M&R i-Image S User manual

i-Image™ S Bv2

Part # MAN-i-Image S

V.120617

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 3

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

Contents

1. Safety and Operational Guidelines 4

1.1 Management Responsibilities..................................................................................................................5

1.2 Operator Responsibilities.........................................................................................................................6

2. General Information 7

2.1 Service and Parts.....................................................................................................................................8

2.2 Defined Purpose ......................................................................................................................................9

2.3 Warranty...................................................................................................................................................10

3. Specification 11

4. Assembly and Setup 12

4.1 Assembly..................................................................................................................................................12

4.1.1 Site Preparation ...........................................................................................................................12

4.1.2 Power Requirements ...................................................................................................................12

4.1.3 Network and Internet Connections ..............................................................................................12

4.1.4 Power Box....................................................................................................................................13

5. Operation 14

5.1 Machine Operation...................................................................................................................................14

5.2 Main Control Panel - i-Image S................................................................................................................15

5.2.1 Printer Control Panel....................................................................................................................16

5.3 Tri-Sync Bypass Switch ...........................................................................................................................17

5.4 Startup......................................................................................................................................................17

5.5 Shutdown.................................................................................................................................................18

5.6 Printer Control Software (PCS)................................................................................................................20

5.6.1 Print Mode Settings......................................................................................................................21

5.7 Print Preview Software (PPS)..................................................................................................................22

5.7.1 Print preview Toolbar...................................................................................................................22

5.7.2 Importing Files Manually..............................................................................................................23

5.7.3 Importing Files Automatically.......................................................................................................24

5.7.4 File Information............................................................................................................................24

5.7.5 Display Modes .............................................................................................................................25

5.7.6 Printing Files ................................................................................................................................28

6. Art Preparation and Image Placement 29

6.1 Creating and Exporting Images from Photoshop.....................................................................................32

6.2 Creating and Exporting Images from Illustrator .......................................................................................33

6.2.1 Exporting Files from Illustrator.....................................................................................................34

6.3 ColorPRINT RIP.......................................................................................................................................35

6.3.1 Creating Printer Setups................................................................................................................35

6.3.2 Configuring Printer Device Settings.............................................................................................40

6.3.3 Processing Art Files.....................................................................................................................42

7. Scheduled Maintenance 43

7.1 Scheduled Maintenance Log (Based on a 40 hour work week.) .............................................................60

8. Replacement Parts 61

4 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

1. Safety and Operational Guidelines

DANGER

This symbol identifies situations that endanger people, property, and/or equipment. If such conditions exist,

the equipment must be shut down and all energy sources (electrical, gas, and pneumatic) must be disconnected,

purged, and locked out until the problem is resolved.

Never attempt to bypass or defeat any safety device. Do not attempt to operate the equipment if any safety

device is not functioning properly, or if any doubt exists about proper operation of safety devices.

The product described in this publication may operate at high speed and contain numerous moving parts.

It may employ natural gas or propane, mechanical or pneumatic forces, and/or hazardous voltages, and may

create other conditions that could, through misuse, abuse, unauthorized alteration or retrofitting, inattention, or

lack of understanding, result in injury, death, or damage to the product or to other equipment. In addition,

improper operation may also depreciate the value of the machine and other assets of the owner, and impair the

working efficiency of the machine.

Energy Sources

M&R equipment may use one of more of the following energy sources:

Compressed Air (Pneumatic Energy)

Electricity

Gas (Natural Gas or Propane)

Each form of energy presents its own unique hazards and requires appropriate precautions.

Danger From Compressed Air (Pneumatic Energy)

Only qualified personnel should be allowed to work on pneumatic components or assemblies. Before work is

started on pneumatic components or assemblies, equipment should be disconnected from the air supply and all

pneumatic lines should be purged to prevent accidental operation of pneumatic assemblies. All pneumatic pipes

and hoses should be checked frequently for damage and wear.

Danger From Electrical Energy

Only qualified personnel should have access to electrical enclosures or work on electrical systems, and

enclosures should be locked when not in use. Electrical equipment should be checked regularly.

Danger From Gas (Natural Gas or Propane)

Only qualified personnel should be allowed to work on gas components or assemblies. Before work is started on

gas components or assemblies, gas supply valve should be closed and locked. Gas pipes and equipment should

be checked regularly.

WARNING

Failure to follow safety and maintenance procedures or to take appropriate corrected action when required can

result in severe or fatal personal injuries, property damage, and/or damage to the equipment.

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 5

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

1.1 Management Responsibilities

1. Ensure that this equipment is used only for the purposes set forth in the “Defined Purpose” section of

this manual.

2. Ensure that all employees involved with the operation of this equipment or working near it read,

understand, and act in accordance with the operational and safety standards set forth in this manual,

including the Operator Responsibilities listed below.

