BUTLER Engineering & Marketing S.p.A. a s.u. - Via Balduina 5/7 - 42010 Rio Saliceto (RE - Italy)

Tel. +39 0522 647911, Fax +39 0522 649760 e-mail: info@butler.it / www.butler.it P. 1/62

SPEED32HPR – SPEED32HP

SPEED32SP - SPEED32L

USER MANUAL

Code 2025-M351-00

(05/2021)

TABLE OF CONTENTS

0WARNINGS .................................................................................................................................................. 3

0.1 Preliminary safety informaon .............................................................................................................. 3

1INTENDED USE ............................................................................................................................................ 4

2TRAINING OF DESIGNATED PERSONNEL .................................................................................................... 4

2.1 General prevenon measures ............................................................................................................... 4

3EQUIPMENT COMPOSITION........................................................................................................................ 5

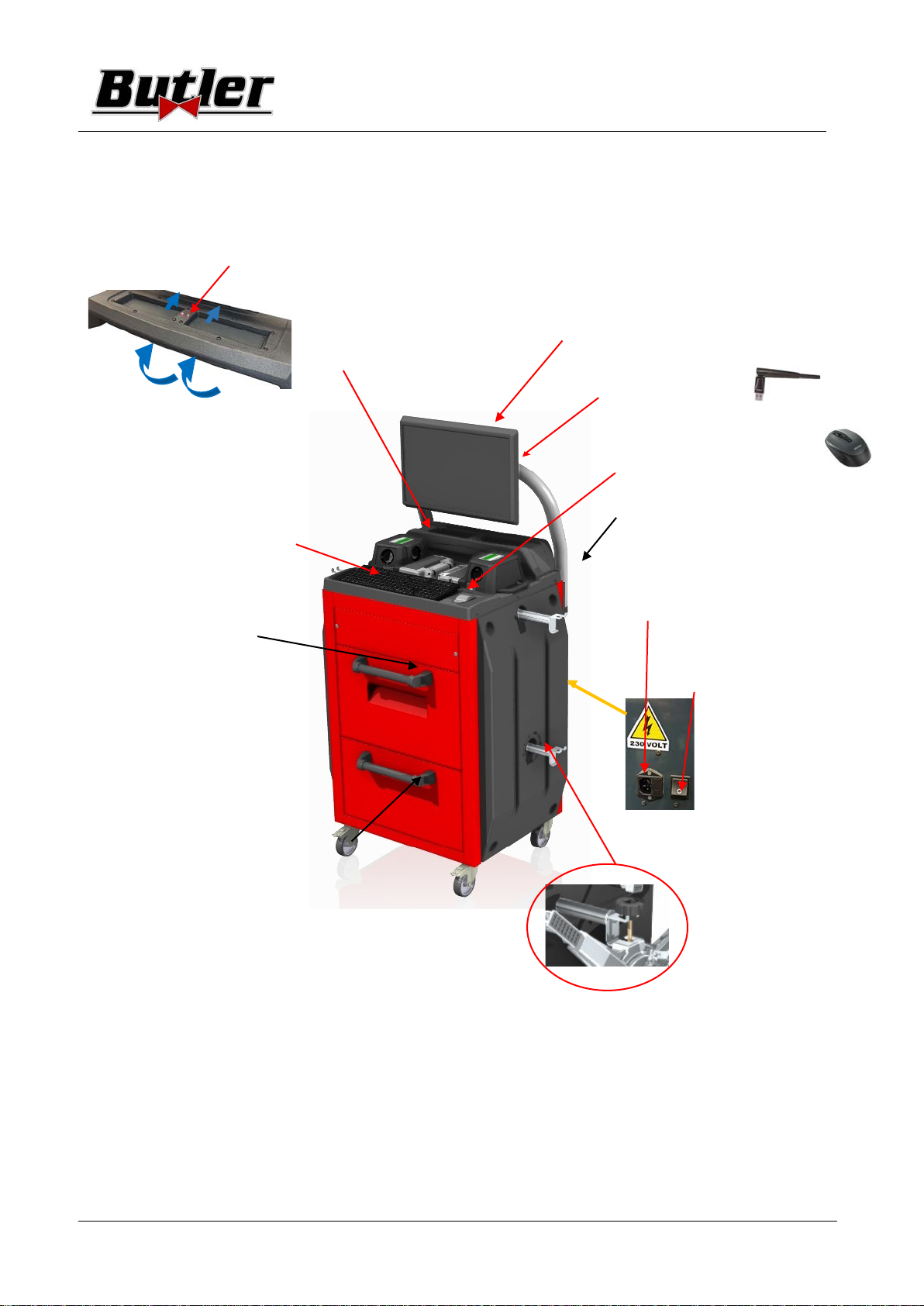

3.1 Cabinets of the Models SPEED32HPR/SPEED32HP ............................................................................... 5

3.2 Cabinets of the Models SPEED32SP ...................................................................................................... 6

