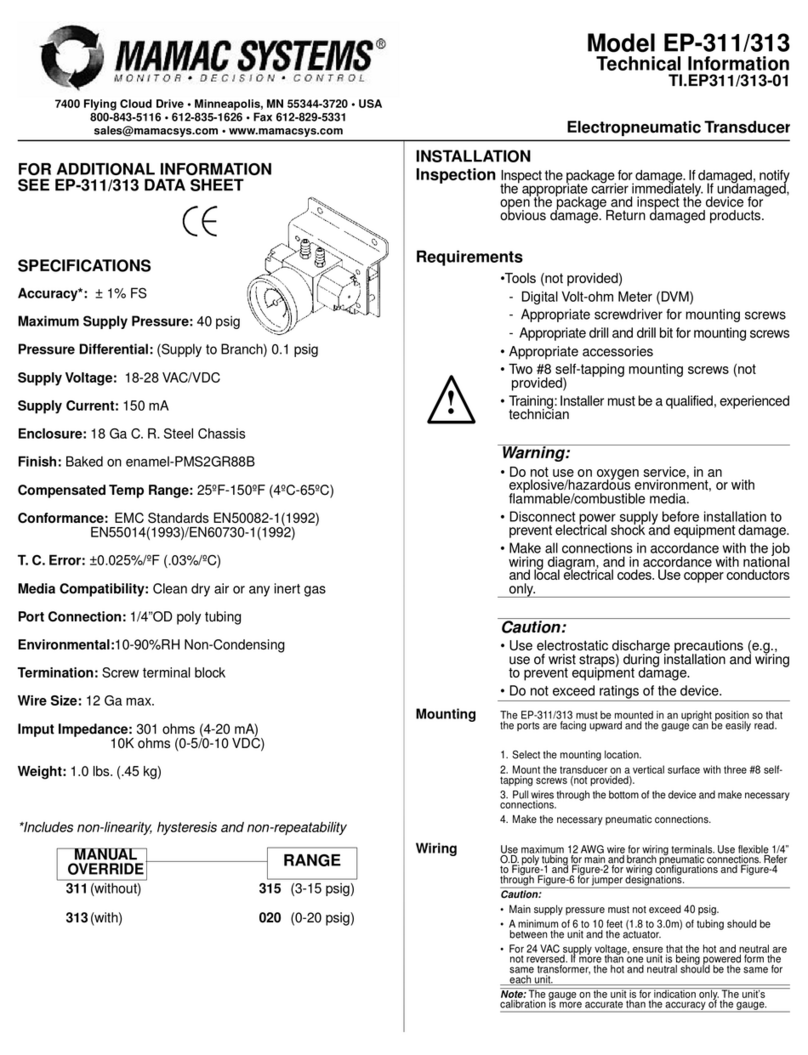

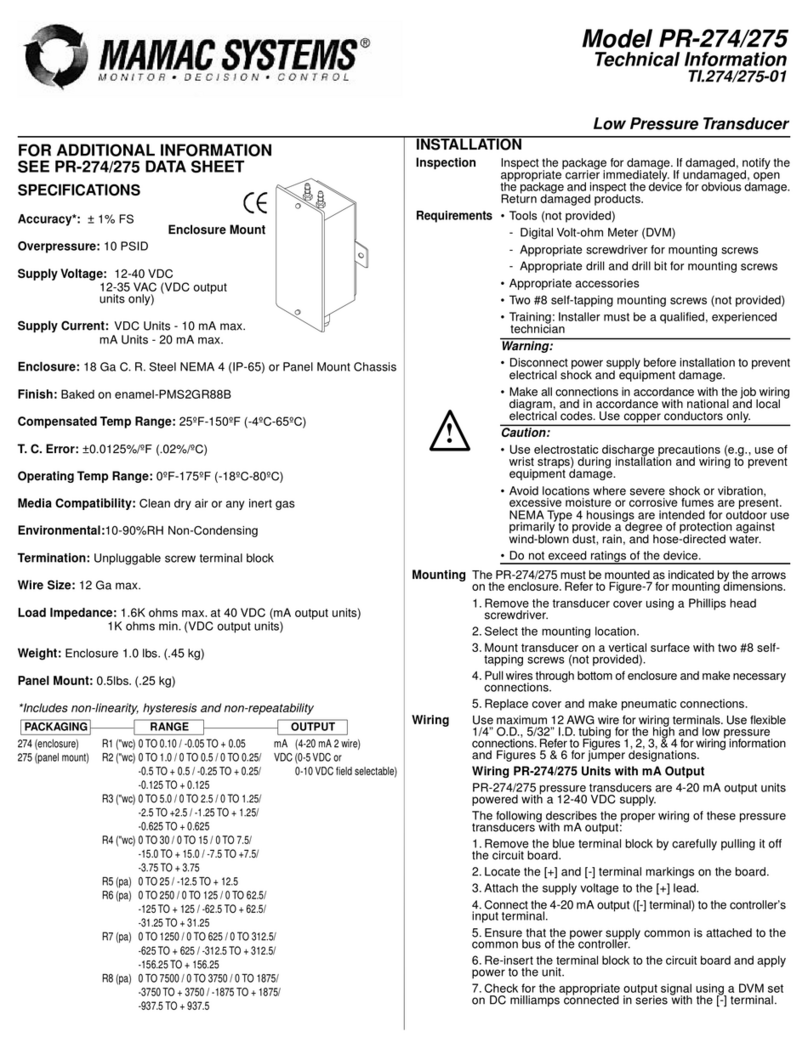

Legend

S=Span Adjust

Z=ZeroAdjust

+=SupplyVoltage

-=Common (Neutral)

