Malone Tedd-Air Series User manual

2

Table of Contents

1. EC DECLARATION OF CONFIRMITY················································ 3

2. GENERAL INFORMATION······························································· 4

3. TECHNICAL DATA ········································································· 5

4. DESCRIPTION ··············································································· 6

5. SAFETY INFORMATION·································································· 6

6. SAFETY DECALS············································································ 7

7. OPERATING THE MACHINE···························································· 8

8. MAINTEANCE AND LUBRICATION ·················································11

9. MALONE LIMITED WARRENTY······················································13

10. SPARE PARTS SECTION ·································································15

Operator Manual “Tedd-Air 570” Tedders

3

EC DECLARATION OF CONFORMITY

We,

Malone Farm Machinery

Ballyglass,

Claremorris,

Co.Mayo

F12 AP11

Republic of Ireland

Declare under our sole responsibility that:

The product (type): Tedder....................................................................................................

Product code: Tedd-Air .........................................................................................................

Serial No:...............................................................................................................................

Date: ..............................................................

Manufactured by the above company

Conforms to EU Engineering Regulations and other relevant EU guidelines.

Signed....................................................................................................................................

(on behalf of Malone Farm Machinery)

...............................................................................................................................................

(Status)

Operator Manual “Tedd-Air 570” Tedders

4

1. GENERAL INFORMATION

Thank you for purchasing a Malone product. You have purchased a strong, reliable and efficient rotary

tedder. To fully utilize the qualities of the tedder, please ensure you read this manual, and this ensures a

longer working life, greater safety and optimal performance.

BEFORE OPERATING THIS MACHINE READ CARFULLY THE

INSTRUCTIONS GIVEN IN THIS MANUAL

USING YOUR OPERATOR’S MANUAL

Read, understand and follow the instructions in this manual, doing so will promote safe, productive and

reliable service.

This manual was prepared to help you use, and maintain your new machine safely. Reading your

operator’s manual will help you and others avoid injury or damage to the machine. This machine can

cause serious property damage, personal injury or even death if it is misused. For your safety, as well as

the safety of others, you must follow the safety precautions in this operator’s manual.

This manual is an important part of your machine. It should remain with the machine if and when it is

sold. If it is damaged or lost, you may contact your dealer, or Malone Farm Machinery company to get a

replacement.

Before delivering this machine, your dealer performed a pre-delivery inspection to ensure best

performance.

If you have any queries, please contact Malone Farm Machinery who will be able to give you the correct

assistance and advice.

Contact: Malone Farm Machinery LTD

Ballyglass,

Claremorris,

Co. Mayo

F12 AP11

Ireland

Tel: +353 (0) 94 93 60 500

Email: [email protected]

Website: www.malonefm.com

The contents of this manual can be modified only by the manufacturer and without

notice to the Client. Malone Farm Machinery shall not be liable for errors or faults in

this manual.

Operator Manual “Tedd-Air 570” Tedders

5

2. TECHNICAL DATA

Type Tedd-Air 570

Number of rotors 4

Diameter of rotors 1.60 m

Number of tines 7

Type of tines Double Hook Tines

Working width 5.74 m

Width of the machine 5.74 m

Transport width 2.78 m

Height (transport mode) 2.60 m

Length 2.30 m

Working speed up to 15 km/h

Transport speed (max) 30 km/h

Weight 830 kg

Necessary tractor power 80 HP / 60 KW

PTO shaft speed 540 rpm

Rotor Speed at 540 rpm PTO 151

Tyres 16 X 6.50 - 8

3 Hitch point CAT 2

Lifting to transport position Hydraulic – Single acting

PTO Shaft

Length between the joints

Safety coupling 900 Nm

Operator Manual “Tedd-Air 570” Tedders

6

DESCRIPTION

The ‘Tedd-Air 570” is specially designed for forage tedding and spreading by means of rotating spring

tines (double hook tines) attached to rotors. Forward angled rotors allow the spring tines to gently collect,

turn and lay the forage behind the machine. Gentle airing and even tedding, accelerates the drying process.

The need for extended drying time and dependency on spells of good weather is reduced to preserve

valuable nourishing substances. The tedder is constructed with support wheels so that the height of each

rotor remains constant to the working surface; this allows the tedder to collect the forage cleanly and

consistently in spite of its large working width and permits efficient operation on sloping or rough terrain.

