M&R CHALLENGER II Series User manual

The M&R

111802MS

$75.00

M&R Printing Equipment, Inc.

www.mrprint.com

Toll Free 1-800-736-6431

MAN-CH2

IMPORTANT!

The product described in this publication may employ hazardous voltages or might cre-

ate other conditions that could, through misuse, inattention, or lack of understanding,

result in personal injury, or damage to the product or to other equipment. It is imperative,

therefore, that personnel involved in the installation, maintenance, or use of this product

understand the operation of the product and the contents of this publication.

This document is based on information available at the time of its publication. While

efforts have been made to be accurate, the information contained herein does not pur-

port to cover all details or variations in hardware, software, features or specifications, nor

to provide for every possible contingency in connection with installation, operation and

maintenance. Features may be described herein which are not present in all variations of

this product. M&R Printing Equipment, Inc. assumes no obligation of notice to holders of

this document with respect to changes subsequently made.

M&R Printing Equipment, Inc. makes no representation or warranty, expressed, implied

or statutory with respect to, and assumes no responsibility for the accuracy, complete-

ness, sufficiency or usefulness of the information contained herein. No warranties of mer-

chantability or fitness for purpose shall apply.

A publication of M&R Printing Equipment, Inc. All information contained herein is derived in part from proprietary and

patent data of M&R Printing Equipment, Inc. This publication may not be reproduced, copied, or transmitted in any form

without prior permission from M&R Printing Equipment, Inc. Printed in the U.S.A. All Rights Reserved. 2002.

i

IMPORTANT!

The information listed below will prove helpful when ordering replacement parts,

requesting service or repairs. Please fill in the following information. The Model

No., Serial No., Schematic No. and Machine No. are all located on the

Manufacturers Rating Plate mounted to the equipment. Should you have any

questions regarding this information, please do not hesitate to contact our

Equipment Service Department at 1 (800) 736-6431 during normal business

hours.

Product Name:

Model No.

Serial No.

Schematic No.

Machine No.

Date of Installation:

Installed By:

Introduction

Valued Customer,

Thank you and congratulations on your purchase of your new M&R Challenger Series II semi-auto-

matic Textile Screen Printing System.

The M&R Challenger Series II has set the industry standard for affordable, high performance automat-

ic textile screen printing. Designed for quick set-ups and high volume production, the M&R Challenger

Series II is loaded with time saving, cost cutting features.

Incorporating a sophisticated servo-driven index system to insure accurate, consistently smooth index

cycles, even at the highest possible production speeds, the M&R Challenger Series II delivers a full 20”

x28” print area.

A thorough understanding of the operation and maintenance of your new M&R Challenger Series II will

insure maximum production rates and a long service life for your investment. This Operator’s Manual

is provided to help guide you, and your employees, in the proper procedures for set-up, operation and

preventive maintenance of your new M&R Challenger Series II.

Should you have any questions regarding the operation or maintenance of your new M&R Challenger

Series II, M&R’s world wide Technical Service and Support Network is available to you during regular

business hours (8:30am - 5:00pm C.S.T.) at 1 (800) 736-6431, or, on week ends or holidays, call our

24 hour Emergency Service Hotline at 1 (630) 462-4715 for technical support 24 hours a day, seven

days a week.

On behalf of all of us here at M&R, thank you for selecting M&R as your equipment supplier.

Michael J. Sweers

Director of Technical Services

M&R Printing Equipment, Inc.

M

&

R

P

r

i

n

t

i

n

g

E

q

u

i

p

m

e

n

t

,

I

n

c

.

W

o

r

l

d

w

i

d

e

T

e

c

h

n

i

c

a

l

S

e

r

v

i

c

e

N

e

t

w

o

r

k

Table of

Contents Disclaimer

Model Description

Introduction

Safety Precautions................................................1

Specifications........................................................5

Screen Frame & Image Size................................11

Installation Instructions.......................................13

Tri-Lok Pre-Registration System.........................15

Set Up Instructions/Central Off-Contact.............21

Omni/Uni Flash....................................................23

Quartz Flash........................................................27

Operator Controls................................................31

E 300 Operator Interface.....................................41

Recommended Lubricants/Tools.........................63

Preventive Maintenance Procedures...................65

Pallet Leveling Procedure..................................111

Proximity Switch Location.................................115

Index Lift Cylinder Cushion Adj.........................118

Idec Relay Location...........................................119

Alarm Messages on E 300 Operator Interface..121

Trouble Shooting Procedure..............................123

Kebco Frequency Drive.....................................127

Servo Amplifier Alarm List.................................133

Recommended Spare Parts..............................129

Replacement Parts............................................131

Warranty Information........................................

Glossary

Electrical Schematics

Safety Precautions &

Specifications

Set-Up &

Operation

Maintenance and

Trouble Shooting

Replacement Parts and

Warranty Information

Glossary and

Electrical Schematics

Challenger

Series II

Safety Precautions

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois 1

SAFETY PRECAUTIONS

FUNDAMENTAL SAFETY INSTRUCTIONS:

Please read all information regarding safety precautions

as presented in the Operator’s Manual.

The fundamental requirement to assure safe and trouble-

free operation of this equipment, is a thorough understand-

ing of the safety information contained in this Operator’s

Manual.

This Operator’s Manual includes important instructions to

assure safe operation of this equipment. This Operator’s

Manual, and especially the safety instructions as described

there-in, must be observed by everyone who will operate

this equipment. In addition to the safety instructions and

regulations described in this Operator’s Manual, rules and

regulations of the equipment owners place of business

must also be observed.

Obligation of the Equipment Operator:

The equipment Operator is obliged to guarantee that only

staff who are acquainted with the fundamental regulations

according to workers protection and accident prevention,

and, are completely knowledgeable in the operation of this

equipment have fully read the Safety Chapter and the

Warning Instructions of this manual, and understand the

instructions as they relate to operation of this equipment.

Equipment Operators must be continually evaluated to

assure that they fully understand the operation of this

equipment.

Obligation of Personnel:

Every person that will be engaged in the operation of this

equipment must comply with the following before operation

of the equipment is to begin.

1. Observe the fundamental regulations of worker’s pro-

tection and accident prevention.

2. Read the Safety Chapter and Warning Instructions of

this Operator’s Manual and confirm by signature that they

understand the instructions as described in the manual.

Dangerous Situations during Operation of the

Equipment:

The M&R Challenger Series II has been designed and con-

structed in accordance with safety standards as described

by Nationally Recognized Testing Laboratories, such as

Underwriters Laboratories in the United States, and the

European Economic Community (CE) Standards and

Directives. However, it is possible that dangerous condi-

tions which can cause serious injury or loss of life for the

user or third persons, or damage to the equipment or prop-

erty could occur.

This equipment must be used only for the defined purpose

as described in the Operator’s Manual, and must be main-

tained in perfect running condition in accordance with

described Safety Regulations.

Conditions which may compromise operator safety must be

identified and corrected immediately.

Defined Purpose:

The M&R Challenger Series II is specifically designed to

apply (print) screen printed textile inks on textile substrates.

Any other use of the equipment which does not meet the

Defined Purpose as described above is not permitted.

In accordance with the Defined Purpose of this equipment,

it is necessary to observe all instructions as outlined in the

Operator’s Manual and to perform the preventive mainte-

nance procedures as described in the manual.

Guarantee and Liability:

In principle, our general terms of sale and delivery are valid

and these are at the Operator’s disposal. Guarantee and lia-

bility claims for persons or property damage are excluded if

they originate for one or more of the following reasons.

1. A non-defined use of the equipment

2. Improper installation or use of the equipment

3. Operation of the equipment with defective safety

devices

4. Non-Observance of instructions as described in the

Operator’s Manual for transportation, storage, instal-

lation, operation, maintenance, set-up and take-

down of the equipment.

5. Modification of the equipment.

6. Failure to replace worn or defective parts of the

equipment.

7. Defective repairs made to the equipment.

8. Dangerous conditions which are a result of the

improper use of the equipment.

