Malone ProCut 2000 User manual

2

Table of Contents

1. DECLARATION OF CONFIRMITY ···················································· 3

2. GENERAL INFORMATION······························································· 4

3. TECHNICAL DATA ········································································· 5

4. DESCRIPTION ··············································································· 5

5. SAFETY INFORMATION·································································· 6

6. SAFETY DECALS············································································ 8

7. PRE-OPERATION CHECKLIST························································· 9

8. OPERATING THE MACHINE···························································· 9

8. MAINTEANCE AND LUBRICATION ·················································10

9. MALONE LIMITED WARRENTY······················································11

10. SPARE PARTS SECTION ·································································13

Version C - 14/01/2022

Operator Manual—Topper

3

DECLARATION OF CONFORMITY

We,

Malone Farm Machinery

Ballyglass,

Claremorris,

Co.Mayo

F12 AP11

Republic of Ireland

Declare under our sole responsibility that:

The product (type): Topper ...................................................................................................

Product code: Topper ............................................................................................................

Serial No:...............................................................................................................................

Date: ..............................................................

Manufactured by the above company

Conforms to EU Engineering Regulations and other relevant EU guidelines.

Conforms to UK Engineering Regulations and other relevant UK guidelines.

Signed....................................................................................................................................

(on behalf of Malone Farm Machinery)

...............................................................................................................................................

(Status)

Operator Manual—Topper

4

Operator Manual—Topper

1. GENERAL INFORMATION

Thank you for purchasing a Malone product. You have purchased a strong, reliable and efficient rotary

topper. To fully utilize the qualities of the Topper, please ensure you read this manual, and this ensures a

longer working life, greater safety and optimal performance.

BEFORE OPERATING THIS MACHINE READ CARFULLY THE

INSTRUCTIONS GIVEN IN THIS MANUAL

USING YOUR OPERATOR’S MANUAL

Read, understand and follow the instructions in this manual, doing so will promote safe, productive and

reliable service.

This manual was prepared to help you use, and maintain your new machine safely. Reading your

operator’s manual will help you and others avoid injury or damage to the machine. This machine can

cause serious property damage, personal injury or even death if it is misused. For your safety, as well as

the safety of others, you must follow the safety precautions in this operator’s manual.

This manual is an important part of your machine. It should remain with the machine if and when it is

sold. If it is damaged or lost, you may contact your dealer, or Malone Farm Machinery company to get a

replacement.

Before delivering this machine, your dealer performed a pre-delivery inspection to ensure best

performance.

If you have any queries, please contact Malone Farm Machinery who will be able to give you the correct

assistance and advice.

Contact: Malone Farm Machinery LTD

Ballyglass,

Claremorris,

Co. Mayo

F12 AP11

Ireland

Tel: +353 (0) 94 93 60 500

Email: [email protected]

Website: www.malonefm.com

The contents of this manual can be modified only by the manufacturer and without

notice to the Client. Malone Farm Machinery shall not be liable for errors or faults in

this manual.

