Makita HR4030C Manual

Other Makita Rotary Hammer manuals

Makita

Makita HR2450 Series User manual

Makita

Makita HR140DWMJ User manual

Makita

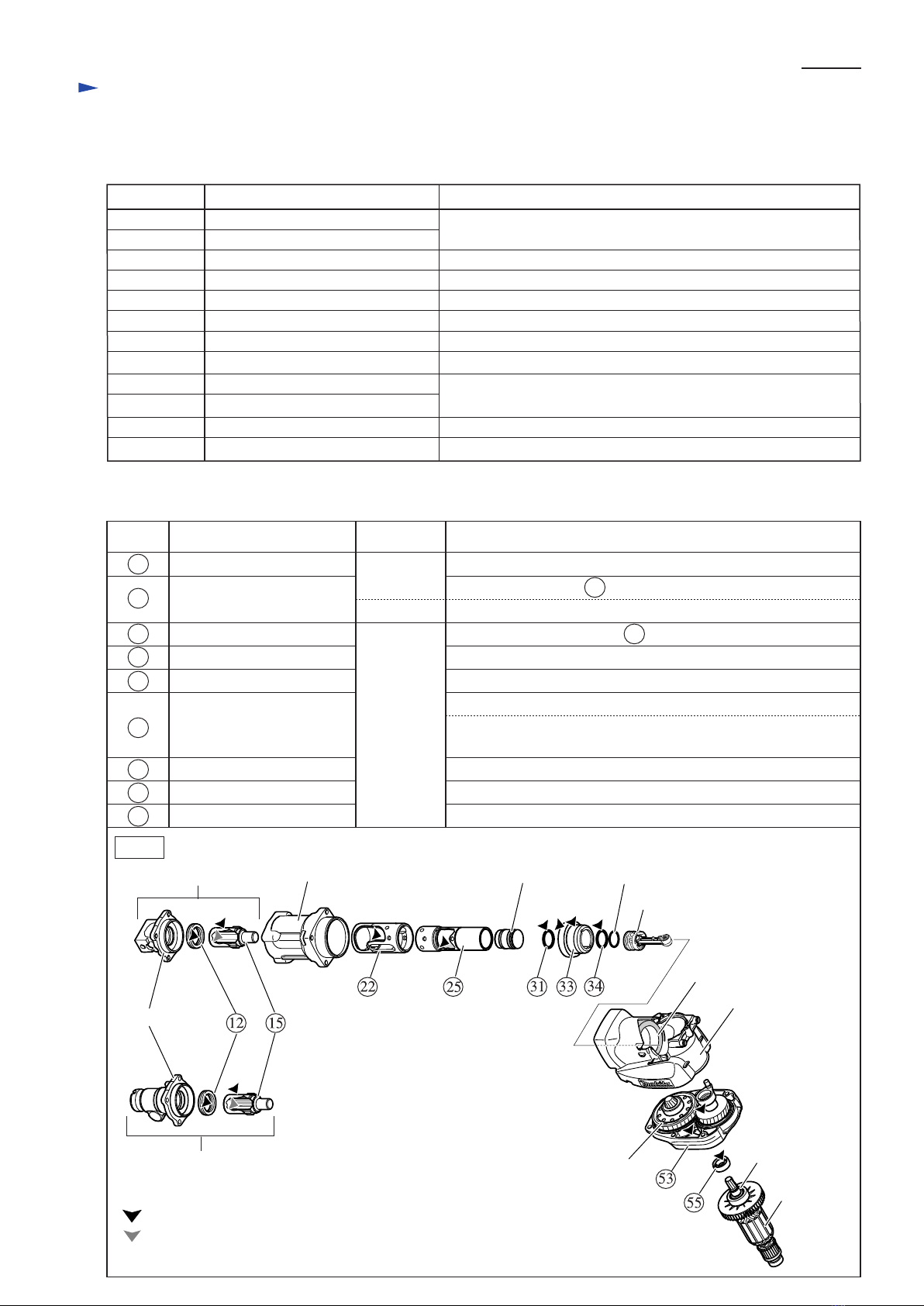

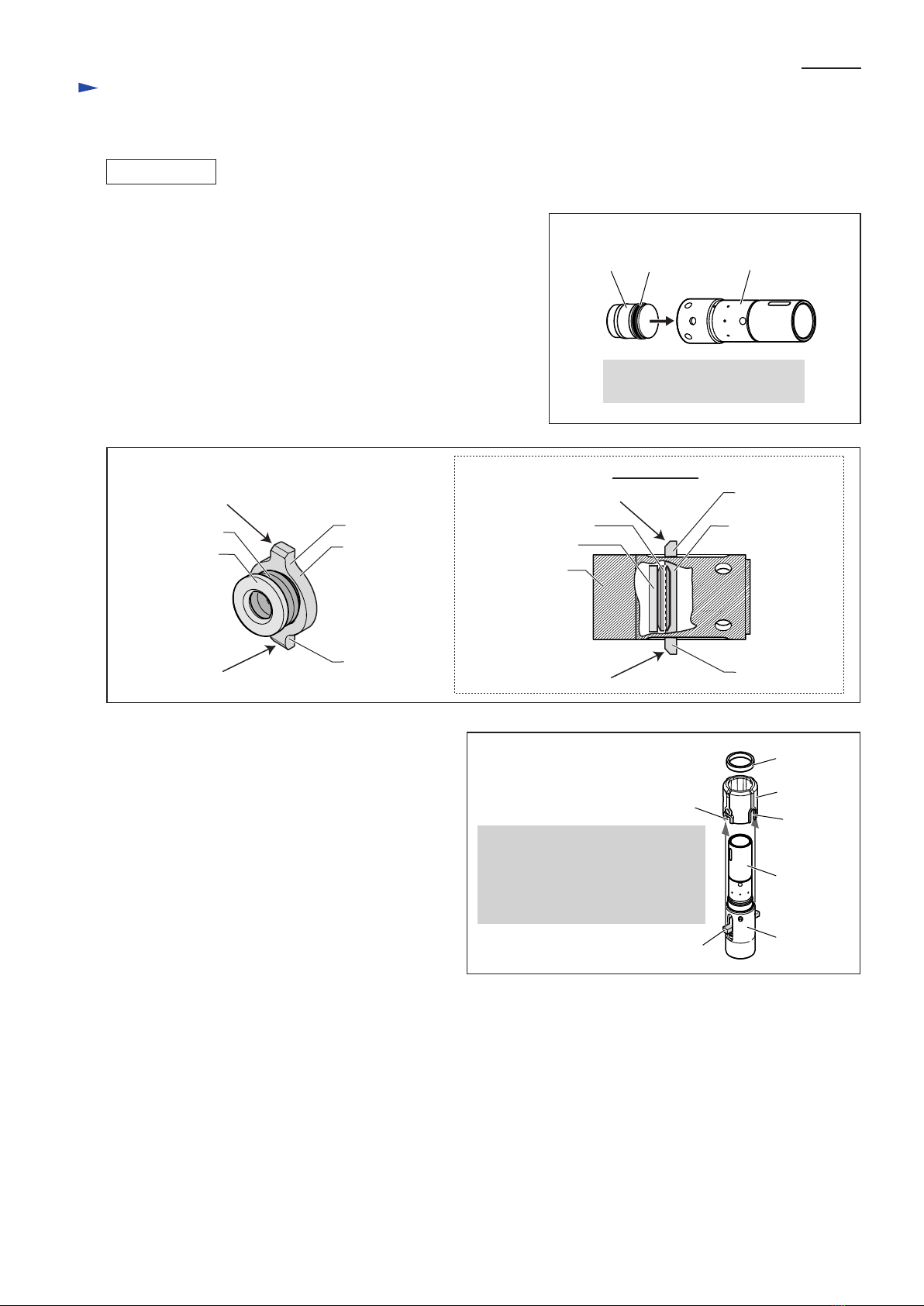

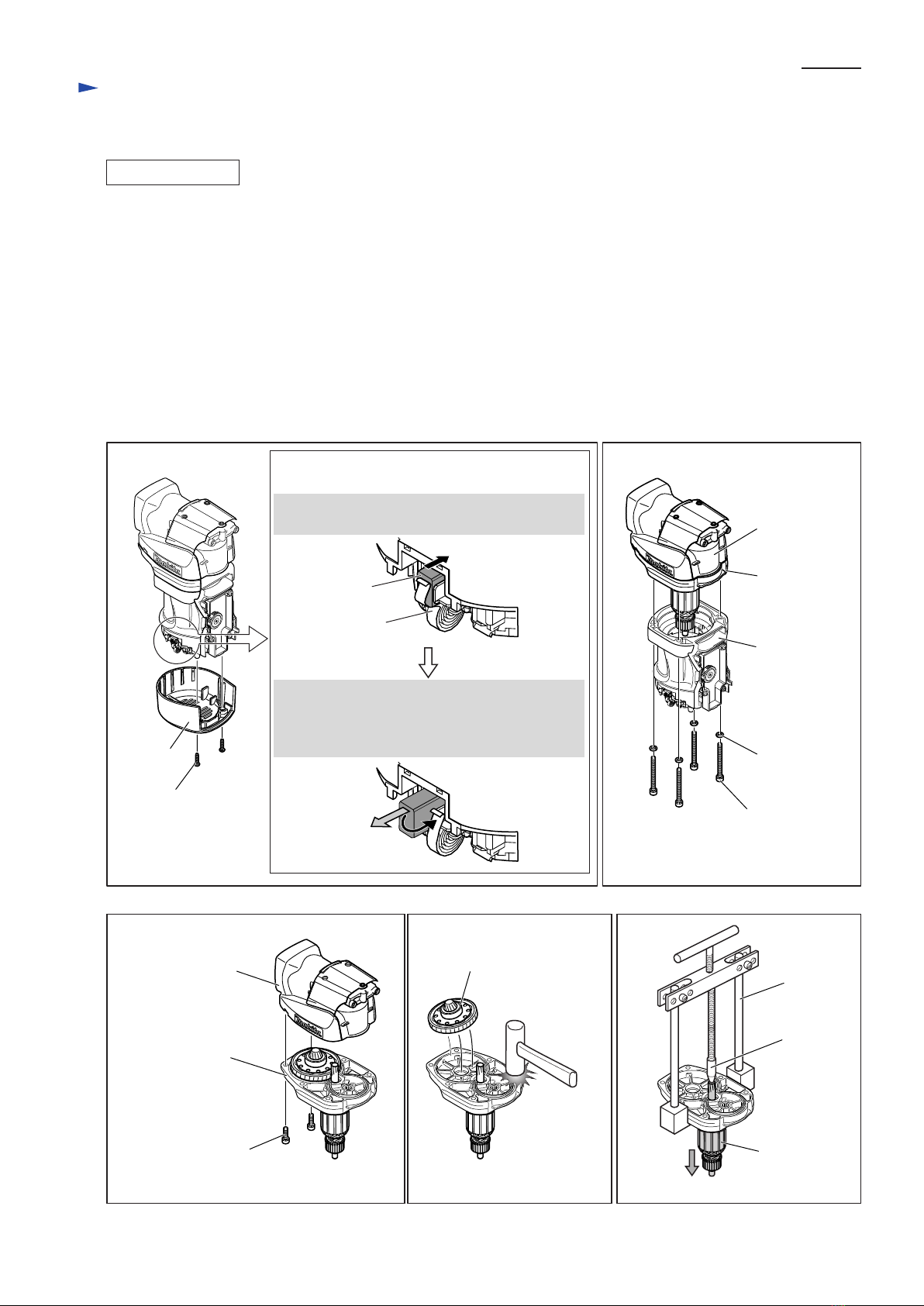

Makita HR1840 User manual

Makita

Makita HR5001C Manual