The spring tines are made of high quality steel and fixed in a manner that enables spring flexibility. The

machine can be attached to any type of tractor that has three-point linkage (CAT 2) and hydraulic

connections. It machine is driven by a “cardan” PTO shaft.

SAFETY INFORMATION

In the interest of safety, it is important that great care is adopted at all times during the attachment,

transportation, operation and maintenance of this machine. Both the owner and the operator of the

machine should read and understand the following section to ensure the safety of themselves and all other

persons who enter into the close proximity of these machines.

In addition to the instructions stated here always abide by general safety and accident regulations.

• Safety and warning decals placed on the machine give important instructions for safe work take

them into consideration for your safety and the safety of others.

• While driving on public roads always abide traffic signs and road regulations.

• Familiarise yourself with the controls and functions of the machine and practice them in a safe

location before attempting to work.

• Never approach this machine whilst it is working or running. Always switch off the machine and

wait until it has stopped fully before approaching.

• Do not wear loose fitting clothing in the vicinity of this machine.

• Check no one is near, or on, the machine before attempting to start or transport it. Ensure your

visibility is kept clear at all times.

• Implements should always be attached according to the manufacturer’s instructions and fastened

correctly to the prescribed devices using the correct components.

• When disconnecting the machine from the tractor, select a firm level site and use the supports legs.

• Take care when disconnecting the machine from the tractor.

• Ensure controls for the machine are positioned such that the machine cannot accidentally be started

during transport.

• For transportation on the road, prepare and secure the machine according to the manufacturer’s

instructions.

Operator Manual “Tedd-Air 570” Tedders

7

• Never leave the driver seat whilst the tractor of the machine is running.

• Never attempt to operate a machine without its safety devices fitted or incorrectly secured.

• Always place the machine in a safe position before leaving the tractor. Lower the implement

completely, switch off the engine and remove the ignition key.

• Never permit anyone between the machine and the tractor whilst either is working or when the

machine is in a raised position.

• Be aware at all times of the width, height and length of any machinery you are operating, especially

when transporting on the public highway or near obstructions.

• Ensure the work area is clear of obstructions before starting work (clear stones, wires, glass or any

other dangerous objects from the work site before attempting to start work).

• Do not operate the machine without safety guards or if the guards are damaged.

• Do not drive the machine through the forage when the rotor is on the ground and not rotating. This

causes damage to the tines and tine arms.

Please Note: The manufacturer does not guarantee the tedder compliance with the applicable

laws, in particular those relating to accidents prevention and pollution, of non-EU countries.

The adjustment of the tedder to these regulations will be entirely under the Client’s own

responsibility. The manufacturer is not liable for any kind of damage that could arise from the

non-compliance of those rules.

SAFETY DECALS

Read the operator’s manual carefully before you operate the machine.

Keep away from the folding area of the rotors .

Keep away from all moving/rotating parts

Operator Manual “Tedd-Air 570” Tedders

8

OPERATING THE MACHINE

When connecting the tedder on the tractor for the first time, check the length of the PTO shaft according to

the PTO shaft manufacturer′s manual. Use only PTO shafts with a built-in safety coupling.

To connect the machine to the tractor, make sure the front axle weight of the tractor is sufficient (use

front weights if necessary) to lift the tedder. Make sure the tractor is aligned with the tedder. Make sure

the three-point hitch arms of the tractor are at an equal height. Fit the lower arms to the linkage pins (CAT

2) of the tree-point hitch. Attack the top link of the tractor to the machine with a pin (CAT2 top link).

Once the tedder has been attached to the three-point linkage of the tractor, raise tedder, check if the

transport pin is in the correct position & retract the stands. Turn off the tractor before installing the PTO

shaft. Make sure that the PTO shaft telescopes smoothly. Connect the machine PTO shaft to the tractor

PTO shaft. Remove dust cup from the hydraulic hose. Connect the hydraulic hose to the tractor. Permitted

maximum oil pressure is 210 bar (21 MPa). Put the end of the control cord of the ram safety lock in the

tractor cab.

