Makita HR2511 User manual

Other Makita Rotary Hammer manuals

Makita

Makita HR2430 Manual

Makita

Makita DHR400 User manual

Makita

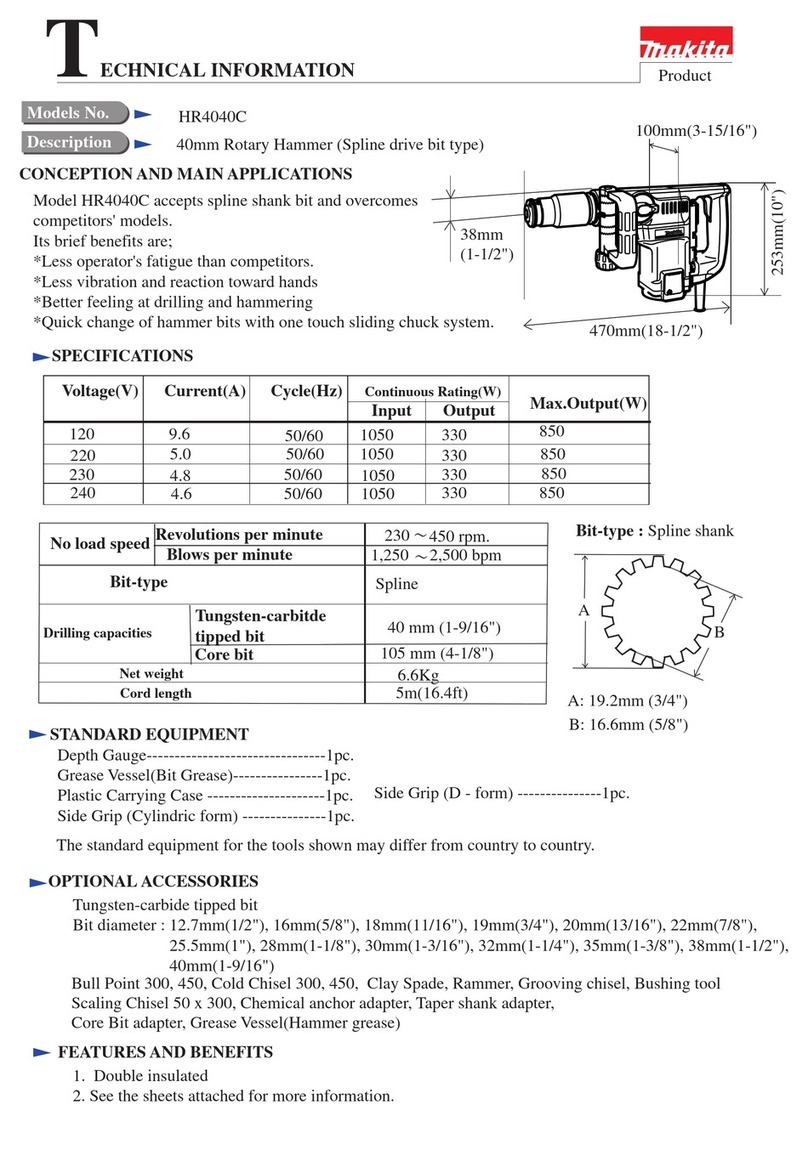

Makita HR4040C Manual

Makita

Makita HR3000C User manual

Makita

Makita BHR200 User manual

Makita

Makita DHR400 User manual

Makita

Makita HR140D User manual

Makita

Makita HR2800 User manual

Makita

Makita HR3000C User manual

Makita

Makita HR3000C User manual

Makita

Makita HR140DSMJ User manual

Makita

Makita BHR162 User manual

Makita

Makita HPR2410 Operating and maintenance manual

Makita

Makita HR2470 User manual

Makita

Makita HR2601 User manual

Makita

Makita HR5000 User manual

Makita

Makita HR2400 User manual

Makita

Makita HR2010 User manual

Makita

Makita DHR164 User manual

Makita

Makita HR140DWMJ User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions