Maple Systems HMI5097XL User manual

1010-1018 Rev 06 www.maplesystems.com

Introduction

Thank you for purchasing a Maple Systems HMI5000L Series graphic

industrial operator interface terminal. This booklet describes the steps

necessary for installing the HMI5043L, HMI5043LB, HMI5070L,

HMI5070LB, HMI5070NL, HMI5097XL, HMI5097NXL, HMI5100L,

HMI5121XL, and HMI5150XL models. The HMI5000L Series

touchscreens are configured using the EZwarePlus software (purchased

separately).

For information on programming and configuring the HMI, please refer to

the EZwarePlus Programming Manual (P/N 1010-1015) available on

the EZware software DVD.

For additional information, please refer to the Support Center section of

the Maple Systems website, www.maplesystems.com. The Support

Center provides links to information such as Manuals, FAQs, Technical

Notes, Training Videos, Sample Projects, Controller Information Sheets,

and Controller Cables.

Static Awareness

Do NOT remove the rear cover of the HMI5000L Series product –doing

so will void the warranty. When the rear cover is removed the circuitry

inside is exposed to possible damage by electrostatic discharge during

handling.

Minimize the possibility of any electrostatic discharge by:

Handling the HMI at a static-free, grounded workstation.

Discharging personal static by grounding yourself prior to

handling the HMI.

Connecting the chassis ground (FG or ⏚) connector of the HMI

to a clean earth ground.

Placing the HMI in an antistatic bag during transport.

HMI5000L Series

Installation Guide

2 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

Unpacking the Unit

Carefully unpack the HMI. Check all material in the container against the

packing list. Maple Systems will not accept responsibility for shortages

against the packing list unless notified within 30 days. The equipment

and accessories were inspected and tested by Maple Systems before

shipment. Examine the equipment carefully; if any shipping damage is

evident, notify the carrier immediately. Maple Systems is not responsible

for claim negotiations with the carrier. Save the shipping container and

packing material in case the equipment needs to be stored, returned to

Maple Systems, or transported for any reason.

Packing List

HMI5000L Series Touchscreen

Power Connector

Mounting Clamps

USB Stick Clamp and Spare Fuse (Not on all models)

HMI5000L Series Installation Guide

Warranty

Maple Systems warrants each product to be free from electrical and

mechanical defects in materials and workmanship for a period of one (1)

year for the LCD display and two (2) years for all other parts and labor

from the date of shipment.

This warranty does not apply to defects in the Products caused by

abuse, misuse, accident, casualty, alteration, negligence, repair not

authorized by Maple Systems, use on current or voltages other than

specified by Maple Systems, or application or installation not in

accordance with published instruction manuals. This warranty is in lieu of

any other warranty either expressed or implied.

Maple Systems liability is limited to the repair or replacement of the

Product only, and not costs of installation, removal, or damage to user

property or other liabilities.

If Maple Systems is unable to repair or replace a nonconforming product,

a refund may be offered in the amount paid to Maple Systems for such

product in full satisfaction of its warranty obligation. Maximum liability of

Maple Systems is the cost of the product.

HMI5000L Installation Guide 3

1010-1018 Rev 06 www.maplesystems.com

Information furnished by Maple Systems is believed to be accurate and

reliable. However, no responsibility is assumed by Maple Systems for the

use of this information, or for any infringements of patents or other rights

of third parties which may result from its use. No license is granted by

implication, or otherwise, under any patent or patent rights of Maple

Systems. Maple Systems retains the right to revise or change its

products and documentation at any time without notice.

Installation of HMIs

CE Compliance

The HMI5000L Series Graphic HMIs have been tested to conform to

European CE requirements, which meet or exceed the noise emissions

and immunity requirements as set forth in the EN55022 (Emissions) and

EN55024 (Immunity) standards. The products are designed to withstand

electrical noise in harsh industrial environments. They also conform to

requirements that limit electrical emissions. However, this does not

guarantee that the products will be totally immune from possible

malfunction in cases where severe electrical noise occurs.

Therefore, follow these guidelines for proper wire routing and grounding

to ensure the proper operation of the HMI5000L.