Before placing the machine into working position, you must remove the transport

pin. After that the machine must be first lowered to the ground. Pressure tedder rams, pull the cord to

release the transport locks and lower the wings on the hydraulic rams

A: Transport position of the transport pin B: Working position of the transport pin

Operator Manual “Tedd-Air 570” Tedders

9

To make a turn or to drive to another position in the field, operate the tractor hydraulics to lift the rotors

from the ground

Wheel Positions:

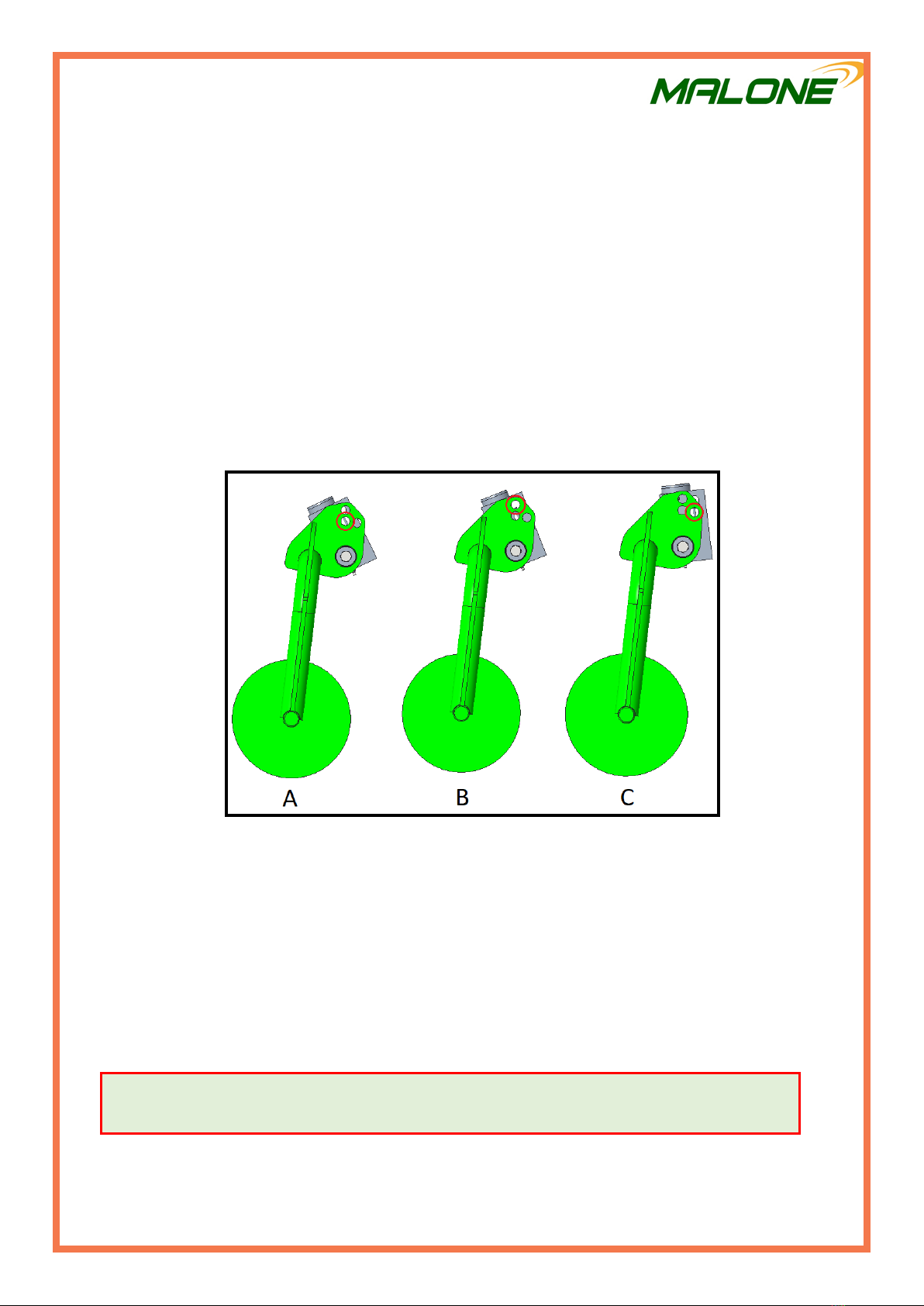

There are three wheel-position during the operation with a lever. The wheel position selected will dictate

the working position of the machine, flexibility is retained by the pivoting headstock. The three wheel

positions available are:.

