10 ENGLISH

8. Dress properly.

Do not wear loose clothing or jewellery, they can

be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when work-

ing outdoors. Wear protecting hair covering to

contain long hair.

9. Use safety glasses and hearing protection.

Also use face or dust mask if the cutting operation

is dusty.

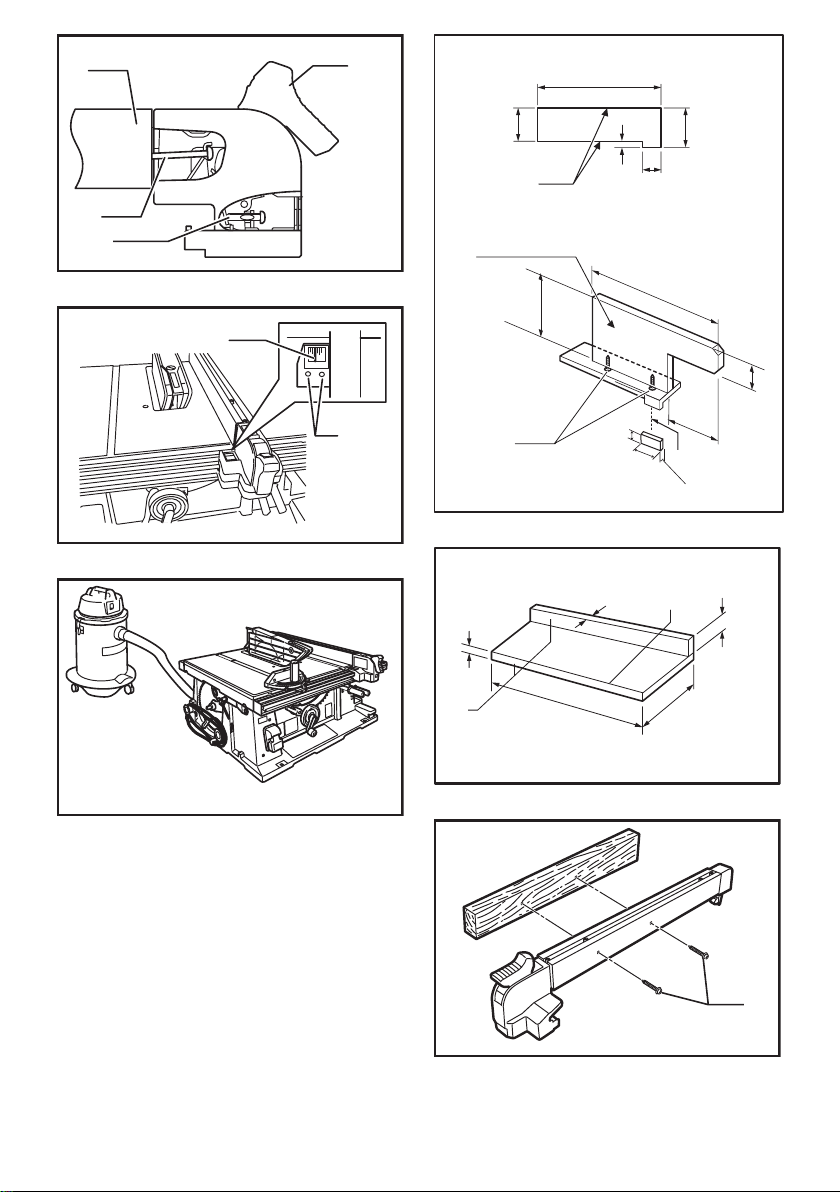

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord.

Never carry the tool by the cord or yank it to dis-

connect it from the socket. Keep the cord away

from heat, oil and sharp edges.

12. Secure work.

Use clamps or a vice to hold the work. It is safer

than using your hand and it frees both hands to

operate the tool.

13. Do not overreach.

Keep proper footing and balance at all times.

