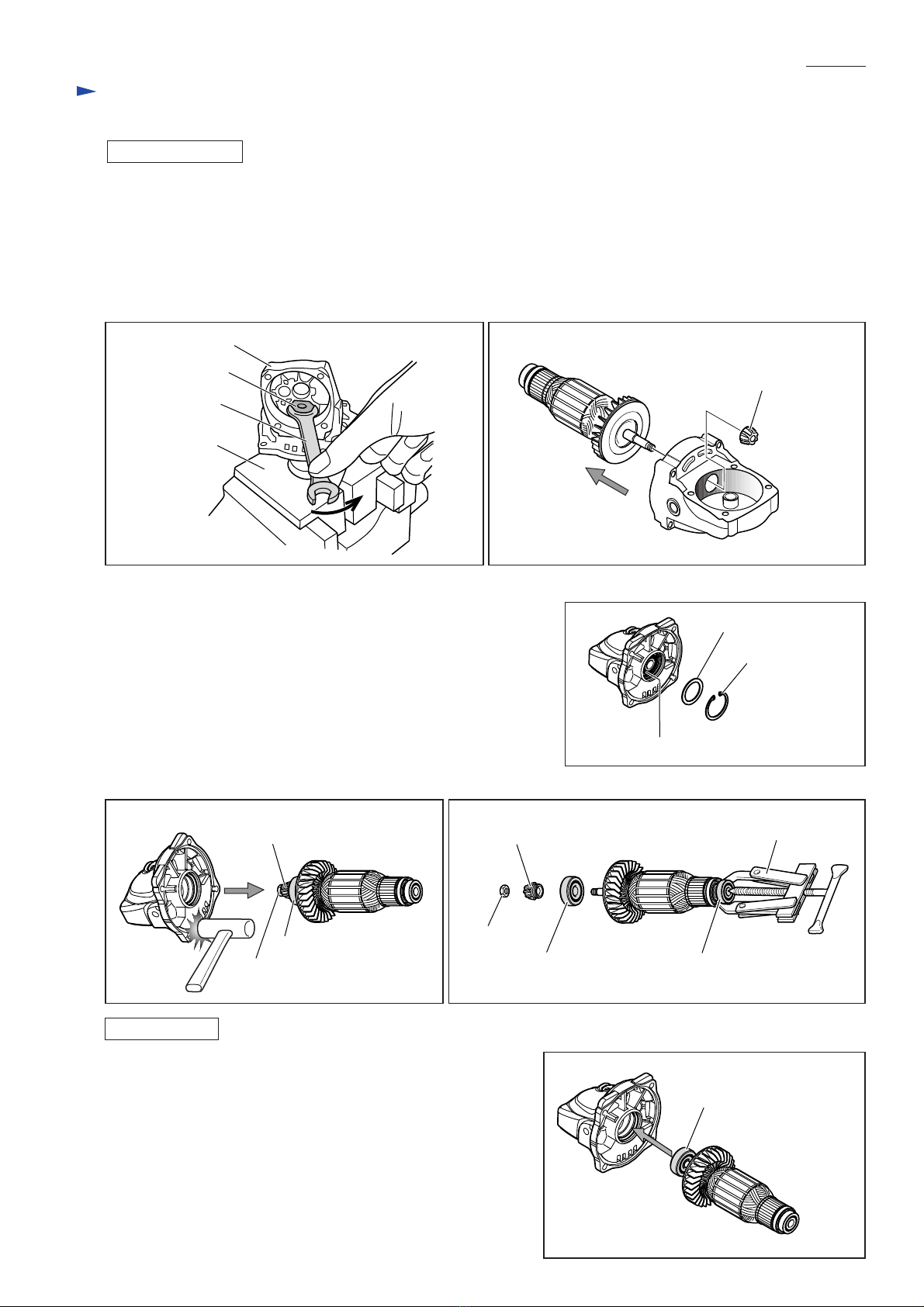

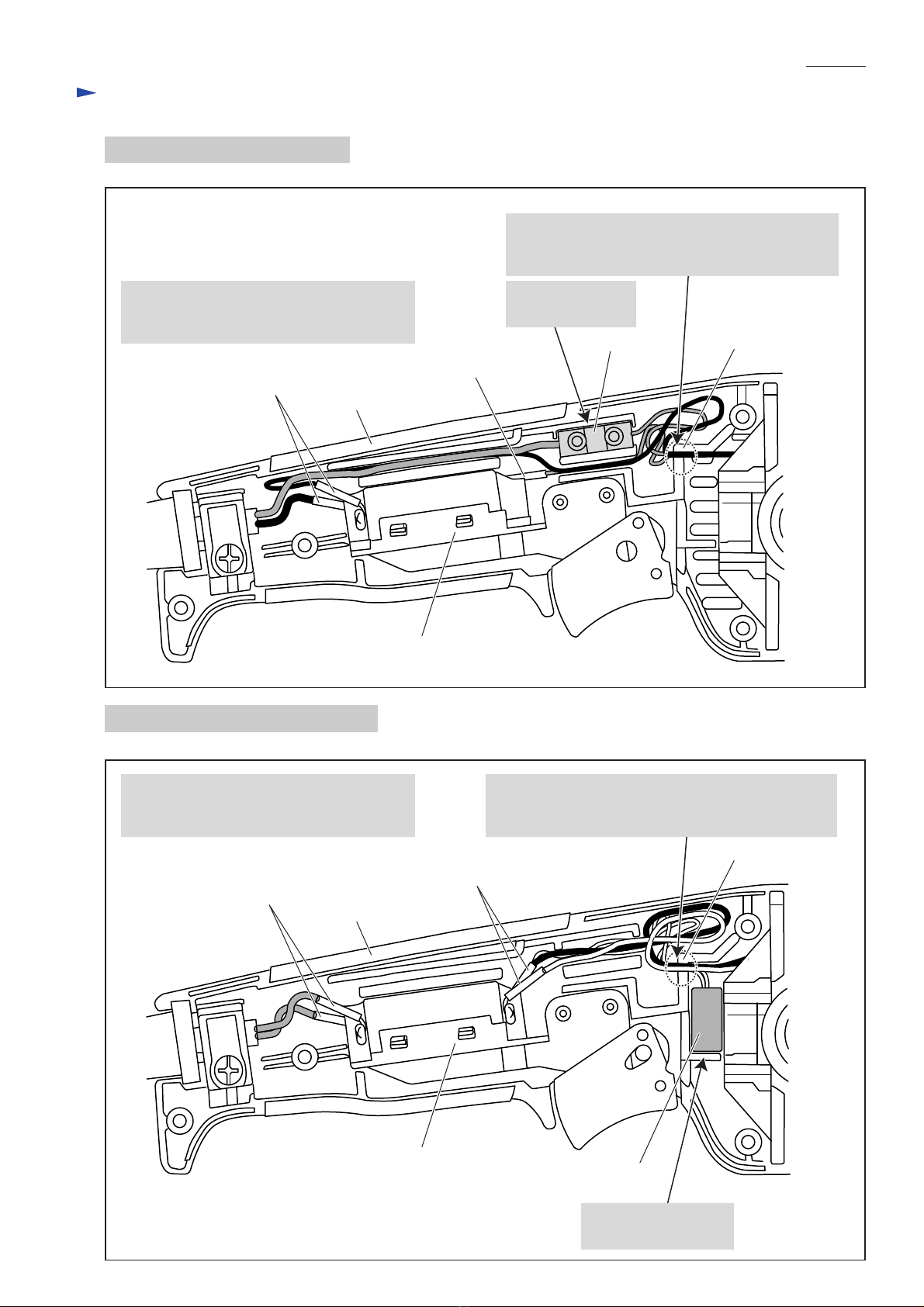

[3] -1. Armature, Small spiral bevel gear*3, Ball bearing 6000DDW

DISASSEMBLING Fig. 2

Pan head screw

M5x18 (4pcs)

Tapping screw

5x25 (4pcs)

1) After removing Carbon brush, separate Gear housing

together with Armature from Motor housing complete

by unscrewing four M5x18 Pan head screws. (Fig. 2)

2) Separate Bearing box from Gear housing by unscrewing

four 5x25 Tapping screws. (Fig. 2)

CAUTION: Unplug the machine and remove the wheel and the wheel cover from the machine

for safety before repair/ maintenance in accordance with the instruction manual!

Code No.

1R004

Description

Retaining ring pliers ST-2

[1R291 can be used instead of 1R004.]

Removal/installation of Ring spring 11 (GA5010/GA6010)

Removal/installation of Ring spring 7 (GA5020/GA6020)

1R005 Retaining ring pliers RT-2N Removing Retaining ring R-30

Installation of Large spiral bevel gear*1(GA5010/GA6010)

1R030 Bearing setting pipe 25-17.2

1R036 Bearing setting plate 17.2

Removal/installation of Hex nut M7

Removing Large spiral bevel gear (GA5010/GA6010)

Disassembling Shaft lock section

1R039 Armature holder 41.5 [one set required]

1R258 V block [2pcs required]

1R268 Spring pin extractor M3

1R269 Bearing extractor

Removing Lock sleeve and Lock spring 16--- Adjustable wrench

Removal/installation of Hex nut M7--- Wrench 11

Disassembling Shaft lock section1R350 Ring 60

Use for

Fig. 1

Large spiral bevel gear*2

Outside surface

Lock spring 1639

Surface that contacts Large spiral bevel gear*1

Spindle49

Item No. Description Portion to lubricate

39

49

Bearing box

Motor housing

complete

Gear housing

*2: Different spiral bevel gears are used

by different models as follows:

GA5020/ Spiral bevel gear 34B

GA6020/ Spiral bevel gear 35B

*3: Different spiral bevel gears are used

by different models as follows:

GA5010 and GA5020/ Spiral bevel gear 13

GA6010 and GA6020/ Spiral bevel gear 11

Removing Ball bearing 696ZZ

*1: Different spiral bevel gears are used by different models

as follows:

GA5010/ Spiral bevel gear 34A

GA6010/ Spiral bevel gear 35A