Model PR-264

Pressure Transducer

Technical Information

Rev. 0

7400 Flying Cloud Drive • Minneapolis, MN 55344-3720 • USA

800-843-5116 • 952-835-1626 • Fax 952-829-5331

www.mamacsys.com

IS.PR264-00

For additional information, see the accompanying data sheet for this transducer.

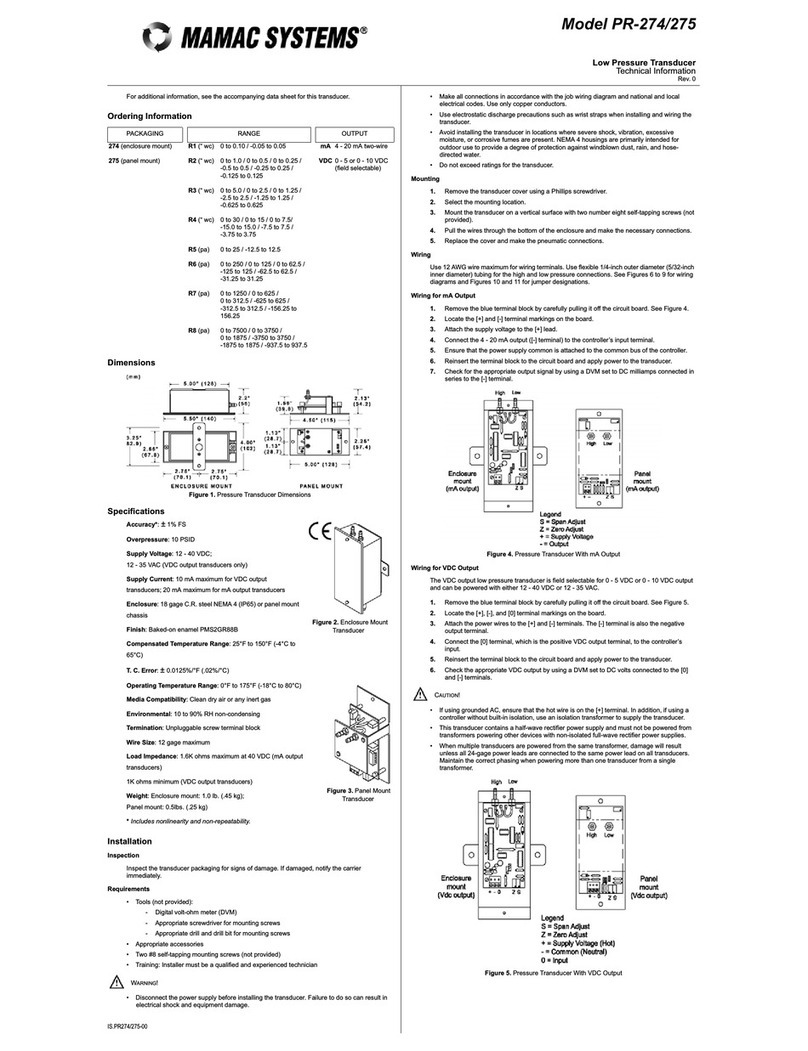