0=Output

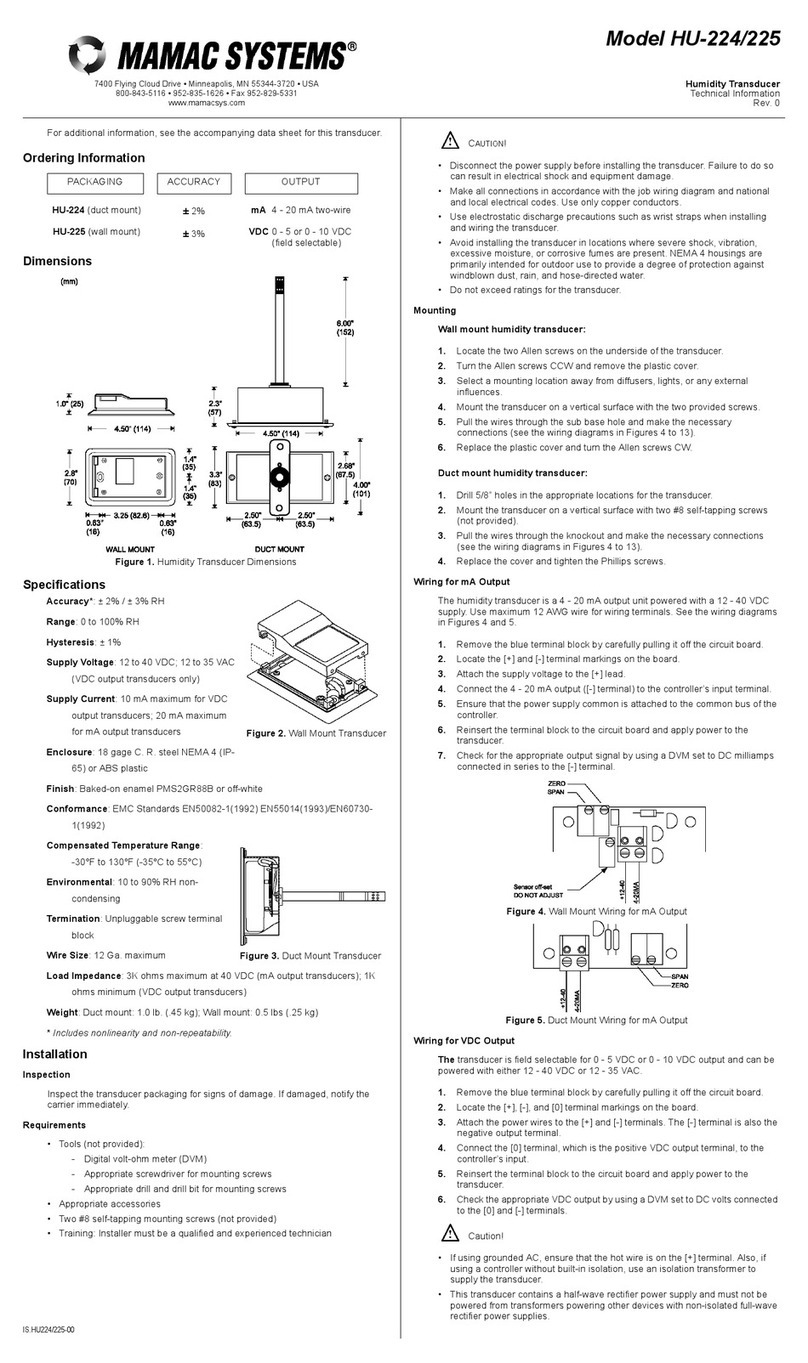

Legend

S=Span Adjust

Z=ZeroAdjust

+=SupplyVoltage

-=Signal

PR-276 PressureTransducerswithmAOutput.

Wiring PR-276 UnitswithVDC Output

PR-276 pressuretransducerswithVDC outputarefieldselectable0-5

VDC or0-10 VDC outputand can be powered witheither12-40 VDC

or12-35VAC.The following describesthe properwiring ofthesepressure

transducerswithVDC output:

1.Removethe blue terminalblock bycarefullypulling itoff the circuit

board

2.Locatethe (+),(-),and (0)terminalmarkingson the board.

3.Attachthe powerwirestothe (+)and (-) terminals.The (-) terminal

isalsothe negativeoutputterminal.

4.Connectthe (0)terminal,whichisthe positiveVdcoutputterminal,

tothe controller’sinputterminal.

5.Re-insertthe terminalblock tothe circuitboardand applypowerto

the unit.

6.Check the appropriateVdcoutputusing avoltmeterseton DC volts

across the (0)and (-) terminals.

PR-276 PressureTransducerswithVDC Output.

