Makita AN942 Manual

Other Makita Nail Gun manuals

Makita

Makita AN711H User manual

Makita

Makita AF505N User manual

Makita

Makita GN01 User manual

Makita

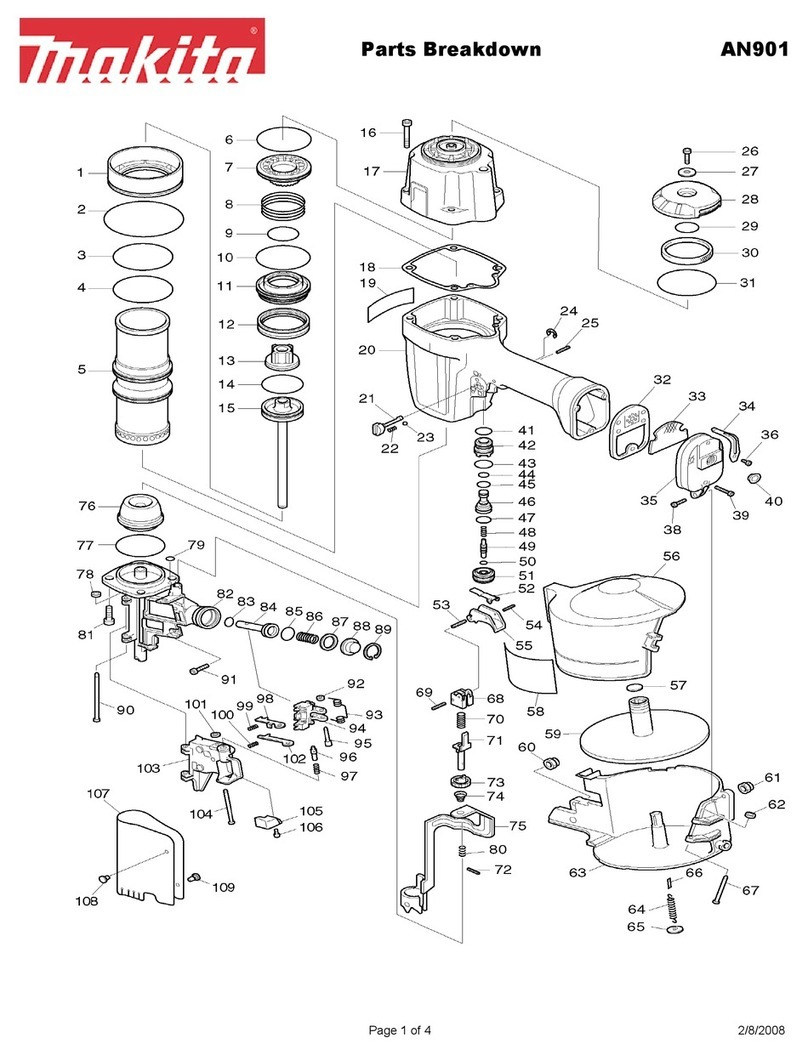

Makita AN901 Quick start guide

Makita

Makita AF505 User manual

Makita

Makita AN923 User manual

Makita

Makita AN911H User manual

Makita

Makita AF600 User manual

Makita

Makita DBN600 User manual

Makita

Makita BL1815N Manual

Makita

Makita AF505 User manual

Makita

Makita GN420C User manual

Makita

Makita GN420C User manual

Makita

Makita AF505 Quick start guide

Makita

Makita AN610H User manual

Makita

Makita DPT353ZJ User manual

Makita

Makita DBN500 User manual

Makita

Makita AF506 User manual

Makita

Makita GN420C User manual

Makita

Makita AN611 User manual

Popular Nail Gun manuals by other brands

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes

Senco

Senco Fusion Technology F-35XP operating instructions

Grizzly

Grizzly G1847 instruction manual

Ryobi

Ryobi R18N18G Original instructions

Black & Decker

Black & Decker 492848-00 instruction manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN TN90 user manual

Metabo HPT

Metabo HPT NR 3690DC Instruction and safety manual

Surtek

Surtek CN650 User manual and warranty

Parkside

Parkside PET 25 B1 Operation and safety notes

Senco

Senco AirFree 25 operating instructions