A: Left B: Straight C: Right

CAUTION: When changing from working to transport mode select a flat site and be sure

that the lever is in the position B and the rotors are not rotating.

Note: The term “Right” or “Left” indicated in the description is to be understood when looking at the

implement from the rear.

Operator Manual “Tedd-Air 570” Tedders

10

Rotor Height

The rotor height can be adjusted in order to achieve the required clearance of the front spring tines from

the ground (about 2cm). Adjustment is made with the tractor top link. This setting is a default setting. The

height adjustment of the tines must be adapted to the field conditions in practice. Ensure during work that

the spring tines do not ‘break’ the surface of the ground as this may cause damage to the machine and also

contaminate the forage with soil. If possible, take the swathes in between the rotors.

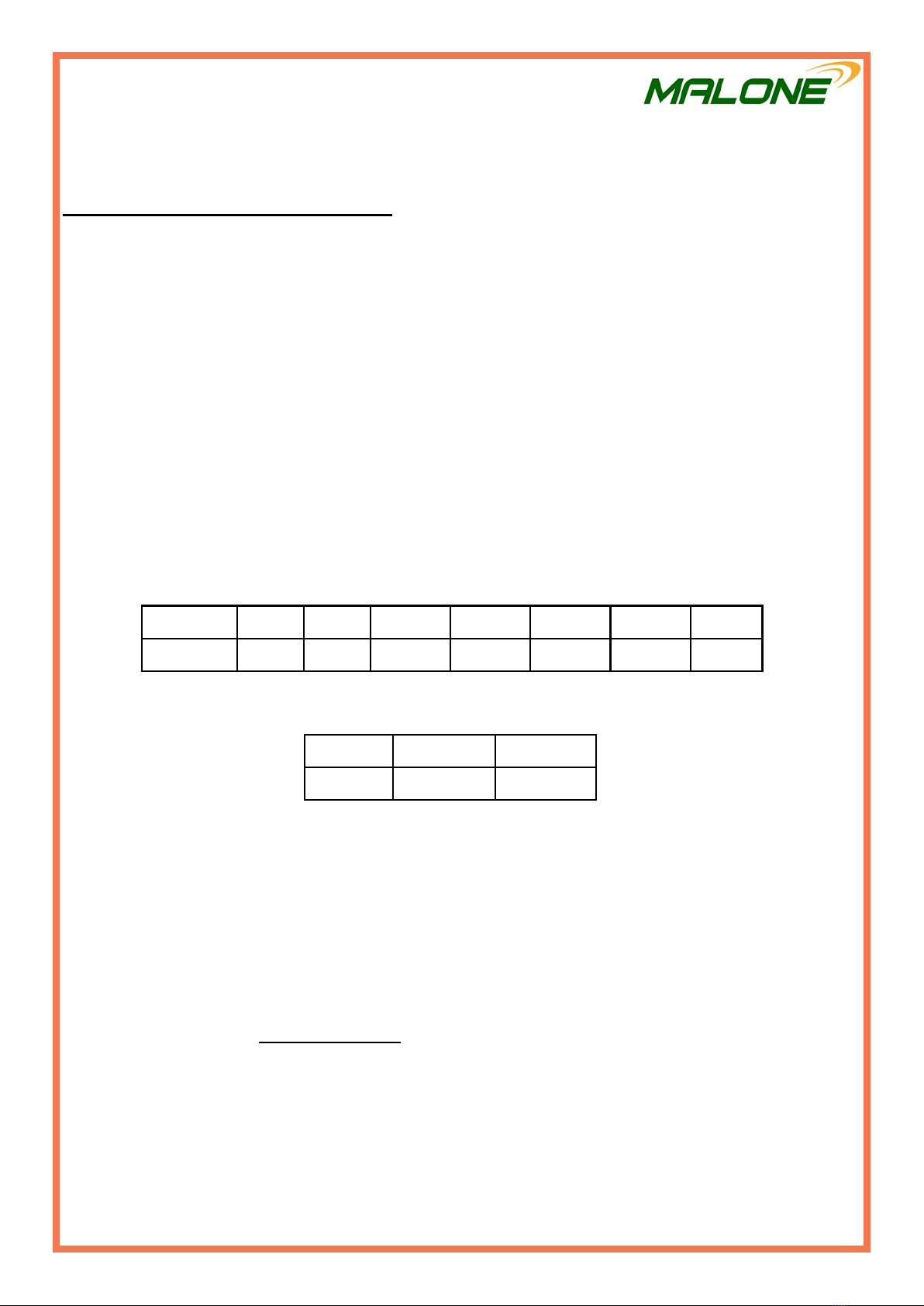

Rotor Angle

The rotor angle can be adjusted to any of three positions, the angle choices are: A, B and C. The angle

