Malone PROCUT 3000 MP User manual

Centre Pivot Mower

PROCUT 3000 MP

Operators Manual

Issue: 002

Malone Farm Machinery

Ballyglass, Claremorris,

Co. Mayo, F12 AP11

Republic of Ireland

www.malonefm.com

ENSURE ALL OPERATORS ARE FAMILIAR WITH THIS

OPERATORS MANUAL, BEFORE USING THE MACHINE

Operator Manual –PROCUT 3000 MP

2

BLANK PAGE

Operator Manual –PROCUT 3000 MP

3

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS .........................................................................................3

2. GENERAL INFORMATION ..................................................................................5

3. TECHNICAL DATA................................................................................................6

4. DESCRIPTION........................................................................................................6

5. SAFETY INFORMATION......................................................................................7

Transportation safety.........................................................................................................7

6. SAFETY DECALS...................................................................................................8

7. PRE-OPERATION CHECKLIST......................................................................... 10

8. OPERATING THE MACHINE ............................................................................11

Attaching to the tractor.................................................................................................... 11

Attaching PTO to tractor ................................................................................................. 11

Attaching the hydraulics to the tractor............................................................................. 11

Transport into working position....................................................................................... 12

9. MAINTENANCE AND LUBRICATION.............................................................. 14

Filling quantities and lubrication ..................................................................................... 14

Gearbox....................................................................................................................... 14

Cutter bed.................................................................................................................... 15

Storage............................................................................................................................ 16

Disc and blade maintenance ............................................................................................ 16

10. MALONE LIMITED WARRANTY ..................................................................... 17

11. SPARE PARTS SECTION ....................................................................................20

Operator Manual –PROCUT 3000 MP

4

EC DECLARATION OF CONFORMITY

We,

Malone Farm Machinery

Ballyglass,

Claremorris,

Co.Mayo

F12 AP11

Republic of Ireland

Declare under our sole responsibility that:

The product (type): Centre Pivot Mower

Product code: 3000 MP

Serial No:

Date:

Manufactured by the above company

Conforms to EU Engineering Regulations and other relevant EU guidelines.

Signed

(on behalf of Malone Farm Machinery)

(Status)

Operator Manual –PROCUT 3000 MP

5

2. GENERAL INFORMATION

Thank you for purchasing a Malone product. You have purchased a strong, reliable and

efficient Centre Pivot Mower. To fully utilize the qualities of the 3000 MP, please ensure you

read this manual, and this ensuresa longer working life, greater safety and optimal

performance.

BEFORE OPERATING THIS MACHINE READ CARFULLY THE INSTRUCTIONS

GIVEN IN THIS MANUAL

USING YOUR OPERATOR’S MANUAL

Read, understand and follow the instructions in this manual, doing so will promote safe,

productive and reliable service.

This manual was prepared to help you use and maintain your new machine safely. Reading

your operator’s manual will help you and others avoid injury or damage to the machine. This

machine can cause serious property damage, personal injury or even death if it is misused.

For your safety, as well as the safety of others, you must follow the safety precautions in this

operator’s manual.

This manual is an important part of your machine. It should remain with the machine if and

when it is sold. If it is damaged or lost, you may contact your dealer, or Malone

FarmMachinery company to get a replacement.

Before delivering this machine, your dealer performed a pre-delivery inspection to ensure

best performance.

If you have any queries, please contact Malone Farm Machinery who will be able to give you

the correct assistance and advice.

Contact: Malone Farm Machinery LTD

Ballyglass,

Claremorris,

Co.Mayo

F12 AP11

Ireland

Tel: +353 (0) 94 93 60 500

Email: stores@malonefm.com

Website: www.malonefm.com

The contents of this manual can be modified only by the manufacturer and without notice to

the Client. Malone Farm Machinery shall not be liable for errors or faults in this manual.

Operator Manual –PROCUT 3000 MP

6

3. TECHNICAL DATA

Weight

[Kg]

960

Transport Width

[m]

2.03

Transport Height

[m]

3.8

Cutting width

[m]

3.0

Number of cutting discs

7

PTO Speed

[rpm]

540

Power Requirement (min)

[Kw (HP)]

74 (100)

RPM, cutting discs

[rpm]

3200

Hydraulic connections

1 x Single action control unit

1 x Double action float control unit

4. DESCRIPTION

The Malone Procut 3000MP mower is built exclusively for the intended use in the agriculture

sector for the cutting of common grass and cereal crops.

The cutting unit is hydraulically balanced using a hydraulic cylinder. The pressure exerted by

the cutting unit on the ground can be easily adjusted by adjusting the oil pressure in

thehydraulic cylinder by easily reading the oil pressure on the pressure gauge mounted on the

mower headstock.

Operator Manual –PROCUT 3000 MP

7

5. SAFETY INFORMATION

In the interest of safety, it is important that great care is always adopted during the

attachment, transportation, operation and maintenance of this machine. Both the owner and

the operator of the machine should read and understand the following section to ensure the

safety of themselves and all other persons who enter into the close proximity of these

machines. Never operate the machine if unauthorized persons are in the area. Stop operation

of the machine if unauthorized persons approach. Explain to them the potential hazards so

they understand why you will not continue until they have left the area. You are responsible

for safe operation of the mower. The most important safety device on the equipment is a safe

operator.

In addition to the instructions stated here always abide by general safety and accident

regulations.

Never turn on the PTO when the mower is the transport position.

Never turn on the PTO when people/ animals are in close proximity to the machine

Transportation safety

Make sure you are in compliance with all local regulations regarding transporting equipment

on public roads and highways.

Ensure the cutting units is locked in with the mechanical lock on the machine

Ensure that the machine is securely attached to the tractor.

Be aware of any height restrictions on route i.e.: overhead wires, bridges, etc. It may

be necessary to lower the tractor lift arms to proceed under low ceiling objects.

Operator Manual –PROCUT 3000 MP

8

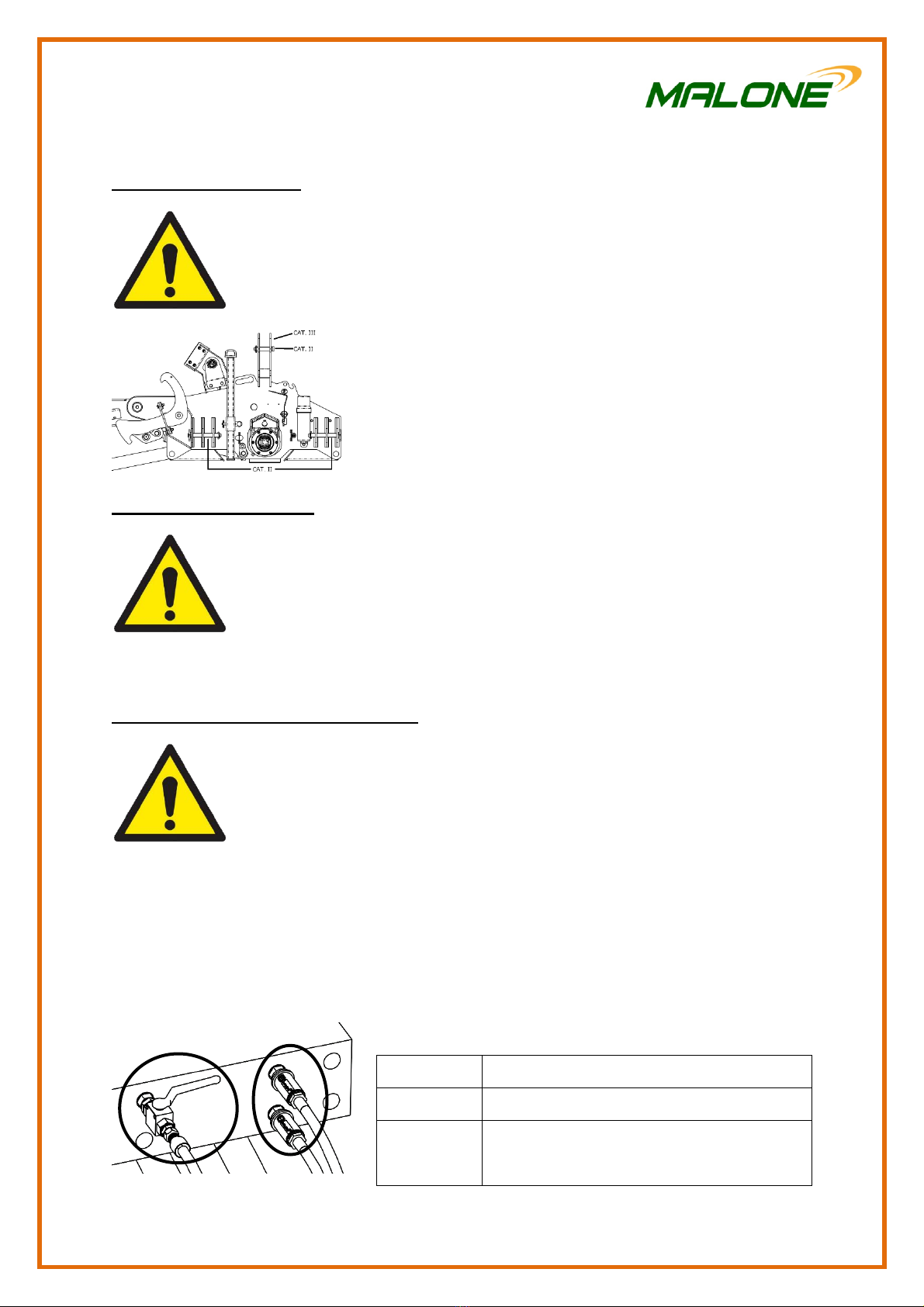

6. SAFETY DECALS

Read the operator’s manual carefully before you operate the machine.

This decal shows the grease points on the machine. Greasing is

important for personal safety and maintaining a good

mechanical condition of the machine.

Fall Hazard –Stand clear of the mower bar when going from

transport position to cutting position and back to transport

position.

PTO rotation hazard –Please ensure that body and clothing

remain a good distance from the rotation PTO shaft.

Risk of injury to hands near moving parts –NEVER place

hands near any of the moving objects when in operation.

Operator Manual –PROCUT 3000 MP

9

Risk from loose chippings –Keep a safe distance while the

machine is in operation due to risk of fly objects/ debris coming

from the cutting bar.

Stop the tractor before maintenance –The tractor engine must

ALWAYS be stopped before carrying out repairs or

maintenance to the machine.

Risk of injury to feet –The safety guard must always be in

place when operating the machine.

Mowing height –The label indicates the optimal height for

mowing operation.

Lifting point –Use the appropriate point for safe lifting of

mower

Operator Manual –PROCUT 3000 MP

10

7. PRE-OPERATION CHECKLIST

It is important for both personal safety and maintaining the good mechanical condition of the

mower that this checklist is followed.

Grease every 20 hour of operation.

Ensure the blades on the cutting bed are in good condition

Ensure all hardware are in good condition and secure

Operator Manual –PROCUT 3000 MP

11

8. OPERATING THE MACHINE

Attaching to the tractor

When connecting the tractor to the mower

Ensure the tractor cannot roll.

No one is standing between the tractor and

attachment

The mower is fitted with attaching points for category II.

Connect the top link onto the machine first.

Mount the machine on the lift arms secondly.

Attaching PTO to tractor

The tractor must be turned off when connecting the PTO

shaft to the tractor

When the PTO shaft has been connected, ensure the safety

clip has been firmly attached the tractor.

Attaching the hydraulics to the tractor

Only connect the hydraulics when the system is depressurised.

Pressurised hydraulics can cause serious injuries.

Check all joints, hoses and fittings regularly for leaks or visible

damage. The system is under high pressure and can cause

serious injury if failure occurs.

Avoid physical contact with hydraulic oil. Hydraulic oil

contains additives that can some serious consequence to your

health.

Reduce risk of contamination of dirt into hydraulic system.

When connecting hose to tractor, ensure fittings are clean of

dirt and oil. Contaminates can damage components in the

tractor and/or mower.

The mower requires two double acting hydraulic outputs.

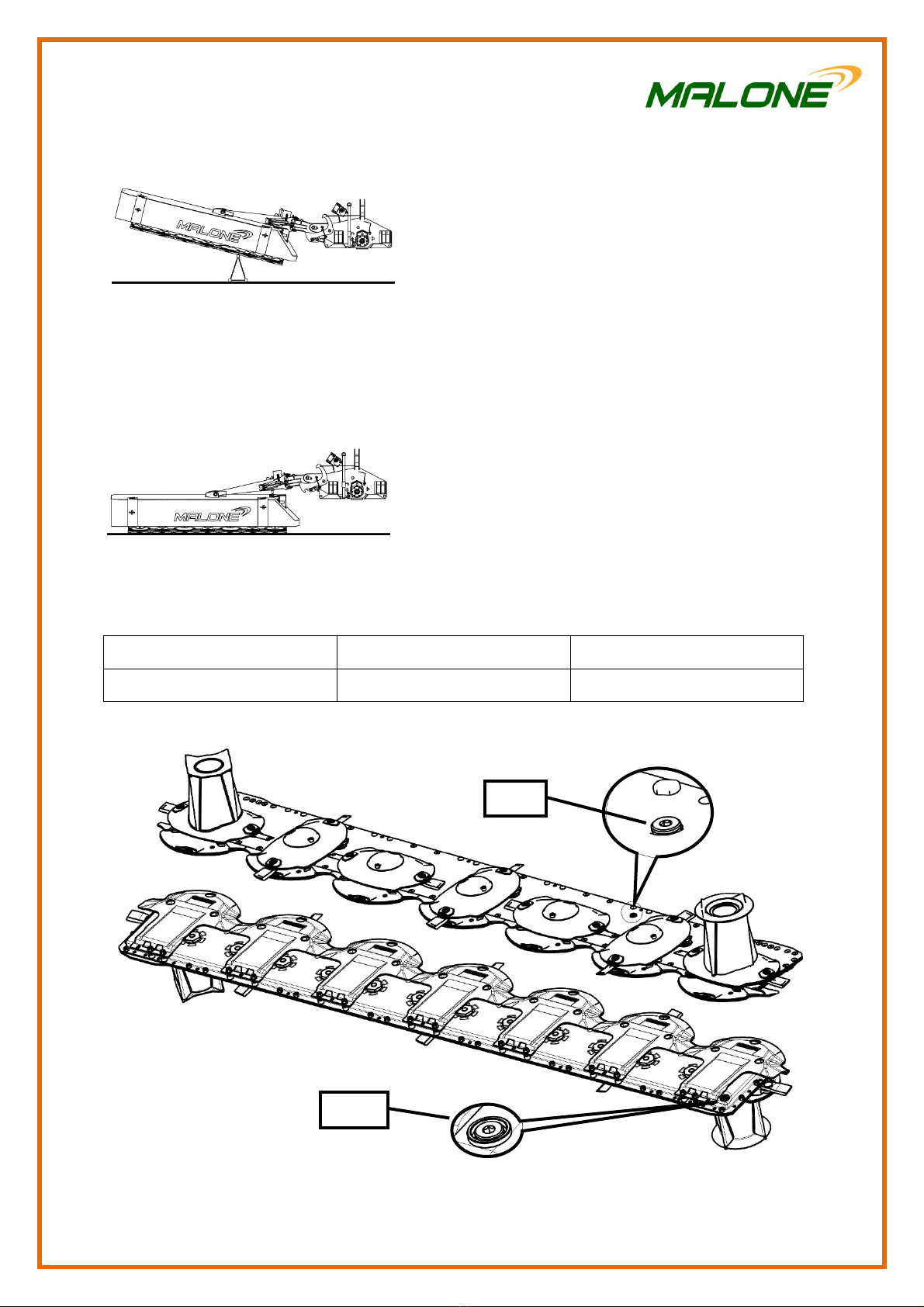

Hydraulic

Function

1

Adjusting the ground pressure

2

Raising/lowering (Turning at headlands)

Work/ transport positions

1. 2.

Operator Manual –PROCUT 3000 MP

12

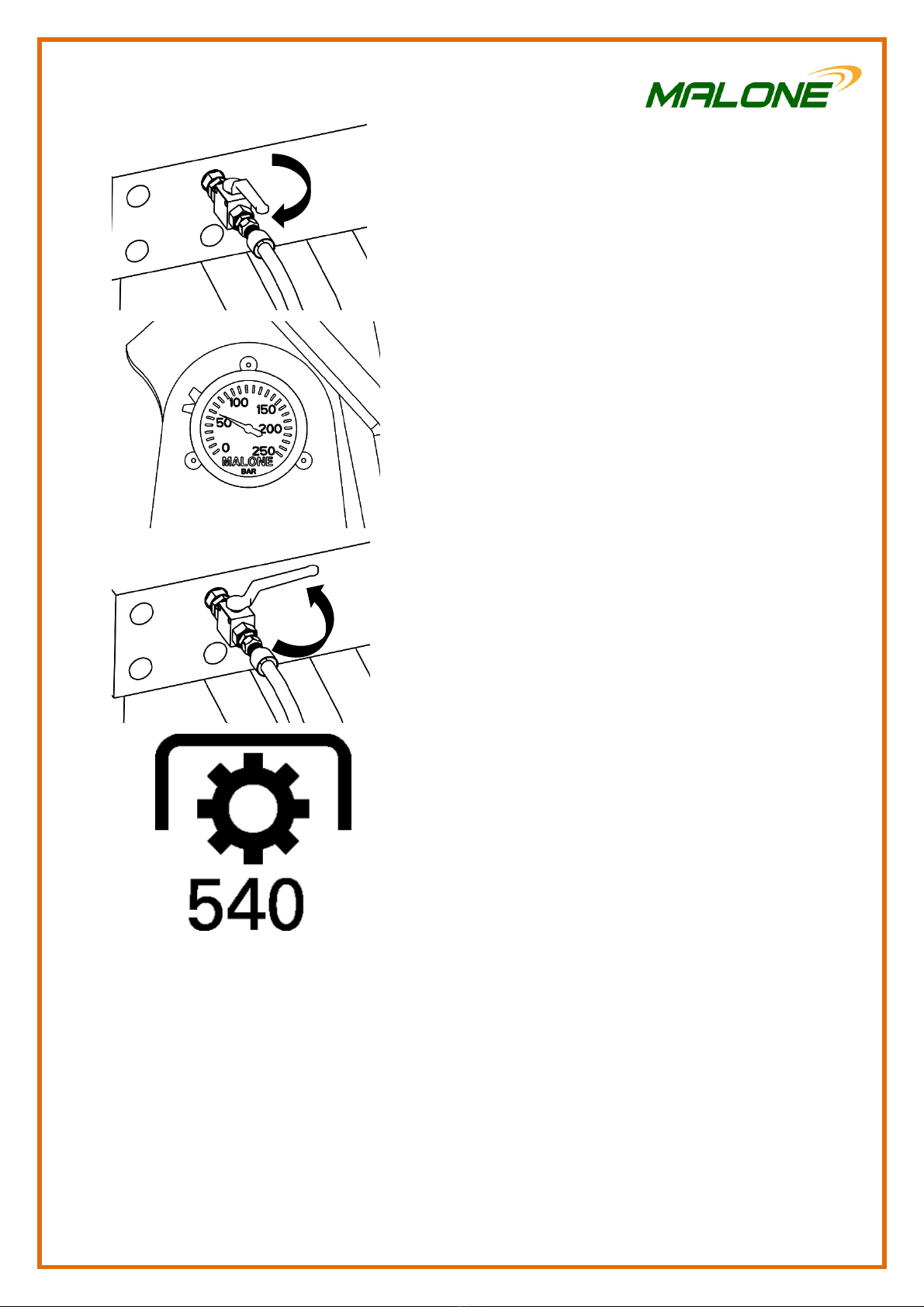

Transport into working position

The lower link arms will need to be around 80cm from the

ground.

Pull rope to release the locking lever

Lower the cutting frame to the ground level.

Release the locking lever rope

Set the settings on the tractor for the lifting ram into

floatation mode

Operator Manual –PROCUT 3000 MP

13

Open the floatation ram hydraulic lever to the open

position

Set the pressure on the gauge to approx 70 bar

Shut off the floatation ram hydraulic lever to the closed

position

Turn on the PTO at 540 RPM and start cutting operation.

Operator Manual –PROCUT 3000 MP

14

9. MAINTENANCE AND LUBRICATION

Check, and tighten (if required), all nuts, bolts and fixing’s after the first few hours of work

and at regular intervals thereafter. Grease every 20 hours of operation. Good maintenance of

a machine will ensure a safe working environment and long service life of the machine.

Filling oil quantities and lubrication type

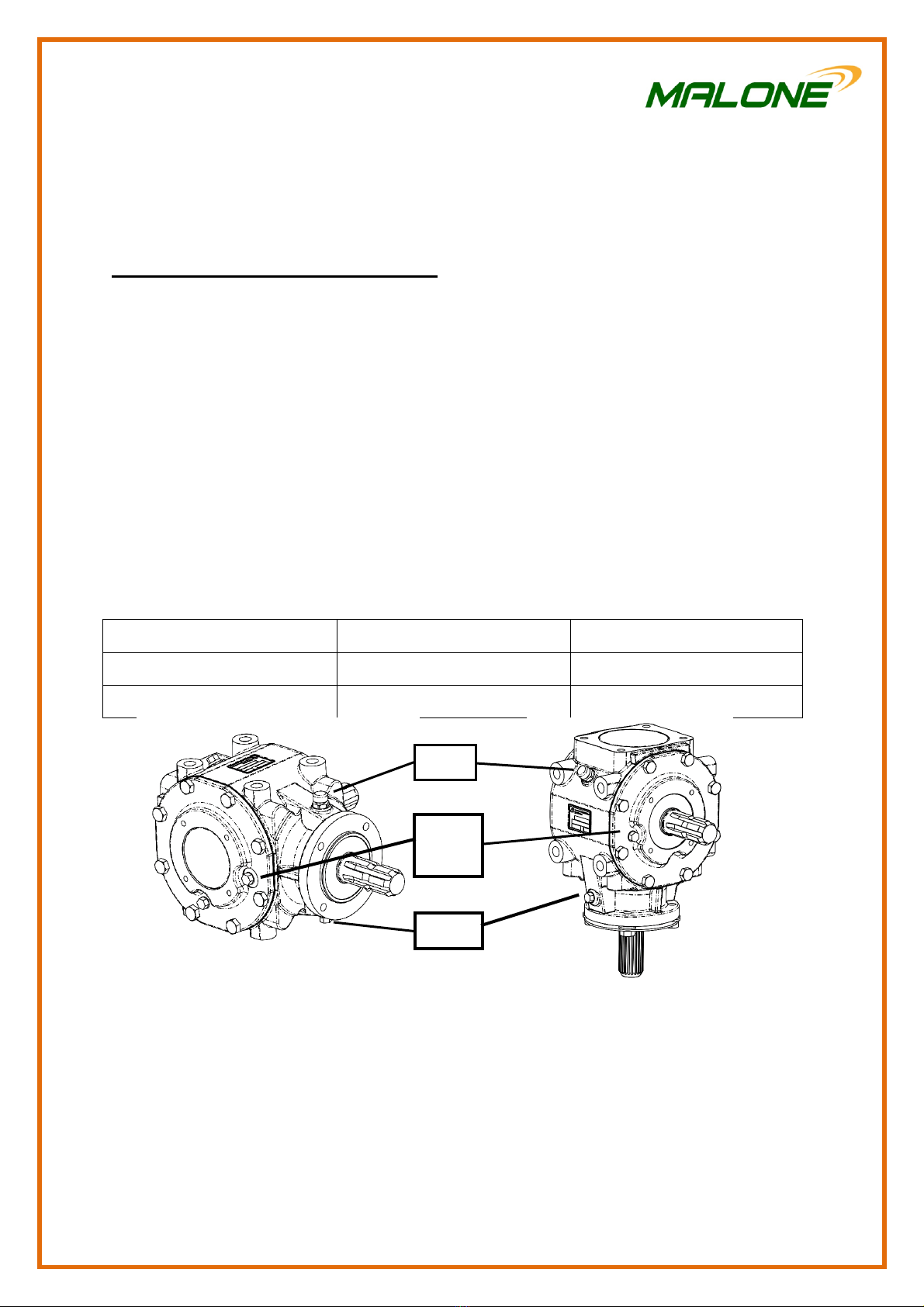

Gearbox

You will need a 13mm spanner to access the drain and oil level plug, and a 19mm spanner to

access the fill plug.

Place the mower and cutter-bar on level ground.

Remove the fill and drain plug.

Drain the used oil into a suitable container. Wait until all the oil has been fully

drained off.

Refit the drain plug and remove the oil level plug on the gearbox.

Insert the correct amount of oil into the gearbox through the fill plugs slowly until oil

starts to seep through the oil level plug.

Replace the oil level plug and fill plug and ensure all plugs have been correctly

tightened.

Quantity (Litre)

Type

Primary Gearbox

1.5

SAE 90

Secondary Gearbox

1.5

SAE 90

Primary Gearbox

Secondary Gearbox

Oil

level

Drain

Fill

Operator Manual –PROCUT 3000 MP

15

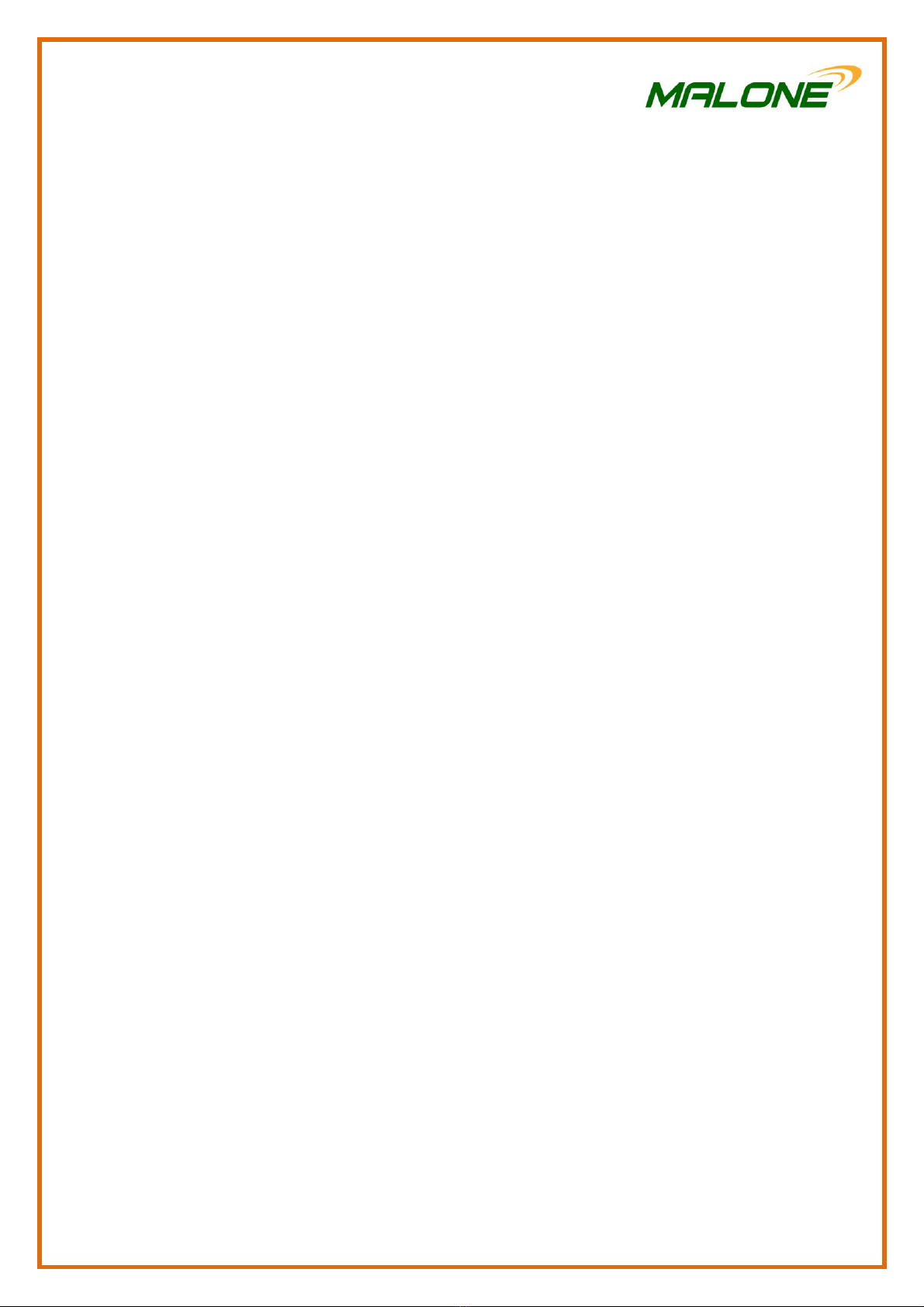

Cutterbar

You will need a 8mm allen key to open the fill and

drain plugs on the cutter bar.

When draining the cutter bar oil from the bed

pan, place the cutter bar on a elevated height on a

secure stand at a tilt.

Remove the drain plug and empty the used oil from the cutter bar into a suitable

container.

After all of the oil has been drained, return the drain plug and ensure it has been

tightened to 3-3.5 kgm (30 - 35Nm).

Remove the stand and lower the cutter bar

frame to a level ground position.

Open the fill plug on top of the cutter bar and fill the cutter bar with the correct

amount and type of oil into the bed pan.

Quantity (Litre)

Type

Cutter bed

4.0

SAE 90

Fill

Drain

Operator Manual –PROCUT 3000 MP

16

Storage

The machine should be stored on a firm level site and cannot tip over, in a safe, clean

and dry location where itis protected from the elements. If the machine is not properly

secured when parked it can result in serious injury and death.

Parking Vertical

Lift the cutter frame to its vertical position until the frame rests in its v-block and the

mechanical lock has been engaged.

Fold out the three stabilisers legs.

Lower the mower till all the three legs rests on the ground.

Ensure the hydraulics has been depressurised.

Turn off the engine of the tractor before disconnecting the PTO shaft from the tractor

and hydraulics.

Disconnect the top link and lower link arms from the mower frame.

Parking Horizontal

Lower the stabiliser leg and ensure the locking pin has been secured on it.

Lower the mower until the stabiliser leg and cutter bar rests on the ground.

Ensure the hydraulics has been depressurised.

Turn off the engine of the tractor before disconnecting the PTO shaft from the tractor

and hydraulics.

Disconnect the top link and lower link arms from the mower frame.

Disc and blade maintenance

For cutting and a longer service life carefully check discs, blades and bolts daily. Replace

worn or damaged blades and hardware immediately using only Malone recommended parts.

Replace blades, bolts and nuts in pairs to maintain balance. Ensure the cutting edge of blades

face the disc rotation direction.

Operator Manual –PROCUT 3000 MP

17

10.MALONE LIMITED WARRANTY

Malone Ballyglass, Claremorris,Co. Mayo, Ireland (hereinafter called “the company”)

warrants to the original retail purchaser that new products sold and registered with the

company, shall be, at the time of delivery, free from defects in material and workmanship,

and that such equipment is covered under Limited Warranty providing the machine is used

and serviced in accordance with the recommendations in the Operator’s manual. This

Limited Warranty covers the equipment for a period of one year starting from the date the

equipment is commissioned.

The email or post submission of the pre-delivery inspection (PDI) form by the dealer

(importer) is taken as evidence of the delivery of the machine to the original retail purchaser.

This is compulsory, and is required to record the machine in the Malone warranty system.

These conditions are subject to the following exceptions:

Parts of the machine which are not of Malone manufacture, such as blades,

PTO shafts, slip clutches, hydraulic cylinders, etc. are not covered by this Limited

Warranty, but are subject to the warranty of the original manufacturer. Warranty

claims applying to these types of parts must be submitted in the same way as if they

were parts manufactured by Malone. However, compensation will be paid in

accordance with the warranty agreement of the manufacturer concerned.

This Limited Warranty does not apply to failure through normal wear and tear,

to damage resulting from negligence or from lack of inspection, from misuse, from

lack of maintenance and/or if the machine has been involved in an accident, lent out

or used for purposes other than those for which it was intended by the company.

This Limited Warranty will not apply to any product that has been altered or

modified in any way without the express permission of the company, or if parts not

approved by Malone are used in repair.

The company take no responsibility for any additional costs, including loss of

oil and/ or consumables incurred during the failure and repair of a product

The company cannot be held responsible for any claims or injuries to the

owner or to the third party, nor to any resulting responsibility.

Also, on no account can the company be held liable for incidental or

consequential damages (including loss of anticipated profits) or for any impairment

due to failure, a latent defect or a breakdown of a machine.

The customer will be responsible for the following costs:

Normal maintenance such as greasing, maintenance of oil levels, minor

adjustments, etc. as specified in the Operator’s manual.

Labour charges other than originally agreed, incurred in the removal and

replacement of components.

Dealer’s travel time and travel costs to and from the machine.

Parts defined as normal wear items such as, but not limited to PTO shafts, chains, tyres,

bearings, tines, slip clutches, etc. that are not covered under the Limited Warranty.

Operator Manual –PROCUT 3000 MP

18

The importer will be responsible for the following costs:

All warranty labour charges.

The warranty is dependent on the strict observance of the following:

The machine has been put in service by the Malone dealer according to our

instructions.

The online pre-delivery inspection (PDI) form has been correctly completed

by the dealer.

A printed version of the PDI form has been signed and dated by the original

retail purchaser. This copy is to be stored by the dealer and made available to

Malone when requested.

The warranty claim is submitted using the Malone claims system.

The warranty claim must be submitted by the original retailing Malone dealer

only.

The decision of the company in all cases is final.

Damaged parts should be held by the dealer until credit has been given, or a

returns request has been issued.

Parts must be returned to Malone, with the Malone claim number written

clearly on each individual part. These parts must be free from dirt and oil. If a part is

returned in an unfit state, the claim will be refused.

If damaged parts have been returned to the company and warranty is refused,

the dealer is allowed a period of one month from the date of receiving our

notification to request the return of the damaged parts to the dealer site.

Further conditions - limits of application and responsibility:

This Limited Warranty cannot be assigned or transferred to anyone without

the prior written consent of the company.

Malone dealers have no right or authority to assume any obligation or take

any decision on the company's behalf, whether expressly or tacitly.

Technical assistance given by the company or its agents for repairing or

operating equipment does not lead to any responsibility on the company's behalf and

cannot under any circumstances bring novation or derogation to the conditions of the

present Limited Warranty.

The company reserves the right to incorporate changes in its machines without

prior notice and without obligation to apply these changes to machines previously

manufactured.

The present Limited Warranty excludes any other responsibility, whether legal

or conventional, express or implied, and there are no warranties extending beyond

those defined herein.

No part of this manual may be copied or published by means of printing, photocopying,

microfilm or any other process whatsoever without prior permission in writing by Malone

Farm Machinery. All instructions, pictures and specifications in this manual are based on the

Operator Manual –PROCUT 3000 MP

19

latest information that was available at the time of publication. Your mower may comprise

improvements, features or options that are not covered in this manual.

Operator Manual –PROCUT 3000 MP

20

11. SPARE PARTS SECTION

To be assured of the latest design improvements purchase your genuine replacements from

the Original Equipment Manufacturer through your local Dealer.

Always quote:

Machine Type

Serial Number

Part Code

Part Position Number & Page Number

Part Description

For more details, please check the spare parts catalogue/manual.

USE ONLY GENUINE SPARE PARTS

Web: www.malonefm.com - Email: warranty@malonefm.com

Table of contents

Other Malone Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Gaspardo

Gaspardo PINTA Use and maintenance

Rotomec

Rotomec CYCLONE C30-CE5 Operator's manual

Krone

Krone Big Pack 1290 HDP Original operating instructions

horsch

horsch Leeb 8 GS operating instructions

Ferrari

Ferrari FX Multipla Operating and service manual

Krone

Krone Big Pack 890 HS Original operating instructions