Coolingsystem

This charger is equippedwith cooling fan for heated battery in order to enable the battery

to prove its own performance. Sound

of

cooling

air

comes out during cooling, which

means not trouble on the charger.

Yellow light will flash for warning inthe followingcases.

Trouble on coolingfan

Incompletecooldown of battery, such

as,

beingcloggedwith dust

The batterycan be charged in spite

of

the yellow warning light. But the charging time will

be longer than usual in this case.

Check the sound

of

cooing fan, vent on the charger and battery, which can be sometime

cloggedwith dust.

The cooling system is in order although no sound of cooling fan comes out,

if

the yellow

warning lightwill not flash.

Always keepcleanthe vent on charger and batteryfor cooling.

The products should be sent to repair or maintenance,

if

the yellow warning light will

frequently flash.

Conditioningcharge

Conditioningchargecan extend the life of battery by automatically searchingthe optimum

charging condition for the batteriesinevery situations.

The battery employed in the followingconditions repeatedly, will be worn out shortly, and

yellow warning light may flash.

1.

Rechargeof battery with its high temperature

2.

Rechargeof battery with its low temperature

3.

Rechargeof full charged battery

4. Over-dischargeof battery(continueto discharge battery in spite of down of power.)

5.

Rechargeunder brokencooling system

The charging time of such batteryis longer than usual.

CAUTION:

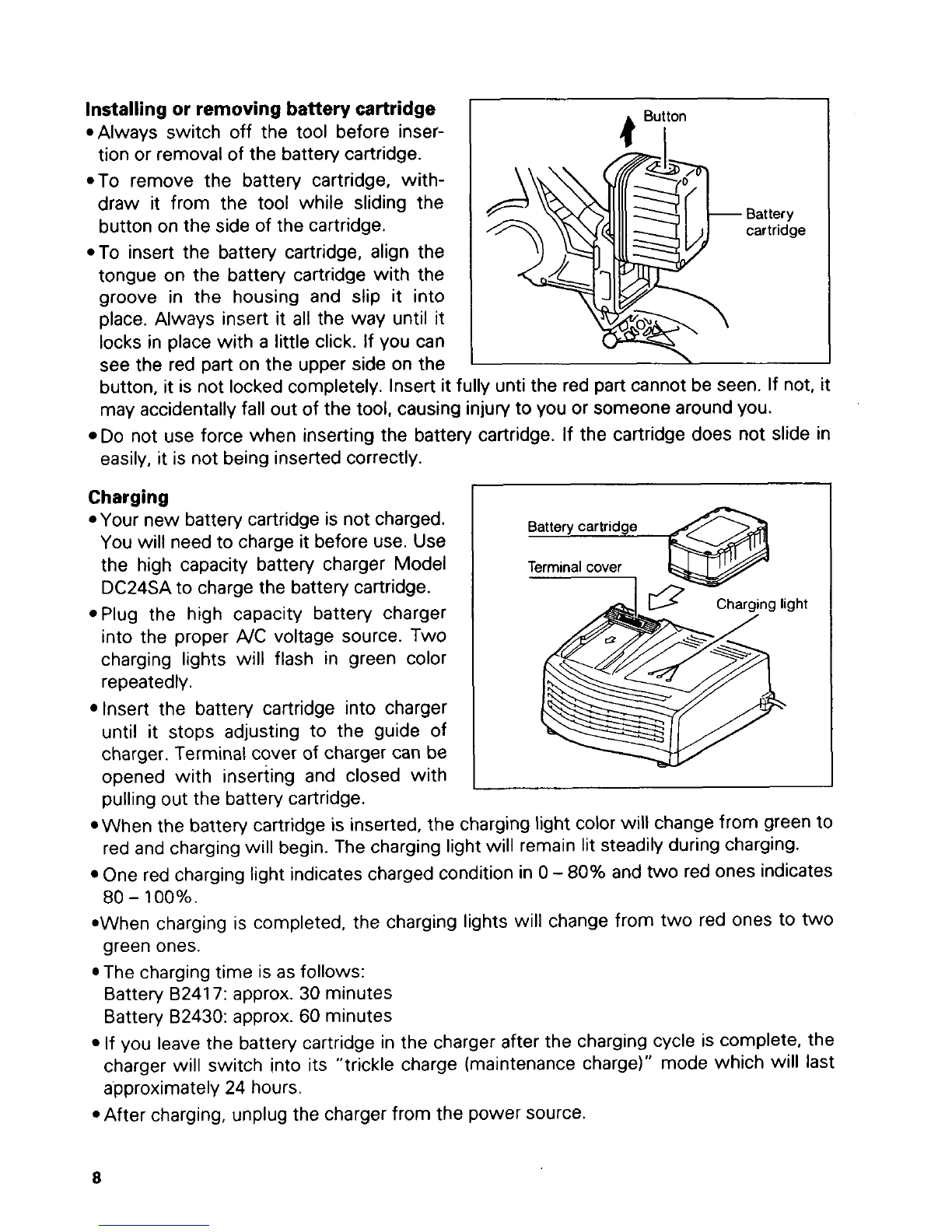

*The high capacity battery charger ModelDC24SA

is

for chargingMakita battery cartridge.

Neveruse itfor other purposes

or

for other manufacturer's batteries.

Whenyou charge

a

new battery cartridgeor

a

battery cartridge which has not been used

for

a

long period of time, it may not accept

a

full charge. This

is

a

normal condition and

does not indicate

a

problem.You can rechargethe batterycartridge fully after

discharging

itcompletely and recharging

a

couple

of

times.

If

you charge

a

batterycartridge from

a

just-operated tool or

a

batterycartridge which has

been left in

a

locationexposed to direct sunlight or heat for

a

longtime, the charging light

may flash in redcolor. If this occurs, wait for

a

while.When the temperature on battery is

more than approx.

70°C.

two charging lights may flash in red color, and when approx.

50°C

-

70°C, one charginglight in redcolor. Chargingwill begin after the battery cartridge

is cooled by the coolingfan installed in the charger.

9