14. Maintain tools with care.

Keep cutting tools sharp and clean for better and

safer performance. Follow instructions for lubrica-

tion and changing accessories. Inspect tool cord

periodically and if damaged have it repaired by an

authorized service facility. Inspect extension cords

periodically and replace, if damaged. Keep han-

dles dry, clean and free from oil and grease.

15. Disconnect tools.

When not in use, before servicing and when

changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool

before turning it on.

17. Avoid unintentional starting.

Do not carry a plugged-in tool with a nger on the

switch. Ensure switch is o when plugging in.

18. Use outdoor extension leads.

When tool is used outdoors, use only extension

cords intended for outdoor use.

19. Stay alert.

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts.

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of mov-

ing parts, free running of moving parts, breakage

of parts, mounting and any other conditions that

may aect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated in this instruction manual.

Have defective switches replaced by an autho-

rized service facility. Do not use the tool if the

switch does not turn it on and o.

21. Warning.

The use of any accessory or attachment, other

than those recommended in this instruction man-

ual or the catalog, may present a risk of personal

injury.

22. Have your tool repaired by a qualied person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be car-

ried out by qualied persons using original spare

parts, otherwise this may result in considerable

danger to the user.

23. Use of power supply via an RCD with a rated

residual current of 30 mA or less is always

recommended.

ADDITIONAL SAFETY RULES FOR

TOOL

SAVE THESE INSTRUCTIONS.