3. Ensure that all recommended preventive maintenance is carried out according to M&R guidelines.

4. Should any problem arise which compromises the safe operation or normal functioning of this

equipment, ensure that the equipment is immediately shut down, sources of power to the equipment are

shut off and secured, and that personnel not trained to repair - and directly involved in repairing - the

equipment are removed from the immediate area and not allowed to return until the equipment has been

returned to a safe and fully-functional condition.

5. Provide, and compel use of, any personal protection devices that may be required for the safe operation

of this equipment.

6. Make no modification to equipment or equipment software without written approval from M&R.

7. Provide - and support with written documentation - necessary employee training to ensure safe

operation, including but not limited to instruction in:

a. the operation of this machine

b. the use of personal protection devices

c. preventive maintenance procedures

6 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

1.2 Operator Responsibilities

Note: 'Operator Responsibilities' pertain to all employees who work on or near the equipment; this

includes, but is not limited to those who clean, maintain and repair the equipment as well as those who

operate it. In general, all those who work on or near the equipment have a duty to use reasonable and

ordinary care for their own safety when in the vicinity of the machine. Failure to use reasonable and

ordinary care subjects people and property to serious personal injury and/or death and to destruction of

personal and/or company property. M&R expressly disclaims any and all liability, whether in contract, tort

or by statute, for damages, whether in the nature of personal injury/death and/or property damage, and

whether direct, indirect, consequential or incidental, as a result of a failure to use reasonable and

ordinary care.

1. Ensure that this equipment is used only for the purposes set forth in the “Defined Purpose” section of

this manual.

2. Read, understand, and act in accordance with the safety and operational standards and guidelines set

forth in this manual.

3. Install and maintain the equipment and safety devices in accordance with this manual; this includes

checking the equipment and safety devices for external or visible damage at least once per shift, and

making sure all safety and danger notices are in place and in readable condition.

4. Make no modification to equipment or equipment software without written approval from M&R.

5. Ensure that all other employees working on or near this equipment are knowledgeable in its safe

operation, and closely supervise inexperienced employees; keep bystanders away from the equipment.

6. Make sure the area around the equipment is clear and free of obstructions, clean up spills immediately,

and remove ink and other contaminants at the end of each shift.

7. Ensure that any and all safety guards (including but not limited to safety bar, foot switch, yellow cycle

interruption cords, infrared safety beam or hand switches) provided with this equipment for the purpose

of protecting personnel by automatically stopping the equipment are in place - and are not removed,

disabled or rendered ineffective during operation.

8. Wear any personal protection devices required for the safe operation of this equipment.

9. Avoid wearing anything that could become entangled in moving parts; for example, but not by way of

limitation, tie back, pin up, or cover long hair.

10. Do not attempt to operate this equipment if you are sick, fatigued, or under the influence of alcohol

and/or drugs including, but not limited to, prescriptions and over-the-counter medications that warn

against the operation of equipment.

11. Avoid standing on any part of the equipment not intended for that purpose.

12. Immediately shut down the equipment, disconnect and lock out all sources of power (electrical, gas,

and/or pneumatic); and purge all lines under pressure if the equipment fails to be fully operational or if

any safety device fails to operate properly, and ensure that the equipment stays offline until the safety

device is again operational.

13. Perform - and document - preventive maintenance at intervals described in the Operator's Manual.

14. Keep this Operator's Manual in clean, easily readable condition near the equipment at all times so it can

be quickly accessed by operators and maintenance personnel.

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 7

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

2. General Information

This Document

This document is based on information available at the time of its publication. While every effort has been made to

be accurate, the information contained herein does not purport to cover all details or variations in hardware,

software, features, or specifications, or to provide for every possible contingency in connection with installation,

operation and maintenance. Features may be described herein which are not present in all models of this product.

M&R Printing Equipment, Inc. and its subsidiaries reserve the right to alter specifications in the manufacture of

their products, and they assume no obligation of notice to holders of this document with respect to changes

subsequently made.

M&R Printing Equipment, Inc. and its subsidiaries make no representation or warranty, expressed or implied,

whether pursuant to statute or case law with respect thereto, and assume no responsibility for, the accuracy,

completeness, sufficiency or usefulness of the information contained herein. No warranties of merchantability or

fitness for a particular purpose shall apply.

This is a publication of M&R Printing Equipment, Inc. and its subsidiaries. All information contained herein is

derived in part from proprietary and patent data of M&R Printing Equipment, Inc., and may not be copied,

electronically reproduced, or transmitted in any form without prior written permission, in each case made and

provided.

Any product names used in the documentation are used for identification only and may be trademarks of their

respective owners. The M&R Companies does not claim any rights to those marks.