5

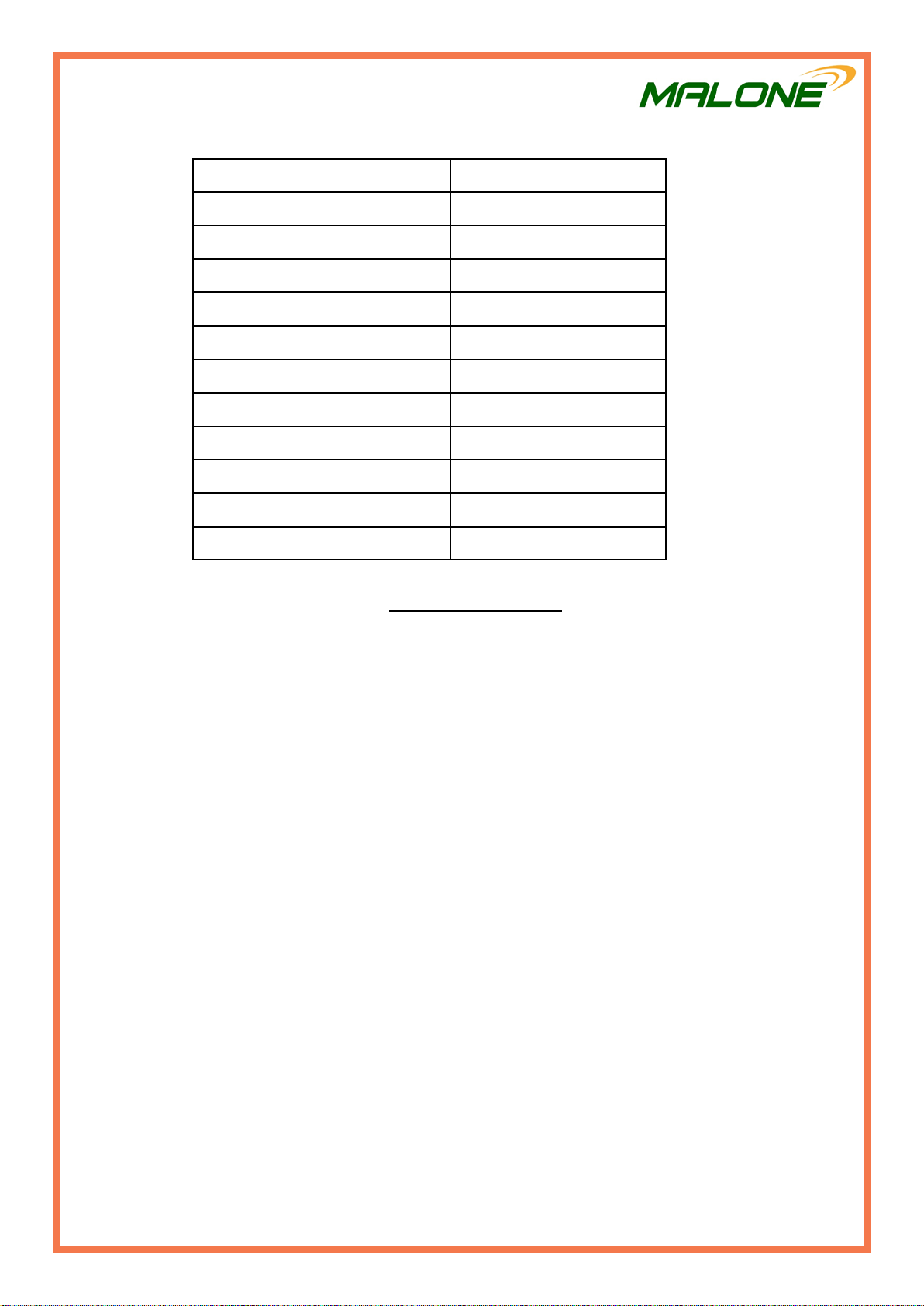

2. TECHNICAL DATA

Operator Manual—Topper

3. DESCRIPTION

Built for tractors from 30HP upwards this rotor machine is ideal to tackle growth up to 30mm diameter. It

is fitted with two heavy duty blades which are fixed to a single rotor on a direct drive from a centrally

mounted gearbox.

This gearbox is specifically designed for this type of machine as it has an extended bearing housing and

heavy duty bearings to support the cutting rotor.

Power is transmitted through a heavy duty P.T.O. shaft which is fitted with a shear bolt torque limiter. This

protects the transmission from overload. Cutting height adjustment is by two side-mounted, wide based

skids. This machine needs a tractor with minimum 30hp and maximum 60hp.

Type Topper Pro Cut 2000

Number of rotors 1

Diameter of rotor 1.50 m

Working width 1.50 m

Width of the machine 1.80 m

Length 2.20 m

Weight 830 kg

Necessary tractor power 30 HP / 22 KW

PTO shaft speed 400-540 rpm

3 Hitch point CAT 2

Lifting to transport position Hydraulic – Single acting

Length between the joints 1.20 m

6

SAFETY INFORMATION

In the interest of safety, it is important that great care is adopted at all times during the attachment,

transportation, operation and maintenance of this machine. Both the owner and the operator of the

machine should read and understand the following section to ensure the safety of themselves and all other

persons who enter into the close proximity of these machines. Never operate the machine if unauthorized

persons are in the area. Stop operation of the machine if unauthorized persons approach. Explain to them

the potential hazards so they understand why you will not continue until they have left the area. You are

responsible for safe operation of the Topper. The most important safety device on the equipment is a safe

operator. Hazards associated with topping maybe pinch points, noise exposure, splinters, eye injury,

impact trauma and trip/slip/fall. In addition to the instructions stated here always abide by general safety

and accident regulations.

• Never carry out any maintenance or repair work on the unit while the tractor engine is running.

• Never carry out any maintenance or repair work on the Topper if it is in a raised position, unless it is

supported independently of the tractor hydraulics in a secure manner.

• Never put hands or fingers near the Topper while the tractor is running.

• The operator should be wearing reflective safety clothing, hearing protection, a hard hat, steel toe

boots and gloves. Any other persons who will be working nearby must also wear hearing protection.

• Person MUST BE OVER 18 to operate these Toppers.

• Safety and warning decals placed on the machine give important instructions for safe work take

them into consideration for your safety and the safety of others.

• While driving on public roads always abide traffic signs and road regulations.

• Familiarise yourself with the controls and functions of the machine and practice them in a safe

location before attempting to work.

• Never approach this machine whilst it is working or running. Always switch off the machine and

wait until it has stopped fully before approaching.

• Do not wear loose fitting clothing in the vicinity of this machine.

• Check no one is near, or on, the machine before attempting to start or transport it. Ensure your

visibility is kept clear at all times.

• Implements should always be attached according to the manufacturer’s instructions and fastened

correctly to the prescribed devices using the correct components.

• When disconnecting the machine from the tractor, select a firm level site and use the supports legs.

• Take care when disconnecting the machine from the tractor.

• Ensure controls for the machine are positioned such that the machine cannot accidentally be started

during transport.

• For transportation on the road, prepare and secure the machine according to the manufacturer’s

instructions.

• Never leave the driver seat whilst the tractor of the machine is running.

• Never attempt to operate a machine without its safety devices fitted or incorrectly secured.

• Always place the machine in a safe position before leaving the tractor. Lower the implement

completely, switch off the engine and remove the ignition key.

Operator Manual—Topper

7

• Never permit anyone between the machine and the tractor whilst either is working or when the

machine is in a raised position.

• Be aware at all times of the width, height and length of any machinery you are operating, especially

when transporting on the public highway or near obstructions.

• Ensure the work area is clear of obstructions before starting work (clear stones, wires, glass or any

other dangerous objects from the work site before attempting to start work).

• Do not operate the machine without safety guards or if the guards are damaged.

Transportation safety

• Make sure you are in compliance with all local regulations regarding transporting equipment on

public roads and highways.

• Ensure the weight is at the lowest point when transporting.

• Ensure that the machine is securely attached to the tractor.

Please Note: The manufacturer does not guarantee the Topper compliance with the

applicable laws, in particular those relating to accidents prevention and pollution, of non-EU

countries. The adjustment of the Topper to these regulations will be entirely under the

Client’s own responsibility. The manufacturer is not liable for any kind of damage that could

arise from the non-compliance of those rules.

Operator Manual—Topper

8

SAFETY DECALS

Safety decals must be replaced if stickers are missing or become illegible

Operator Manual—Topper

Read the operator’s manual carefully before

you operate the machine. Reading the

operators manual ensure safe operation of the

machine

Keep clear of the machine when the rotors

are in motion. Entanglement can happen if a

person comes in contact with the rotating

blade.

Danger of cutting hands. Keep hands away

from rotating blade if machine is in operation.

Tighten gearbox nuts daily and check gearbox

oil level. Loose nuts on the gearbox or low oil

level can result in damage to the machine

which may lead to an accident.

9

Operator Manual—Topper

PRE - OPERATION CHECKLIST

It is important for both personal safety and maintaining the good mechanical condition of the Topper

that this checklist is followed.

• Grease every 20 hours of operation and pre / post season.

• Ensure tractor is of sufficient weight to be stable with the Grass Topper attached.

• Ensure that the Topper is properly attached to the tractor's 3 point linkage and that the mechanical

retainers such as linch pins are installed.

• Check that the PTO shaft is properly fitted and that protective covers are in good condition.

• Check for damaged, worn, missing parts and replace if necessary.

• If you are in any doubt about the mechanical condition of the Topper, you are advised not to use it

and consult Malone Engineering regarding your concern. (If the Topper's warranty has expired,

you may contact another competent mechanical engineer).

