4ENGLISH

2.

Do not use the power tool if the switch does not turn

it on and off.

with the switch is dangerous and must be repaired.

3.

Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools.

the risk of starting the power tool accidentally.

4.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool.

tools are dangerous in the hands of untrained users.

5. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

6. Keep cutting tools sharp and clean.

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7.

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed.

from those intended could result in a hazardous situation.

Battery tool use and care

1.

the manufacturer.

when used with another battery pack.

2. -

nated battery packs.

3.

When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys, nails,

screws or other small metal objects, that can make a

connection from one terminal to another.

4.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact acciden-

additionally seek medical help.

the battery may cause irritation or burns.

Service

1.

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

2. Follow instruction for lubricating and chang-

ing accessories.

3.

Keep handles dry, clean and free from oil and grease.

Cordless miter saw safety warnings

1.

Keep hands out of path of saw blade. Avoid contact

with any coasting blade. It can still cause severe injury.

2. Check the saw blade carefully for cracks or

deformation before operation.

Replace damaged blades immediately.

3. Replace the kerf board when worn.

4. -

turer which conform to EN847-1.

5. Do not use saw blades manufactured from

high speed steel.

6. Wear eye protection.

7. Wear hearing protection to reduce the risk of

hearing loss.

8. Wear gloves for handling saw blade (saw

blades shall be carried in a holder wherever

practicable) and rough material.

9. Connect miter saws to a dust collecting device

when sawing.

10.

Select saw blades in relation to the material to be cut.

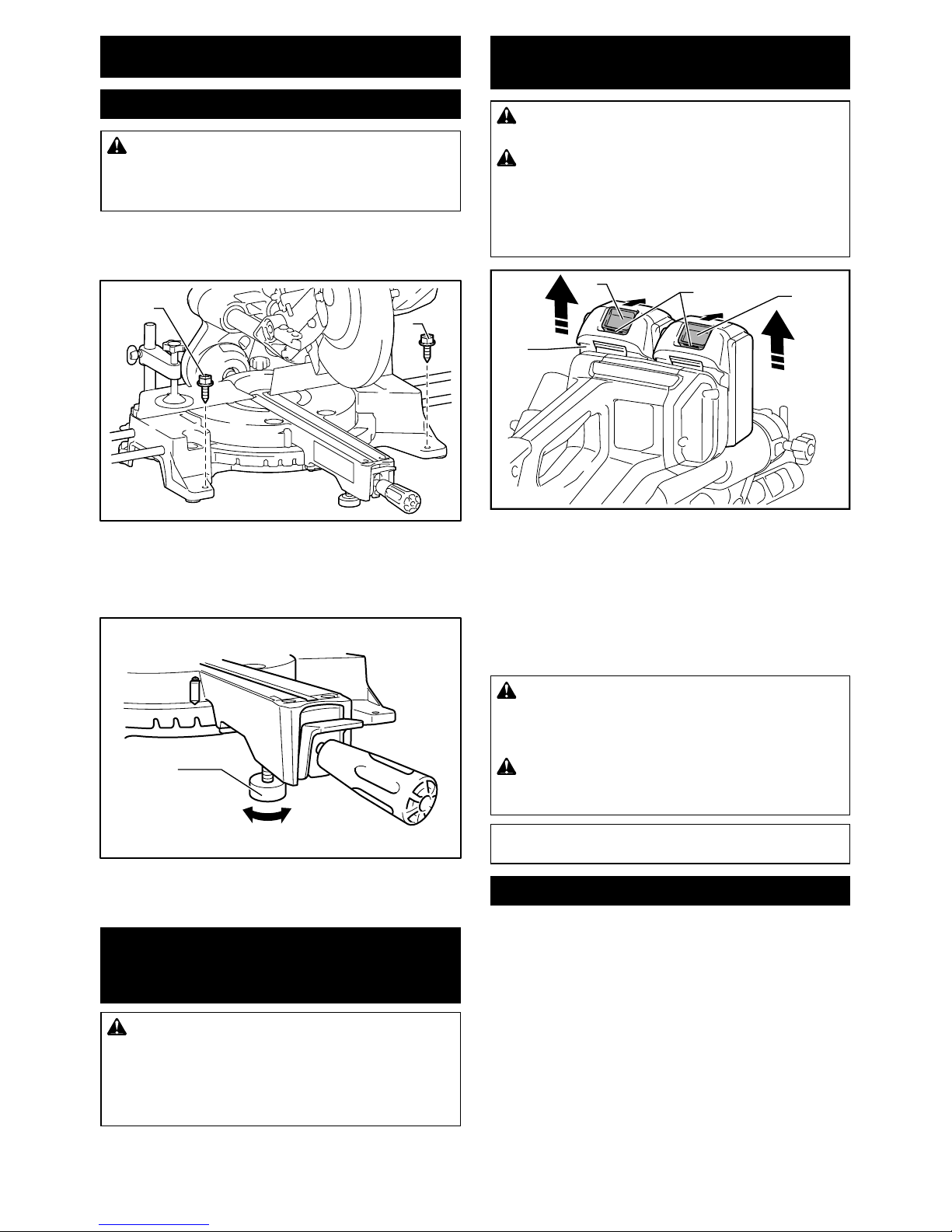

11. Always secure all moving portions before car-

rying the tool. When lifting or carrying the tool,

do not use the guard as a carrying handle.

12.

Do not operate saw without guards in place. Check

blade guard for proper closing before each use. Do

not operate saw if blade guard does not move freely

and close instantly. Never clamp or tie the blade

guard into the open position.

13.

chips and cut-offs.

14. Use only saw blades that are marked with a

maximum speed equal to or higher than the no

load speed marked on the tool.

15.

not replace the laser or LED with a different

type.

16. Never remove any cut-offs or other parts of the

workpiece from the cutting area whilst the tool

is running with an unguarded saw blade.

17.

Do not perform any operation freehand. The work-

guide fence with the vise during all operations. Never

use your hand to secure the workpiece.

18. Ensure that the tool is stable before each cut.

19. Fix the tool to a work bench, if needed.

20. Support long workpieces with appropriate

additional supports.

21.

Never cut so small workpiece which cannot be

securely held by the vise. Improperly held workpiece

22. Never reach around saw blade.

23.

Turn off tool and wait for saw blade to stop before

moving workpiece or changing settings.

24. Disconnect the plug from the power source

and/or the battery pack from the power tool

before changing blade or servicing.

25. Stopper pin which locks the cutter head down

is for carrying and storage purposes only and

not for any cutting operations.

26. -

ble liquids or gases. The electrical operation of

27.

28.

-

cially the installing surface) or bolt. Damage to

these parts could result in blade breakage.

29. Make sure that the turn base is properly

secured so it will not move during operation.

30. For your safety, remove the chips, small

pieces, etc. from the table top before

operation.

31. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.