8 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

2.1 Service and Parts

Manufacturer's Rating Plate

Most products manufactured by the M&R Companies have a metal manufacturer's rating plate. Below is a label

imprinted with the information from your product's rating plate. Please be prepared to provide this information

when calling. This helps us respond to your needs more quickly.

If this is a replacement manual, please record the information from your product's rating plate on the sample plate

shown below.

Date Installed

Installed by

Optional Features and Special Information

Contacting M&R

If you need service or have questions about your equipment, call the appropriate number and ask for Technical

Support. If you need parts, ask for the Parts Department.

From the United States & Canada

Monday-Friday between 8:30 AM and 5:00 PM

Central Standard/Daylight Time

800-736-6431 Or 630-858-6101

From all other countries

Monday-Friday between 14:30 and 23:00

Greenwich Mean Time (GMT)

+847-967-4461

Outside Regular Hours

Call our After Hours Service:

+630-462-4715

Visit www.mrprint.com for a list of global

contacts

www.mrprint.com

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 9

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

2.2 Defined Purpose

Textile Presses

Textile Presses are designed to print textile inks on textile substrates, as more fully set forth in the manual specific

to that product. Any other use of this equipment is not permitted.

Textile Dryers

Textile Dryers are designed to cure/dry textile inks on textile substrates, as more fully set forth in the manual

specific to that product. Any other use of this equipment is not permitted.

Graphic Presses

Graphic Presses are designed to print graphic inks on rigid and semi-rigid flat substrates, as more fully set forth in

the manual specific to that product. Any other use of this equipment is not permitted.

Graphic Dryers

Graphic Dryers are designed to cure/dry graphic inks on rigid and semi-rigid flat substrates, as more fully set forth

in the manual specific to that product. Any other use of this equipment is not permitted.

Exposure Equipment

Exposure Equipment is designed to produce photographic printing plates and printing screens, as more fully set

forth in the manual specific to that product. Any other use of this equipment is not permitted.

Folding and Packaging Equipment

Folding and Packaging Equipment is designed to fold, transport, and package textile materials, as more fully set

forth in the manual specific to that product. Any other use of this equipment is not permitted.

Ancillary Equipment

Ancillary Equipment is designed to perform specific operations related to processing and handling of substrates,

as more fully set forth in the manual specific to that product. Any other use of this equipment is not permitted.

Digital Equipment

Digital Printers are designed to print water based inks on textile substrates and screens, as more fully set forth in

the manual specific to that product. Any other use of this equipment is not permitted.

10 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

2.3 Warranty

Limited Warranty

Your Warranty does not apply to damages sustained due to equipment misuse, whether intentional or negligent,

and such misuse may void your warranty. Misuse includes - but is not limited to - the items listed below. In

addition, M&R Printing Equipment, Inc. accepts no responsibility for personal injury or property damage caused by

misuse.

1. Use of the equipment for any non-defined purpose

2. Improper installation or use of the equipment

3. Operation of the equipment with defective safety devices

4. Operation of the equipment with safety devices removed, disabled, not working in whole or in part or in

any manner rendered ineffective for the purpose for which they were designed

5. Failure to comply with instructions for transportation, storage, installation, operation, maintenance,

setup, and take-down of the equipment as described in the Operator's Manual

6. Unauthorized modification of the equipment or equipment software

7. Failure to replace worn or defective parts

8. Failure to use M&R supplied replacement and repair parts

9. Defective repairs made to the equipment

10. Dangerous conditions which result from improper use of the equipment

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 11

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

3. Specification

Specifications 6

i-Image S

Electrical Requirements 1 2,3

208/230 V, 1 ph, 5 A, 50/60 Hz, 1.15 kW

Industrial Printheads

1

Maximum Image Area

51 x 66 cm (20" x 26")

Maximum Screen Frame Profile

4.1 cm (1.63")

Maximum Screen Frame Size

66 x 91 cm (26" x 36")

Overall Size (H x W x D)

127 x 152 x 168 cm (50" x 60" x 66")

Screens per Shift 5

100

Shipping Weight

363 kg (800 lb)

1If incoming voltage differs from the voltage(s) listed in this brochure, calculate amperage accordingly. Other

electrical configurations are available: Contact M&R for details.

2An uninterruptable power supply (UPS) is highly recommended to protect electrical components.

3110 V electrical configuration is optionally available.

5Approximate number of screens the model is capable of printing in an 8-hour shift. Your results may vary.

6Confirm the latest specifications on our website, www.mrprint.com .

12 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

4. Assembly and Setup

4.1 Assembly

Inspection

Carefully inspect for signs of damage in transit. If equipment has been damaged in transit, notify the Freight

Forwarder immediately. M&R is not responsible for damage that occurs during transportation.