setting is determined and selected by the choice of hole in the wheel axle fixing bracket the attachment pin

is located in. The standard and most commonly used position is the hole position B.

For large quantities of forage where more intensive scattering is required the rotor angle should be

increased by selecting the hole position A, alternatively, for lesser quantities of forage the rotor angle can

be decreased by selection of the hole position C.

Position A, B and C

PTO rpm and tractor speed

If the forage is heavy drive with higher speed and not so high tractor speed. The dryer the forage the

smaller the P.T.O. speed to be chosen in order to avoid damages to the forage. Tractor speed must be

adapted to the condition of the forage

After placing the machine into the transport position, you must add the transport pin to the correct

position (please see page 8).

Please Note: The rotor height & angle, PTO shaft rpm and tractor speed described above

are standards and must be adapted to the field conditions in practice.

Operator Manual “Tedd-Air 570” Tedders

11

To place the machine into the transport position you need to keep pulling the cord while at the same

time using the tractor hydraulics, until the machine locks to transport mode (this is necessary for the

Tedd-Air 570 model –The Tedd-Air 840 is lockable without pulling the cord)

To disconnect the tedder from the tractor. Always position the tractor on the solid ground before you

disconnect the tedder from the tractor. Make sure that no person is near the tedder when you are

disconnecting the tractor. The tedder can be disconnected from the tractor in the transport position or in

the work position. When disconnecting in transport mode, make sure the wheel supports of the centre

rotors are in the closer position to the dish. This ensures the most stable position for the tedder. Switch off

the tractor and release the pressure from the tractor hydraulic system. Disconnect the tedder PTO shaft

from the tractor PTO shaft and attach the PTO shaft to the provided mount. Make sure that the stands are

in parking position. Disconnect the top link from the headstock. Disconnect the hydraulic hose from the

tractor and put it to the support on the headstock, after you installed the dust cap. Disconnect the lower

arms from the linkage pins on the headstock. Remove the end of the ram lock control cord form the tractor

cab.

MAINTENANCE AND LUBRICATION

Check, and tighten (if required), all nuts, bolts and fixing after the first few hours of work and at

regular intervals thereafter.

Bolt quality 8.8:

M6 M8 M10 M12 M14 M16 M20

Nm 10 25 50 85 135 210 410

Bolt quality 10.9

M12 M14

Nm 130 195

• Check daily (before and after operation) that the spring tines and their holders are securely

fastened.

• Lubricate the PTO shaft as in the manufacturer’s handbook.

• Grease the pivot joints and the drive line every 8-10 working hours.

• Tyres cold pressure 250 kPa (36 PSI).

• Central Gear box (0,8 lt. type EP220 oil) change oil after 50 working hours for the first time

and then after every 400 working hours.

• Lateral gear boxes maintenance free. (0,5 kg grease Vanguard Liplex EP1 or similar)

Operator Manual “Tedd-Air 570” Tedders

12

Periodic attention

An inspection and maintenance check is necessary for the tedder every year. The tedder should be

overhauled from time to time during the year to see if lubrication or maintenance is needed.

Maintenance overhaul consists of:

• Examination of the safety mechanism for transport.

• Examination of nuts & bolts – tighten them if required.

• Spring tine adjustment.

• Examination of PTO shaft protections cover.

• Lubrication according to the instructions for maintenance and lubrication.

Storage

The machine should be stored on a firm level site in a safe, clean and dry location where it is protected

from the elements. It is advisable that prior to storage of the tedder at the end of the season that the

machine be lubricated thoroughly and the opportunity taken to check the machine for worn or damaged

parts - replacements can then be ordered and fitted so that the machine is ready for the next seasons work.

