8ENGLISH

2. Direct the exhaust so as to minimize distur-

bance of dust in a dust lled environment.

3. If dust or objects are emitted in the work area,

reduce the emission as much as possible to

reduce the health hazards and risk of injury.

Noise hazards

1. Unprotected exposure to high noise levels can

cause permanent, disabling, hearing loss and

other problems such as tinnitus (ringing, buzz-

ing, whistling or humming in the ears).

2. Conduct a risk assessment regarding noise

hazards in the work area and implement appro-

priate controls for these hazards.

3. Appropriate controls to reduce the risk may

include actions such as damping materials to

prevent workpieces from "ringing".

4. Use appropriate hearing protection.

5. Operate and maintain the tool as recom-

mended in these instructions, to prevent an

unnecessary increase in noise levels.

6. Take noise reduction measures, for exam-

ple placing workpieces on sound damping

supports.

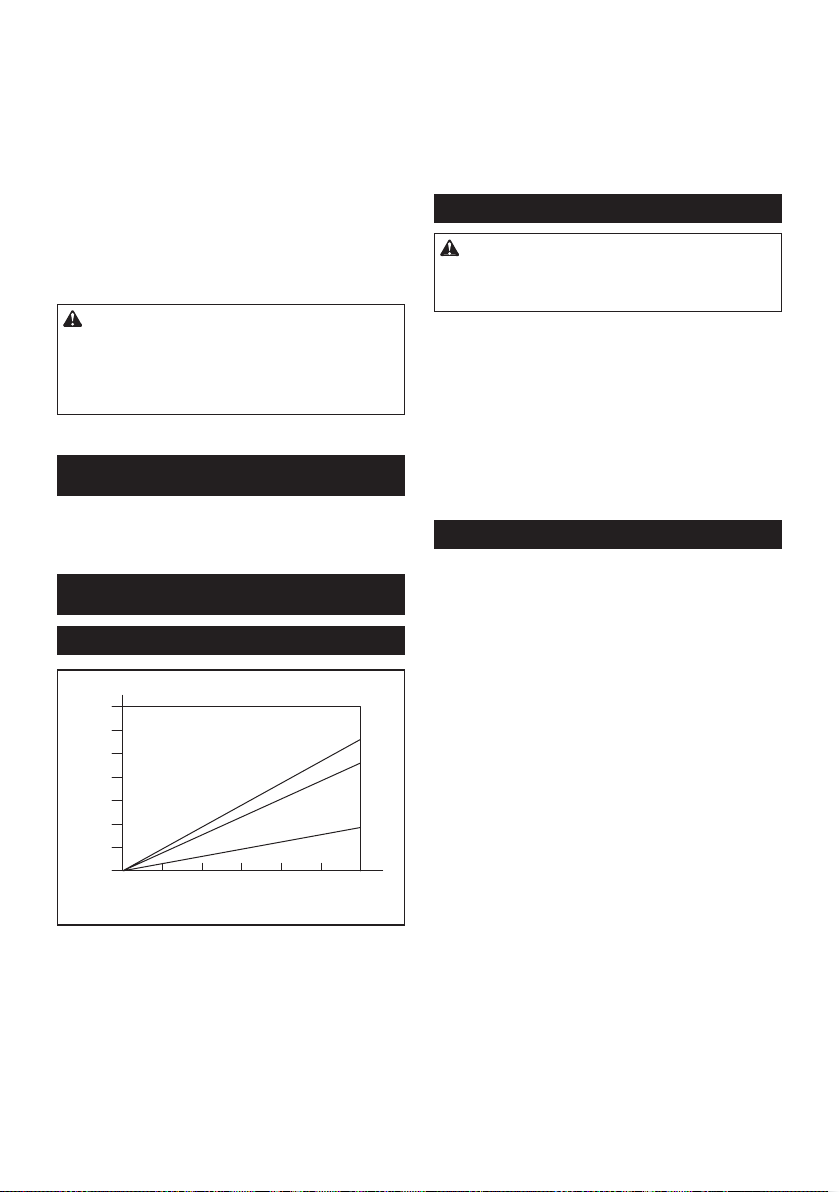

Vibration hazards

1. The vibration emission during operation

depends on the gripping force, the contact

pressure force, the working direction, the

adjustment of energy supply, the workpiece,

the workpiece support. Conduct a risk assess-

ment regarding vibration hazards and imple-

ment appropriate controls for these hazards.

2. Exposure to vibration can cause disabling

damage to the nerves and blood supply of the

hands and arms.

3. Wear warm clothing when working in cold

conditions, keep your hands warm and dry.

4.

If you experience numbness, tingling, pain or

whitening of the skin in your ngers or hands,

seek medical advice from a qualied occupational

health professional regarding overall activities.

5. Operate and maintain the tool as recom-

mended in these instructions, to prevent an

unnecessary increase in vibration levels.

6. Hold the tool with a light, but safe, grip

because the risk from vibration is generally

greater when the grip force is higher.

Additional warnings for pneumatic tools

1. Compressed air can cause severe injury.

2. Always shut off air supply, and disconnect tool

from air supply when not in use.

3. Always disconnect the tool from the com-

pressed air supply before changing acces-

sories, making adjustments and/or repairs,

when moving away from an operating area to a

different area.

4. Keep ngers away from trigger when not

operating the tool and when moving from one

operating position to another.

5. Never direct compressed air at yourself or

anyone else.

6. Whipping hoses can cause severe injury.

Always check for damaged or loose hoses or

ttings.

7. Never carry a pneumatic tool by its hose.

8. Never drag a pneumatic tool by its hose.

9. When using pneumatic tools, do not exceed

the maximum operating pressure ps max.

10. Pneumatic tools should only be powered

by compressed air at the lowest pressure

required for the work process to reduce noise

and vibration, and minimize wear.

11. Using oxygen or combustible gases for oper-

ating pneumatic tools creates a re and explo-

sion hazard.

12. Be careful when using pneumatic tools as the

tool could become cold, affecting grip and

control.

Additional warnings for tools with contact actuation

capability

1. Do not rest your nger on the trigger when

picking up the tool, moving between operating

areas and positions or walking, as resting

nger on trigger can lead to inadvertent opera-

tion. For tools with selective actuation, always

check the tool before use to ascertain the

correct mode is selected.

2. This tool has either selective actuation for con-

tact actuation or continuous contact actuation

by actuation mode selectors or is a contact

actuation or continuous actuation contact tool

and has been marked with the symbol above.

Its intended uses are for production applica-

tions such as pallets, furniture, manufactured

housing, upholstery and sheathing.

3. If using this tool in selective actuation mode,

always ensure it is in the correct actuation

setting.

4. Do not use this tool in contact actuation for

applications such as closing boxes or crates

and tting transportation safety systems on

trailers and lorries.

5. Be careful when changing from one driving

location to another.

Safety devices

1. Make sure all safety systems are in working

order before operation. The tool must not oper-

ate if only the trigger is pulled or if only the contact

arm is pressed against the wood. It must work only

when both actions are performed. Test for possible

faulty operation with fasteners unloaded and the

pusher in fully pulled position.

2. Securing the trigger in the ON position is very

dangerous. Never attempt to fasten the trigger.

3. Do not attempt to keep the contact element

depressed with tape or wire. Death or serious

injury may occur.

4. Always check contact element as instructed

in this manual. Fasteners may be driven acci-

dentally if the safety mechanism is not working

correctly.