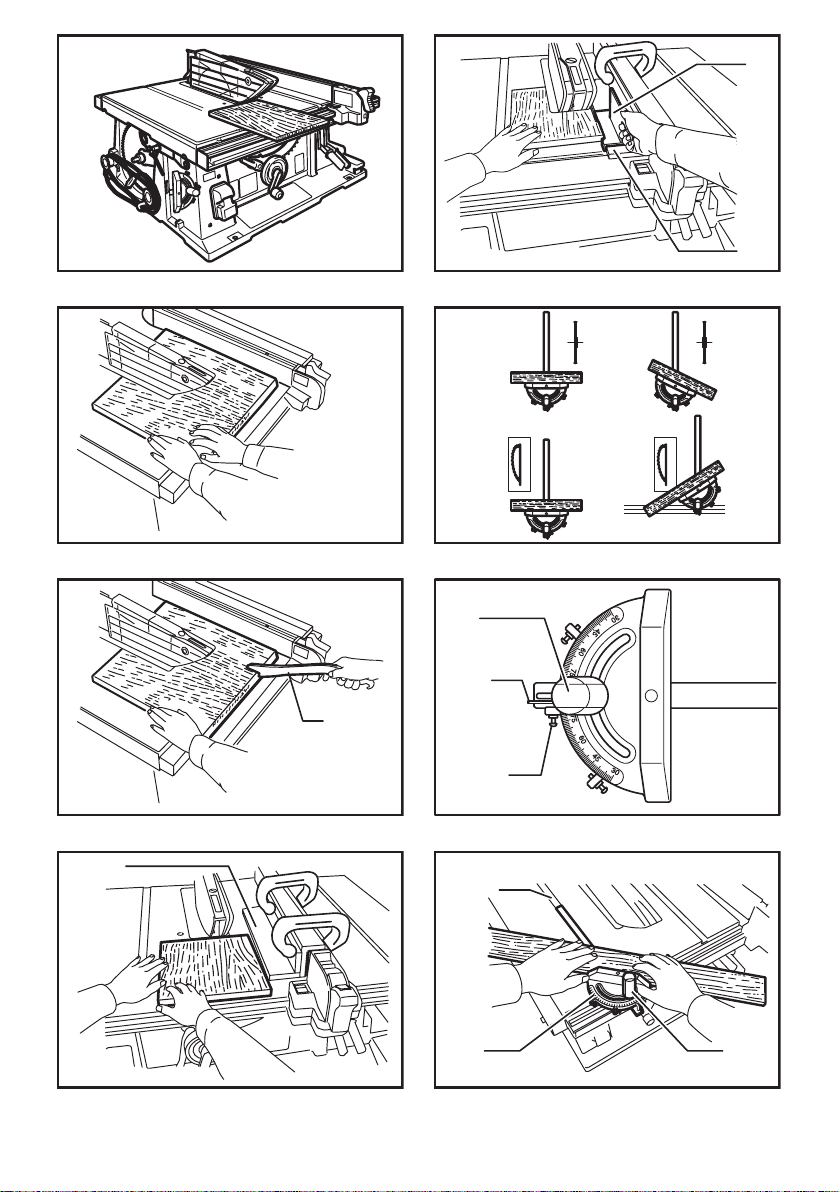

1. Wear eye protection.

2. Do not use the tool in presence of ammable

liquids or gases.

3. NEVER use the tool with an abrasive cut-o

wheel installed.

4. Check the blade carefully for cracks or damage

before operation. Replace cracked or damaged

blade immediately.

5. Use only saw blades recommended by the

manufacturer and which conform to EN847-1,

and observe that the riving knife must not be

thicker than the width of the cut by the saw

blade and not thinner than the body of the

blade.

6. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive cut-o wheels may cause an injury.

7. Select the correct saw blade for the material to

be cut.

8. Do not use saw blades manufactured from

high speed steel.

9. To reduce the emitted noise, always be sure

that the blade is sharp and clean.

10. Use correctly sharpened saw blades. Observe

the maximum speed marked on the saw blade.