Steering stabilisers

In the unlikely event that the stabiliser rams below, prevent the tedder staying rigid on a straight path,

please remove the accumulators below to top up the hydraulic fluid in this closed system of cylinders. This

is caused by leakage of oil though the rod. Please use (HD-46 oil). Please copy and paste the URL link

from the below QR code to view a video of this maintenance process completed in detail.

Operator Manual “Tedd-Air 570” Tedders

13

MALONE LIMITED WARRANTY

Malone Ballyglass, Claremorris, Co. Mayo, Ireland (hereinafter called “the company”) warrants to the

original retail purchaser that new products sold and registered with the company, shall be, at the time of

delivery, free from defects in material and workmanship, and that such equipment is covered under

Limited Warranty providing the machine is used and serviced in accordance with the recommendations

in the Operator’s manual. This Limited Warranty covers the equipment for a period of one year starting

from the date the equipment is commissioned.

The email or post submission of the pre-delivery inspection (PDI) form by the dealer (importer) is taken

as evidence of the delivery of the machine to the original retail purchaser. This is compulsory, and is

required to record the machine in the Malone warranty system.

These conditions are subject to the following exceptions:

• Parts of the machine which are not of Malone manufacture, such as tyres, tines, PTO shafts, slip

clutches, hydraulic cylinders, etc. are not covered by this Limited Warranty, but are subject to the

warranty of the original manufacturer. Warranty claims applying to these types of parts must be

submitted in the same way as if they were parts manufactured by Malone. However, compensation

will be paid in accordance with the warranty agreement of the manufacturer concerned.

• This Limited Warranty does not apply to failure through normal wear and tear, to damage resulting

from negligence or from lack of inspection, from misuse, from lack of maintenance and/or if the

machine has been involved in an accident, lent out or used for purposes other than those for which it

was intended by the company.

• This Limited Warranty will not apply to any product that has been altered or modified in any way

without the express permission of the company, or if parts not approved by Malone are used in

repair.

• The company take no responsibility for any additional costs, including loss of oil and/ or

consumables incurred during the failure and repair of a product

• The company cannot be held responsible for any claims or injuries to the owner or to the third party,

nor to any resulting responsibility.

• Also, on no account can the company be held liable for incidental or consequential damages

(including loss of anticipated profits) or for any impairment due to failure, a latent defect or a

breakdown of a machine.

The customer will be responsible for the following costs:

• Normal maintenance such as greasing, maintenance of oil levels, minor adjustments, etc. as

specified in the Operator’s manual.

• Labour charges other than originally agreed, incurred in the removal and replacement of

components.

• Dealer’s travel time and travel costs to and from the machine.

• Parts defined as normal wear items such as, but not limited to PTO shafts, chains, tyres, bearings,

tines, slip clutches, etc. that are not covered under the Limited Warranty.

Operator Manual “Tedd-Air 570” Tedders

14

The importer will be responsible for the following costs:

• All warranty labour charges.

The warranty is dependent on the strict observance of the following:

• The machine has been put in service by the Malone dealer according to our instructions.

• The online pre-delivery inspection (PDI) form has been correctly completed by the dealer.

• A printed version of the PDI form has been signed and dated by the original retail purchaser. This

copy is to be stored by the dealer and made available to Malone when requested.

• The warranty claim is submitted using the Malone claims system.

• The warranty claim must be submitted by the original retailing Malone dealer only.

• The decision of the company in all cases is final.

• Damaged parts should be held by the dealer until credit has been given, or a returns request has been

issued.

• Parts must be returned to Malone, with the Malone claim number written clearly on each individual

part. These parts must be free from dirt and oil. If a part is returned in an unfit state, the claim will

be refused.

• If damaged parts have been returned to the company and warranty is refused, the dealer is allowed a

period of one month from the date of receiving our notification to request the return of the damaged

parts to the dealer site.

Further conditions - limits of application and responsibility:

• This Limited Warranty cannot be assigned or transferred to anyone without the prior written consent

of the company.

• Malone dealers have no right or authority to assume any obligation or take any decision on the

company's behalf, whether expressly or tacitly.

• Technical assistance given by the company or its agents for repairing or operating equipment does

not lead to any responsibility on the company's behalf and cannot under any circumstances bring

novation or derogation to the conditions of the present Limited Warranty.