NEMA Rating

The HMI5000L Series is rated for NEMA 4 (indoor) or IP65/IP66

installations. This means that when the HMI is properly mounted to a

NEMA 4 panel or other NEMA 4 rated enclosure, the front enclosure of

the HMI will provide protection to the inside of the panel from splashing

water, wind-blown dust, rain, or hose-directed water. The HMI must be

installed according to the instructions in this manual to be properly

sealed.

4 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

Environmental Considerations

The HMI5000L is designed to operate in temperatures from 0° to

50°C (32° to 122°F). It is intended for indoor installations and may not be

suitable for use in certain outdoor applications. Avoid installing the

HMI5000L touchscreens in environments with severe mechanical

vibration or shocks. Do not install the HMI in enclosures with rapid

temperature variations or high humidity. Either case will cause

condensation of water inside the device and eventual damage to the

HMI.

Warning: Do not operate the HMI in areas subject to explosion

due to flammable gases, vapors, or dusts.

Warning: Conform to UL508 (ISBN 0-7629-0404-6) machine

safety standards for use in Pollution Degree 2 Environments.

Warning: If wiring can potentially be exposed to lightning or

power surges, use appropriate surge suppression devices.

Safety Precautions

Please observe the following precautions and ensure compliance with all

local and national electrical standards when installing the HMI. Failure to

comply with these restrictions could result in loss of life, serious personal

injury, or equipment damage.

Warning: Do not connect the HMI to an AC power source. This

will cause permanent damage to the HMI.

Warning: A Hard-wired EMERGENCY STOP should be fitted in

any system using an HMI to comply with ICS Safety

Recommendations.

Warning: Do not attempt to use a DC power supply that does

not meet the HMI’s power requirements. This may cause

malfunction or permanent damage to the HMI.

Warning: An internal fuse (except HMI5043L/LB) is designed to

prevent damage from overcurrent conditions; though it is not

guaranteed. DC voltage sources should provide proper isolation

from AC power and similar hazards.

Warning: Do not power the HMI with a DC power supply used

for inductive loads or for input circuitry to the programmable logic

controller. Severe voltage spikes caused by these devices may

damage the HMI.

HMI5000L Installation Guide 5

1010-1018 Rev 06 www.maplesystems.com

Control Panel Design Guidelines

Pay careful attention to the placement of system components and

associated cable routing. This can significantly enhance the performance

and integrity of the control application.

Cable Routing and Noise Immunity

Follow these guidelines when routing cables to the HMI:

Always route the HMI communication cable and the power cable

away from any AC voltage or rapidly switching DC control lines.

Never bundle the HMI cables together with 120VAC power wires

or with relay wiring.

Try to keep at least 8 inches (20 cm) of separation between the

HMI cables and other power wiring. If voltages greater than

120VAC are used in the system, greater separation is required.

If the HMI cables must come near AC wiring, make sure they

cross at 90 degrees.

Run AC power wires in a separate grounded conduit to reduce

electrical noise interference.

Keep the cable lengths for the HMI as short as possible. Do not

coil excess cable and place it next to AC powered equipment.

Cover any equipment used in the enclosure that operates at high

frequency or high current levels with a grounded metal shield.

Power Supply Selection

The power supply used to power the HMI should provide an output of

+24 VDC ±20% measured at the HMI power connector. A 24VDC

regulated power supply dedicated to the HMI is recommended. Use a

power supply with adequate current rating. A power line filter installed at

the AC input to the HMI power supply is highly recommended as a

safeguard against conducted RF noise, which is often present on factory

power lines. The wires connecting the output of the power line filter to the

power supply should be kept as short as possible to minimize any

additional noise pickup. The case of the power line filter should be

connected to a quiet earth ground. The power line filter should have a

current rating of at least 3 Amps with common mode and differential

mode attenuation. In applications that may have high frequency noise

present, a resistor (~1 MΩ) and capacitor (~4700 pF) should be used in

parallel to clean earth ground on the DC output of the power supply.

Do not use the power supply used to provide power to the HMI to power

switching relays, solenoids, or other active devices.

