Features and benefits P 2 / 15

BJR240

Incredible low vibration with counterbalancing

system in its gear unit.

Model No. LoadedNo loaded

BJR240 8.7m/sec.2 10.3m/sec.2

Mod. A 11.5m/sec.2 19.8m/sec.2

Mod. B 20.4m/sec.2 20.9m/sec.2

Mod. C 14.4m/sec.2 16.2m/sec.2

Mod. D 8.1m/sec.2 9.4m/sec.2

MAKITA

Lower noise level

Comparison of the specifications

Model No. LoadedNo loaded

BJR240 82 dB 94 dB

85 dB 94 dB

85 dB

85 dB 94 dB

97 dB

95 dB91 dB

MAKITA

BJR240

MAKITA

The figures on loaded condition are based on

the cutting of chip board 19mm in thickness.

The figures on loaded condition are based on

the cutting of chip board of 19mm in thickness.

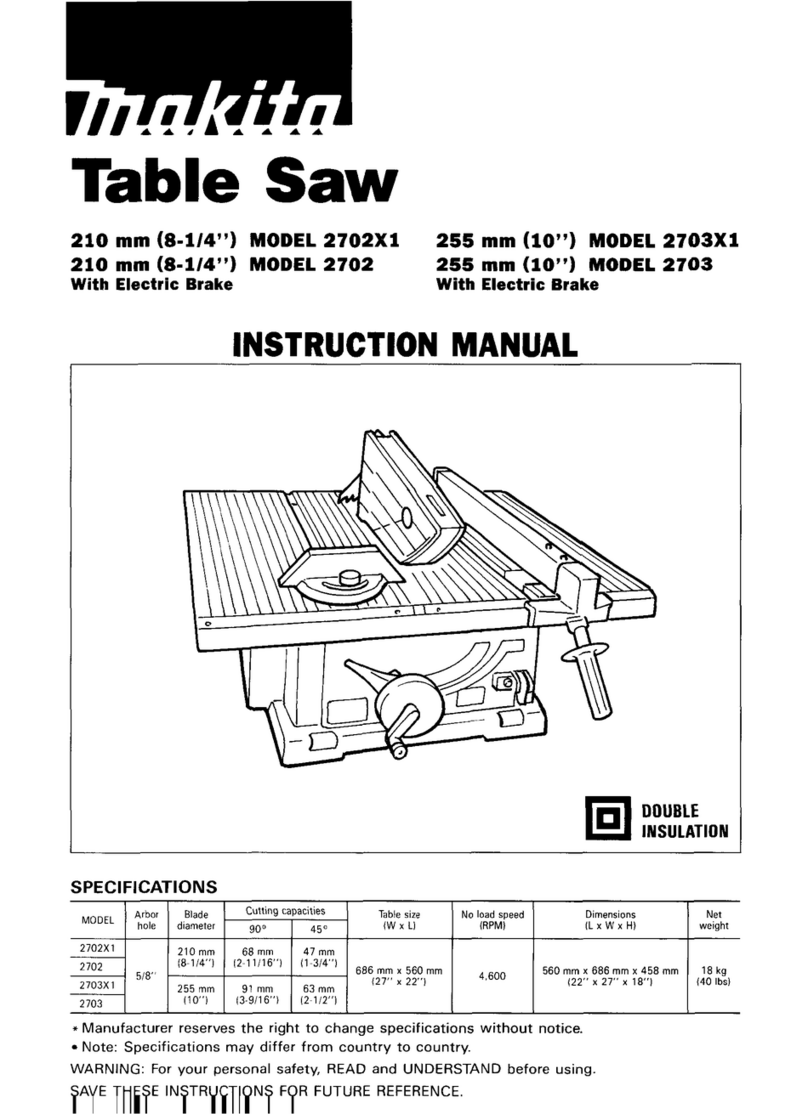

Push-in Lock System has

made it possible to install

the blade quickly.

New tool-less blade change system

Lock off push-out system has

enabled to take off the hot saw

blade of just after work, without

touching it.

Externally accessible

carbon brush

Tool-less shoe

adjustment

Electric High /Low

speed change switch

Palm fitting

soft grip

Lock off button can be

pushed from both of left

and right.

Switch with big trigger

for easy operation

24V Ni-MH Battery with

new charging system

The fastest cutting speed among

the cordless recipro saws.

See the graph in "Comparison of Products"

at page 3.

Comparison of products

Model No.

Specifications

Voltage

Tool-less

system

Length of Stroke

: mm (1-1/4")

Strokes per

Minute :spm.(min-1) High

Dimensions

including

battery

Weight including

battery :Kg (lbs)

Low

High

Low

Suppressing the vibration

Externally accessible brush

for replacing blade

for adjusting shoe

Palm fitting soft grip

Height : mm(")

Width : mm(")

Length : mm(")

32 (1-1/4)

0 - 2,700

0 - 2,300

24

Yes

Yes

Yes

Yes

Yes

469 (18-1/2)

230 (9)

*255 (10)

88 (3-1/2)

4.4 (9.7)

*4.9 (10.8)

29 (1-1/8) 28 (1-1/8) 25 (1)

0 - 2,900 0 - 2,900

0 - 2,400

24

Yes

Yes

Yes

463 (18-1/4)

232 (9-1/8)

80 (3-1/8)

3.9 (8.6)

JR180D

23 (7/8)

0 - 2,700

18

No No

No Yes

No

Yes

Yes

NoYes

Yes

Yes

No

447 (17-5/8)

206 (8-7/8)

95 (3-3/4)

3.5 (7.7)

32 (1-1/4)

19 (3/4)

0 - 2,300 0 - 2,600

24 24 19.2

No No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

495 (19-1/2)

213 (8-3/8)

76 (3)

448 (17-5/8)

240 (9-1/2)

83 (3-1/8)

3.9 (8.6) 4.3 (9.5)

393 (15-1/2)

202 (8)

76 (3)

4.5 (9.9)

*255 (10) and *4.9 (10.8) are the data when battery B2430 is attached.

Competitor A

Competitor B

Competitor C

Competitor D

Mod. A

Mod. B

Mod. C

Mod. D

Mod. D

Competitor A

Competitor B

Competitor C

Competitor D

Mod. A

Competitor

A Competitor

B Competitor

C Competitor

D

Mod. B Mod. C