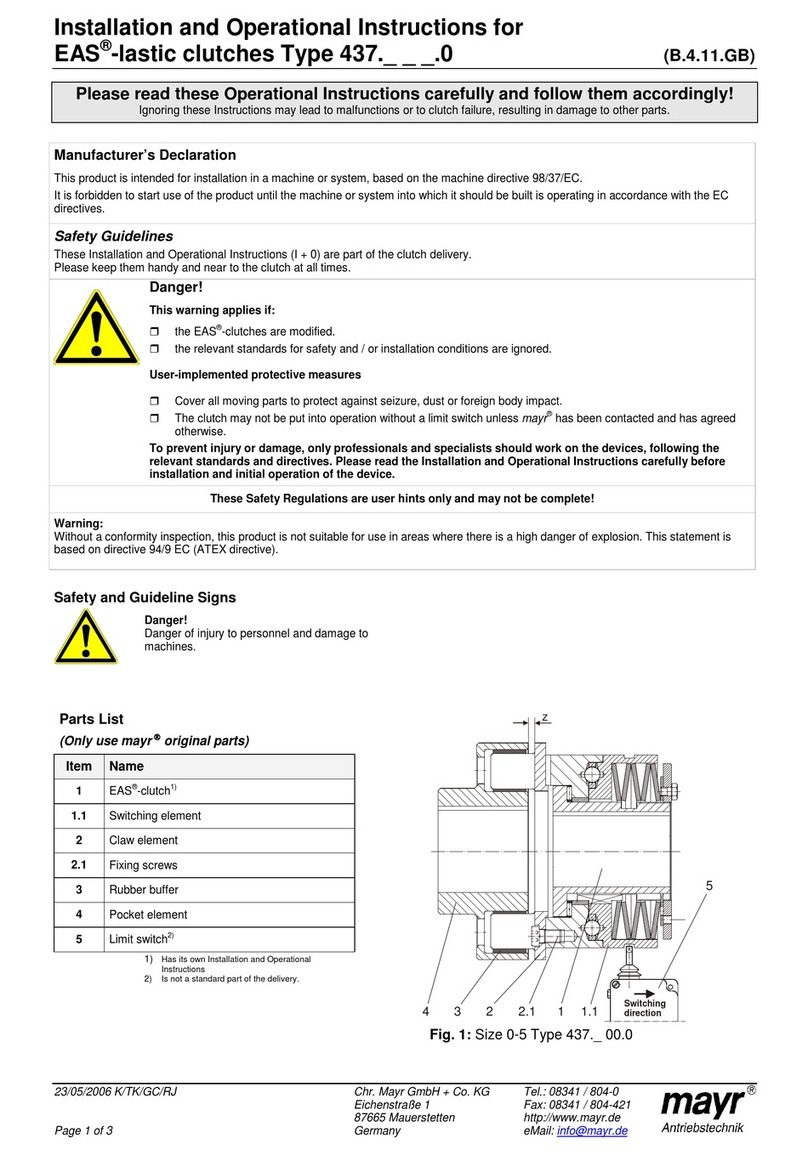

Description of Safety Symbols and

Instructions:

This symbol signifies or alerts the

equipment operator of conditions

or areas of the equipment which

present imminent danger to the

health of the equipment Operator.

Non-observance of these

instructions has serious health

consequences, and can lead to

highly dangerous injuries.

DANGER!

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

2

This symbol signifies a possible

imminent danger for life and health

of persons and equipment

Operators.

Non-observance of these

instructions can have serious

health consequences and can

lead to highly dangerous injuries.

This symbol signifies a possible

danger.

Non-observance of these

instructions can lead to light

injuries or damage to the equip-

ment or property.

This symbol gives important

instructions for the proper use of

the equipment.Non-observance

of these instructions can lead to

equipment failure.

This symbol is used to describe

operating tips or especially useful

information.

This information will enable the

Operator to use all equipment

functions for optimal perfor-

mance.

Organizational Measures:

Equipment operators are responsible to provide personal

protection when operating this equipment. All safety

devices must be checked each day before operation of the

equipment can begin.

Safety Devices:

Before beginning operation of the equipment, all safety

appliances must be checked for proper operation.

Safety devices may only be removed after.....

1. The equipment is shut down.

2. The electrical power has been dis-connected from the

equipment.

3. In case of delivery of partial components, the Operator

must install safety devices in accordance with regula-

tions.

Exploratory Safety Measures:

The Operator’s Manual must be kept on or near the equip-

ment at all times. All safety and danger notices must be kept

in readable condition at all times.

Training of Equipment Operator’s

Only properly trained Operators may run the equipment.

The competence of personnel who are to operate, maintain,

set-up and shut down the equipment must be confirmed.

Unskilled staff may work with the equipment only when

supervised by experienced equipment Operators.

Equipment Control System:

Never make any modifications to software.

Only experienced Operators may actuate the control sys-

tem.

Safety Measures during Normal Operation:

Operate the equipment only if all safety devices are fully

operational.

Before starting the equipment, check to be sure no-one will

be endangered by the operation of the equipment.

Check the equipment and safety devices at least once per

shift for external or visible damage.

Danger by Electrical Energy:

Work on the electrical system must

be carried out by qualified person-

nel only.

Check the electrical equipment

regularly for any sign of defect or

loose connections.

Electrical enclosures must be kept

securely locked at all times.

Only authorized personnel with a

key are allowed access to electrical

enclosures.

Danger by Pneumatic Energy:

Only personnel with experience with pneumatic power sys-

tems may work with pneumatic components or assemblies.

Before starting any work on pneumatic components or

assemblies, the compressed air supply must be com-

pletely drained from the equipment to prevent any oper-

ation of pneumatic controls or assemblies.

CAUTION!

i

IMPORTANT!

OPERATING

TIP!

DANGER!

WARNING!

Safety Precautions

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois 3

All pneumatic piping and/or hoses must be checked at reg-

ular intervals for signs of wear or failure.

Maintenance & Trouble Shooting:

Preventive maintenance must be performed at regular inter-

vals as described in the Operator’s Manual.

Equipment operator’s must be informed before any preven-

tive maintenance can be performed.

All power systems such as electrical, pneumatic,

hydraulic or mechanical must be dis-connected and

locked out before preventive maintenance may begin.

Structural Modification of the Equipment:

Modifications of equipment are specifically not allowed with

out written authorization from M&R Printing Equipment, Inc.

Cleaning of the equipment:

Clean away all ink or other contaminant’s at the end of each

day.

Equipment Noise:

Under normal operating conditions as described under

Defined Purpose, this equipment will not produce sound

above the level of 65 db. Depending on local conditions, a

higher continuous sound level may result that could lead to

hardness of hearing. In this case, the operational staff must

wear appropriate safety clothing or protection.

CAUTION: The information con-

tained in this Operator’s Manual

has been provided to eliminate

problems from occurring. Be sure

to read through this Operator’s

Manual fully before operating your

press.

There are numerous safety features

utilized in the operation of this

equipment. Please be sure you

know the location of these safety

devices and how they operate

before attempting to operate this

equipment.

SAFETY FEATURES -

1. All equipment is provided with either a safety bar, foot

switch, yellow safety cords, infrared safety beam, yellow

floor mats or hand switch to stop the equipment. Please

know the type on your equipment and its location and func-

tion before operating. NEVER ATTEMPT TO BY-PASS OR

DEFEAT ANY SAFETY DEVICE OR APPLIANCE. IN THE

EVENT THAT ANY OR ALL SAFETY DEVICES ARE NOT

OPERATING OR FUNCTIONING PROPERLY, DO NOT

ATTEMPT TO OPERATE THIS EQUIPMENT!

2. Safety guards have been provided to protect the opera-

tor from all moving parts. Please do not remove these

Safety Guards any time the equipment is in operation.

3. This Operator’s Manual includes information regarding

the proper preventative maintenance procedures. When

ever personnel are performing preventative maintenance

procedures, be sure that all electrical and pneumatic

power is disconnected from the equipment, and that

disconnects are locked in the “OFF” position.

4. Never work on the table surface under the print stations

unless the power “ON/OFF” switch is placed in the “OFF”

position.

OPERATOR SAFETY INSTRUCTIONS -

All industrial equipment, including screen printing equip-

ment, requires a combination of high electrical, pneumatic,

hydraulic or mechanical power for operation. In addition,

automatic screen printing equipment, by its nature, expos-

es operators to parts and assemblies which operate at high

speeds and contain numerous moving parts. As with all

complex industrial equipment, care should be exercised to

carefully observe proper operating procedures and safety

precautions.

Although every effort has been made to design and con-

struct safe, dependable equipment, it is impossible to fore-

see all circumstances under which this equipment may be

utilized, or to anticipate all possible combinations of factors

which may cause a hazardous condition or situation. It is

therefore imperative that the equipment Operator, as well as

all other personnel engaged in any phase of the set-up,

operation or preventative maintenance of this equipment

consider safety first an important part of their job.

The following general safety considerations are offered as

an aid to users of M&R Printing Equipment to assist them

in becoming safety conscience.

1. READ THE OPERATOR’S MANUAL before attempting

to lift, move, operate or perform maintenance on any piece

of machinery. Become intimately familiar with all equipment

controls, their locations, their operation and their effect on

equipment function. Keep this Operator’s Manual in a clean

location immediately adjacent to the equipment for a quick

and handy reference.

2. BEFORE ATTEMPTING TO START THE EQUIPMENT

inspect all areas around and adjacent to moving parts for

possible obstructions: tools, rags, crating remnants etc. Be

certain that all Safety Guards, covers, access doors etc., are

properly installed prior to starting operation.

CAUTION!

Safety Precautions

Safety Precautions

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

3. PRACTICE GOOD HOUSEKEEPING: Maintain and area

adjacent to NOT ON the equipment for tool and color stor-

age. Clean up all spills and eliminate all potential trip points

from the operating areas around the equipment to prevent

slipping or falling into the working zone of the equipment.

Do not stand on equipment elements not intended for

this purpose. Maintain a maximum clear area around the

equipment for unobstructed movement of the Operator.

Perform Preventative Maintenance at the intervals specified

in this Operator’s Manual.

4. AVOID WEARING LOOSE CLOTHING , long hair, neck

ties etc., when operating this equipment as these can easi-

ly become entangled in moving parts. Safety shoes are like-

wise recommended. Avoid horseplay around the equip-

ment.

5. DO NOT ATTEMPT to operate this equipment if you are

sick, excessively fatigued or under the influence of alcohol

or prescription drugs. Shut off the equipment immediately if

any malfunction occurs or appears imminent. Report any

unsafe equipment or condition promptly in order that cor-

rection can be made as soon as possible.

6. BY-STANDERS should stay well away from the equip-

ment so as not to distract the operator or accidentally move

a control element. Avoid talking to the operator while the

equipment is in operation.

7. WHEN CHANGING SET-UP, performing maintenance

work, cleaning the equipment etc., it is imperative that the

main electrical and pneumatic power supplies be discon-

nected to avoid accidental operation and possible resultant

injury. This is particularly important in the event more than

one person is involved in such duties.

8. A WRITTEN SAFETY PROGRAM should be installed by

all companies owning M&R Printing Equipment. This pro-

gram should cover inspection, maintenance and safety

training on the proper use of the machinery.

WARNING! DO NOT WORK

WITHIN THE INDEX TABLE

OPERATING AREA UNLESS ALL

SAFETY PRECAUTIONS HAVE

BEEN OBSERVED!

4

WARNING!

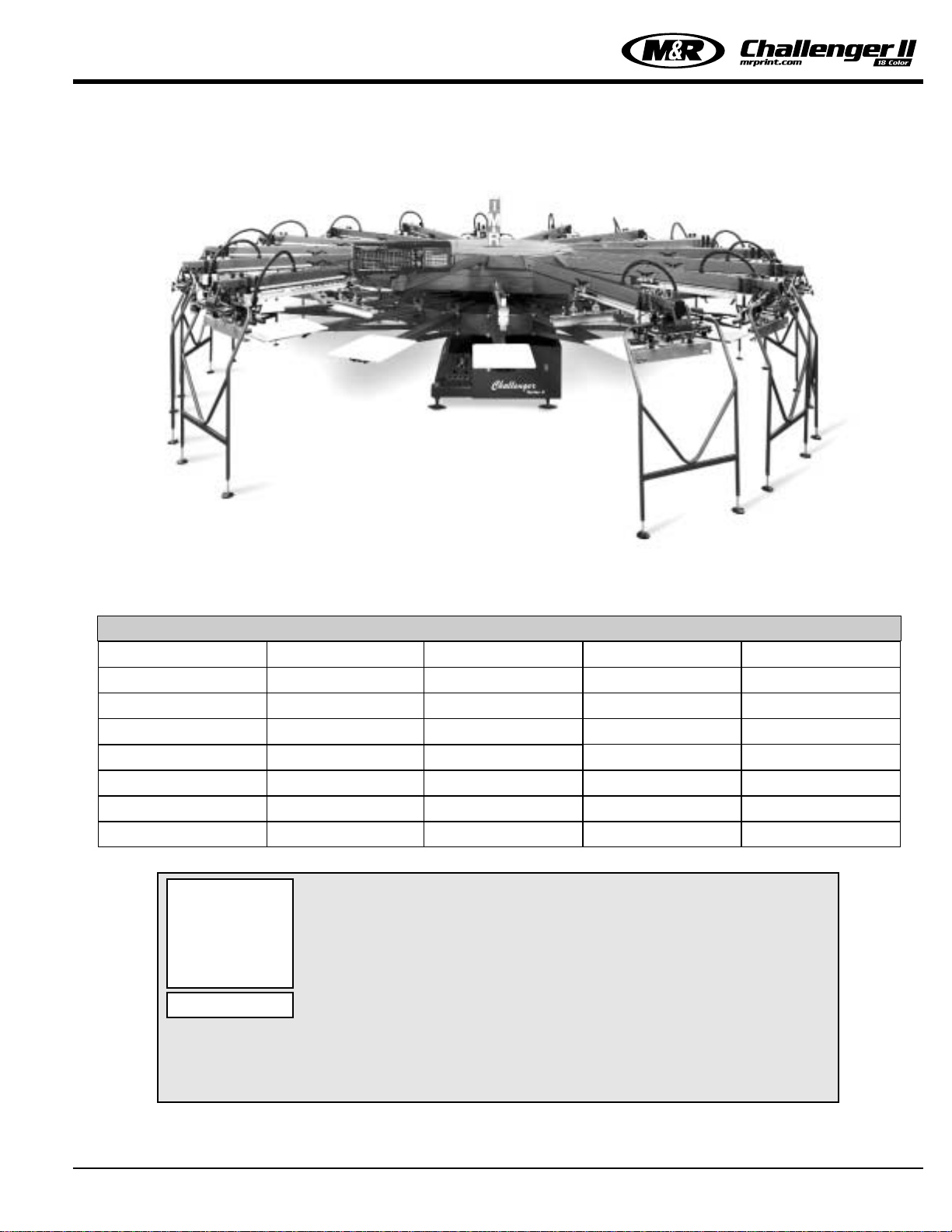

SPECIFICATIONS CHALLENGER Series II (Pneumatic Models)

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois 5

MODEL No. 12 COLOR 14 COLOR

Maximum Image Size 20” x 28” (50 x 70 cm) 20” x 28” (50 x 70 cm)

Maximum Frame O.D. 26” x 43” (66 x 109 cm) 26” x 43” (66 x 109 cm)

Total Set-Up Diameter 18’ (5.49 m) 19’ 6” (5.94 m)

Compressed Air Req. 100 P.S.I. @ 60scfm 100 P.S.I. @ 72 scfm

Electrical Requirements 208/240 v, 3 ph, 17 Amps 208/240 v, 3 ph, 17 Amps

Shipping Weight 7500 lbs. (3402 kg) 8000 lbs. (3629 kg)

Standard Pallet Size 16” x 22” (40.6 x 55.8 cm) 16” x 22” (40.6 x 55.8 cm)

The electrical specifications indicated are based on mathematical calculations which

assume ideal conditions exist for electrical supply line values, material used in the

installation of electrical service and site preparation. Although every effort has been

made to provide accurate electrical specifications, M&R Printing Equipment, Inc., does

not assume any liability for damages, whether consequential or incidental, that may

result from the use of the indicated electrical specifications. M&R Printing Equipment,

Inc.,encourages the use of a licensed Electrician for the installation of electrical service

to this equipment. The equipment when installed must be electrically grounded in

accordance with local codes, or in the absence of local codes, with the National

Electrical Code ANSI/NFPA 70- Latest Edition.

M&R Printing Equipment, Inc. reserves the right to alter specifications in the manufac-

ture of its products.

Specifications

i

IMPORTANT!