4.1.1 Site Preparation

The i-Image S unit is intended to be set up and installed by factory trained service technicians. Any moving of the

unit after installation and calibration may affect the printers quality. It is highly recommended the final position and

location of the machine be determined at the time of installation.

If unit is moved after it is initially setup, re-level for correct operation.

Location must be in a light safe environment, typically in the screen room, away from Power Washers and over

spray. The unit should also be placed away from any source of wind or breeze such as screen drying fans or

heavy traffic areas.

The i-Image S must be setup in a proper working environment. The humidity in the room the machine operates in

must be between 40% and 80%. The temperature in the room the machine operates in should be relatively

comfortable with the temperature not exceeding 85F.

4.1.2 Power Requirements

It is Very Important that the unit be connected to a dedicated electrical service. Any high amperage drawing

devices such as power washers and exposure units can have a direct adverse effect on the printers performance.

The unit is supplied with a standard line cord, however an electrical plug rated for the correct electrical service

must be installed by a licensed electrician. Plug line cord into the receptacle next to On/Off switch on the rear of

the unit.

IMPORTANT: The printer system is designed to be powered up at all times, as maintenance functions

are performed at set intervals to keep the printheads at optimum operational status. Because certain

maintenance functions are performed on a continuous basis, an uninterrupted power supply (UPS) is

recommended.

IMPORTANT: Do not plug other items into the same outlet as power fluctuations may cause printing

problems.

4.1.3 Network and Internet Connections

The unit should be supplied with an Ethernet connection to network with the art department. It is also

recommended to have internet access for the i-Image S to allow remote access for diagnosis and troubleshooting.

Have enough Ethernet cable to reach to the base of the unit and an internal IT support person on hand during the

installation.