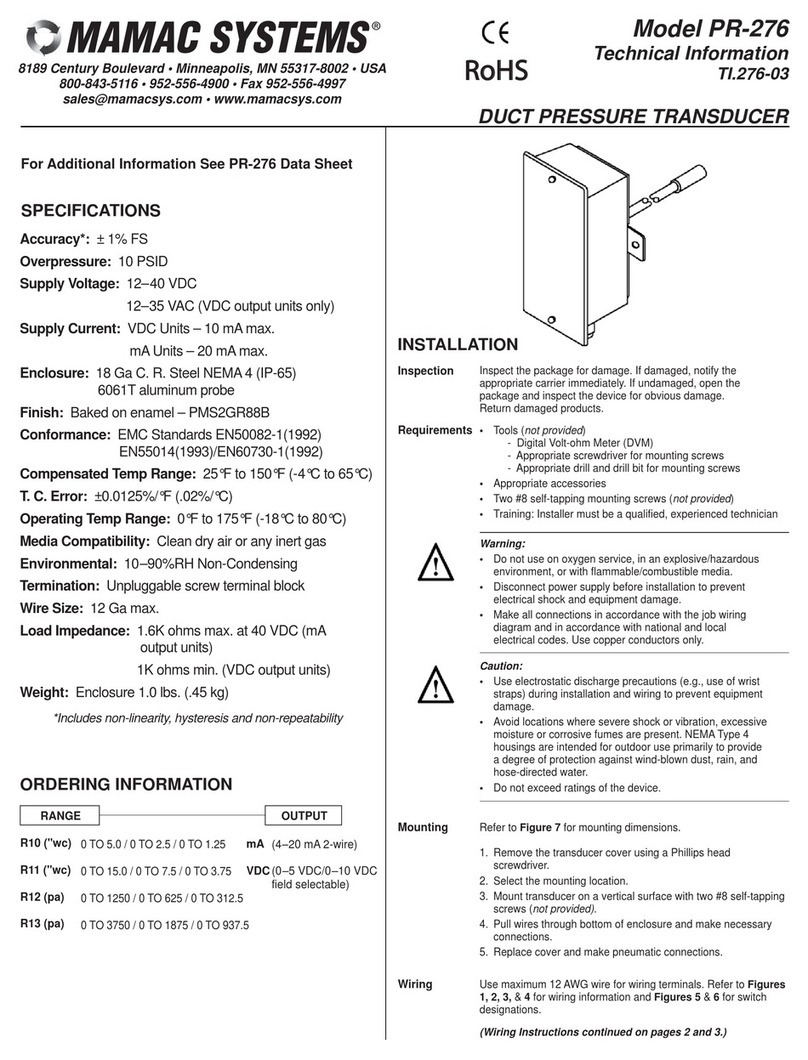

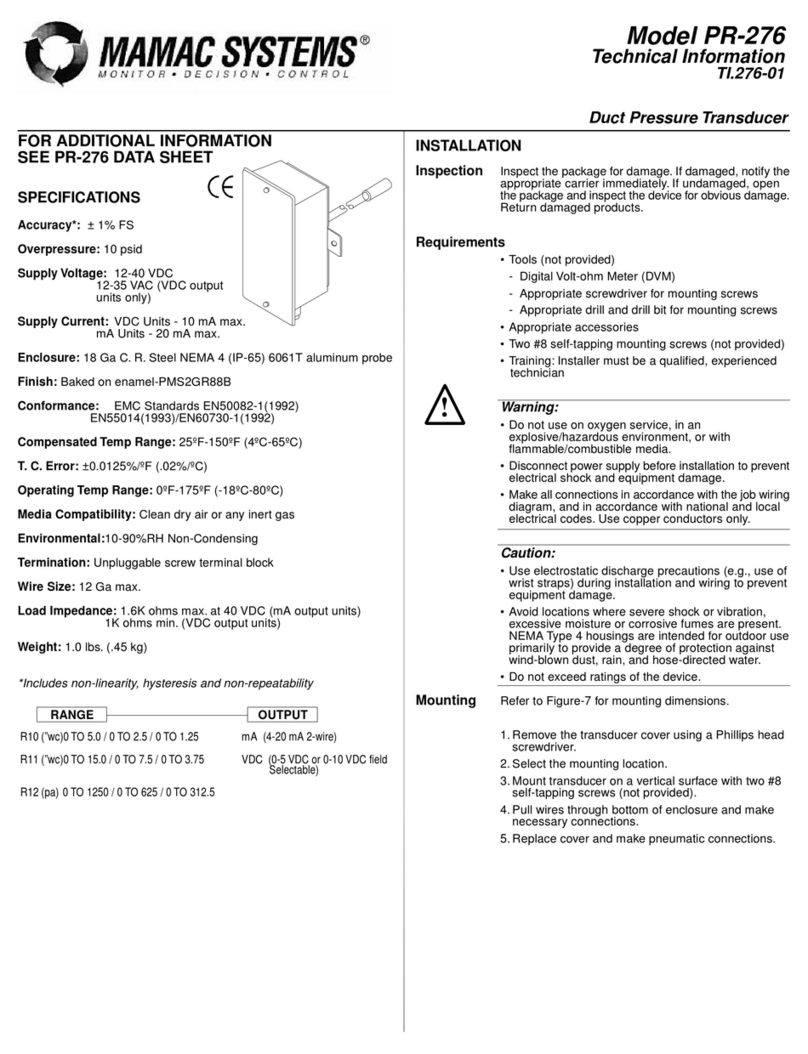

Ordering Information

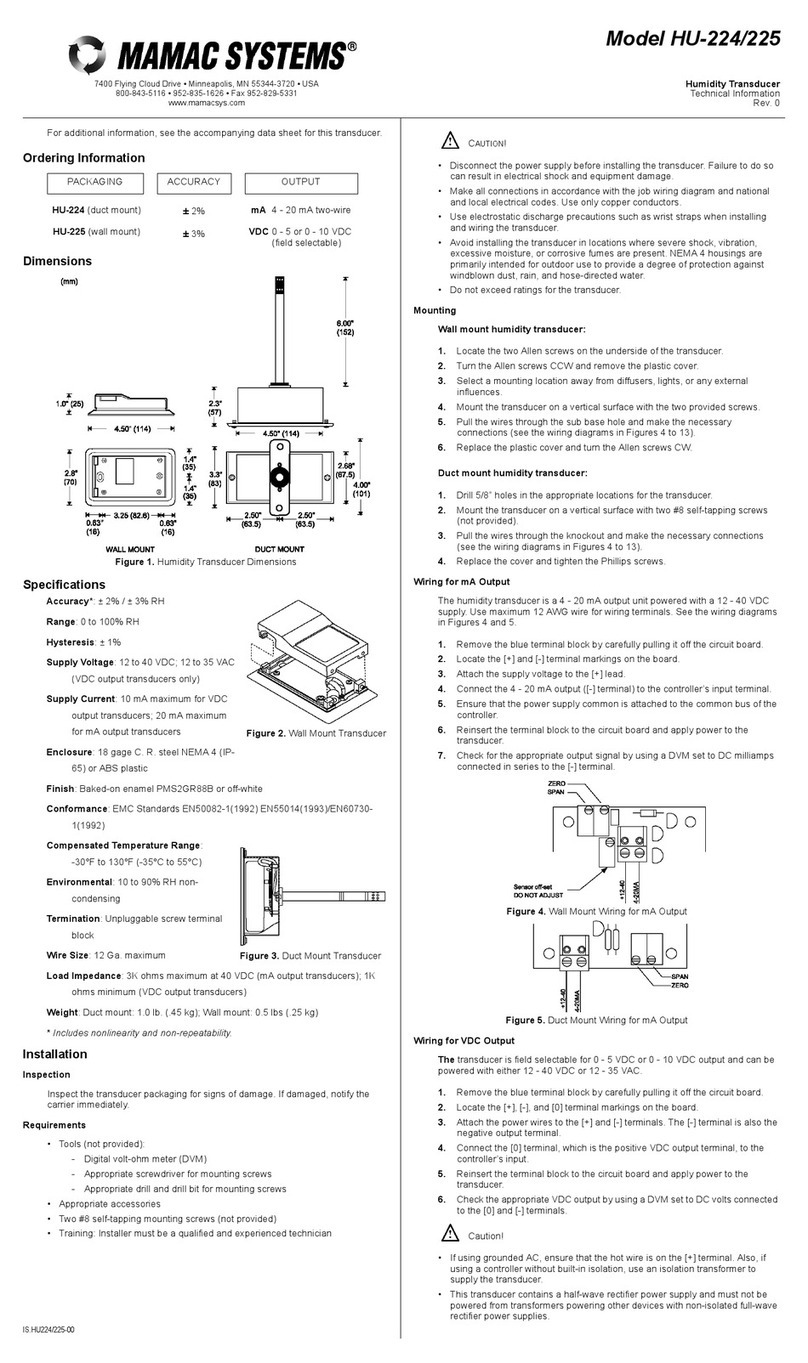

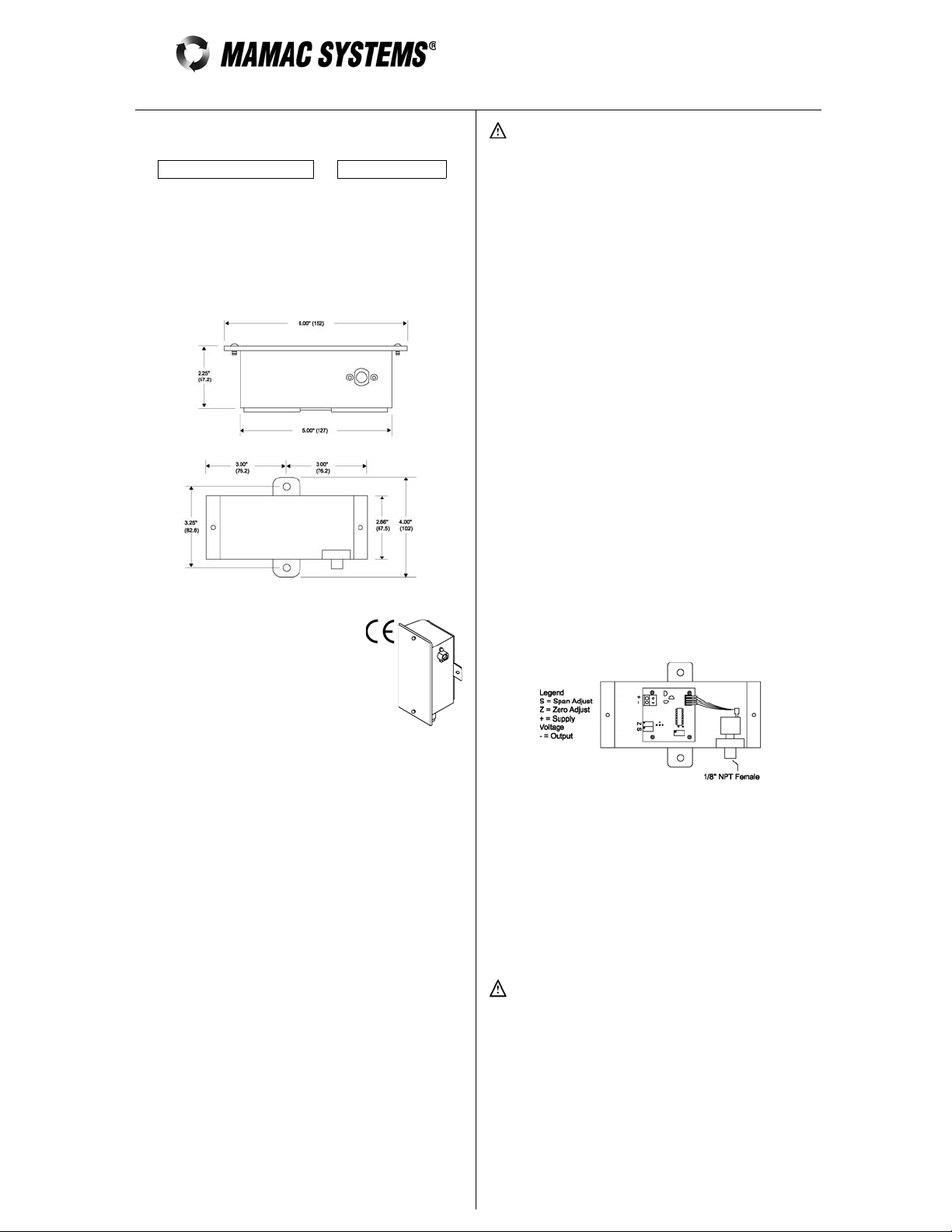

Dimensions

Figure 1. Pressure Transducer Dimensions

Specifications

Accuracy*:±1% FS

Overpressure: 300%

Burst Pressure: 500%

Supply Voltage: 12 - 40 VDC;

