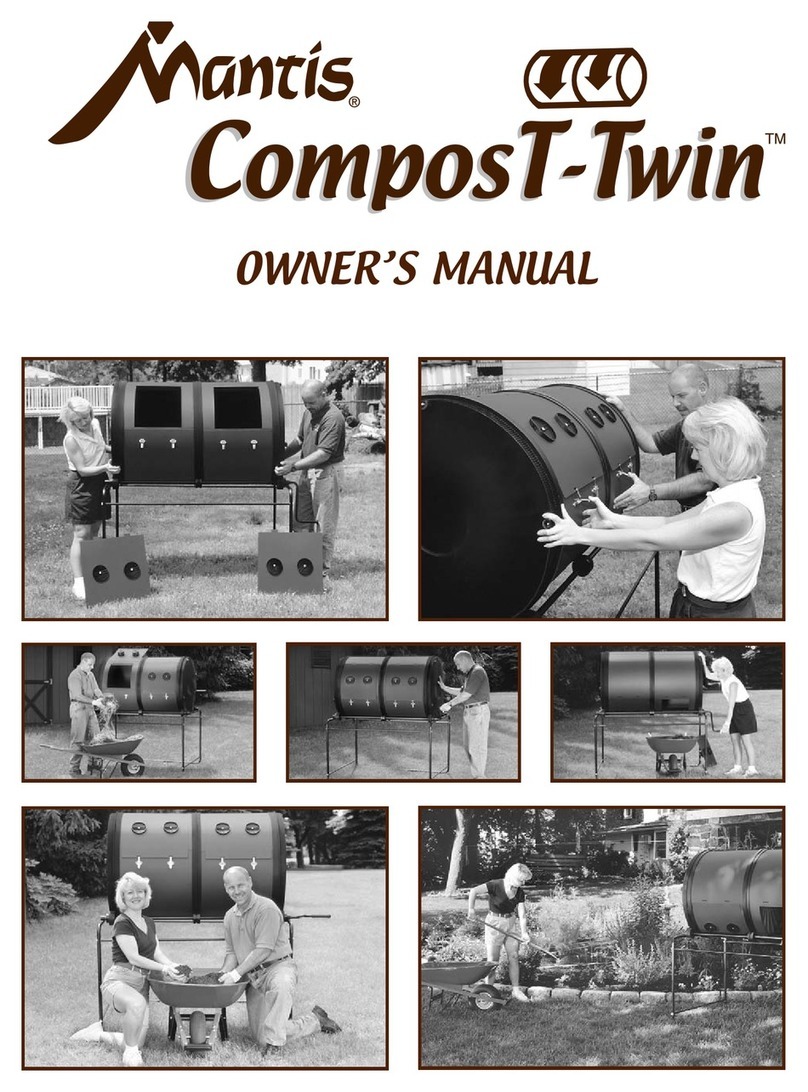

Welcome to the world of Mantis gardening!

