Table of contents

Foreword......................................................8

1. Safety.......................................................14

1.1 Notes on representation .........................14

1.2 Qualication and training of personnel ...14

1.3 Work place of the operator .....................15

1.4 Danger caused by failing to comply

with the safety notes...............................15

1.5 Safety conscious working.......................15

1.6 Safety notes for the operator..................15

1.6.1 Safety and accident prevention

instructions........................................15

1.6.2 Coupling and uncoupling the machine.. 16

1.6.3 Working with the machine.................17

1.6.4 Changing equipment.........................17

1.6.5 Transporting the machine .................18

1.6.6 Hydraulic system ..............................18

1.6.7 Electrical system...............................19

1.6.8 Towed machines ...............................20

1.6.9 Brake system....................................20

1.6.10 Pneumatic brake system ................20

1.6.11 Tyres ...............................................20

1.6.12 Handling crop protection agents.....21

1.6.13 Operating the crop protection sprayer ...21

1.6.14 Maintenance ...................................22

1.7 Loading and unloading ...........................23

1.8 Unauthorized conversion and

manufacture of spare parts.....................23

1.9 Impermissible operating modes..............24

1.10 Spare parts and wear items as

well as auxiliary materials.....................24

1.11 Working in the vicinity of high voltage

power lines ...........................................24

1.12 Phone and radio equipment .................24

1.13 Danger caused by residual energy.......25

1.14 Cleaning and waste disposal................25

1.15 Intended use.........................................25

1.15.1 Specied equipment .......................26

1.15.2 Consequential damage...................26

1.15.3 Effects when using certain

crop protection products .................26

1.15.4 Danger zones and danger points....27

1.15.5 Personal protection equipment.......28

1.15.6 Organizational measures................28

1.15.7 Operating instructions.....................28

1.16 Safety notes on the machine................29

1.17 Instruction sticker..................................29

1.18 Safety stickers ......................................29

1.19 Position of safety stickers.....................32

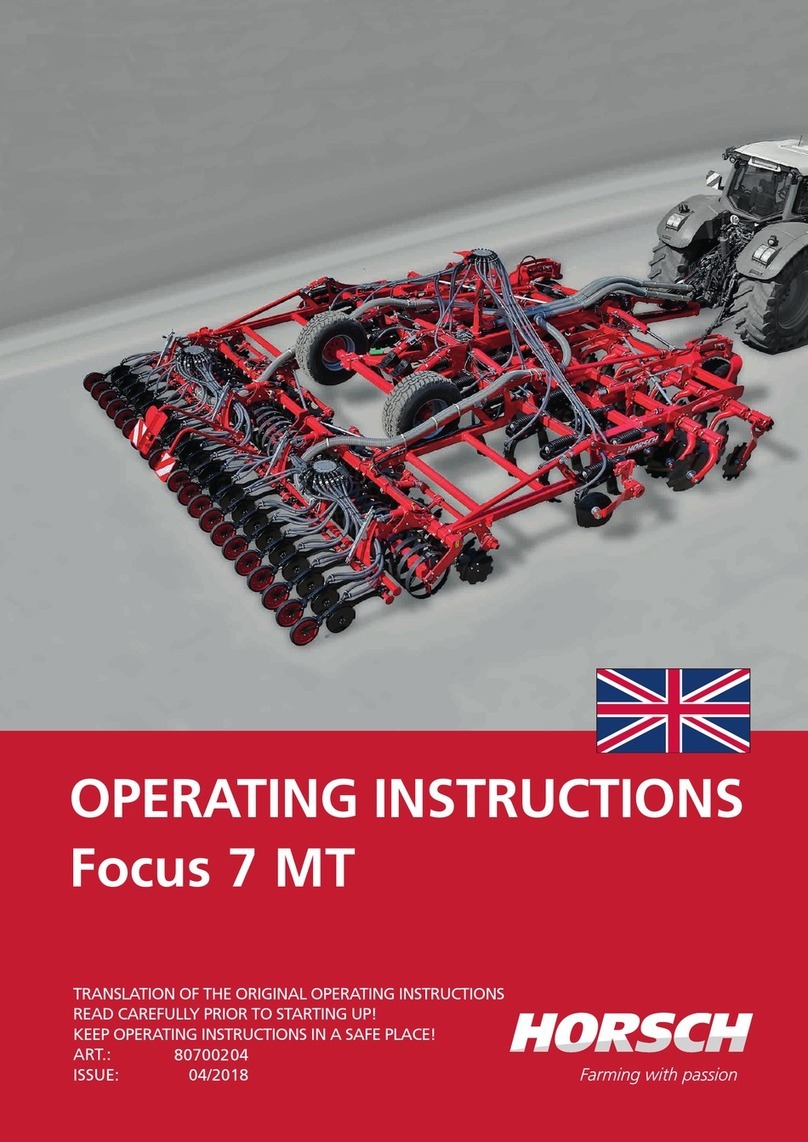

2. Product description................................34

2.1 Overview.................................................34

2.2 Safety and protective features................35

2.3 Fluid circuit LT CCS - components .........36

2.4 Fluid circuit LT CCS Pro - components ..37

2.5 Supply lines between tractor and machine....38

2.6 Trafc-compliant equipment ...................38

2.7 Technical data.........................................39

2.7.1 Dimensions.......................................41

2.7.2 Permissible total weight and tyres ....42

2.8 Nose development data..........................45

2.9 Necessary tractor equipment..................45

3. Design and function...............................47

3.1 Control unit .............................................47

3.2 Connections............................................47

3.3 Folding boom..........................................47

3.4 Nozzles...................................................48

3.5 Spraying line...........................................48

3.6 Spraying control......................................48

3.7 CCS - continuous inside cleaning...........48

3.8 Fluid circuit - function..............................49

3.9 Induction hopper ....................................51

3.10 Spraying pump .....................................52

3.11 Piston diaphragm pump........................53

3.12 Hand washing tank...............................53

3.13 Agitator .................................................53

3.14 Filter......................................................54

3.15 External cleaning system (optional)......55

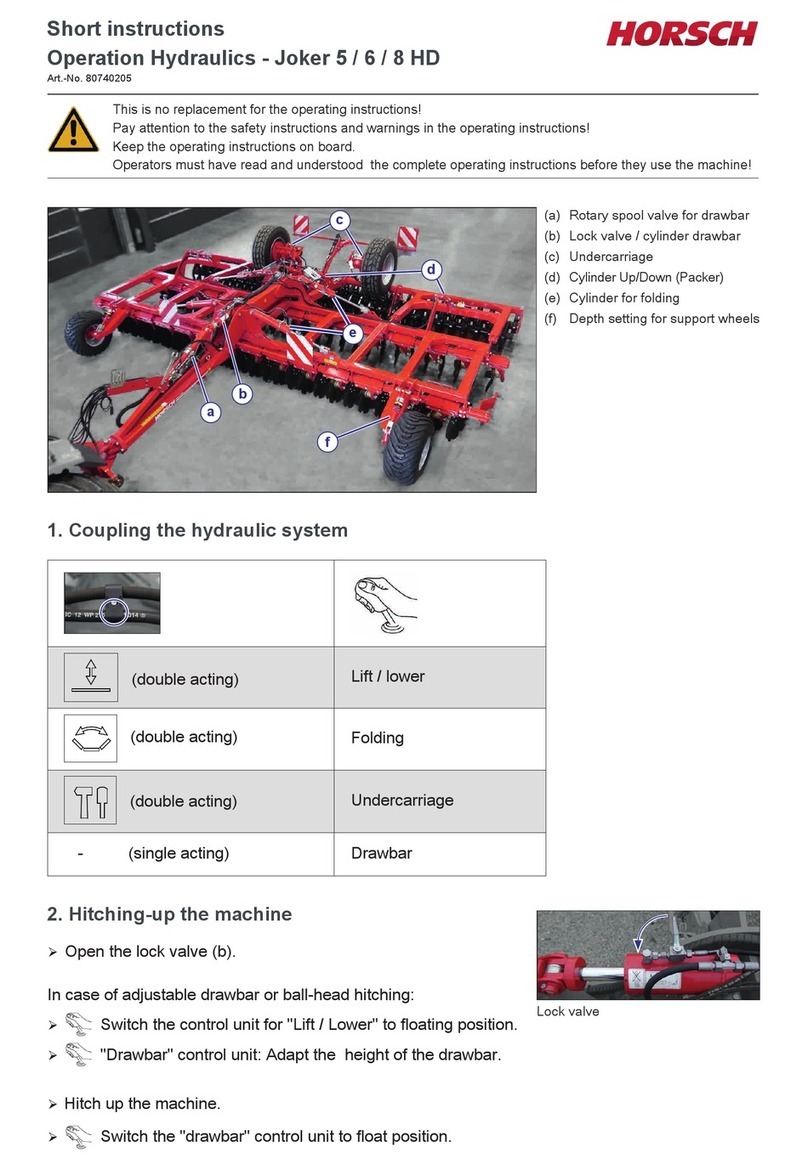

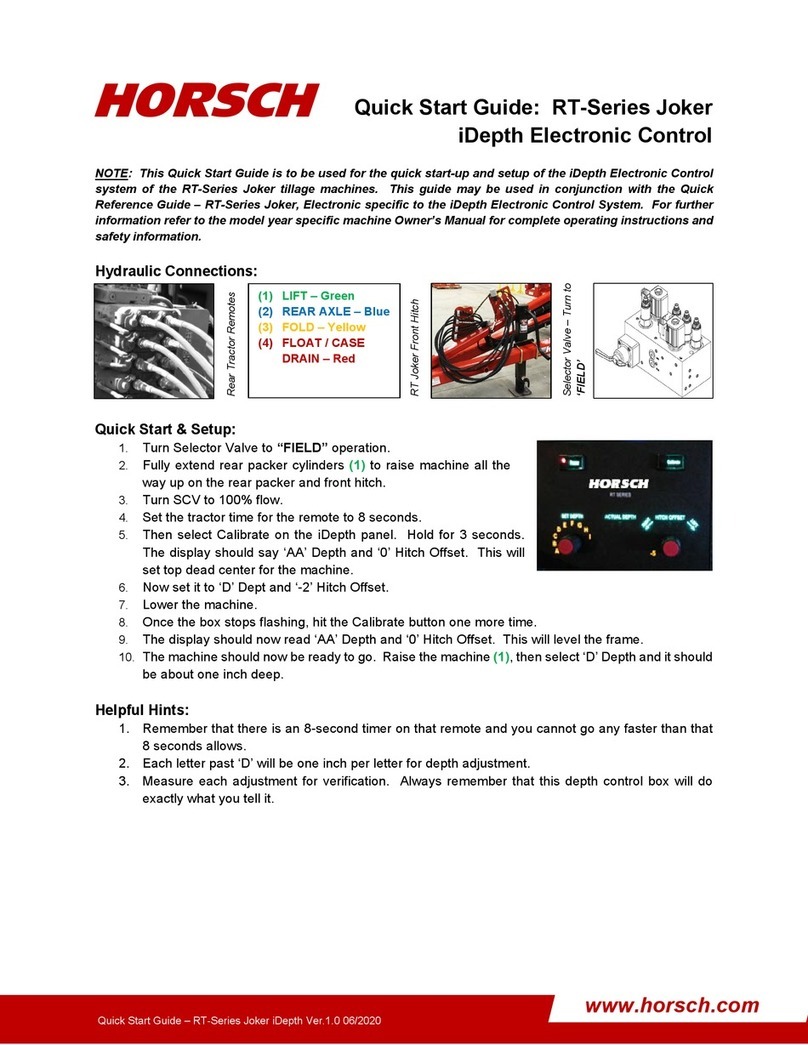

3.16 Hydraulic connections ..........................56

3.16.1 Coupling hydraulic hoses ...............56

3.16.2 Uncoupling hydraulic hoses ...........57

3.17 Pulling tool (optional)............................57

3.18 Lifting points .........................................57

3.19 Transport, document and safety

container ..............................................58

10