14 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

5. Operation

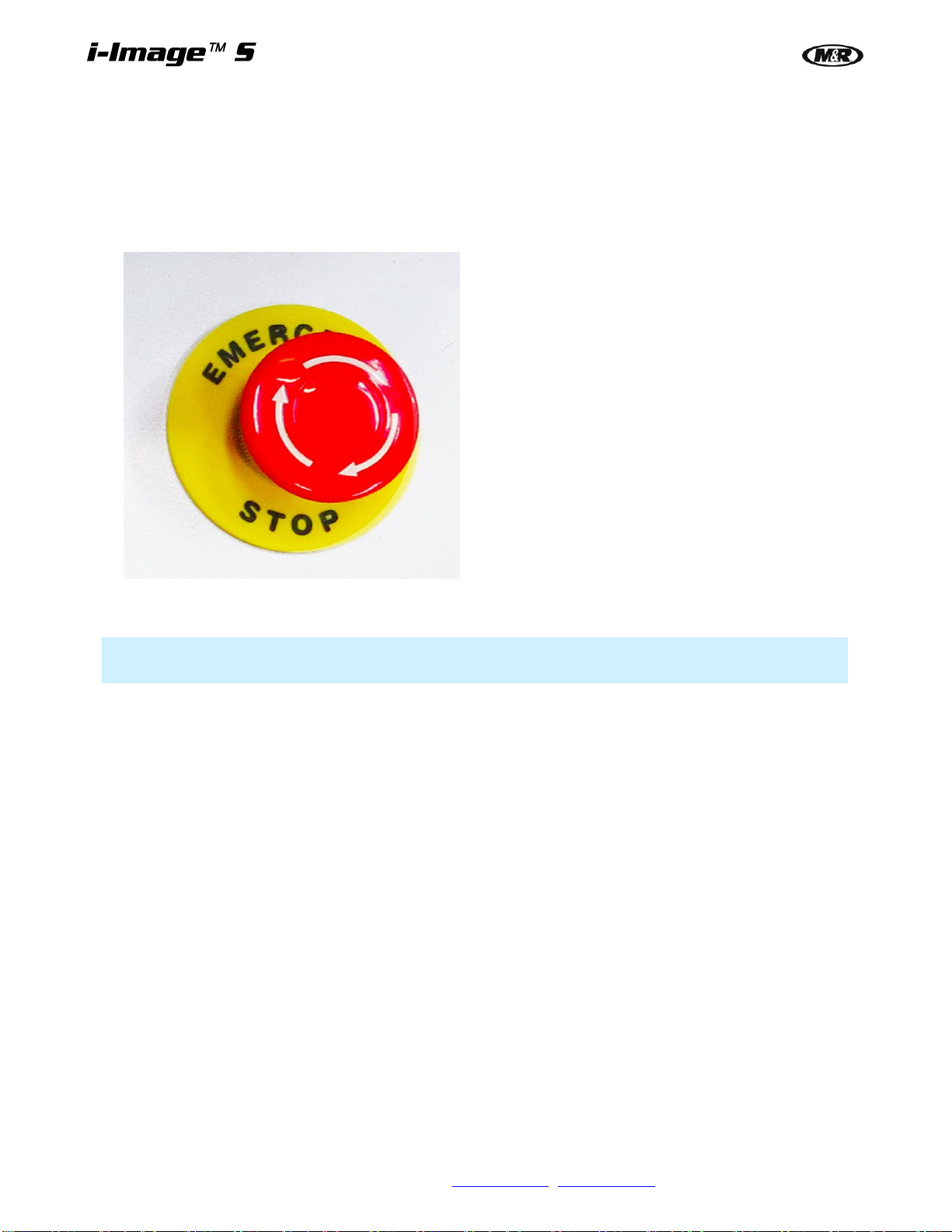

Emergency Stop Button

The red EMERGENCY STOP Button is provided to stop all operation of the equipment in an EMERGENCY

situation. Push the button to activate.

5.1 Machine Operation

IMPORTANT: The computer Operating System should not be upgraded as it may interfere with the i-

Image S programs. Any auto updates can crash the software and any unsaved data will be lost.

The i-Image S is an ink jet printer designed to print a UV blocking dye directly onto the surface of a coated screen,

eliminating the need for film positives. An artist will use ColorPRINT to RIP (or Process) art files. RIP is an

acronym for Raster Image Processor which breaks down art files so the information can be sent and read by the

printer. The files can be sent to the i-Image S workstation via an internal server network (recommended method)

or hand held flash drive. The operator then prints the files directly onto the coated screen surface.

The operating principles of the machine are fairly simple. Ink is supplied to the Printheads using fluid pumps that

draw ink from the main tank located in the base of the machine filling a small sub-tank located inside the

Printhead assembly. The sub-tank has a positive and negative air regulating system that balances the ink

pressure when not in use. This air regulating system is the source of the clicking valves that are heard during

operation.

When the machine is not in use the Printheads will go into a standby mode, known as "Capping." This ensures

the Printhead nozzles stay clean and clear from debris and contaminants. We recommended leaving the machine

powered "ON" during the workweek, even overnight, and fully shut down only for extended periods of five or more

days. This increases the longevity of the valves and ink delivery system. See complete Startup and Shutdown

procedures in this manual for details.

The main components of the i-Image S is the Print Gantry assembly on which the Printhead assembly travels (X-

Axis) and the screen table assembly on which the screen frame is loaded (Y-axis). These components are

controlled by software known as Printer Control Software (PCS). PCS is the interface used by the operator to

control printer functions, such as print modes, cleaning modes and calibrations.

Along with the PCS Software, there is Print Preview Software (PPS) which is used by the operator to import files

and confirm details of each job and color plate being processed.

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 15

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

5.2 Main Control Panel - i-Image S

Number

Name

Function

1

LCD Control

Panel

Used to display information regarding operational, programming, and system

status messages.

2

Print Counter

Display

Used to count the total number of prints.

3

Print Button

Blue button used to start printing process.

4

Power On

Button

Green button turns the power ON.

5

Power Off

Button

Black button turns the power OFF.

6

Emergency

Stop Button

The red Emergency Stop button stops all operation.

To activate, press the button in until it remains depressed.

To deactivate, turn the Emergency Stop button right (clockwise) until it pops

out.