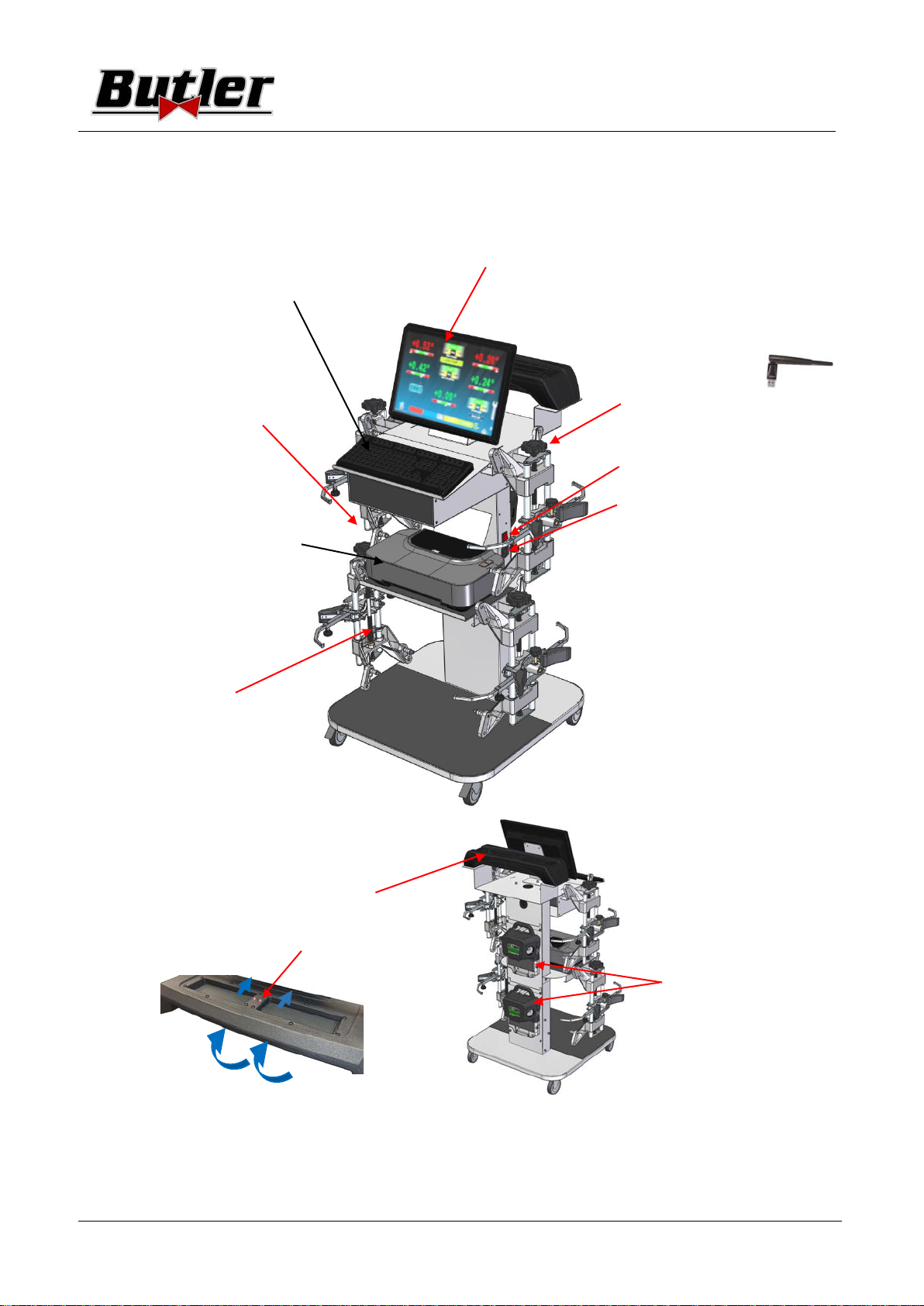

3.3 Cabinets of the Models SPEED32L ........................................................................................................ 7

3.4 Management PC .................................................................................................................................... 8

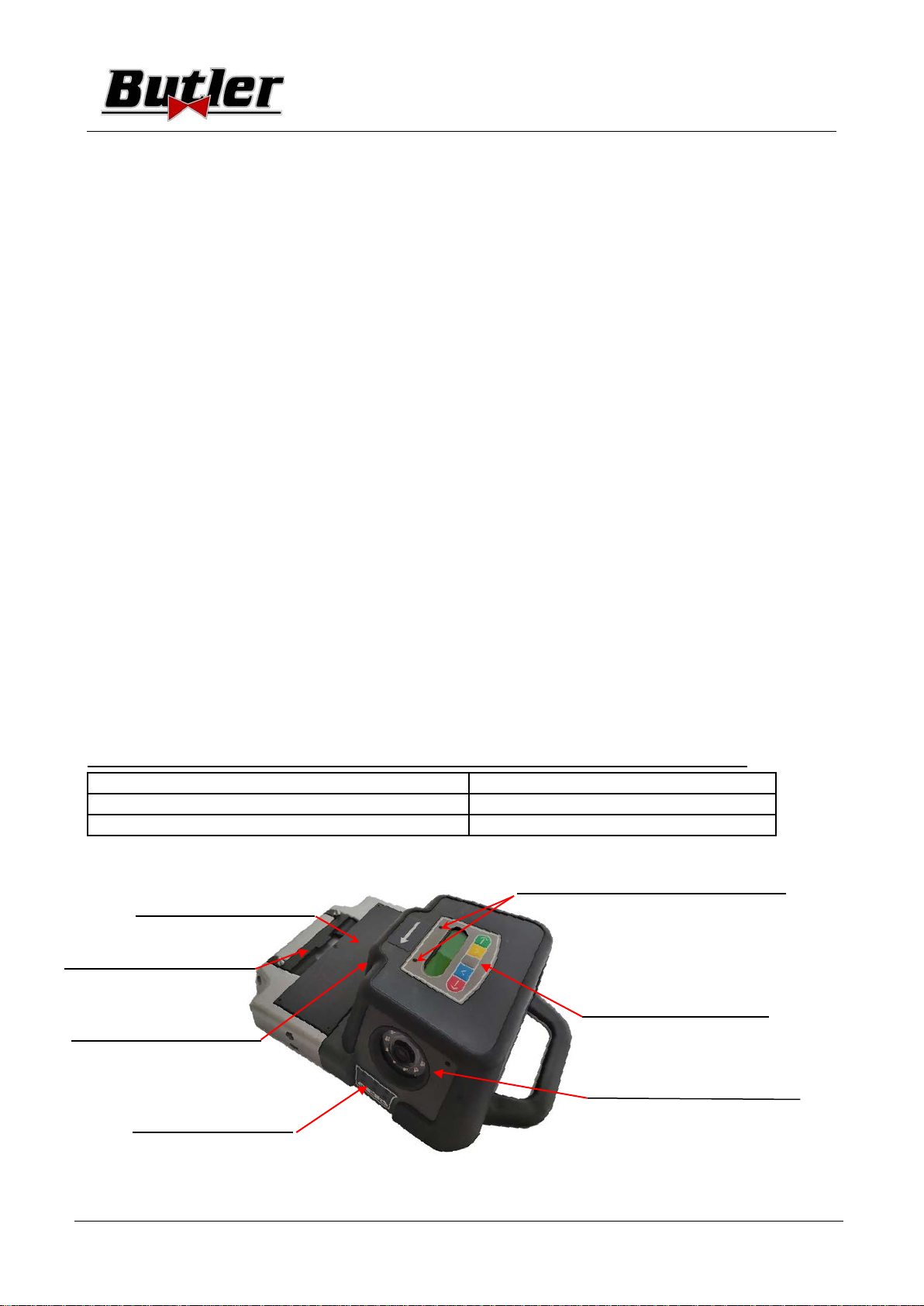

3.5 MEASURING HEADS ............................................................................................................................... 8

3.5.1 Measuring head keypads ................................................................................................................................ 9

3.5.2 LED for adjustment tollerance signalling ......................................................................................................... 9

3.6 Clamps with target ................................................................................................................................. 10

3.7 Turn plates ............................................................................................................................................. 11

3.7.1 Turn plates STDA124 (for models SPEED32HP-SPEED32HPR) ......................................................................... 11

3.7.2 Turn plates S110A7/P (for the models SPEED32SP-SPEED32L) ....................................................................... 11

3.8 Push-pedal ............................................................................................................................................. 11

3.9 Steering lock .......................................................................................................................................... 11

4EQUIPMENT CHARACTERISTICS ................................................................................................................. 12

4.1 Safety devices ........................................................................................................................................ 12

4.2 Precision measuring ranges.................................................................................................................... 12

4.3 Overall dimensions ............................................................................................................................... 12

5TRANSPORTATION AND INSTALLATION ..................................................................................................... 13

5.1 Transportaon and unpacking ............................................................................................................... 13

5.2 Installaon ............................................................................................................................................. 13

5.2.1 Electrical connecon ........................................................................................................................................ 13

5.2.2 Cabinet assembly ............................................................................................................................................. 13