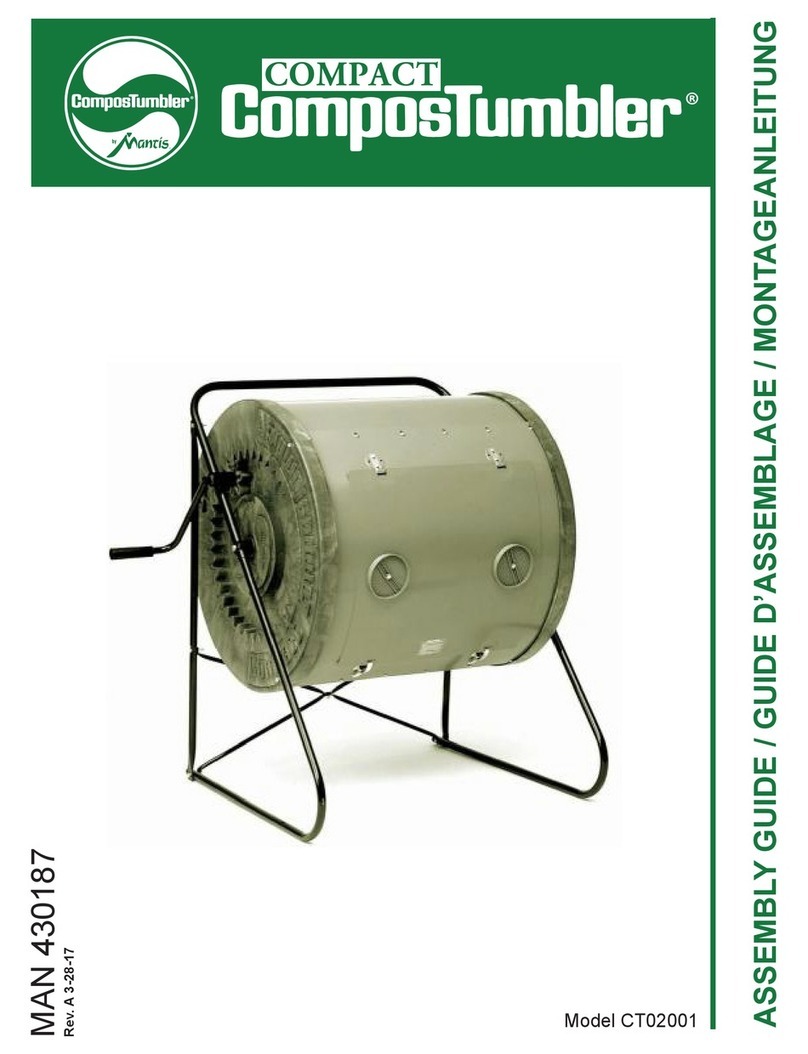

Here’s your new Mantis ComposT-Twin...the

unique dual-chamber composter that will

make gardening easier for you.

With your new ComposT-Twin, you’ll always

have a place to throw your kitchen scraps,

leaves and grass clippings...and you’ll have

aconstant supply of the rich, nutrient-filled

compost your garden loves.

Once you know how to assemble and use

your ComposT-Twin correctly, we guarantee

you’ll love it. So first, please read this

manual and watch the enclosed assembly

video. They show, step by step, how to

assemble your machine and how to get the

best results.

Safety rules & warnings

You will notice throughout this owner’s manual safety

rules and important notes. Make sure you understand

and obey these warnings for your own protection.

An important part of the safety system

incorporated in this composter is

the information label found on the

door of the composter. This label

must be replaced in time; it is your

responsibility to replace this label

when it becomes hard to read. The

location of this label, part number

(P/N 200600), is illustrated on page

42.

Table of contents

Safety rules & warnings .......................................... 41

Safety labels ............................................................. 41

Box contents ............................................................ 42

Support frame assembly ......................................... 44

Support frame assembly layout ............................. 44

Support frame parts list .......................................... 45

Drum parts list ......................................................... 48

Drum assembly layout ............................................. 49

Drum assembly ........................................................ 50

Maintenance instructions ....................................... 55

Using your ComposT-Twin ...................................... 55

The right mix of materials ...................................... 56

Using compost ......................................................... 57

Troubleshooting tips ............................................... 58

Limited warranty information ................................ 59

Safety label identification

Warnings

•Check and tighten all of the 2” bolts (part no.

200500) on the frame assembly every two months.

•Keep childen away from the ComposT-Twin.

•Remove the drum from the frame before relocating

the unit.

•Do not overload the ComposT-Twin. Maximum

load is 600 pounds.

Mantis customer service

If you have any difficulty following the assembly

instructions, contact your Mantis representation for

assistance. We welcome your feedback as we strive to

build quality and ease of use into all of

our gardening products.

WARNING:

CAUTION:

(4.87 m)

Place the ComposT-Twin on smooth level ground.

Remove the ComposT-Twin door when emptying compost.

Keep hands and loose clothing away from gears when

turning the ComposT-Twin.

Balance the load inside the chambers before you release

the handles.

WARNING:

41

GB

SAFETY WARNING

ATTENTION: THIS SYMBOL POINTS OUT

OUR IMPORTANT SAFETY INSTRUCTIONS.

TOREDUCE THE POTENTIAL FOR

ACCIDENTS, COMPLY WITH THE SAFETY

INSTRUCTIONS IN THIS MANUAL.

s

!s

!