FEATURES AND BENEFITS

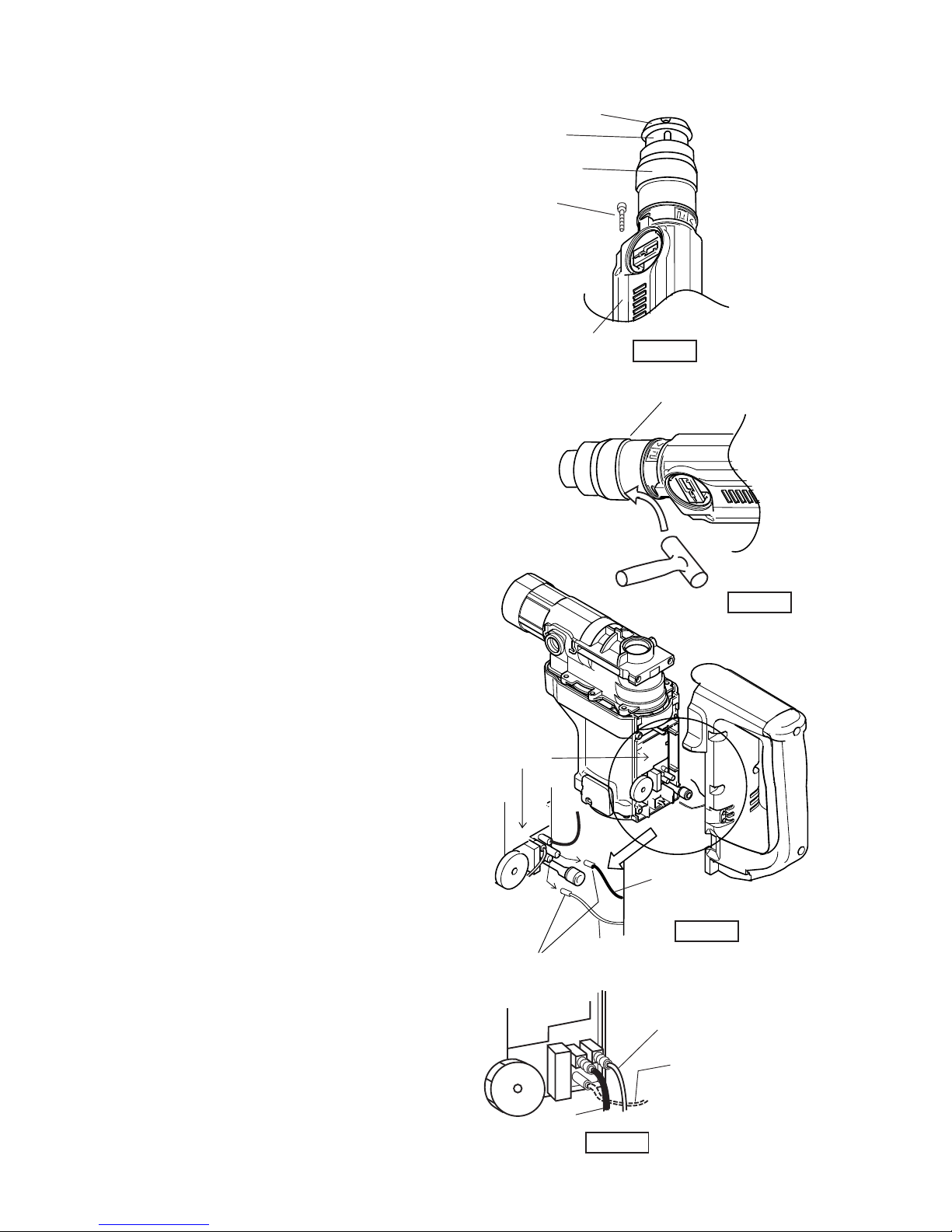

Spline shank hammer bit can be accepted.

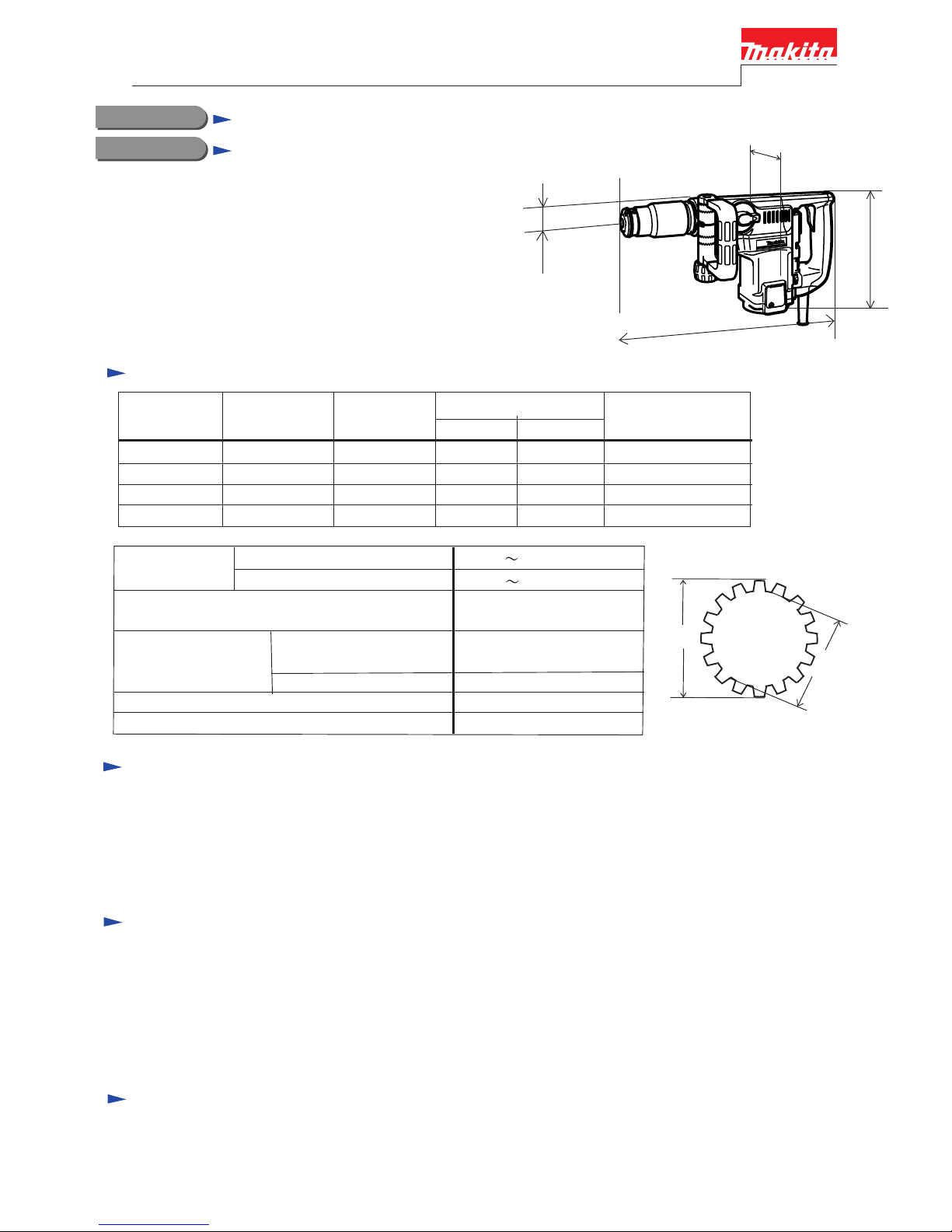

Hammer bits for HR3520B, HR3850B and HR5000

can be used also with this HR4040C.

In case of employing as a demolition hammer,

the BOSCH type shank bit of 3/4" hex / 21/32"round can be

used also with HR4040C.

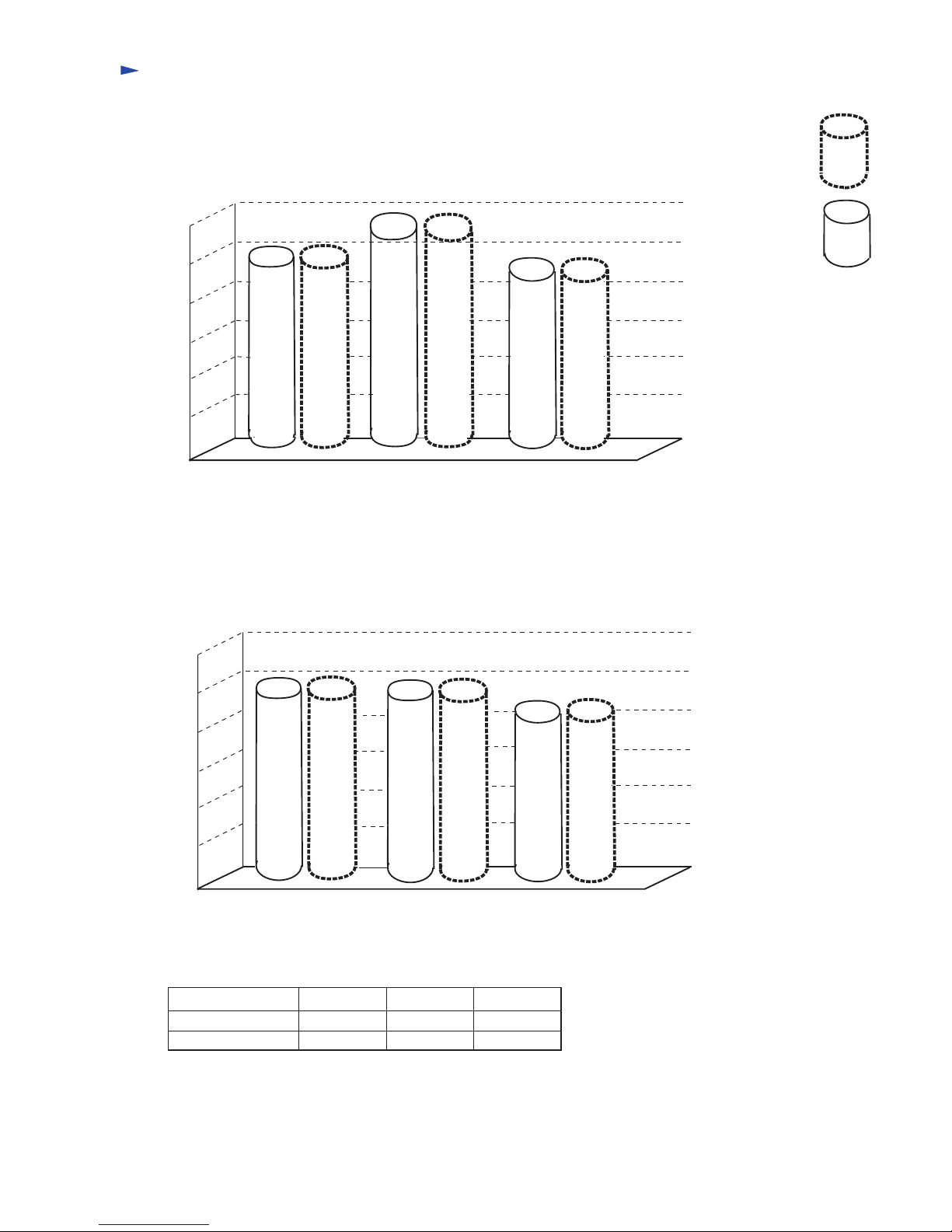

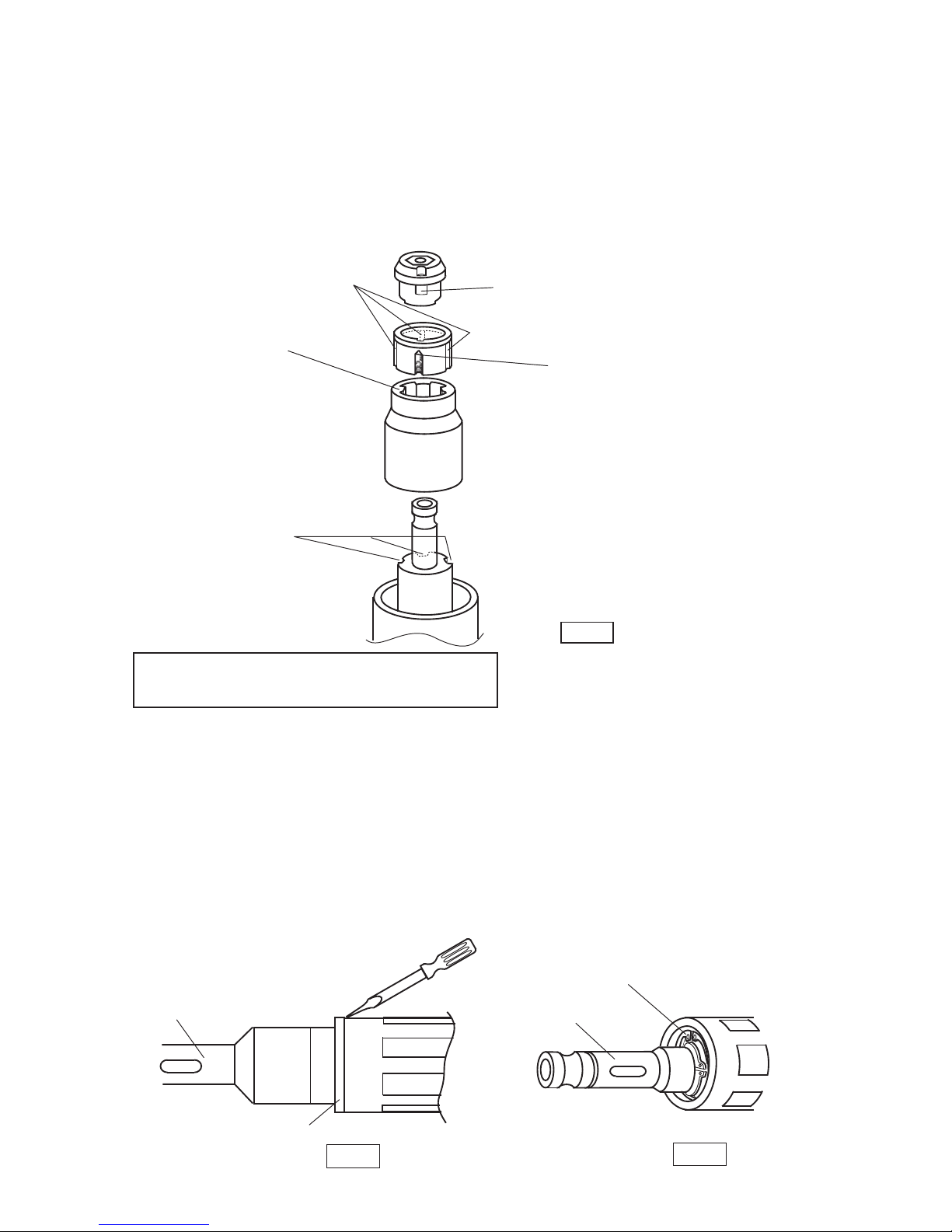

Simple slide locking chuck

Simple slide lock for securing inserted bit

Chisels can be locked at 12 positions through 360

°

.

By turning change ring while pushing it forward, the angle of chisel can be adjusted without taking

out inserted chisels.

Full resin covered body to protect the user from the electric shock.

The followings are the same features and benefits as those of HR4000C, HR5001C etc.

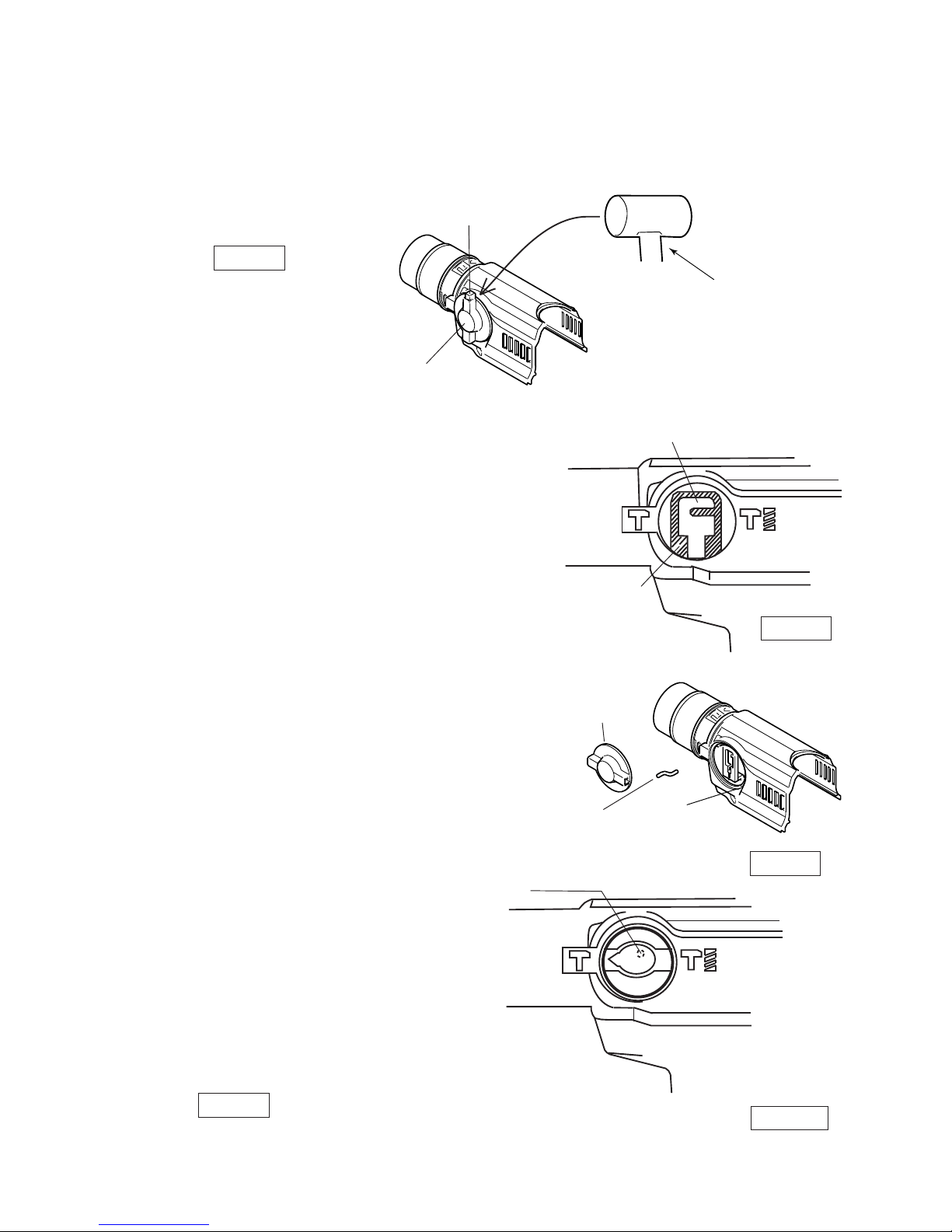

Simple slide lock for securing inserted tools

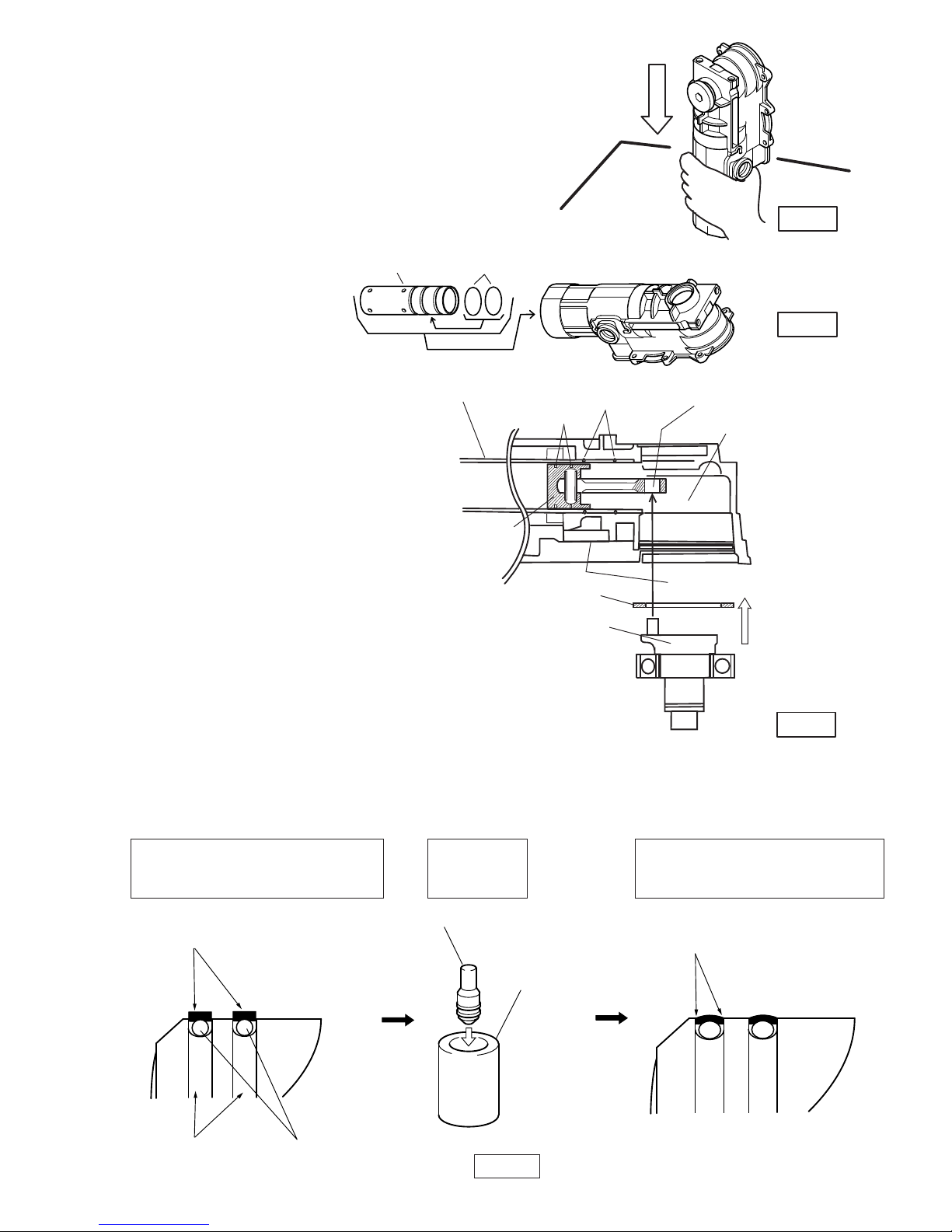

Its color tells how your machine is.

Green: On with no problem

Red : Approx. 8 hours before carbon brushes wear out

Off : Possibly trouble in switch or power supply cord

New dust sealing front cap prevents particles of dust from coming in

through the front of machine.

Electronic Speed Control Dial Optimum hammering speed can be selected in accordance with materials or tools.

Setting at low speed, ideal for such a light chipping works as scraping tiles,

removing bricks joint.