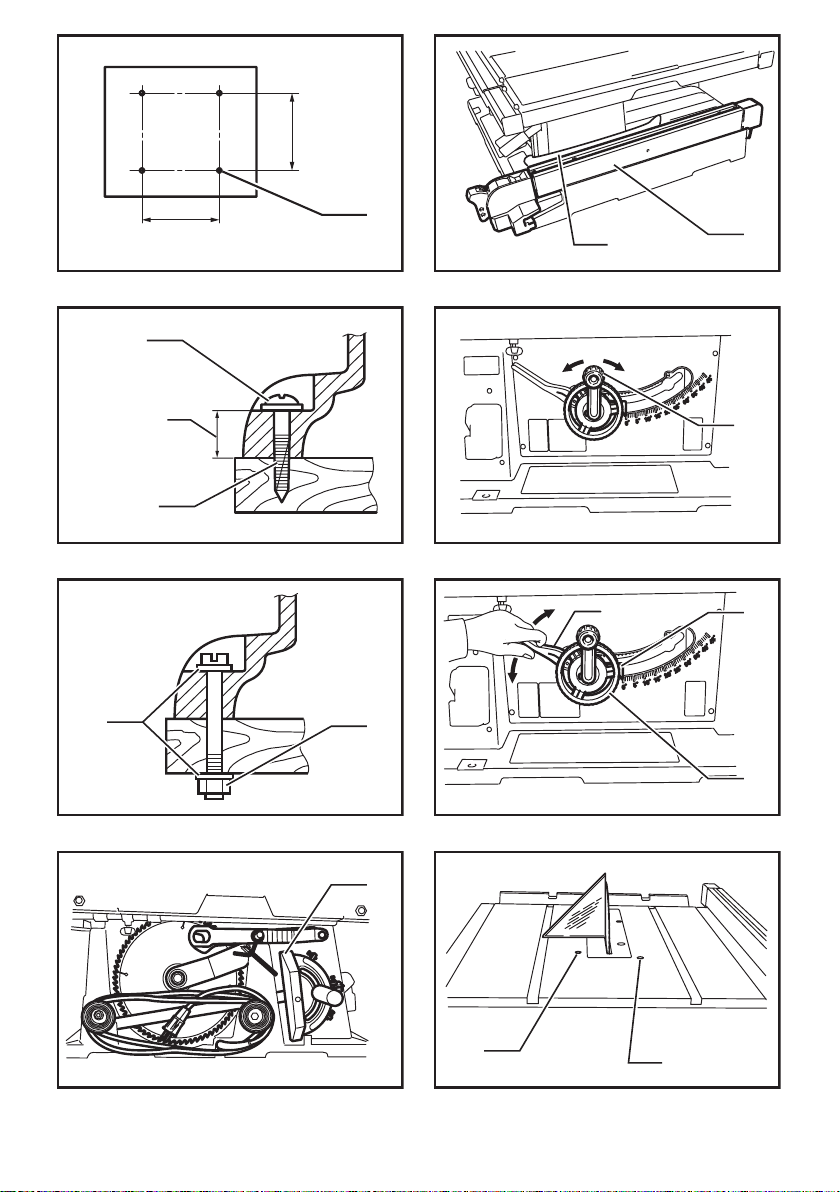

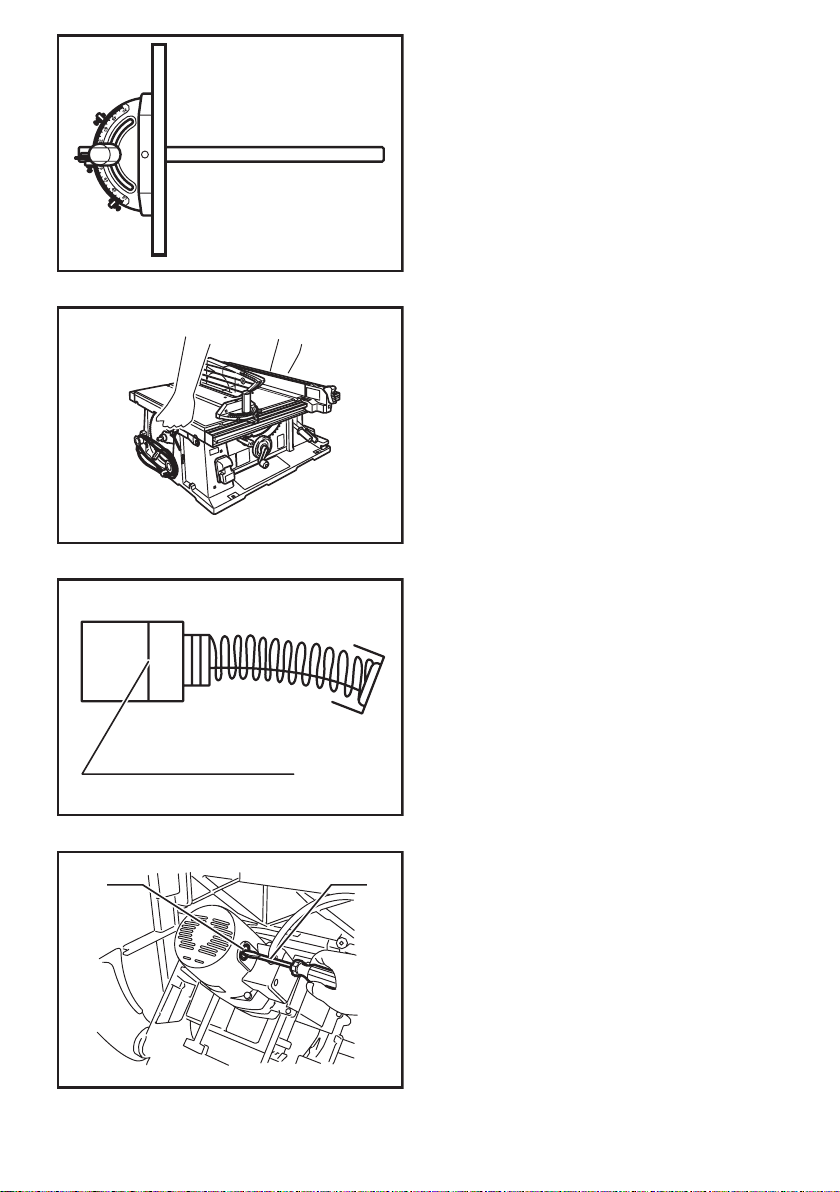

11. Clean the spindle, anges (especially the

installing surface) and hex nut before install-

ing the blade. Poor installation may cause

vibration/wobbling or slippage of the blade.