16 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

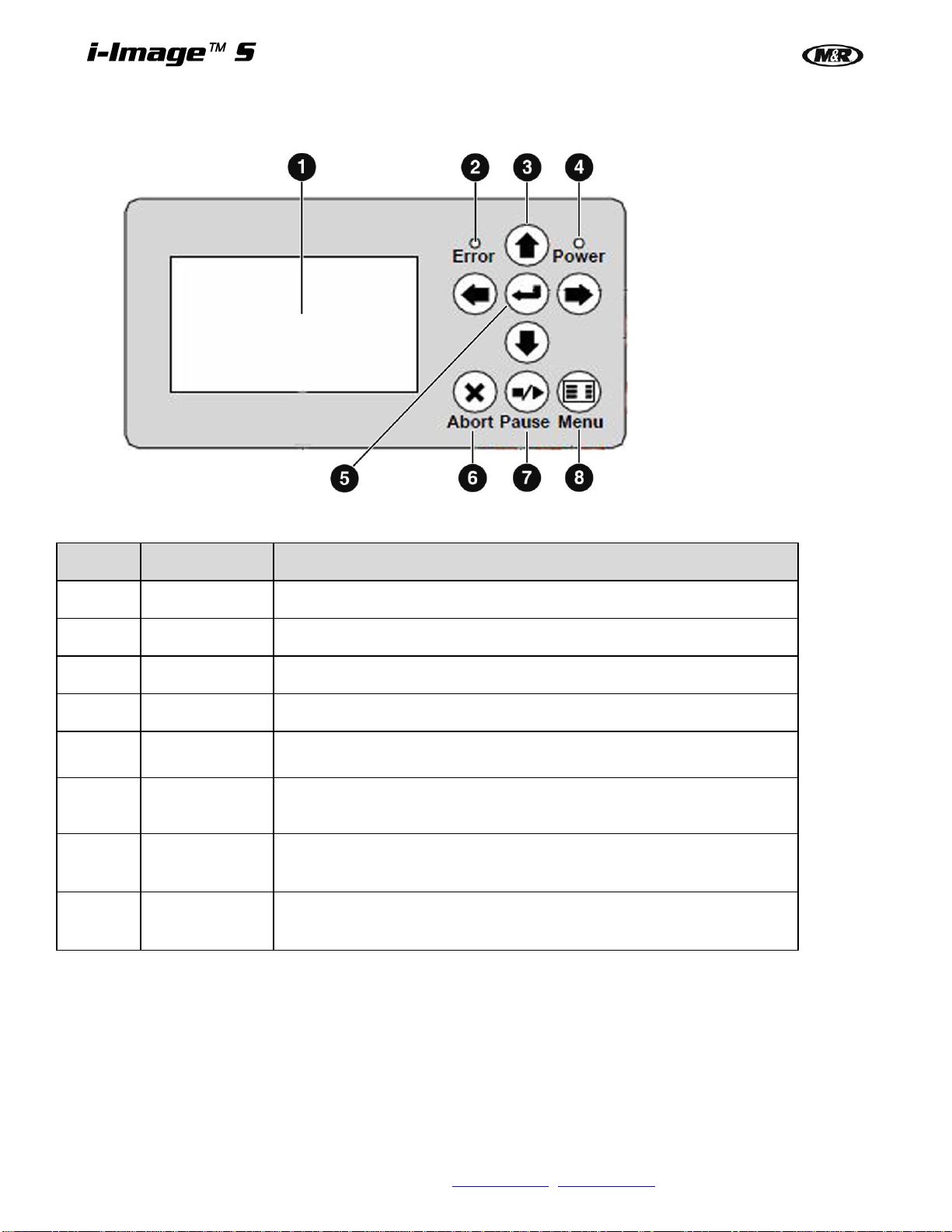

5.2.1 Printer Control Panel

Number

Name

Function

1

LCD Display

Displays operational and diagnostic text messages.

2

Error Light

Flashes (On) when error message is displayed on LCD screen.

3

Arrow Keys

Used to select settings or change parameters.

4

Power Light

Illuminates when the power is On.

5

Enter Button

Used to confirm or enter menu selection. The four arrows move the

printhead and platen while in READY mode.

6

Cancel/Abort

Button

Press to stop the print job and during the Shutdown procedure.

7

Pause/Resume

Button

Press this button to stop the printhead; press the button again to resume

printing.

8

Menu Button

Press this button to toggle between the display of the menus and the

printer status.

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 17

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

5.3 Tri-Sync Bypass Switch

When the Switch (1), which is located under the main control panel is switched to the on position, the Tri-Sync

unit is bypassed.

5.4 Startup

A service technician will turn ON the Main Power on the rear of the unit during the installation and startup.

Note: Only personnel trained on the machine should operate the i-Image S.

IMPORTANT: Before printing, always do a nozzle check. See Printing Nozzle Checks in the

Daily/Scheduled Maintenance section of this manual.

It is recommended that the machine remain powered 'ON' during the work week, even overnight, and fully shut

down only for extended periods of five or more days. This increases the longevity of the valves and ink delivery

system.

1. Turn the Printhead Valve Lever (1) to the down vertical position.

2. Press the Power On button (2) to turn the printer on.

18 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

5.5 Shutdown

1. Turn the Printhead valves Lever (1) up to the vertical closed position. Rotate valve levers up until they

make contact to the metal stop plate.

Note: Follow this procedure for Long term shutdown only.

2. Press and hold Abort button (2) for 3-4 seconds. When the LCD screen displays Do you really want to

turn off the printer? Use Arrow Left key to select Yes and then press the Enter button (3).

