Makita BFR540 Manual

Other Makita Power Screwdriver manuals

Makita

Makita DFR452 User manual

Makita

Makita DFS451Z User manual

Makita

Makita 6821 User manual

Makita

Makita DFL083F User manual

Makita

Makita 6705D User manual

Makita

Makita BFT020F User manual

Makita

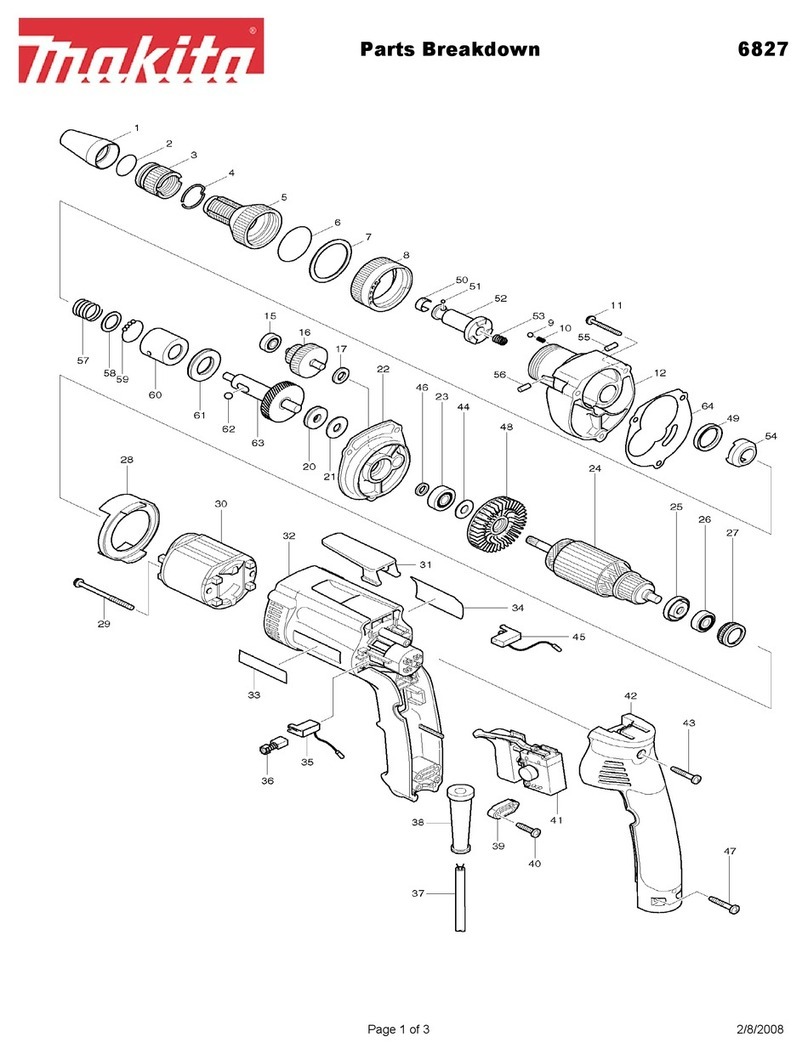

Makita 6827 Quick start guide

Makita

Makita 6891D User manual

Makita

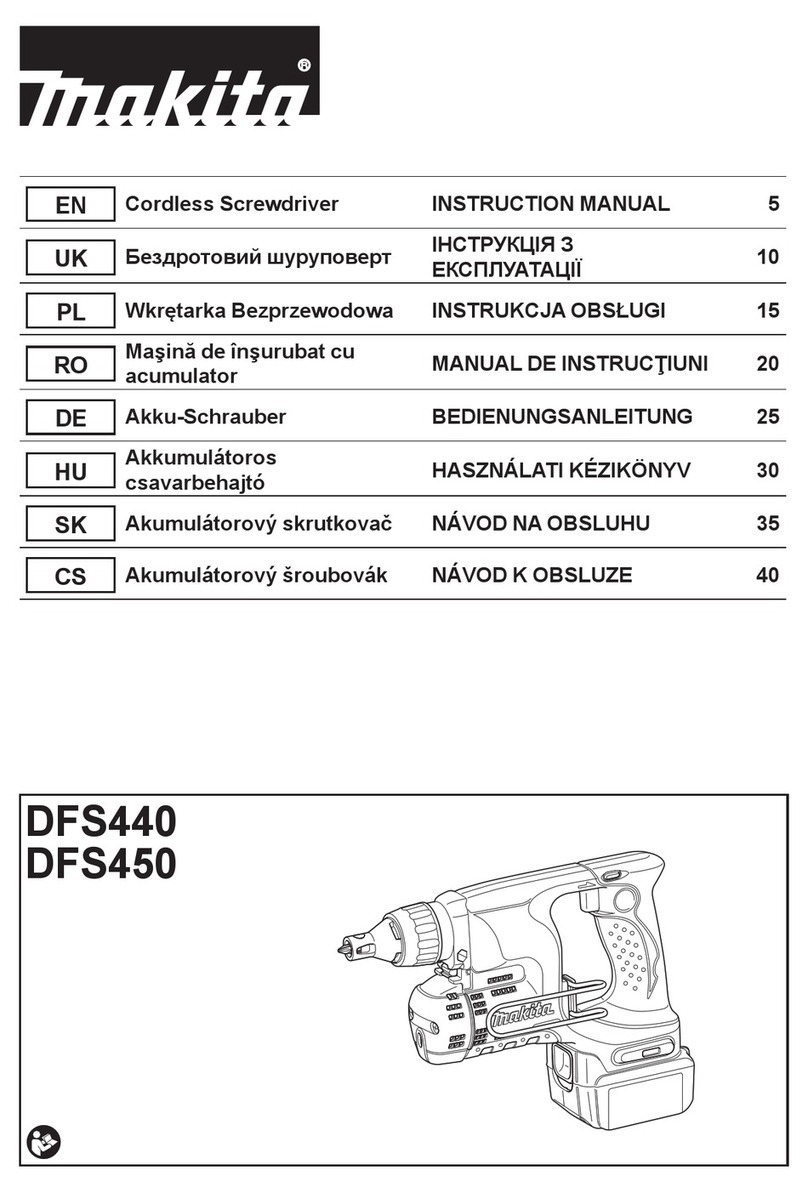

Makita DFS440 User manual

Makita

Makita DFS441 User manual

Makita

Makita BFT041R User manual

Makita

Makita DFL300F User manual

Makita

Makita BFT040F User manual

Makita

Makita 6842 User manual

Makita

Makita 6842 User manual

Makita

Makita DDA460 User manual

Makita

Makita BFS441 User manual

Makita

Makita XSF01 User manual

Makita

Makita DDA351RMJ User manual

Makita

Makita 6723DW User manual

Popular Power Screwdriver manuals by other brands

Festool

Festool TI 15 operating manual

Matatakitoyo Torque Tools

Matatakitoyo Torque Tools MTD Operation manual

Skil

Skil 2346 Operating/safety instructions

DeWalt

DeWalt XR LI-ION DCD931 user manual

Festool

Festool DWC 18-2500 operating manual

EINHELL

EINHELL TE-CD 12/1 Li Series Original operating instructions