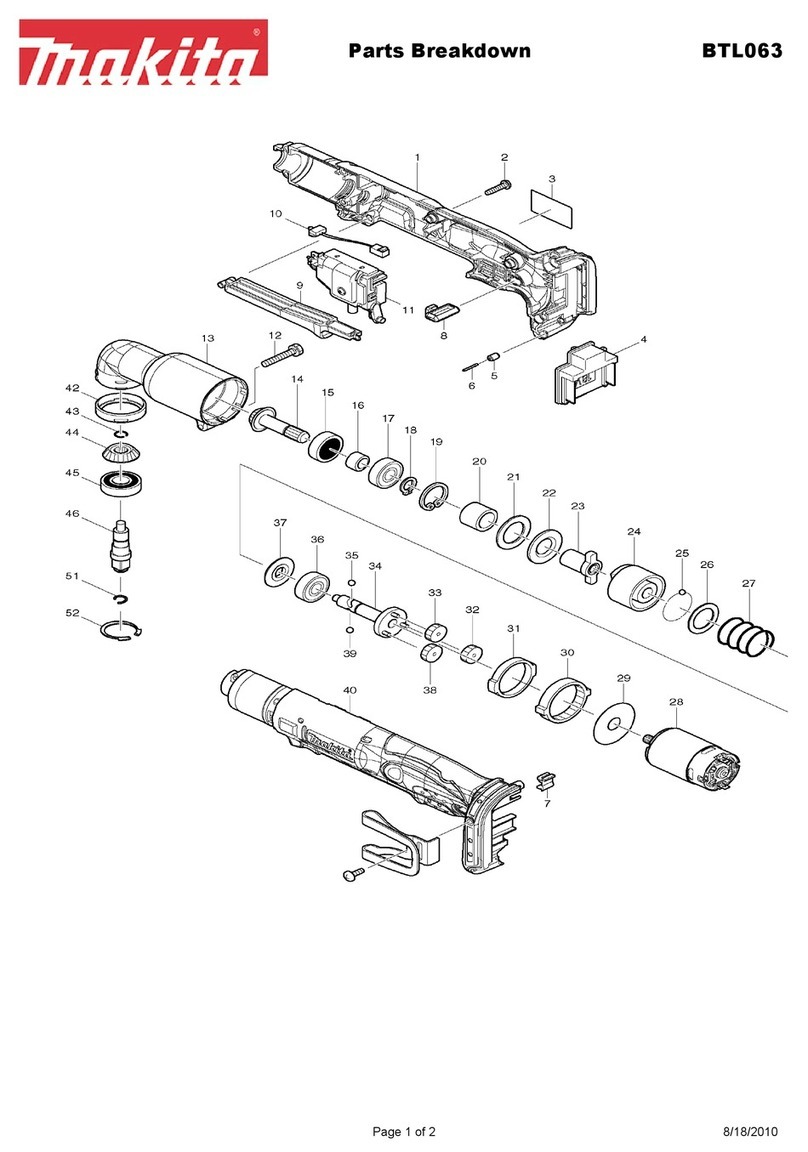

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 119 (4-11/16)

79 (3-1/8)

220 (8-5/8)*1

238 (9-3/8)*2

*1 With Battery BL1815, BL1815N

or BL1820

*2 With Battery BL1830, BL1840

or BL1850

W

H

L

PRODUCT

TECHNICAL INFORMATION

Model No.

Description

P 1/ 14

DTD148

Cordless Impact Driver

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

Model DTD148 Cordless Impact Driver is an advanced version

of the current model DTD147.

It features more compact body (overall length: 119mm) and

higher power than DTD147 while having the following same

benefits as the current model:

• Brushless motor

• Electronic 3-stage impact power selection

with variable power control in each range

• XPT (eXtreme Protection Technology) for use in outdoor

applications or harsh environments

• T-mode (Tightening mode for self-drilling screw)

This product is compatible with 18V- 1.3Ah, 1.5Ah, 2.0Ah, 3.0Ah, 4.0Ah or

5.0Ah Li-ion batteries

BL1815, BL1815N, BL1820, BL1830, BL1840 or BL1850.

Battery

No load speed: min.ˉ¹=rpm

Impacts per min.: min.ˉ¹=ipm

Max. tightening torque*3: N.m [kgf.cm] (in.lbs)

Charging time (approx.): min.

Capacities

Electric brake

Reverse switch

Weight according to EPTA-Procedure 01/2003: kg (lbs)

Variable speed control by trigger

Capacity: Ah

Cell

Voltage: V 18V

0 - 3,600/ 2,100/ 1,100

0 - 3,800/ 2,600/ 1,100

175 [1,780] (1,550)

Standard bolt

High tensile bolt

Machine screw

Driving shank

M5 - M16 (3/16 - 5/8")

M5 - M14 (3/16 - 9/16")

Coarse-thread 22 - 125mm (7/8 - 4-7/8")

M4 - M8 (5/32 - 5/16")

Yes

Yes

Yes

LED job light Yes

1.2 (2.8)*4/ 1.5 (3.3)*5

1.3, 1.5, 2.0, 3.0, 4.0, 5.0

Energy capacity: Wh 24, 27, 36, 54, 72, 90

Li-ion

290

15, 15, 24, 22, 36, 45 with DC18RC

6.35mm (1/4") Hex

Max output (W)

*3 Tightening torque at 3 seconds after seating, when tightening M16 (grade 10.9) high strength bolt.

*4 With Battery BL1815,BL1815N or BL1820

*5 With Battery BL1830,BL1840 or BL1850

Phillips bits

Socket bits

Drill chucks

Drill bits with 6.35mm Hex shank

Hole saws for impact driver

Bit piece

Stopper for impact driver

Hook set (Belt clip)

Tool catcher set

Battery protectors

Li-ion Battery BL1850

Li-ion Battery BL1840

Li-ion Battery BL1830

Li-ion Battery BL1820

Li-ion Battery BL1815N

Li-ion Battery BL1815

Charger DC18SD

Charger DC24SC

Fast charger DC18RC

Automotive charger DC18SE

Four port multi charger DC18SF

Impact power selection Electronic 3 stage (Hard/ Medium/ Soft)

+ Teks screw mode

Hard/ Medium/ Soft

Hard/ Medium/ Soft

Belt clip

Battery*6, Battery cover*7

Charger*6, Plastic carrying case Note: The standard equipment may vary by country or model variation.

*6 Battery and charger are not supplied with “Z” model

*7 Supplied with the same quantity of extra Battery

OFFICIAL USE

for ASC & Sales Shop

PI / SC / NP 海外営業管理承認