• The company reserves the right to incorporate changes in its machines without prior notice and

without obligation to apply these changes to machines previously manufactured.

• The present Limited Warranty excludes any other responsibility, whether legal or conventional,

express or implied, and there are no warranties extending beyond those defined herein.

No part of this manual may be copied or published by means of printing, photocopying, microfilm

or any other process whatsoever without prior permission in writing by Malone Farm Machinery.

All instructions, pictures and specifications in this manual are based on the latest information that

was available at the time of publication. Your Ted-Air 570 may comprise improvements, features or

options that are not covered in this manual.

Operator Manual “Tedd-Air 570” Tedders

15

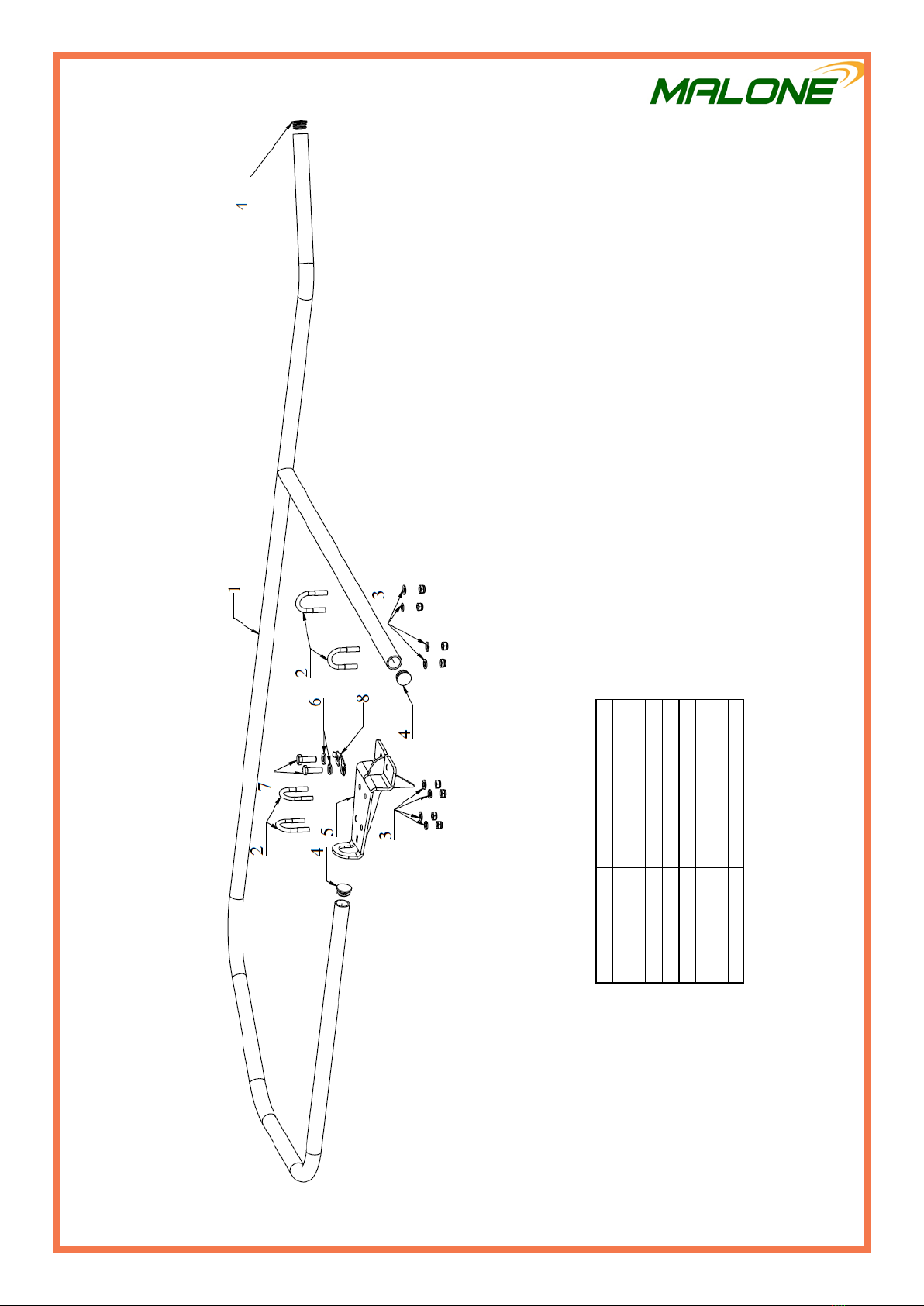

Spare Parts

Tedd - Air 570

16

SPARE PARTS SECTION

To be assured of the latest design improvements purchase your Genuine Replacements from

the Original Equipment Manufacturer through your local Dealer.