Makita

Makita HR4013C Manual

Makita

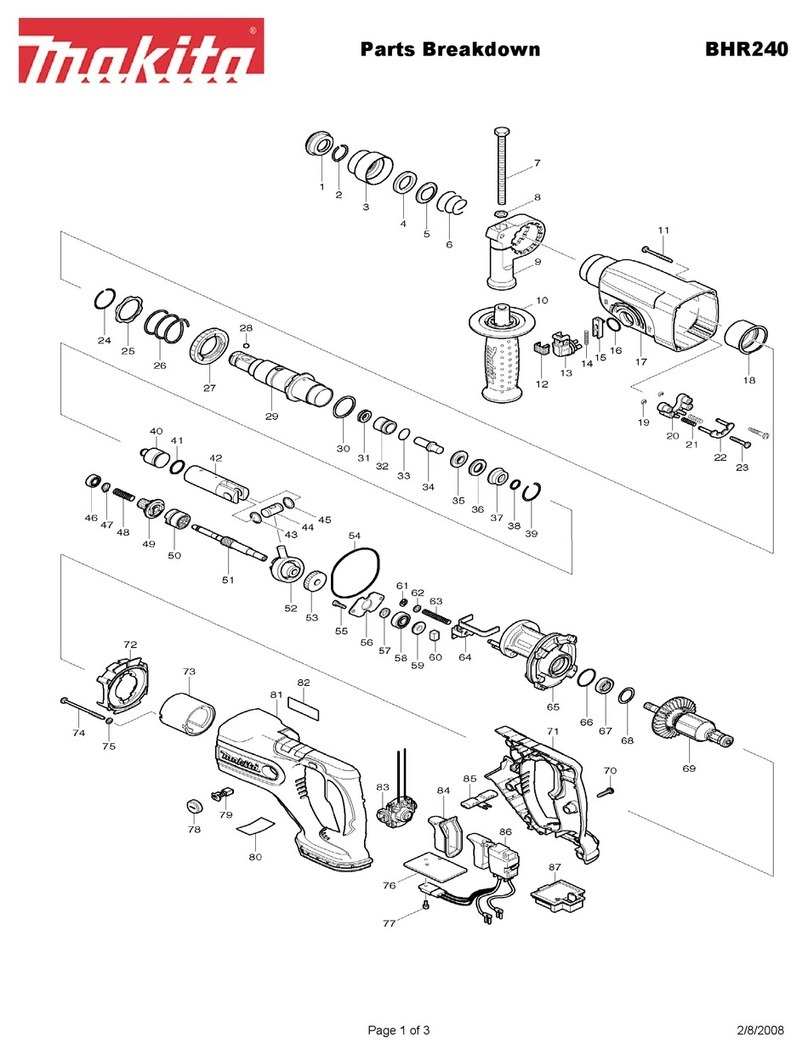

Makita BHR240 Quick start guide

Makita

Makita HR4041C User manual

Makita

Makita HR3540C User manual

Makita

Makita HR2010 User manual

Makita

Makita HR2470 User manual

Makita

Makita HR2460 User manual

Makita

Makita HR2460 User manual

Makita

Makita HR3200C User manual

Makita

Makita HR006G User manual

Makita

Makita HR1830F User manual

Makita

Makita BHR240 User manual

Makita

Makita HR2470 User manual

Makita

Makita HR166D User manual

Makita

Makita HR4003C User manual

Makita

Makita HR166DWMX1 User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions