ModelEP-311/313

TechnicalInformatio

TI.EP311/313-01

7400 Flying Cloud Drive •Minneapolis,MN55344-3720 •USA

800-843-5116 •612-835-1626 •Fax 612-829-5331

sales@mamacsys.com•www.mamacsys.comElectropneumaticTransduce

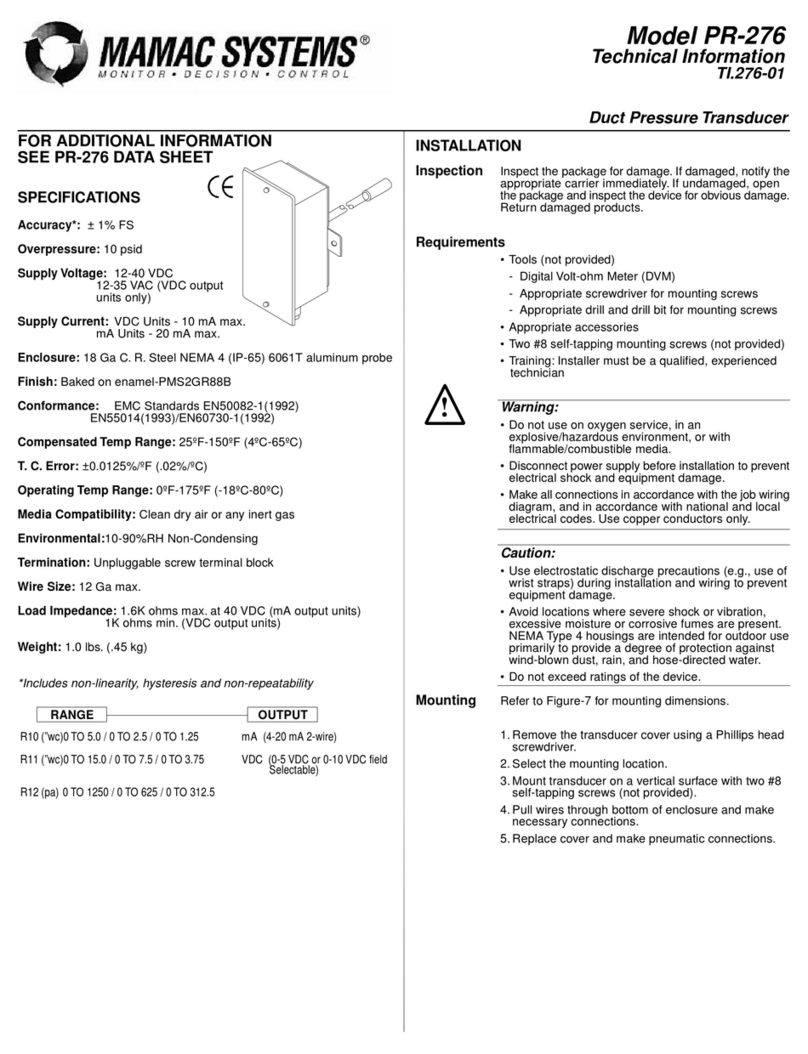

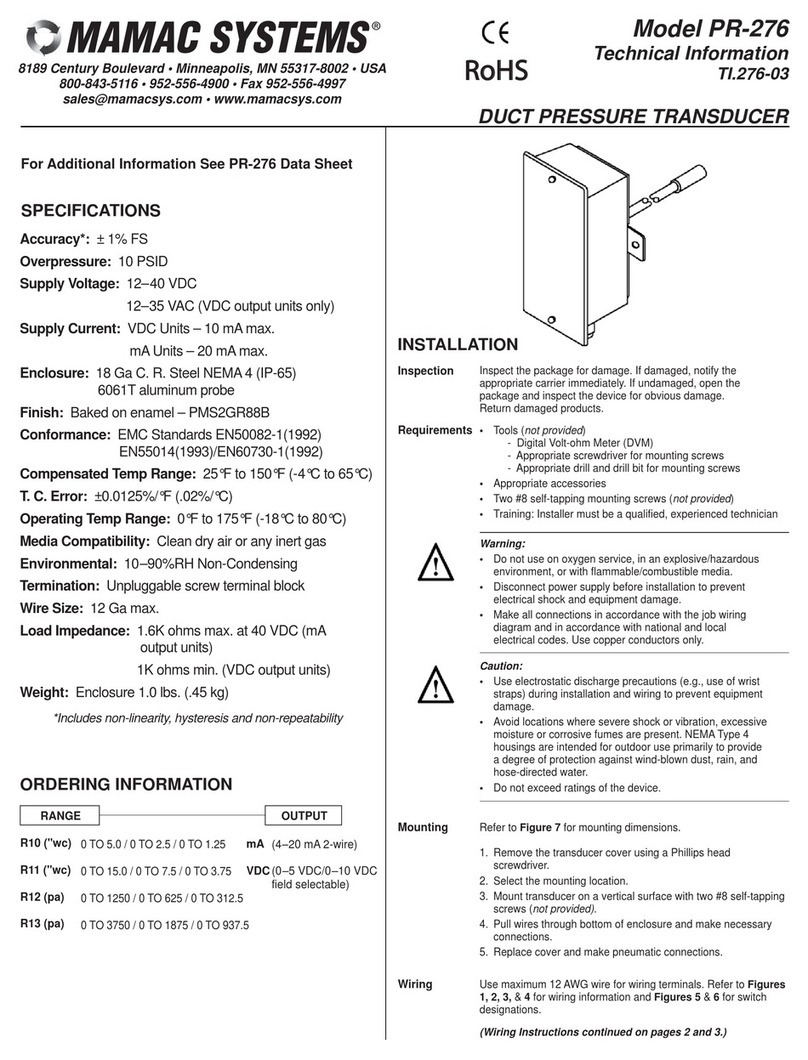

Accuracy*:±1%FS

MaximumSupplyPressure:40 psig

PressureDifferential:(SupplytoBranch)0.1psig

SupplyVoltage:18-28 VAC/VDC

SupplyCurrent: 150 mA

Enclosure:18 GaC.R.SteelChassis

Finish:Baked on enamel-PMS2GR88B

CompensatedTempRange:25ºF-150ºF(4ºC-65ºC)

Conformance:EMCStandardsEN50082-1(1992)

EN55014(1993)/EN60730-1(1992)

T.C.Error:±0.025%/ºF(.03%/ºC)

MediaCompatibility:Clean dryairoranyinertgas

PortConnection:1/4”ODpolytubing

Environmental:10-90%RH Non-Condensing

Termination:Screwterminalblock

WireSize:12 Gamax.

ImputImpedance:301 ohms(4-20 mA)

10Kohms(0-5/0-10 VDC)

Weight: 1.0lbs.(.45 kg)

*Includesnon-linearity,hysteresisand non-repeatability

FORADDITIONALINFORMATION

SEE EP-311/313 DATASHEET

SPECIFICATIONS

MANUAL

OVERRIDE

INSTALLATION

Inspection Inspectthe package fordamage.Ifdamaged,notif

the appropriatecarrierimmediately.If undamaged,

open the package and inspectthe devicefor

obviousdamage.Returndamaged products.

Requirements

•Tools(notprovided)

-DigitalVolt-ohmMeter(DVM)

-Appropriatescrewdriverformounting screws

-Appropriatedrill and drill bitformounting screws

•Appropriateaccessories

•Two#8 self-tapping mounting screws(not

provided)

•Training:Installermustbe aqualified,experienced

technician

Warning:

•Donotuseon oxygen service,inan

explosive/hazardousenvironment, orwith

flammable/combustiblemedia.

•Disconnectpowersupplybeforeinstallation to

preventelectricalshock and equipmentdamage.

•Makeall connectionsinaccordancewiththe jo

wiring diagram,and inaccordancewithnationa

and localelectricalcodes.Usecopperconductors

only.

Caution:

•Useelectrostaticdischarge precautions(e.g.,

useofwriststraps)during installation and wiring

topreventequipmentdamage.

•Donotexceed ratingsofthe device.

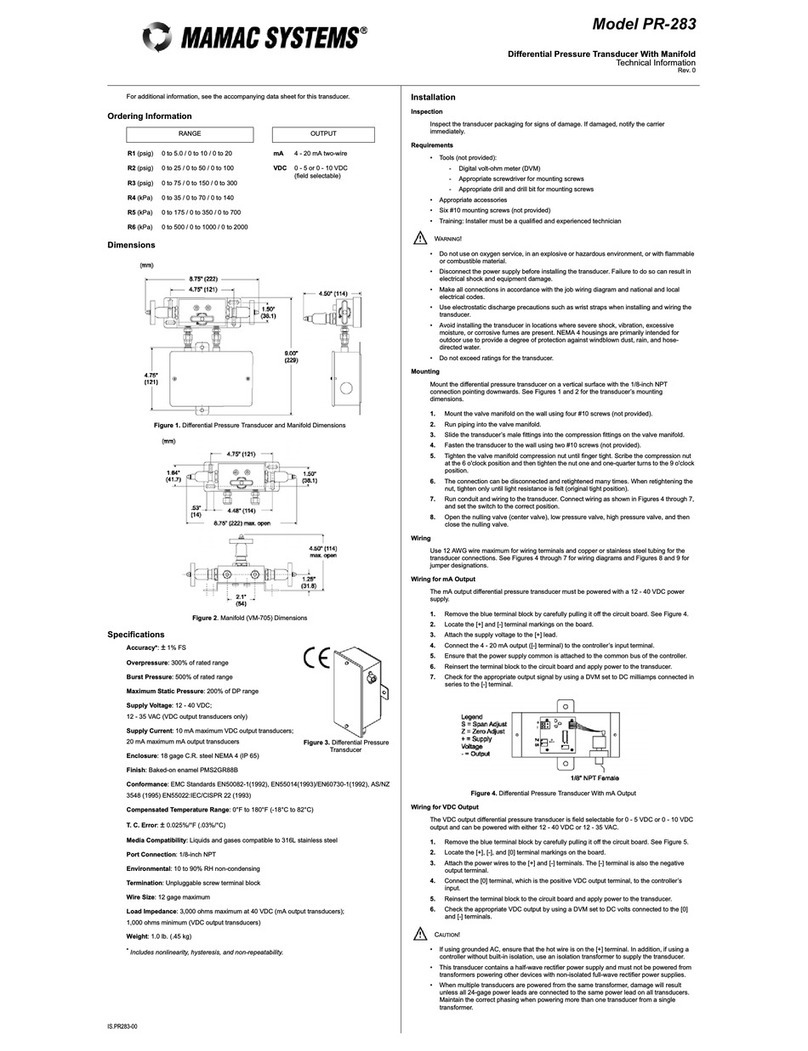

Mounting The EP-311/313 mustbe mounted inan uprightposition sothat

the portsarefacing upwardand the gauge can be easilyread.

1.Selectthe mounting location.

2.Mountthe transduceron averticalsurfacewiththree #8 self-

tapping screws(notprovided).

3.Pull wiresthrough the bottomofthe deviceand makenecessary

connections.

4.Makethe necessarypneumaticconnections.

Wiring Usemaximum12 AWGwireforwiring terminals.Useflexible1/4”

O.D.polytubing formainand branchpneumaticconnections.Refer

toFigure-1and Figure-2forwiring configurationsand Figure-4

through Figure-6forjumperdesignations.

Caution:

•Mainsupplypressuremustnotexceed 40 psig.

•Aminimumof6to10 feet(1.8to3.0m)oftubing shouldbe

between the unitand the actuator.

•For24 VACsupplyvoltage,ensurethatthe hotand neutralare

notreversed.If morethan one unitisbeing powered formthe

sametransformer,the hotand neutralshouldbe the samefor

eachunit.

Note:The gauge on the unitisforindication only.The unit’s

calibration ismoreaccuratethan the accuracy ofthe gauge.

!

311(without)315 (3-15 psig)

313(with)020 (0-20 psig)

RANGE