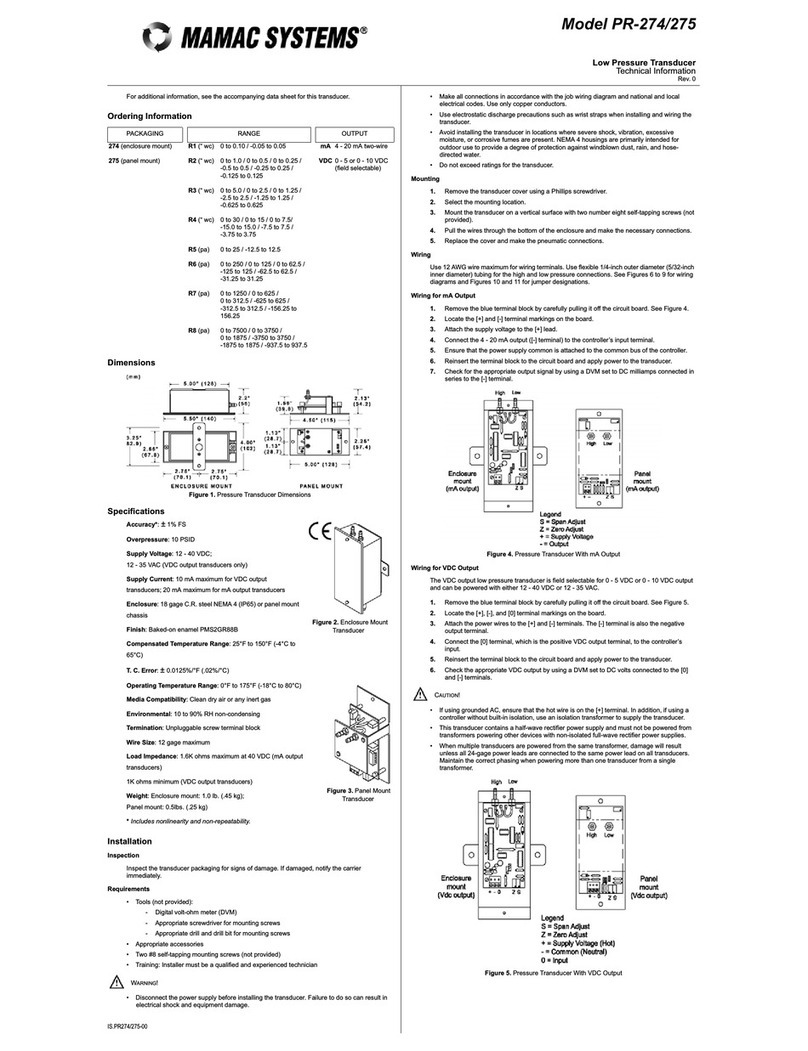

ModelPR-276

TechnicalInformation

TI.276-01

DuctPressureTransducer

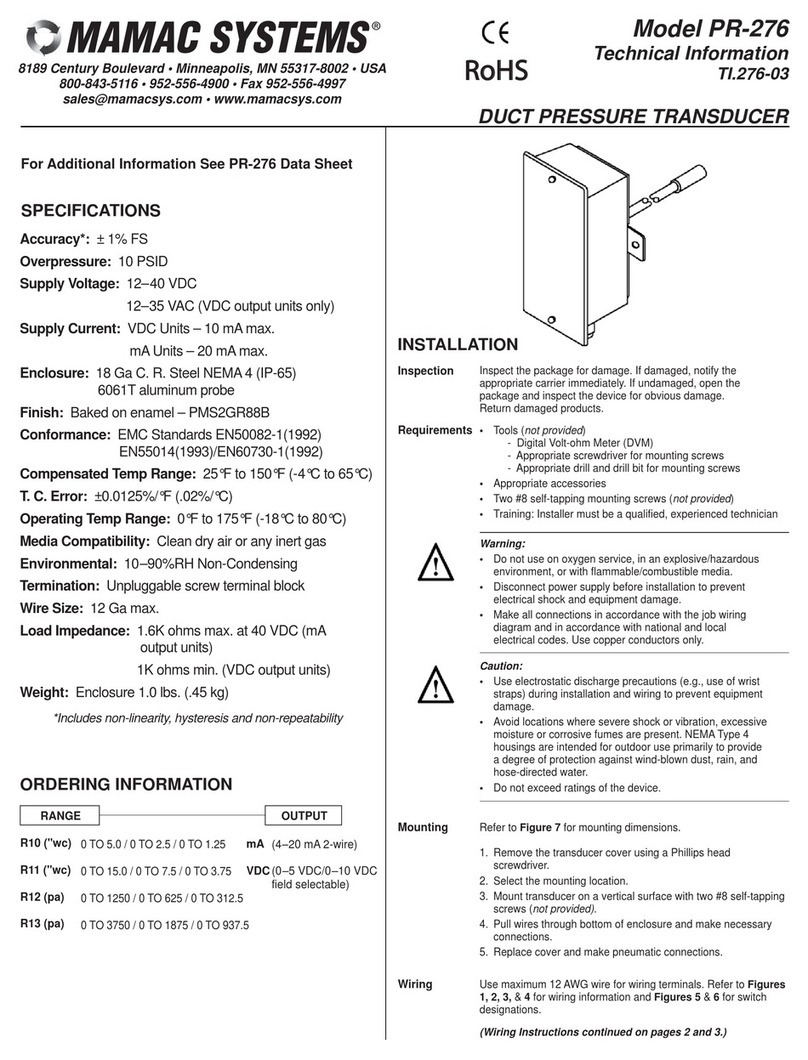

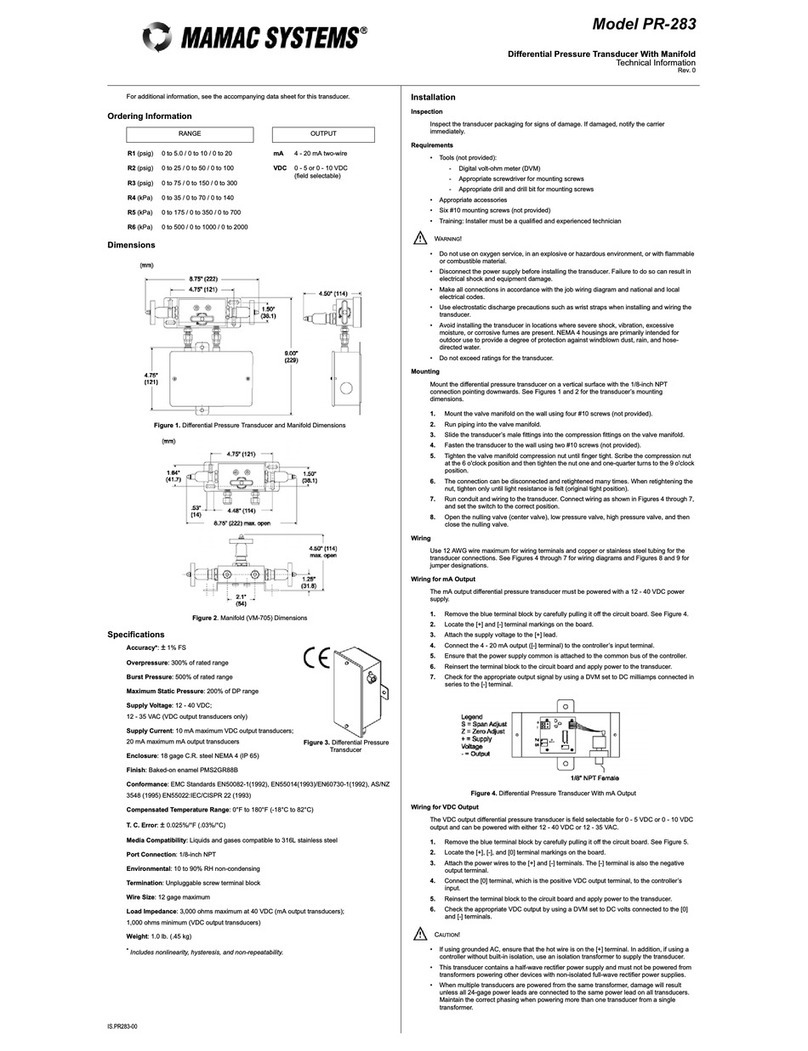

TYPICALAPPLICATIONS(wiring diagrams)

Figure-1and Figure-2

Illustratetypicalwiring diagramsforthe PR-276 Series,4-

20 mA,two-wireoutputductpressuretransducers.

Figure-1Wiring formAOutputDuctPressure

TransducerswithExternalDC Power

Supply.

Figure-2Wiring formAOutputDuctPressure

TransducerswhereControllerorMeterhas

InternalDC PowerSupply.

Page 2of4

+

–+

–

+

–

mAOutput

TranducerOnly12-40 VDC

PowerSupply

Controller/

Meter/

Recorder

Shield/

Ground

InputSignal

Common

+

–

mAOutput

TranducerOnly

+

–

Controller/

Meter/

Recorder