12 - 35 VAC (VDC output transducers only)

Supply Current: 10 mA maximum for VDC output

transducers; 20 mA maximum for mA output

transducers

Enclosure: 18 gage C.R. steel NEMA 4 (IP65)

Finish: Baked-on enamel PMS2GR88B

Conformance: EMC Standards EN50082-1(1992), EN55014(1993)/EN60730-

1(1992)

Compensated Temperature Range: 0°F to 180°F (-18°C to 82°C)

T. C. Error:±0.025%/°F (.03%/°C)

Media Compatibility: Liquids and gases compatible to 316L stainless steel

Port Connection: 1/8-inch NPT

Environmental: 10 to 90% RH non-condensing

Termination: Unpluggable screw terminal block

Wire Size: 12 gage maximum

Load Impedance: 1.6K ohms maximum at 40 VDC (mA output transducers);

1K ohms minimum (VDC output transducers)

Weight: Enclosure 1.0 lb. (.45 kg)

*Includes nonlinearity, hysteresis, and non-repeatability.

Installation

Inspection

Inspect the transducer packaging for signs of damage. If damaged, notify the

carrier immediately.

Requirements

• Tools (not provided):

- Digital volt-ohm meter (DVM)

- Appropriate screwdriver for mounting screws

- Appropriate drill and drill bit for mounting screws

• Appropriate accessories

• Two #8 self-tapping mounting screws (not provided)

• Training: Installer must be a qualified and experienced technician

WARNING!

• Do not use on oxygen service, use in an explosive or hazardous environment,

or use with flammable or combustible material.

• Disconnect the power supply before installing the transducer. Failure to do so

can result in electrical shock and equipment damage.

• Make all connections in accordance with the job wiring diagram and national

and local electrical codes. Use only copper conductors.

• Use electrostatic discharge precautions such as wrist straps when installing

and wiring the transducer.

• Avoid installing the transducer in locations where severe shock, vibration,

excessive moisture, or corrosive fumes are present. NEMA 4 housings are

primarily intended for outdoor use to provide a degree of protection against

windblown dust, rain, and hose-directed water.

• Do not exceed ratings for the transducer.

Mounting

1. Choose a vertical mounting surface for the pressure transducer.

2. Orient the pressure transducer so that the 1/8-inch NPT connection points

downward. See Figure 1.

3. Remove the transducer cover using a Phillips screwdriver.

4. Mount the pressure transducer using two #8 self-tapping screws (not

provided).

5. Pull the wires through the bottom of the enclosure and make the necessary

connections.