16 COLOR

20” x 28” (50 x 70 cm)

26” x 43” (66 x 109 cm)

21’ (6.40 m)

100 P.S.I. @ 72 scfm

208/240 v, 3 ph, 17 Amps

8500 lbs. (3856 kg)

16” x 22” (40.6 x 55.8 cm)

18 COLOR

20” x 28” (50 x 70 cm)

26” x 43” (66 x 109 cm)

22.5’ (6.9 m)

100 P.S.I. @ 72 scfm

208/240 v, 3 ph, 17 Amps

9000 lbs. (4083 kg)

16” x 22” (40.6 x 55.8 cm)

Specifications

SPECIFICATIONS CHALLENGER Series II (AC Models)

MODEL No. 12 COLOR 14 COLOR

Maximum Image Size 20” x 28” (50 x 70 cm) 20” x 28” (50 x 70 cm)

Maximum Frame O.D. 26” x 43” (66 x 109 cm) 26” x 43” (66 x 109 cm)

Total Set-Up Diameter 18’ (5.49 m) 19’ 6” (5.94 m)

Compressed Air Req. 100 P.S.I. @ 21scfm 100 P.S.I. @ 21 scfm

Electrical Requirements 208/230 v, 3 ph, 37 Amps 208/230 v, 3 ph, 40 Amps

Shipping Weight 7500 lbs. (3402 kg) 8000 lbs. (3629 kg)

Standard Pallet Size 16” x 22” (40.6 x 55.8 cm) 16” x 22” (40.6 x 55.8 cm)

The electrical specifications indicated are based on mathematical calculations which

assume ideal conditions exist for electrical supply line values, material used in the

installation of electrical service and site preparation. Although every effort has been

made to provide accurate electrical specifications, M&R Printing Equipment, Inc., does

not assume any liability for damages, whether consequential or incidental, that may

result from the use of the indicated electrical specifications. M&R Printing Equipment,

Inc.,encourages the use of a licensed Electrician for the installation of electrical service

to this equipment. The equipment when installed must be electrically grounded in

accordance with local codes, or in the absence of local codes, with the National

Electrical Code ANSI/NFPA 70- Latest Edition.

M&R Printing Equipment, Inc. reserves the right to alter specifications in the manufac-

ture of its products.

16 COLOR

20” x 28” (50 x 70 cm)

26” x 43” (66 x 109 cm)

21’ (6.40 m)

100 P.S.I. @ 21 scfm

208/230 v, 3 ph, 40 Amps

8500 lbs. (3856 kg)

16” x 22” (40.6 x 55.8 cm)

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

i

IMPORTANT!

6

18 COLOR

20” x 28” (50 x 70 cm)

26” x 43” (66 x 109 cm)

21’ (6.40 m)

100 P.S.I. @ 21 scfm

208/230 v, 3 ph, 40 Amps

9000 lbs. (4083 kg)

16” x 22” (40.6 x 55.8 cm)

Specifications

Carousel Rotation

Bi-directional rotation

Free-wheel capability

Pre-registration performed at the factory

Certification

Panel listed by Underwriter’s Laboratories (UL)

Color Capacity

12, 14, 16 and 18 color models

Control Center

Control panel offers easy navigation, with programming

and prompts in plain language

Digital microprocessor with self-diagnostics

Independent print start/print finish setting

automatically activates and stops print heads in proper sequence.

Multiple print stroke capability

Production speed monitor for more accurate job costing

Test print setting turns individual print heads

on/off during test print cycle

Design and Construction

Improved print heads and pallet arms provide

stability for excellent print quality

Made of rigid steel and aluminum and premium

electronic components

Index System

Adjustable index speed

Servo driven index system for increased speed,

smoothness and consistency

Single or double indexing

Pallet Locator

Synchronizes distance of all pallets from center of press

Pallets

All aluminum

Low profile

Pallet leveling system

Quick release and tool-free for rapid installation

and removal

Rubber coated

Print Area

20” x 28” (50 x 70 cm)

Double index print area: Call for dimensions

Print Carriage Bearings

True close tolerance linear bearing carriage system

for uniform ink deposit

Print Heads

4-point off-contact adjustment on all print heads

Independent print/flood speed controls on each head

Independent print button on each head

Independent reset button on each head

Registration

Enhanced front micro-registration adjustments

Tri-Loc compatible

Visual guides

Screen Clamps

Clamping system holds roller frames without

clamp adapters

Screen Holders

Adjustable rear screen holders accomodate

a wide variety of screen sizes

Compatible with numerous registration systems

including M&R’s Tri-Loc and Newman Pin-Lock

Flip-up front screen holders make setup fast

and mid-run screen changes easy

Squeegees/Floodbars

Calibrated independent and adjustable pressure

settings

Front and rear stop position allows operator to leave

screen clear or flooded (great for water-based inks)

Pressure and angle adjustments independently set

for superior print quality

Stations

14, 16 and 18

Stroke Length

Calibrated stroke length adjustment allows

faster setup

Rear stroke length is adjustable to maximize print

speed and efficiency and to reduce the “working”

of ink

Training

Access to M&R’s Training Center

Warranty

Two Year Limited

Service

24 hour hotline

Options & Accessories

Central Off-Contact

Permits fast, incremental single lever adjustment

of all stations simultaneously

Certification

CE compliant (Built to specifications established by

the European Committee for Standardization)

Control Center

Management Production Software

Modem with cable and module

Revolver print program automatically operates

individual print stations in programmed sequence

and provides multiple flashing with just one flash

unit (Patent No. 5,595,113)

