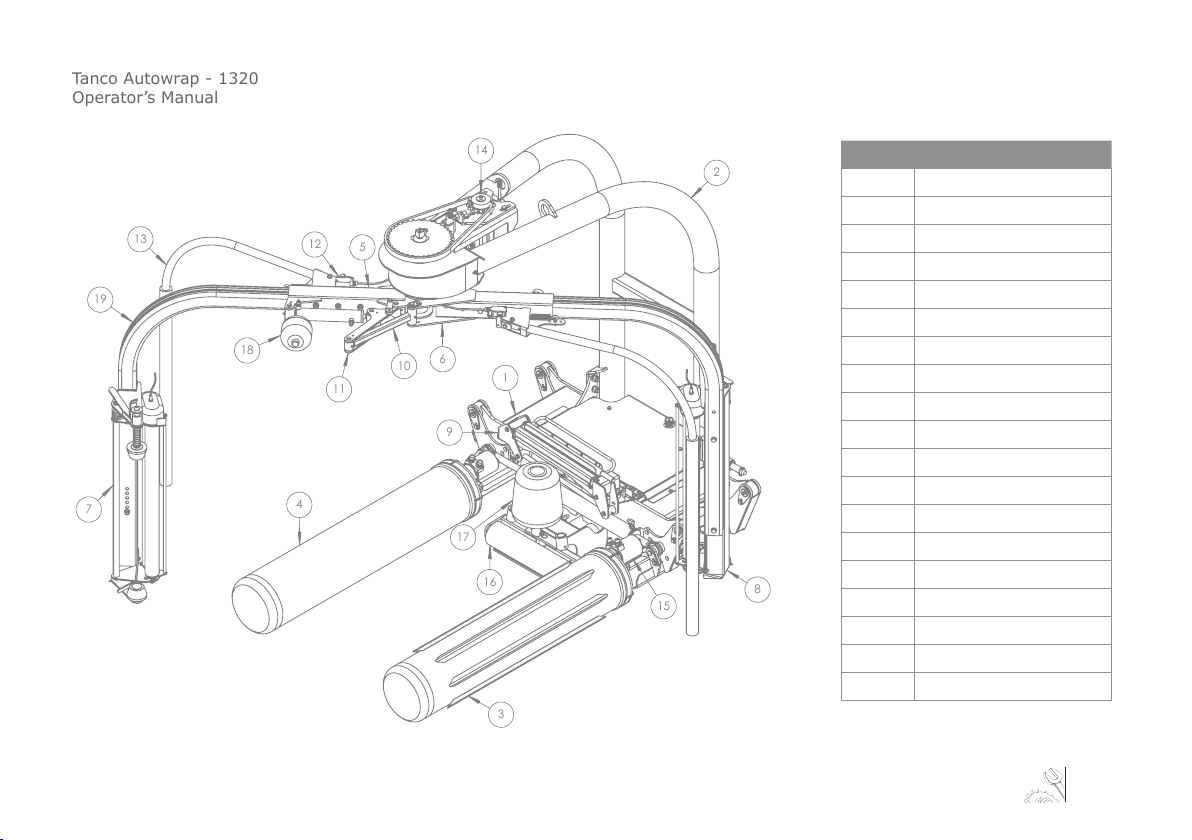

Tanco Autowrap - 1320

Operator’s Manual

2. Intrroduction

Tanco Autowrap Ltd congratulates you on your choice of the TANCO AUTOWRAP 1320 bale wrapping

machine. We are certain you will be satised with the machine, and that you will have the pleasure of your

investment for many years.