Always quote:

• Machine Type

• Year of manufacture

• Serial Number

• Part Code

• Part Position Number & Page Number

• Part Description

Serial Number

Note: The term “right” or “left” indicated in the description is to be

understood when looking at the implement from the rear.

USE ONLY GENUINE SERVICE PARTS

Spare Parts “Tedd-Air 570” Tedders

17

Page 4R-1

Pos Code Description

1MTD4S0105 Main Headstock

2M1102310 Lynchpin D10

3M16- DIN 985 Lock Nut

4Low Hitch Pin

5M9311675N Bolt M16x75

6M8_Straight_Grease Nipple

7Pin F20

8Top Link Pin

9M1481840 Roll Pin D8x40

10 MTD4S0110 Stand Pin

11 MTD4S0106 Stand

13 MTD4S0100R Lower Hitch Right

14 MTD4S0100L Lower Hitch Left

15 MTD4S0101 Pin D25

16 M12316 Washer M16

Spare Parts “Tedd-Air 570” Tedders

18

Page 4R-2

Pos Code Description

1MTD4S0107 Main Chassis

2M9331655N Bolt M16X55 & L/Nut

3M12516 Washer M16

4MTD4J0101 Main Axis Support

5M16621020 Flange Bolt M10X20

6M12510 Washer M10

7MTD4F0108 Nut Locker

8M714128H1 Grease Nipple M8

9MTD4M0105 Hardened Bush

10 MTD4M0108 Bush

11 M14811240 Roll Pin M12X40

12 Hose Clamp

13 M2520114 Washer M14 Nordlock

14 M9331450N Bolt M14X50 & L/Nut

15 M9331450 Bolt M14X50

16 MTD4M0114 Spare Wheel Support

17 M1034430000 Wheel 16x6.50-8

18 Flange Nut M

19 Protection Cup

20 M6921820 Flange Bolt M8x20

21 Manual Holder

22 Castle Nut M36 (Fine)

23 MTD4F0107 Washer

24 MTD4M0107 Rotation shaft

25 MTD4M0109 Hardened Bush

26 M9311060ΝBolt M10X60 & L/Nut

27 MTD4B0102 Custom Washer

28 Headstock Pin

Spare Parts “Tedd-Air 570” Tedders

19

Page 4R-3

Pos Code Description

1Warning Lights

2M10 LOCK NUT

3M12 LOCK NUT

4M16 LOCK NUT

5M6 LOCK NUT

6M12X60 DIN 933 BOLT

7M12X90 DIN 933 BOLT

8M6X20 BOLT

9M10 DOUBLE BUMPER

10 REFLECTIVE BOARD

11 TD4C0100 Reflective Board Mounting

Left

12 TD4C0113 Reflective Board Mounting

Right

14 TD4S0103 Arm Support

15 TD4S0110 Stand Pin

16 TD6S0101 BACK STAND BRACKET

17 TD6S0102 BACK STAND

18 TD6S0103 REFLEVTIVE BOARD

19 TD4X0103 Reflective Board Mounting

20 U BOLT 40X65X12

21 U BOLT 80X110X16

22 A12X24X2 WASHER

23 A16X30X3 WASHER

24 A6X12X1 WASHER

Spare Parts “Tedd-Air 570” Tedders

20

Page 4R-4

Pos Code Description

1MTD4S0104 Safety Guard Pipe

2Round U-Bolt M10

3M12510 Washer M10

4Plastic Pipe Cup

5MTD4S0115 Guard Plate

6M2520112 Nordlock Double Washer M12

7M9331230 Bolt M12X30 12.9

8MTD4B0103 Blots Support

Spare Parts “Tedd-Air 570” Tedders

This manual suits for next models

1

Table of contents

Other Malone Farm Equipment manuals