6 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

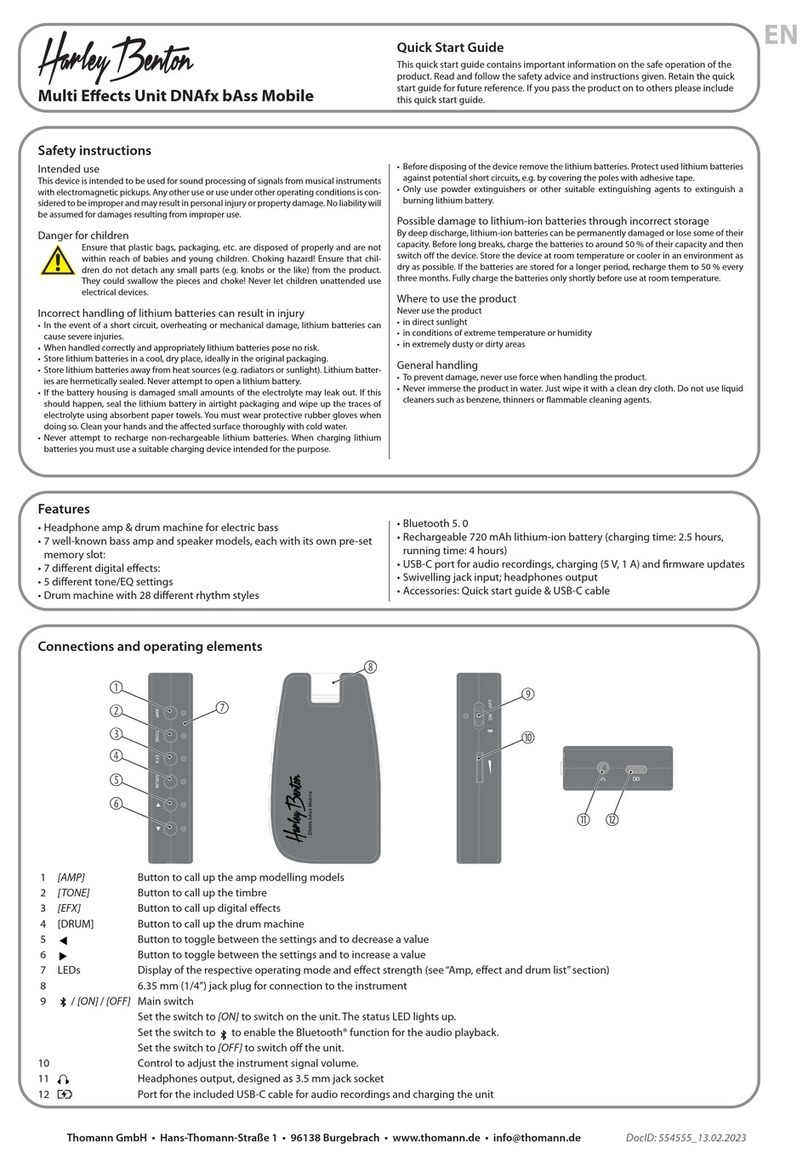

Figure 1: Typical Panel Layout

PLC/Host

Ground wires

HMI is

grounded to

control panel

Ground strap

Quiet ground

(isolated)

AC

Power

Line

Filter

HMI

Power

Supply

Shielded

power cable

Control panel is

tied to a reliable

earth ground

2

1

3

4

5

(rear side)

HMI5100L1

(rear side)

HMI5070L2

2

3

1. Also HMI5121XLand HMI5150XL

2. Also HMI5070LB, HMI5043L, HMI5043LB, HMI5070NL, HMI5097XL, and HMI5097NXL

HMI5000L Installation Guide 7

1010-1018 Rev 06 www.maplesystems.com

Control Panel Grounding

The control panel must be connected to a good, high-integrity earth

ground both for safety considerations and shielding purposes. Maple

Systems cannot overemphasize the importance of good grounding.

Failure to use good grounding procedures during installation may cause

sporadic malfunction of the HMI.

Connect the HMI chassis ground terminal to a reliable earth ground with

a low-resistance path. Refer to Figure 1:

Route all earth ground wires that lead from the HMI, the PLC, the

power supply, and the line filter to a central earth ground point such as a

barrier strip. This will ensure that no ground current from one device

influences the operation of the other devices.

Connect the HMI chassis ground terminal to the control panel using a

heavy-gauge short braided cable (#14 AWG) or ground wire to minimize

resistance. Then, make sure the panel is properly grounded to a clean

earth ground.

Note:If the control panel is made of a non-conductive material, it is

essential that the chassis ground terminal of the HMI is connected to

a clean earth ground point located close to the panel.

Connect the power cable’s shield wire to the HMI’s chassis ground

terminal.

Connect the control panel to earth ground using a copper grounding

rod close to the HMI and control panel.

Hinged doors on control panels do not provide a long-term electrical

connection to the rest of the enclosure. Corrosion develops over time

and prevents good electrical contact. For this reason, a separate wire

braid should be installed from the hinged control panel to the rest of the

enclosure.

For a more in-depth overview of ground wiring techniques, refer to

Technical Note #1027, “OIT Ground Wiring and Electrical Noise Reduction”

in the Technical Notes section of the Maple Systems website.

Installation

It is necessary to follow all installation procedures described in this

chapter for electrical noise immunity and CE compliance. The Maple

Systems HMI is designed to connect easily to a PLC. External rear

connectors provide quick connections for power, communications and

programming wiring.

8 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

Connect the HMI to Power

Use the 3-position connector supplied with the HMI to provide power to

the HMI. The power cable for the HMI should be 18AWG, 2-conductor

wire with a shield drain wire and protective shield (foil/braid). Cable (P/N

6030-0009) may be purchased by the foot from Maple Systems for

constructing power cables.

Always run the DC ground wire directly back to the signal return of the

power supply. Do not use the chassis ground wire as the signal return.

Caution: To prevent possible damage to the HMI, wait ten

seconds after removing power from the HMI before applying

power again.

To connect the HMI to power:

1. Route the power cable from the HMI to the power supply. The power

cable should not be any longer than necessary.

2. Install the cable wires, referencing the chart below (with colors

shown for Maple Systems Cable 6030-0009):

a. Strip the power cable shield to expose 2” of the black and red

wires.

b. Strip about ¼” of insulation from the black and red wires.

c. Connect the red wire to the positive (+) input of the HMI power

connector and the 24V DC positive (+) output of the power

supply.

d. Connect the black wire to the negative (–) input of the HMI power

connector and the 24V DC negative (–) output of the power

supply.

e. Connect the power cable shield wire to the HMI power connector

FG or ⏚input. Connect the other side to chassis ground.

Wire Color

Power Supply Output

HMI Input

Red

+

+

Black

–

–

Shield

Chassis ground

FG or ⏚

Note: The power connector on the HMI5000L Series uses a 3-

position terminal block with screw-down clamps. Lugs are not

required.

HMI5000L Installation Guide 9

1010-1018 Rev 06 www.maplesystems.com

Panel Preparation

To provide a NEMA 4 seal, a metal panel or mounting surface that does

not flex more than 0.010” is required. Thin panels or surfaces may bow

between the mounting clamps and not form a seal with the gasket.

Allow sufficient clearance around the unit for the mounting hardware and

cable connections. Cutout dimensions for each particular HMI model are

available for print and download from the Support Center-Dimensional

Drawings section of the Maple Systems website.

The area of the panel or mounting surface where the gasket comes into

contact must be flat and free of scratches, pits, and other features that

prevent the gasket from sealing properly. If the panel or mounting

surface is not uniform, thick, flat, stiff, or smooth enough, then a sealant

such as silicone may be required.

Note: Clean and deburr the panel cutout before the HMI is installed.

Mount the HMI to the Panel

Note: The clamps for some models may be slightly different than

shown here, but operate essentially the same way.

Steps:

1. Prepare the clamps for the HMI by inserting the screws into the

clamp as shown above. Position the screws so that the ends don’t

protrude past the clamp edge.

2. Set the HMI in the panel cutout and hold it in place until all clamps

are in position.

3. Tighten the screw clamps in an even pattern until the unit is secure.

Recommended torque: 3.5 in/lbs.

Caution: Do not over-tighten the screws; the overlay may warp

or the housing may get damaged.

