ENGLISH

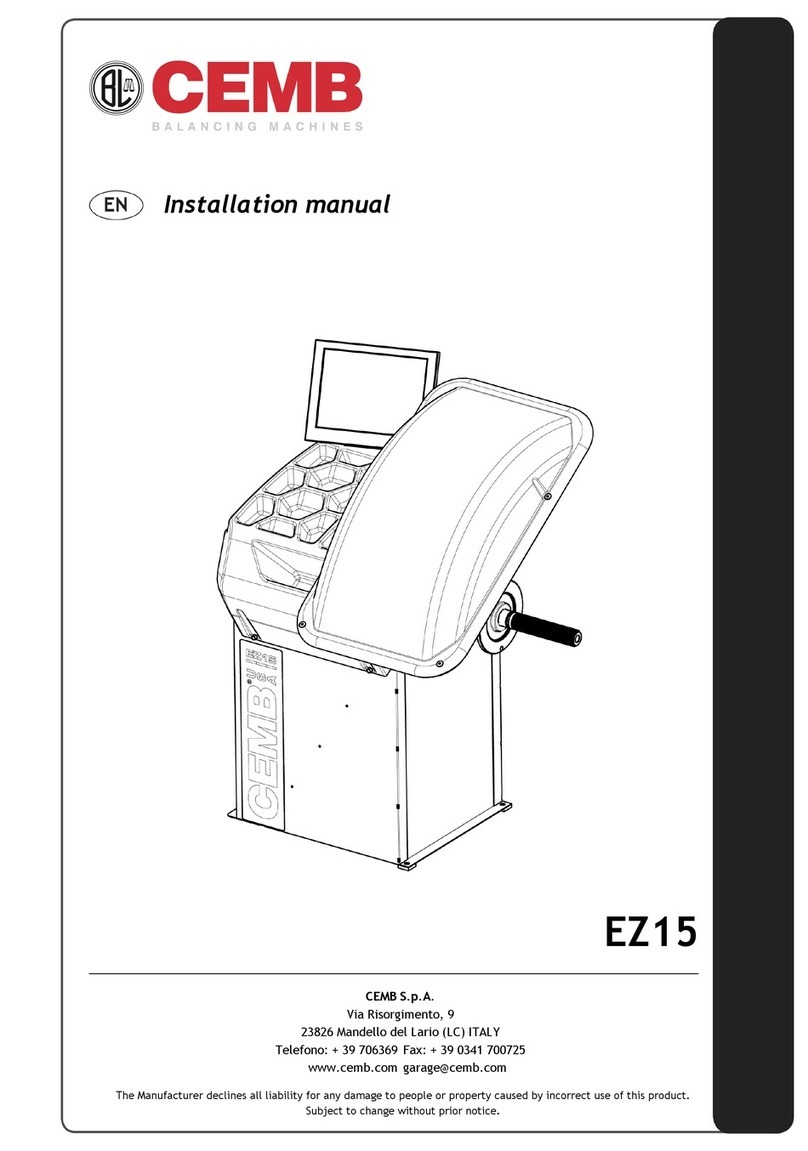

Installation manual Ver. 05-2017

4

2.5 GENERAL WARNINGS

WARNING

▪The machine must be installed, maintained and used according to the instructions given in this manual and ac-

cording to the procedures given from case to case.

▪The employer must train the operators for safe installation, use and maintenance of the machine.

▪Only specialised and specifically trained persons are to be allowed access to the machine for any extraordinary

maintenance operation.

▪Before operating on the electrical parts of the machine cut the power.

▪For the duration of maintenance, “Work in progress” signs must be posted in the department in such a way

that they are visible from all the access areas.

▪Always operate with due caution and wear the personal protection devices (PPD).

▪The machine (and any accessory devices) must always be connected to earth to discharge short-circuit currents

and electrostatic voltages. The mains voltage must correspond to the value shown on the machine identication

plate. It is inadvisable to use cable extensions/socket adaptors. When the machine is not used, disconnect it from

the mains by pulling the plug from the socket.

▪Before carrying out any operation stop the machine.

▪In the event of fire, do not use water but only powder or carbon dioxide fire extinguishers.

▪It is strictly prohibited to deposit combustible material in the vicinity of the machine.

▪Do not deactivate the safety devices or ignore warnings and alarms, be they communicated by the software or

by warning labels fixed on the installation. Should the plates, adhesive labels, decals or any other warning sign

on the machine deteriorate they must be replaced.

▪It is not permitted for any reason whatsoever to modify, tamper with or alter the machine structure, the devices

fitted, the operating sequence, etc. without prior consultation with the manufacturer.

▪All the routine and extraordinary maintenance operations must be recorded in the logbook noting down the

date, time, type of operation, name of the operator and any other useful information.

▪In the event of faults or malfunctioning, contact your local distributor or the manufacturer. All the repair opera-

tions must be performed by qualified technicians.

▪It is strictly prohibited to clean the internal and external electrical parts of the wheel balancer with water.

▪Exclusively use alcohol to clean the machine. Do not use any other chemical product. Do not under any circum-

stances blast with compressed air.

▪Do not leave the machine exposed to the rain or the elements. The ambient storage and operating conditions

must meet the requirements set out in the chapter INSTALLATION.

▪In the event of failure, deformation or malfunctioning of the safety devices, immediately replace them; “Make-

shift” repairs are strictly prohibited. Use only original spare parts for which the machine has been designed

and constructed.

▪The machine and the workplace must be kept perfectly clean.

▪When the maintenance operations have been completed, before restoring the power supply, carefully check that

you have not forgotten tools and/or other materials in the machine operating area. In any event, also during

operation, no object may be placed on the protection shield.

Safety rules