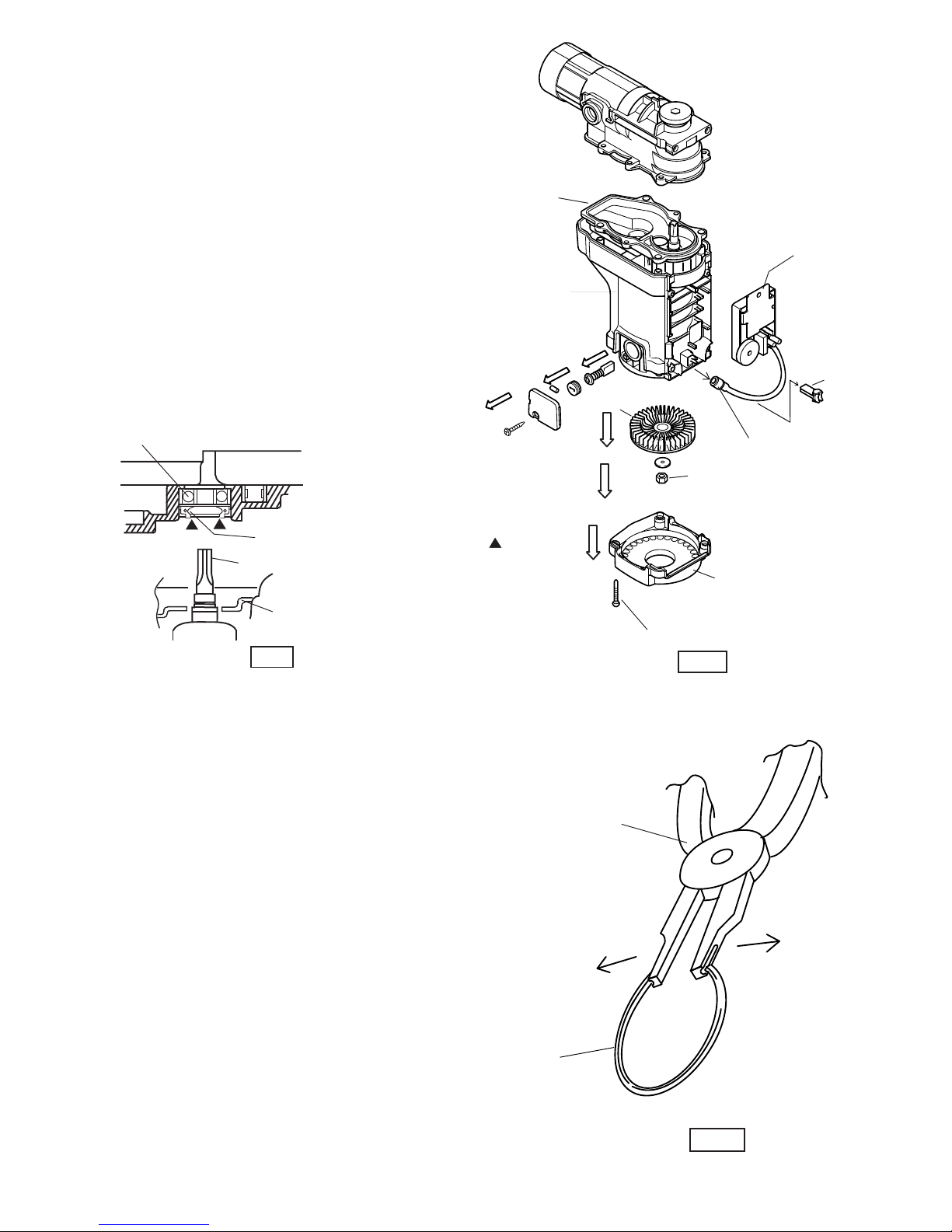

New Torque Limiting System Thanks to the Ball Clutch, stable torque control is assured even after long term use.

Large Rear Handle

Convenient Indicator Lamp

Auto Shut-off Carbon Brushes

Simple Slide Locking Chuck

Further Improvement in Dust proof Structure

Replaceable without removing rear cover of machine.

(HILTI's model requires removal of rear cover.)

Easy Replacement of Power Supply Cord

Body Wholly Covered with Resin No electric shock to operator, even if bit accidentally hits against laid electric cables.

Barrel is also covered with resin, and so, it is possible to do chipping operations while

holding barrel with your hand.

Easy-to-Operate Large Trigger Fatigue-free in fingers even in a long continuous operation.

Can be gripped with both hands - convenient in downward chipping operations.

Big Action Mode Change Lever For easy shift of action mode

Thick Commutator The effective thickness of is segments has been enlarged.

Zig-Zag Varnish on Armature Coil For effective radiation from coil while protecting coil from dusts