Shield/

Ground

InputSignal

Common

Wiring Usemaximum12 AWGwireforwiring terminals.

RefertoFigures1,2,3,&4forwiring information

and Figures5&6forjumperdesignations.

Wiring PR-276 UnitswithmAOutput

PR-276 pressuretransducersare4-20 mAoutputunitspowered

witha12-40 VDC supply.The following describesthe properwiring

ofthesepressuretransducerswithmAoutput:

1.Removethe blue terminalblock bycarefullypulling

itoff the circuitboard.

2.Locatethe [+]and [-]terminalmarkingson the board.

3.Attachthe supplyvoltage tothe [+]lead.

4.Connectthe 4-20 mAoutput([-]terminal)tothe

controller’sinputterminal.

5.Ensurethatthe powersupplycommon isattached to

the common busofthe controller.

6.Re-insertthe terminalblock tothe circuitboard

and applypowertothe unit.

7.Check forthe appropriateoutputsignalusing

aDVMseton DC milliampsconnected inseries

withthe [-]terminal.

Caution:Thisproductcontainsahalf-waverectifier

powersupplyand mustnotbe powered off transformers

used topowerotherdevicesutilizing non-isolated full-

waverectifierpowersupplies.

Caution:If you areusing grounded AC,the hotwire

mustbe on the (+)terminal.Also,ifyou areusing a

controllerwithoutbuilt-inisolation,usean isolation

transformertosupplythe PR-276 transducer.

Caution:When multiplePR-276 unitsarepowered from

the sametransformer,damage will resultunless all 24G

powerleadsareconnected tothe samepowerlead on

all devices.It ismandatorythatcorrectphasing be

maintained when powering morethan one devicefrom

asingletransducer.