12. Use saw-blade guard and riving knife for every

operation for which it can be used, including

all through sawing operations. Always install

the blade guard following the instructions

out-lined in this manual. Through sawing oper-

ations are those in which the blade cuts com-

pletely through the workpiece as in ripping or

cross cutting. NEVER use the tool with a faulty

blade guard or secure the blade guard with a

rope, string, etc. Any irregular operation of the

blade guard should be corrected immediately.

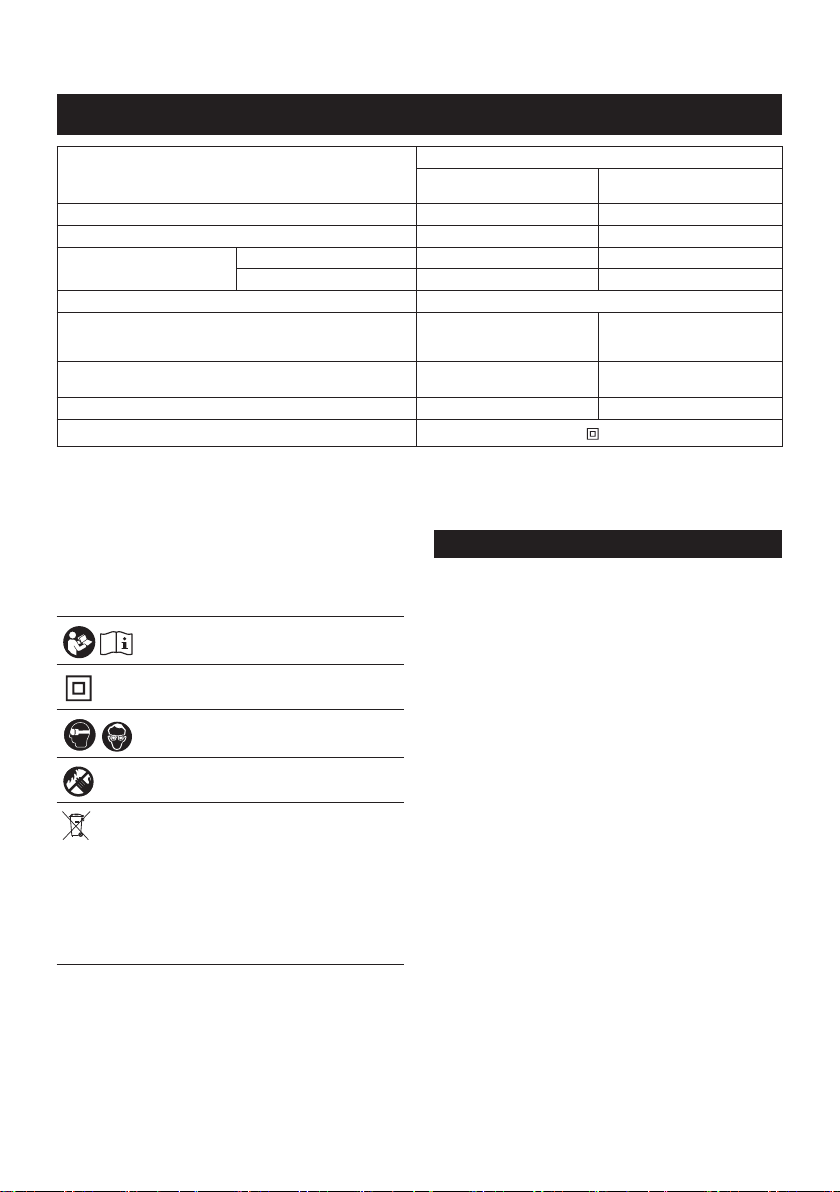

13. Immediately reattach the guard and riving

knife after completing an operation which

requires removal of the guard.