• Malone Engineering takes no responsibility for accidents, injuries or loss of limbs when using the

equipment.

OPERATING THE MACHINE

To connect the machine to the tractor

Make sure the front axle weight of the tractor is sufficient (use front weights if necessary) to lift the

Topper. Make sure the tractor is aligned with the Topper. Check that the three-point linkage arms of the

tractor are at an equal height. Fit the lower arms to the linkage pins (CAT 2) of the tree-point hitch.

Attack the top link of the tractor to the machine with a pin (CAT2 top link). Once the Topper has been

attached to the three-point linkage of the tractor, raise the lift . Turn off the tractor before installing the

PTO shaft. Make sure that the PTO shaft telescopes smoothly. Connect the machine PTO shaft to the

tractor PTO shaft.

Operating instructions

• Ensure the machine is hitched correctly to the tractor as previously described.

• Ensure bystanders are clear from the machine & cannot be hit with debris expelled from the

machine.

• Start up the tractor PTO at a low RPM.

• Build up to operating speed, select a suitable forward gear & proceed to cut grass.

• Do not exceed 540 RPM as the machine is not designed to operate any faster.

10

MAINTENANCE AND LUBRICATION

Check, and tighten (if required), all nuts, bolts and fixing after the first few hours of work and at

regular intervals thereafter. Grease PTO shaft every 20 hours of operation and pre / post season.

Good maintenance of a machine will ensure a safe working environment and long service life of the

machine.

• Lubricate the PTO shaft as in the manufacturer’s handbook.

• Grease the pivot joints and the drive line every 8-10 working hours.

• Central Gear box (80-90 gear oil) change oil after 50 working hours for the first time

and then after every 400 working hours.

Periodic attention

An inspection and maintenance check is necessary for the Topper every year. The Topper should be

overhauled from time to time during the year to see if lubrication or maintenance is needed.

Maintenance overhaul consists of:

• Examination of nuts & bolts – tighten them if required.

• Examination of PTO shaft protections cover.

• Lubrication according to the instructions for maintenance and lubrication.

Storage

The machine should be stored on a firm level site in a safe, clean and dry location where it is protected

from the elements. It is advisable that prior to storage of the Topper at the end of the season that the

machine be lubricated thoroughly and the opportunity taken to check the machine for worn or damaged

parts - replacements can then be ordered and fitted so that the machine is ready for the next seasons work.

Operator Manual—Topper

11

MALONE LIMITED WARRANTY

Malone Ballyglass, Claremorris, Co. Mayo, Ireland (hereinafter called “the company”) warrants to the

original retail purchaser that new products sold and registered with the company, shall be, at the time of

delivery, free from defects in material and workmanship, and that such equipment is covered under

Limited Warranty providing the machine is used and serviced in accordance with the recommendations

in the Operator’s manual. This Limited Warranty covers the equipment for a period of one year starting

from the date the equipment is commissioned.

The email or post submission of the pre-delivery inspection (PDI) form by the dealer (importer) is taken

as evidence of the delivery of the machine to the original retail purchaser. This is compulsory, and is

required to record the machine in the Malone warranty system.

These conditions are subject to the following exceptions:

• Parts of the machine which are not of Malone manufacture, such as tyres, tines, PTO shafts, slip

clutches, hydraulic cylinders, etc. are not covered by this Limited Warranty, but are subject to the

warranty of the original manufacturer. Warranty claims applying to these types of parts must be

submitted in the same way as if they were parts manufactured by Malone. However, compensation

will be paid in accordance with the warranty agreement of the manufacturer concerned.

• This Limited Warranty does not apply to failure through normal wear and tear, to damage resulting

from negligence or from lack of inspection, from misuse, from lack of maintenance and/or if the

machine has been involved in an accident, lent out or used for purposes other than those for which it

was intended by the company.

• This Limited Warranty will not apply to any product that has been altered or modified in any way

without the express permission of the company, or if parts not approved by Malone are used in

repair.

• The company take no responsibility for any additional costs, including loss of oil and/ or

consumables incurred during the failure and repair of a product

• The company cannot be held responsible for any claims or injuries to the owner or to the third party,

nor to any resulting responsibility.

• Also, on no account can the company be held liable for incidental or consequential damages

(including loss of anticipated profits) or for any impairment due to failure, a latent defect or a

breakdown of a machine.