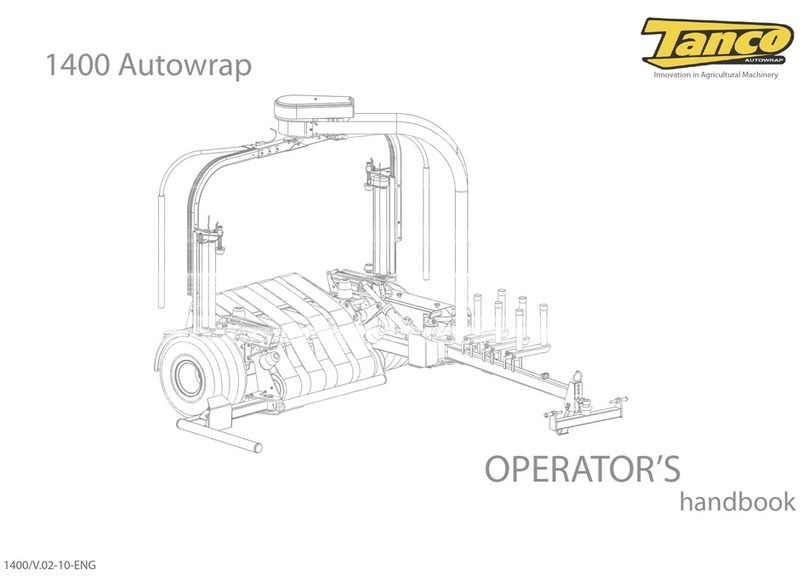

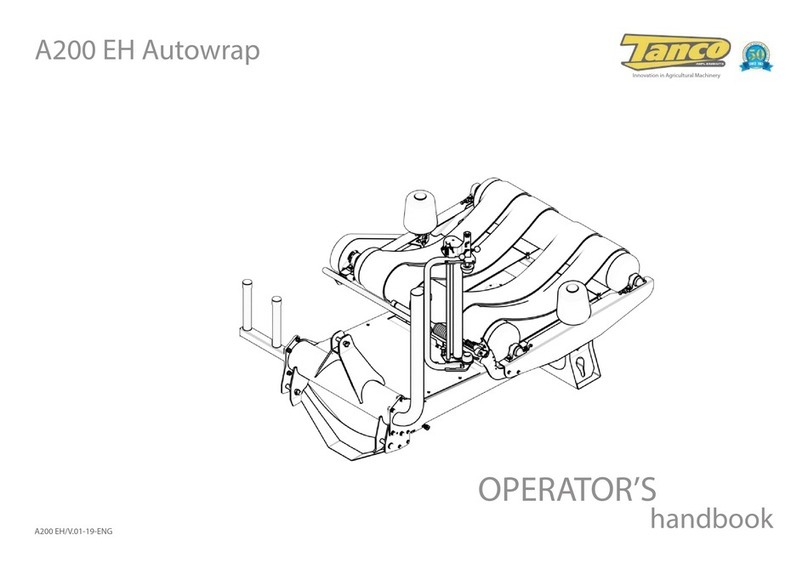

The TANCO AUTOWRAP bale wrapping machine has more features than any other bale wrapping machine

available. The 1320 can pick up the bale, wrap and stack them without the operator leaving the tractor

cab; this is a patented system.

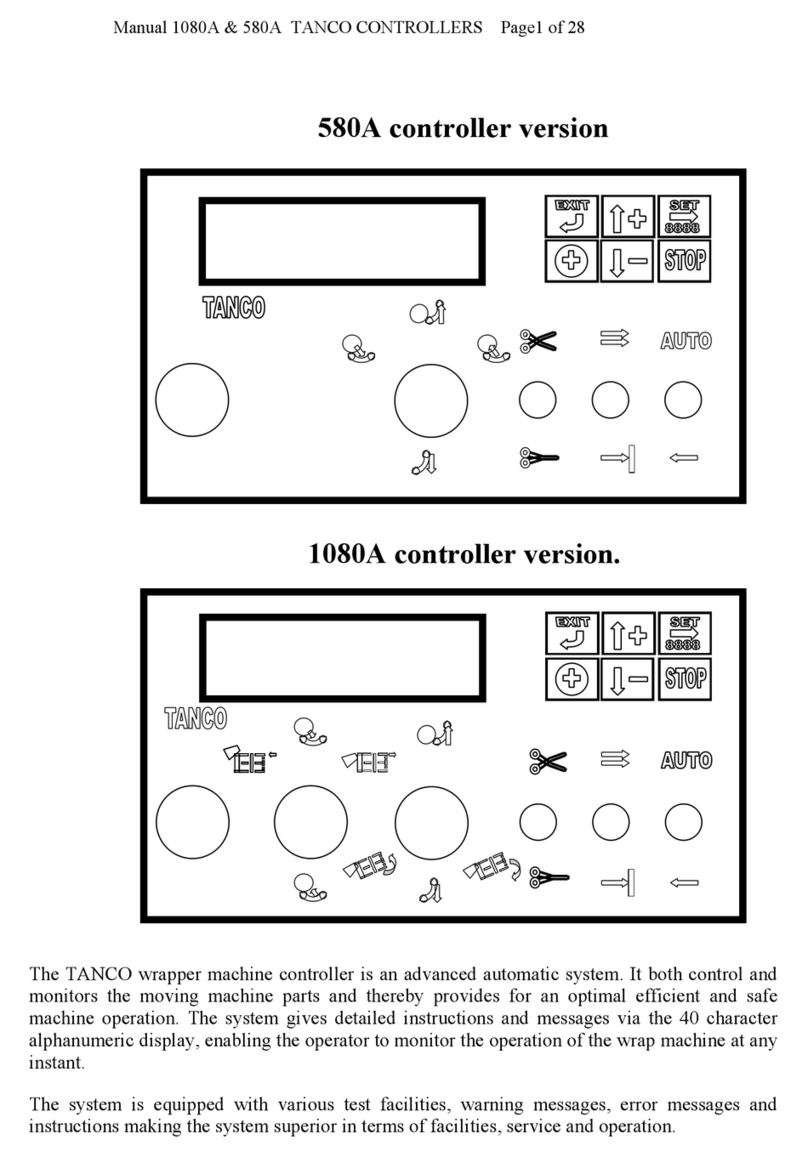

This machine is hydraulically driven by the tractor’s hydraulic system and is controlled from the trac-

tor cab by an automatic control unit. TThe machine can either be mounted to three point linkage, front

mounted with quick-couplers to the tractors front loader or on a wheel loader. Then it’s possible to stack

the bales upon each other. The wrapped bale can be either dropped conventionally to the ground or with

the tting of an optional ‘End Tip’the bale can be dropped on its end.

TANCO AUTOWRAP 1320 is designed to wrap bales of grass, hay or straw, with nominal diameter of 1.1 -

1.5m, and weights up to (1200kg). The original 1300 model was launched in the mid 1980’s and has been

developed into the very reliable and safe machine we have today.

This manual is meant to explain how TANCO AUTOWRAP 1320 is setup, attached to tractor, used and how

it works, and shall together with the spare part's list be a reference for maintenance and troubleshooting.

So take good care of this book; it is a part of the machine.

Read carefully through this manual, and especially the safety instructions, before starting the machine.

Follow the instructions thoroughly, if problems should occur, check the troubleshooting guide to try to

establish the problem. Ask your dealer for advice before you attempt anything that may make the prob-

lem worse.