6. Replace the transducer cover and make the pneumatic connections.

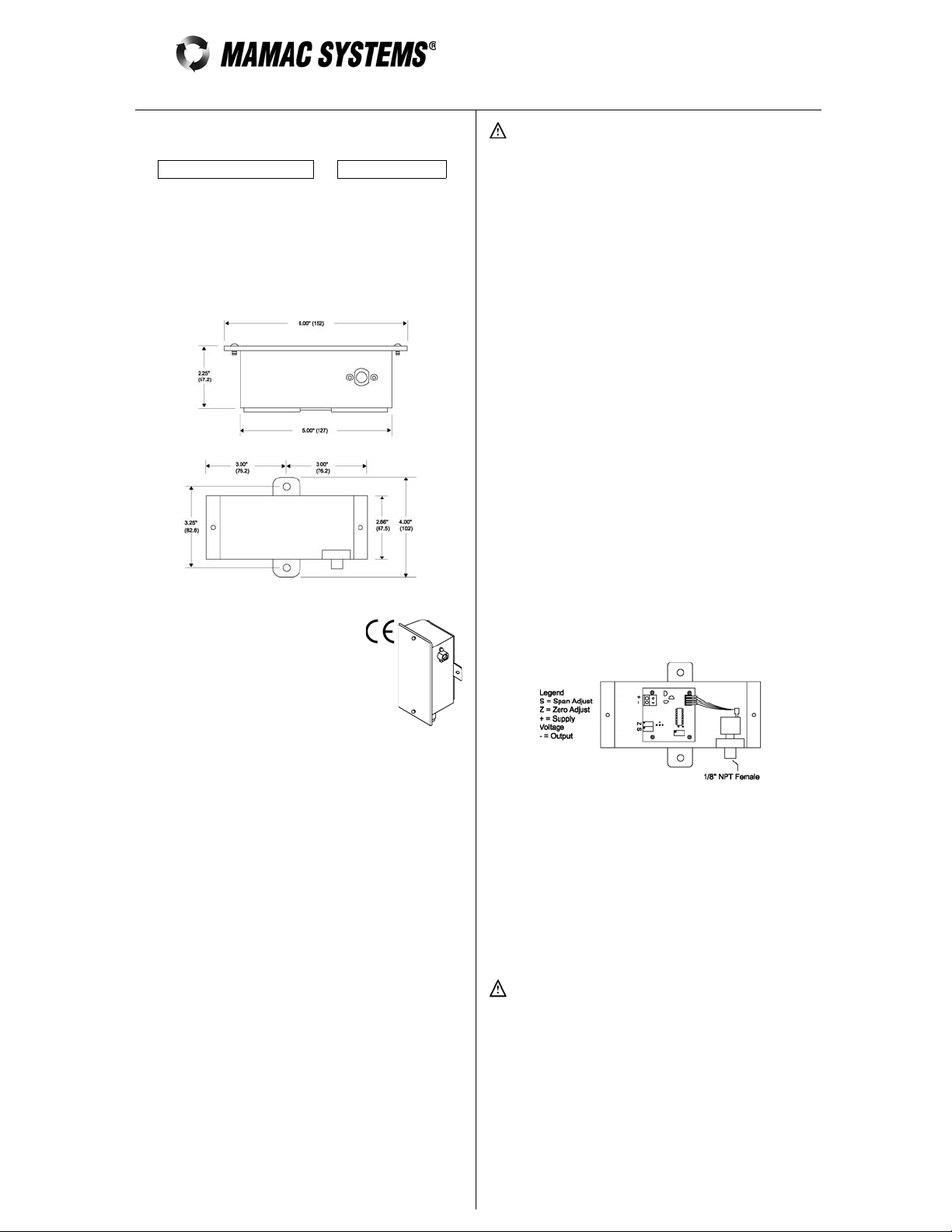

Wiring

Use 12 AWG wire maximum for wiring terminals and copper or stainless steel

tubing for transducer connections. See Figures 5 to 8 for wiring diagrams and

Figures 9 and 10 for jumper designations.

Wiring for mA Output

The mA output pressure transducer must be powered with a 12 - 40 VDC power

supply. See Figure 3.

1. Remove the blue terminal block by carefully pulling it off the circuit board.

2. Locate the [+] and [-] terminal markings on the board.

3. Attach the supply voltage to the [+] lead.

4. Connect the 4 - 20 mA output [[-] terminal) to the controller’s input terminal.

5. Ensure that the power supply common is attached to the common bus of the

controller.

6. Reinsert the terminal block to the circuit board and apply power to the

transducer.

7. Check for the appropriate output signal by using a DVM set to DC milliamps

connected in series to the [-] terminal.

Figure 3. Pressure Transducer With mA Output

Wiring for VDC Output

The VDC output pressure transducer is field selectable for 0 - 5 VDC or

0 - 10 VDC output and can be powered with either 12 - 40 VDC or 12 - 35 VAC.

See Figure 4.

1. Remove the blue terminal block by carefully pulling it off the circuit board.

2. Locate the [+], [-], and [0] terminal markings on the board.

3. Attach the power wires to the [+] and [-] terminals. The [-] terminal is also the

negative output terminal.

4. Connect the [0] terminal, which is the positive VDC output terminal, to the

controller’s input terminal.

5. Reinsert the terminal block to the circuit board and apply power to the

transducer.