The customer will be responsible for the following costs:

• Normal maintenance such as greasing, maintenance of oil levels, minor adjustments, etc. as

specified in the Operator’s manual.

• Labour charges other than originally agreed, incurred in the removal and replacement of

components.

• Dealer’s travel time and travel costs to and from the machine.

• Parts defined as normal wear items such as, but not limited to PTO shafts, chains, tyres, bearings,

tines, slip clutches, etc. that are not covered under the Limited Warranty.

Operator Manual—Topper

12

The importer will be responsible for the following costs:

• All warranty labour charges.

The warranty is dependent on the strict observance of the following:

• The machine has been put in service by the Malone dealer according to our instructions.

• The online pre-delivery inspection (PDI) form has been correctly completed by the dealer.

• A printed version of the PDI form has been signed and dated by the original retail purchaser. This

copy is to be stored by the dealer and made available to Malone when requested.

• The warranty claim is submitted using the Malone claims system.

• The warranty claim must be submitted by the original retailing Malone dealer only.

• The decision of the company in all cases is final.

• Damaged parts should be held by the dealer until credit has been given, or a returns request has been

issued.

• Parts must be returned to Malone, with the Malone claim number written clearly on each individual

part. These parts must be free from dirt and oil. If a part is returned in an unfit state, the claim will

be refused.

• If damaged parts have been returned to the company and warranty is refused, the dealer is allowed a

period of one month from the date of receiving our notification to request the return of the damaged

parts to the dealer site.

Further conditions - limits of application and responsibility:

• This Limited Warranty cannot be assigned or transferred to anyone without the prior written consent

of the company.

• Malone dealers have no right or authority to assume any obligation or take any decision on the

company's behalf, whether expressly or tacitly.

• Technical assistance given by the company or its agents for repairing or operating equipment does

not lead to any responsibility on the company's behalf and cannot under any circumstances bring

novation or derogation to the conditions of the present Limited Warranty.

• The company reserves the right to incorporate changes in its machines without prior notice and

without obligation to apply these changes to machines previously manufactured.

• The present Limited Warranty excludes any other responsibility, whether legal or conventional,

express or implied, and there are no warranties extending beyond those defined herein.

No part of this manual may be copied or published by means of printing, photocopying, microfilm

or any other process whatsoever without prior permission in writing by Malone Farm Machinery.

All instructions, pictures and specifications in this manual are based on the latest information that

was available at the time of publication. Your Topper may comprise improvements, features or

options that are not covered in this manual.

Operator Manual—Topper

13

Spare Parts

Topper

14

SPARE PARTS SECTION

To be assured of the latest design improvements purchase your Genuine Replacements from

the Original Equipment Manufacturer through your local Dealer.

Always quote:

• Machine Type

• Year of manufacture

• Serial Number

• Part Code

• Part Position Number & Page Number

• Part Description

Serial Number

Note: The term “right” or “left” indicated in the description is to be

understood when looking at the implement from the rear.