Electrical

Single phase available

Flash Curing

A full range of M&R flash cure units is available

Optic Shirt Detector

Patent No. 5,883,400

Pallets

Wide range of pallet sizes and styles

Print Heads

Variable frequency AC electric drive heads for the

ultimate in print control

Registration

Pneumatic screen clamps facilitate rapid screen

loading and deliver unmatched stability on a wide

variety of screens

Squeegee/Floodbar

Pneumatic squeegee/floodbar locks (includes

tool-free squeegee/floodbar angle adjustment)

Pressure gauge for squeegee on each print head

Stroke Length

Front stroke length adjustment(standard on

AC heads)

Tri-Loc Rapid Registration System

Dramatically speeds setup

Standard Features

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois 7

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

8

Specifications

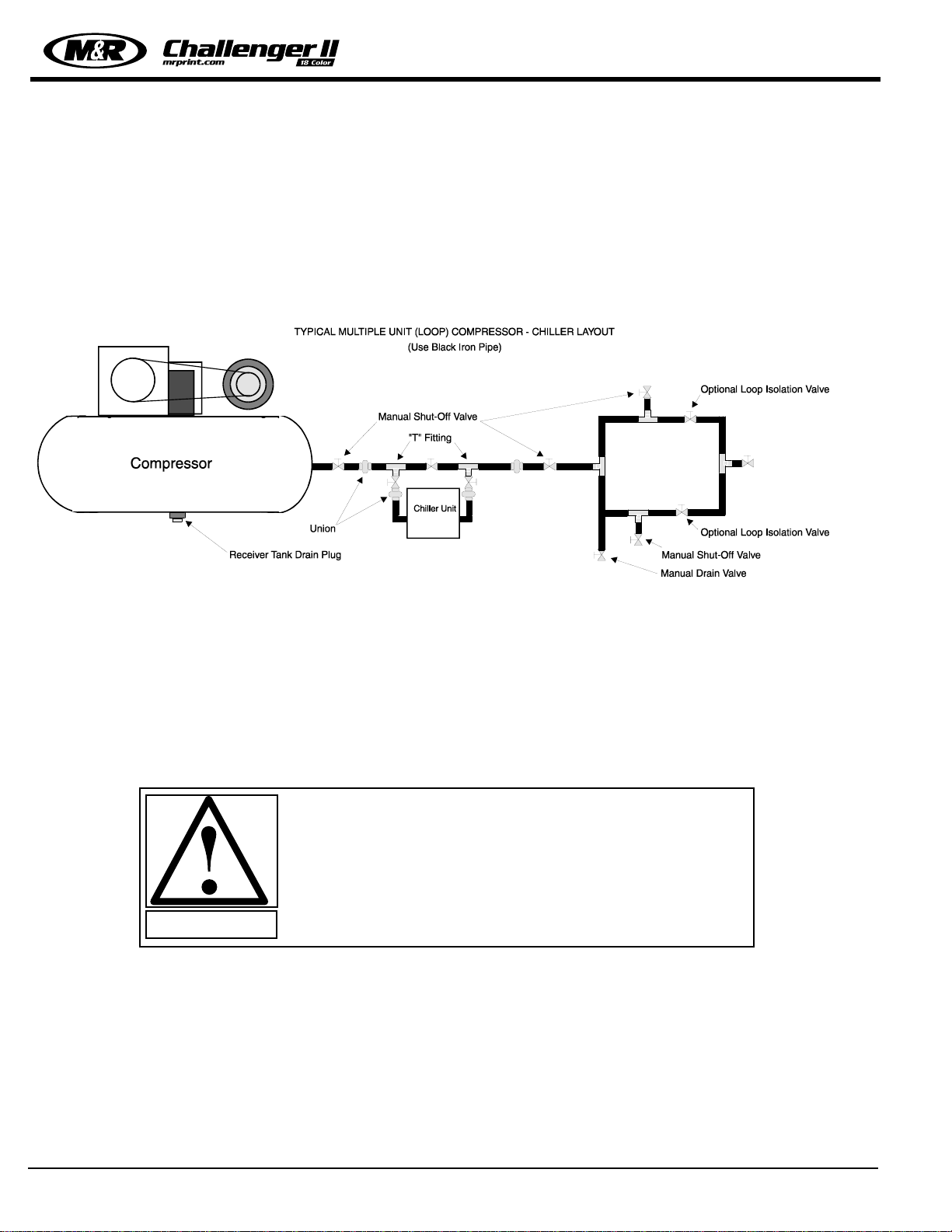

A clean, moisture free compressed air supply is essential for the contin-

ued operation of the M&R Challenger Series II press. We strongly recom-

mend that a refrigerated air chiller be installed in the compressed air sup-

ply line to the Challenger Series II press to prevent moisture damage to

pneumatic seals, valves and air cylinders used in the operation of the print

carriage (See diagram above). Failure to use a refrigerated compressed air

chiller with this equipment may void the warranty for pneumatic compo-

nents such as air cylinders, valves and seals.

Figure 2 Typical Multiple Unit (Loop) Compressor-Chiller Layout

CAUTION!