5.2.3 Clamp / / Target mounng .............................................................................................................................. 14

5.2.4 Fixing of measuring head supports ................................................................................................................. 15

6SWITCHING THE EQUIPMENT ON AND OFF .............................................................................................. 17

6.1 Switching on .......................................................................................................................................... 17

6.2 Switching o .......................................................................................................................................... 17

7AUTOMATIC SWITCHING OFF OF THE MEASURING HEADS ...................................................................... 18

8FLAT BATTERY INDICATION ......................................................................................................................... 18

9PROGRAM CONFIGURATION ...................................................................................................................... 19

9.1 DATABASE Groups Conguraon ........................................................................................................... 20

9.2 Miscellaneous ........................................................................................................................................ 22

10 DIAGNOSIS AND ADJUSTMENT OF A VEHICLE ........................................................................................ 24

10.1 Presentaon page ................................................................................................................................ 24

10.2 Preliminary operaons ........................................................................................................................ 25

10.2.1 Preliminary vehicle control operaons .......................................................................................................... 25

10.2.2 Preparing for measurements ......................................................................................................................... 25

10.3 Selecng the make and model of a vehicle ......................................................................................... 27

10.3.1 “ProView” vehicle search mode .................................................................................................................... 29

10.4 Search for vehicles with plate no. with “SHOOT & GO” ...................................................................... 30