USE ONLY GENUINE SERVICE PARTS

Spare Parts —Topper

15

ITEM QTY PART NUMBER DESCRIPTION

14MNLW16 M16 NORDLOCK WASHER

28M9331240N M12 X 40MM BOLT + NUT

34M9331250N M12 X 50MM BOLT + NUT

44M9331650N M16 X 50MM BOLT + NUT

52M9332060N M20 X 60MM BOLT + NUT

62M9332450N M24 X 50MM BOLT + NUT

71MAT10003 BLADE BAR CARRIER

82MAT10025 SLIDE

93MAT10038 LYNCH PIN

10 1MAT10036 TOP LINK PIN

11 1MAT10011 PTO SHAFT COVER

12 1MAT10010 PTO SHAFT COMPLETE

13 1MAT10031 MAIN TOPPPER BODY

14 1MAT10018 HEADSTOCK

15 2MAT10022 BLADE

16 1MAT10001 BLADE BAR

17 1MAT10013 GEARBOX

18 3MAT10035 SHACKLE

19 2MAT10037 SIDE LINK PIN

20 1MAT10016 STRAP

Spare Parts —Topper

16

Malone Farm Machinery

Ballyglass, Claremorris

Co. Mayo, Ireland. F12 AP11

Tel +353 (0) 94 936 0500

www.malonefm.com

Spare Parts —Topper

Table of contents

Other Malone Farm Equipment manuals

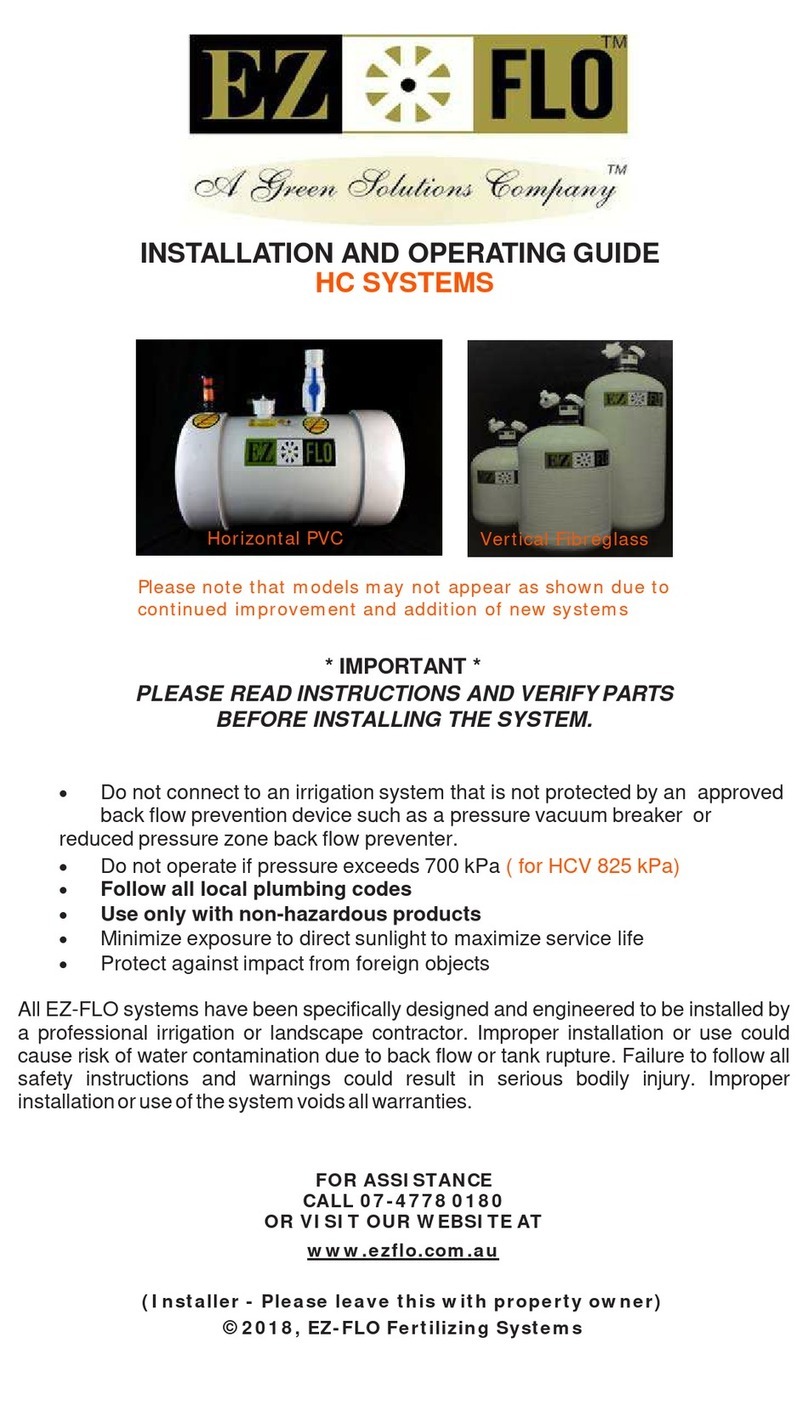

Popular Farm Equipment manuals by other brands

horsch

horsch LEEB 4 LT operating instructions

Jacto

Jacto ADVANCE 3000 AM-18 Operator's manual

GREAT PLAINS

GREAT PLAINS Nutri-Pro NP1330AA Adjustment guide

GREAT PLAINS

GREAT PLAINS HT1100-35 Operator's manual

Snapper

Snapper K50 Service manual

SKY Agriculture

SKY Agriculture Easydrill W 8020 Original instructions