3. Press Power Off button (4) to shut down printer.

M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA 19

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

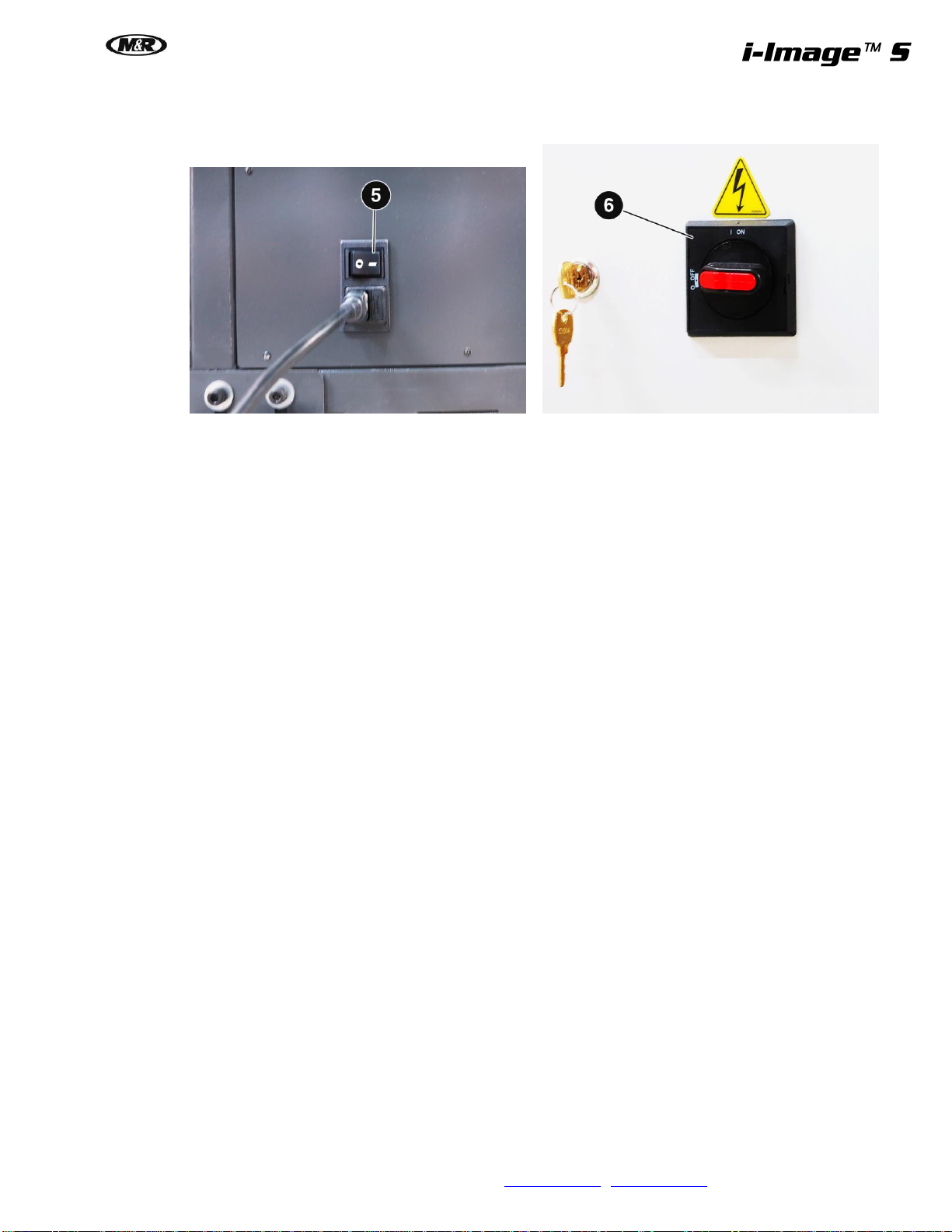

4. If shutting the machine down for an extended period of time, turn OFF the Main Power (5) and Power

Box Disconnect Switch (6) on the side of the unit and shutdown the computer system.