6. Check the appropriate VDC output by using a DVM set to DC volts connected

to the [0] and [-] terminals.

CAUTION!

• If using grounded AC, ensure that the hot wire is on the [+] terminal. In addition,

if using a controller without built-in isolation, use an isolation transformer to

supply the transducer.

• This transducer contains a half-wave rectifier power supply and must not be

powered from transformers powering other devices with non-isolated full-wave

rectifier power supplies.

• When multiple transducers are powered from the same transformer, damage

will result unless all 24-gage power leads are connected to the same power

lead on all transducers. Maintain the correct phasing when powering more than

one transducer from a single transformer.

RANGE OUTPUT

R1 (psig)

R2 (psig)

R3 (psig)

R4 (kPa)

R5 (kPa)

R6 (kPa)

0 to 100 / 0 to 50 / 0 to 25

0 to 300 / 0 to 150 / 0 to 75

0 to 500 / 0 to 250 / 0 to 125

0 to 700 / 0 to 350 / 0 to 175

0 to 2000 / 0 to 1000 / 0 to 500

0 to 3500 / 0 to 1750 / to 875

mA

VDC

4 - 20 mA two-wire

0 - 5 or 0 - 10 VDC

(field selectable)

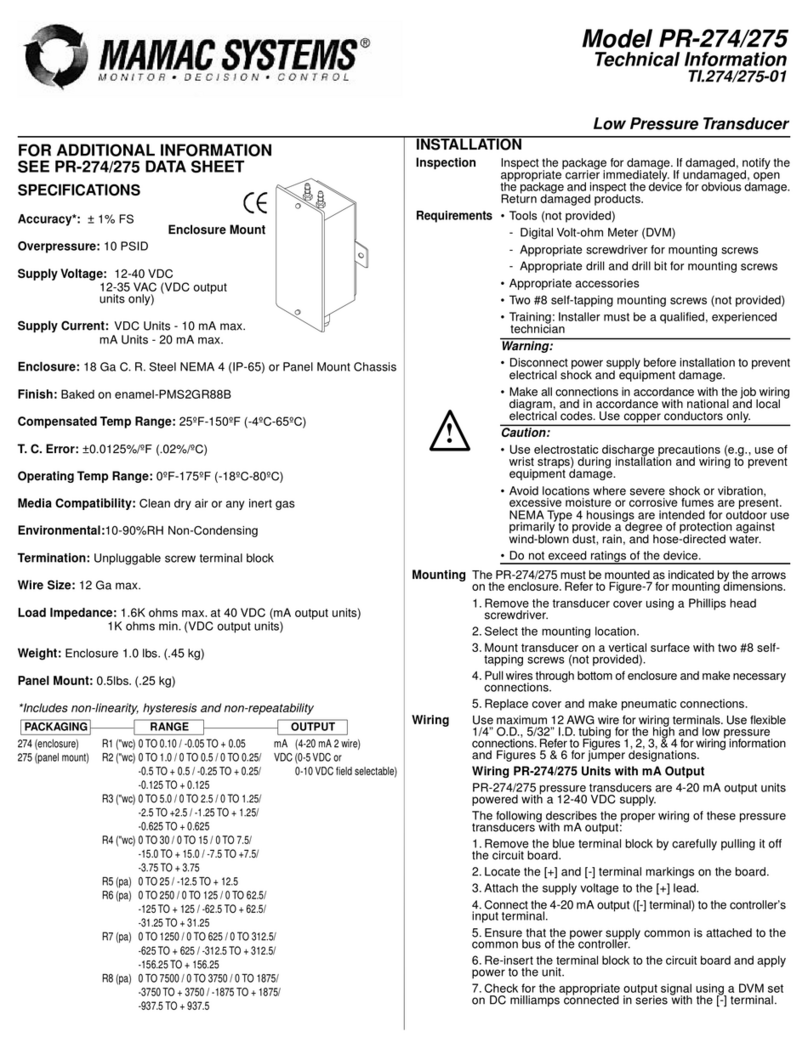

Figure 2. Pressure

Transducer