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois 9

A clean, moisture free compressed air supply is essential for the contin-

ued operation of the M&R Challenger Series II press. We strongly recom-

mend that a refrigerated air chiller be installed in the compressed air sup-

ply line to the Challenger Series II press to prevent moisture damage to

pneumatic seals, valves and air cylinders used in the operation of the print

carriage (See diagram above). Failure to use a refrigerated compressed air

chiller with this equipment may void the warranty for pneumatic compo-

nents such as air cylinders, valves and seals.

CAUTION!

Figure 1 Typical Compressor-Chiller Layout

Specifications

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

10

Specifications

NOTES:

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois 11

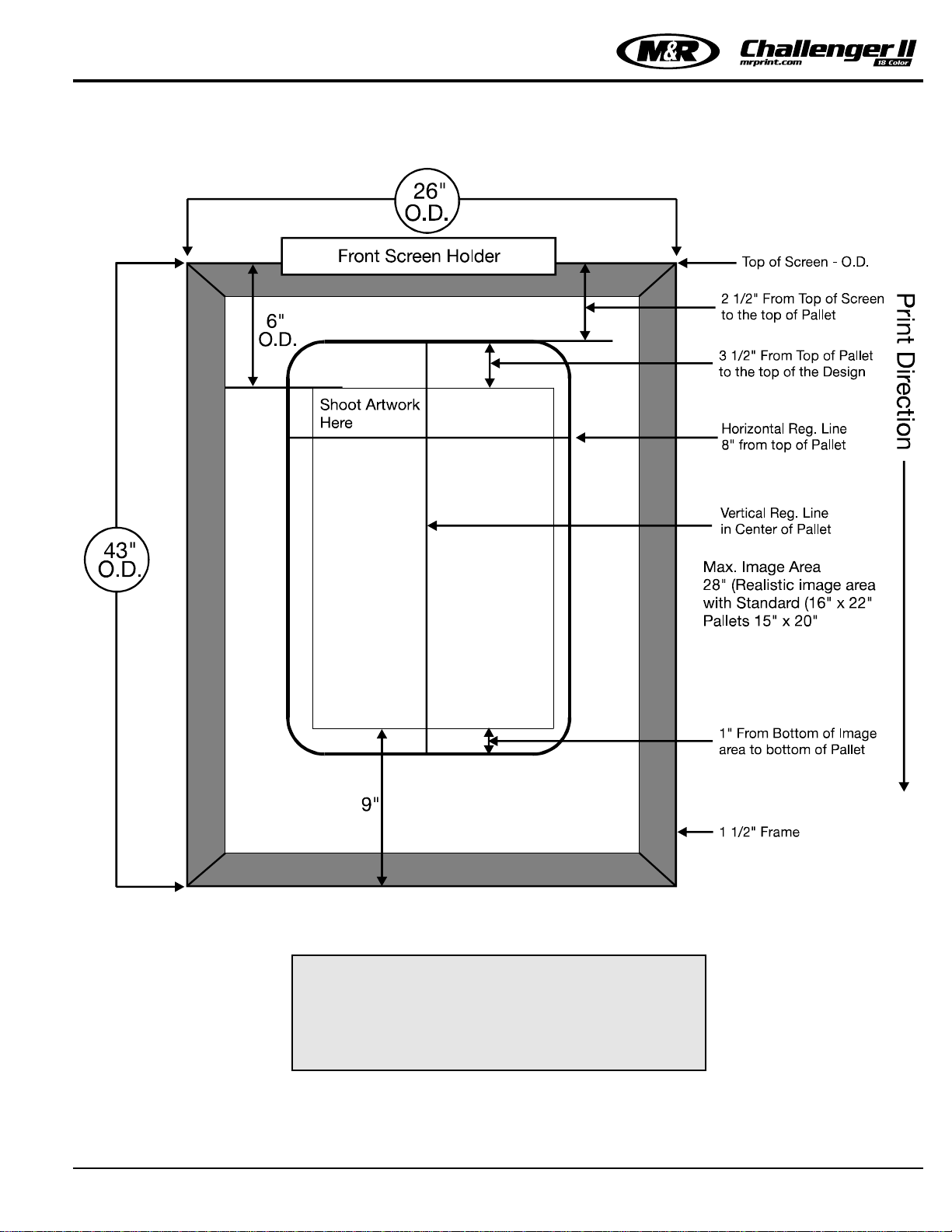

Screen Frame & Image Size

NOTE: Although every effort has been made to provide accurate screen

frame specifications, M&R Printing Equipment, Inc. does not assume

any liability for damages, whether consequential or incidental that may

result from the use or misuse of the indicated specifications. M&R

Printing Equipment, Inc. reserves the right to alter specifications in the

manufacture of its products.

M&R Printing Equipment, Inc. - Glen Ellyn, Illinois

12

Screen Frame & Image Size

Use this chart to determine whether your existing screen frame can be used on the M&R Challenger Series II.

1. Locate where your frames width falls along the left side of the chart.

2. Now find where the frame length falls along the bottom of the chart.

As long as these two dimensions come together within the chart, the frame will fit on the press.

NOTE! 26” wide by 43” long is the maximum screen size when every print station is in use.

This manual suits for next models

4

Table of contents

Other M&R Industrial Equipment manuals