20 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

V.120617

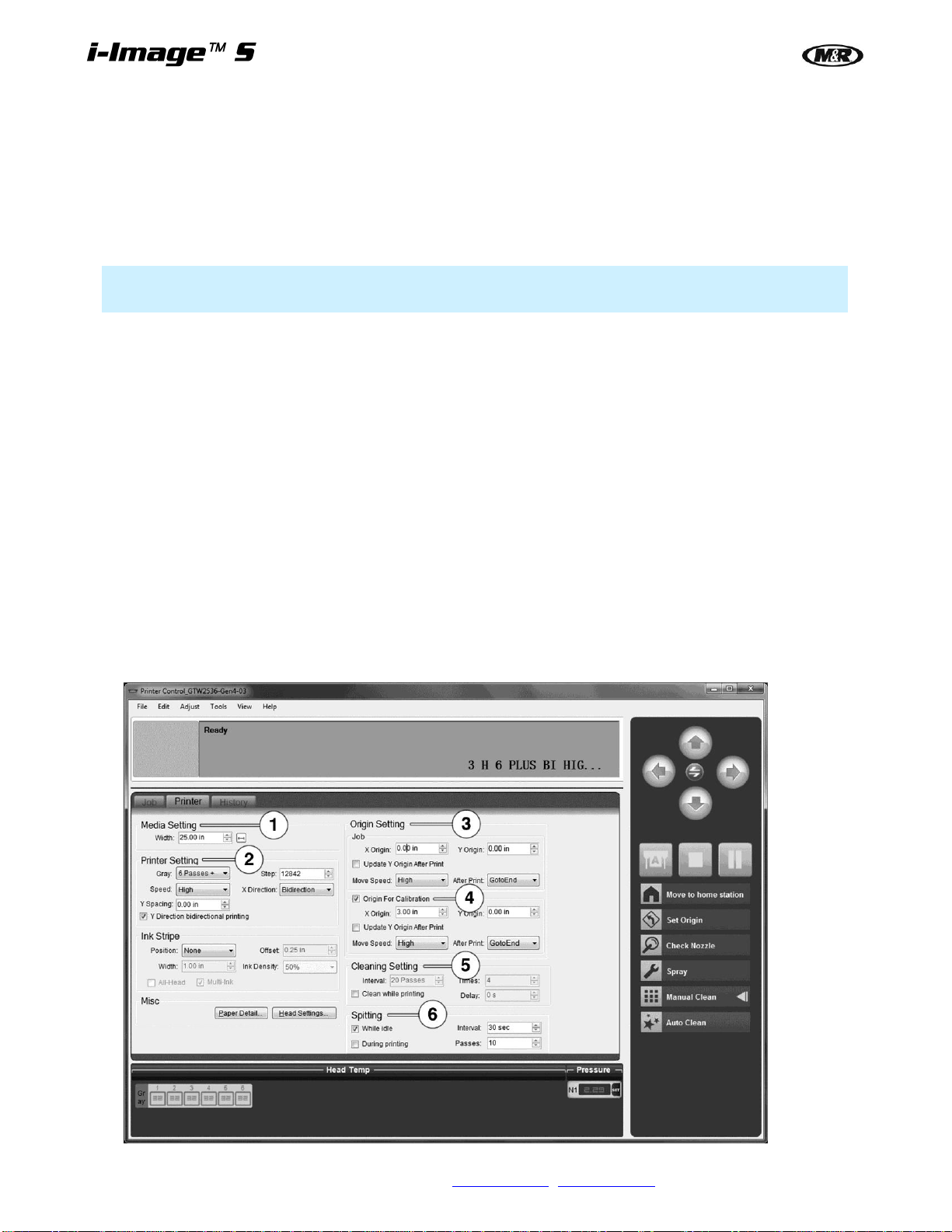

5.6 Printer Control Software (PCS)

Printer Control Software (PCS) is used to control basic day to day functions of the printer such as Print Modes,

Nozzle checks and cleaning modes, as well as automated standby functions and Purge/Wipe/Cap station (PWC)

controls.

PCS Startup

Double click on the PCS desktop icon to open the program.

IMPORTANT: The i-Image S printer must be powered up before the PCS is opened so the software can

connect and interact.

The main Printer Control window displays all the current settings and print modes. The menu bar on the right side

of the screen is used for Nozzle Checks and Cleaning Modes when needed.

PCS Settings

Media Setting (1): Indicates the screen width that is being processed. It can also be overridden by the ripped file

settings.

Printer Setting (2): Indicates Number of Passes, Speed and print modes. This is described in detail in the Print

Mode Settings section of this manual. The i-Image S is 12+ low speed bi-directional only.

Origin Setting (3): The Job origin settings dictate where the image position starts on both X and Y Axes.

Typically both origins are set at Zero and image placement is based off templates from the art department.

The Origin for Calibration (4) is used when printing Nozzle checks giving the operator control over the Nozzle

Check placement.

Cleaning Setting (5): Is factory set to clean when the machine is idle or during start up after a given time period.

Typically the Clean while printing is left unselected or OFF.

Spitting Setting (6): The PCS sends a signal every 30 seconds (interval time setting) for the printhead to fire or

spit ink through the nozzle plate when While idle is selected. This ensures the nozzle ports stay open and free of

air pockets. During printing is left unselected.

Table of contents

Other M&R Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Posch

Posch LogFix 30 operating instructions

SANI Membranes

SANI Membranes Vibro-I 2 Series manual

PRÜFTECHNIK

PRÜFTECHNIK 4.621. EX operating instructions

ABB

ABB HT565244 Operation manual

PCB Piezotronics

PCB Piezotronics 080A153 Installation and operating manual

ABB

ABB Zenith ZTS T Series Operation, maintenance, and installation guide