10 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

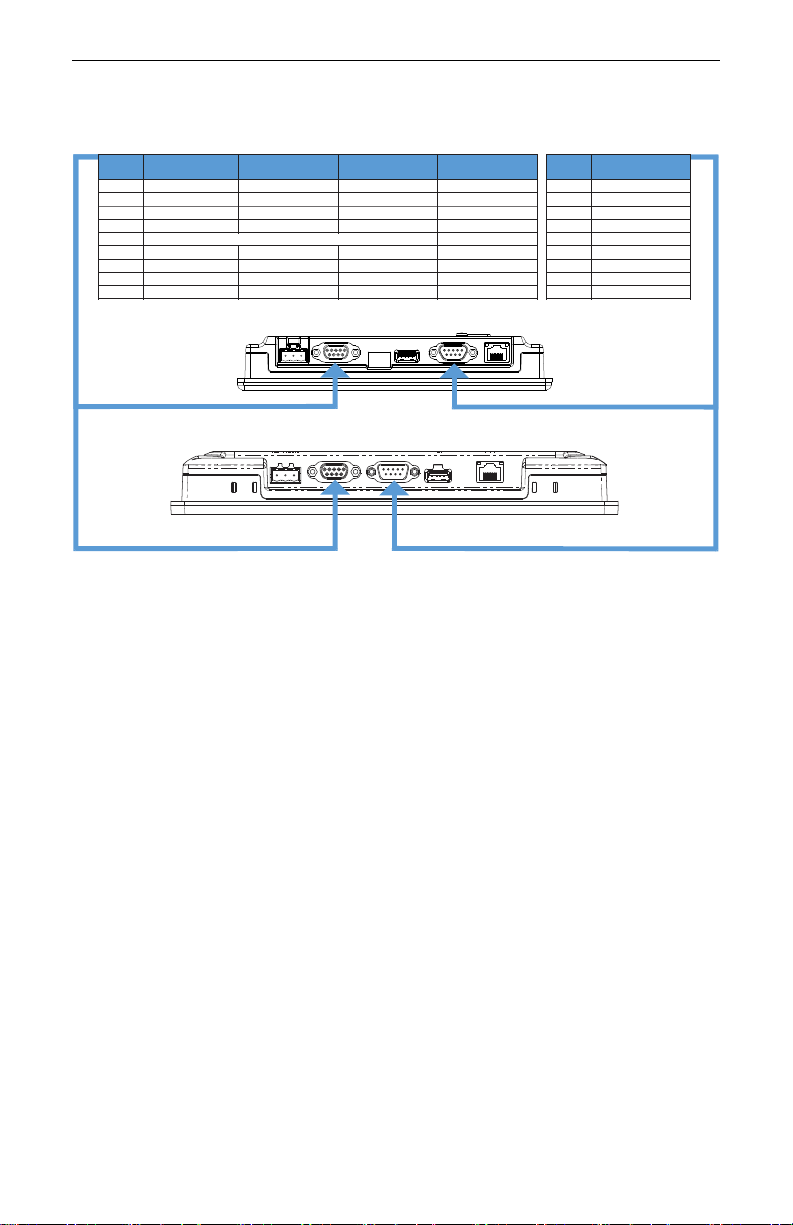

Configuration Wiring

To configure the HMI using the EZwarePlus software, use the Ethernet

Configuration Cable (P/N 7431-0104) or USB Configuration Cable (P/N

7431-0115).

HMI Model

Configuration Cable

P/N 7431-0104

Ethernet (Crossover)

P/N 7431-0115

Mini USB

HMI5043L, HMI5043LB,

X

HMI5070L, HMI5070LB,

HMI5070NL, HMI5097XL,

HMI5097NXL, HMI5100L

HMI5121XL, HMI5150XL

X

X

Ethernet

If using a switch or router between the PC and the HMI, use a straight-

through or crossover cable as required by the switch or router.

USB

A USB driver (included with the EZwarePlus software) must be installed

when downloading from the PC to the HMI via USB connection.

Caution: When connecting two powered devices via USB, a

difference in potential can exist between the ground reference on

each device. If there is a difference in ground potential (voltage),

making a connection via a USB cable can complete a ground

loop that may damage the HMI and PC. We recommend using

the Maple Systems USB Configuration Cable (P/N 7431-0115) to

connect the HMI to the PC. The shield is not connected between

the two ends of the cable, which will prevent a potentially

damaging ground loop from occurring between the devices.

Please refer to Page 6 for proper wiring instructions.

HMI5000L Installation Guide 11

1010-1018 Rev 06 www.maplesystems.com

Maintenance

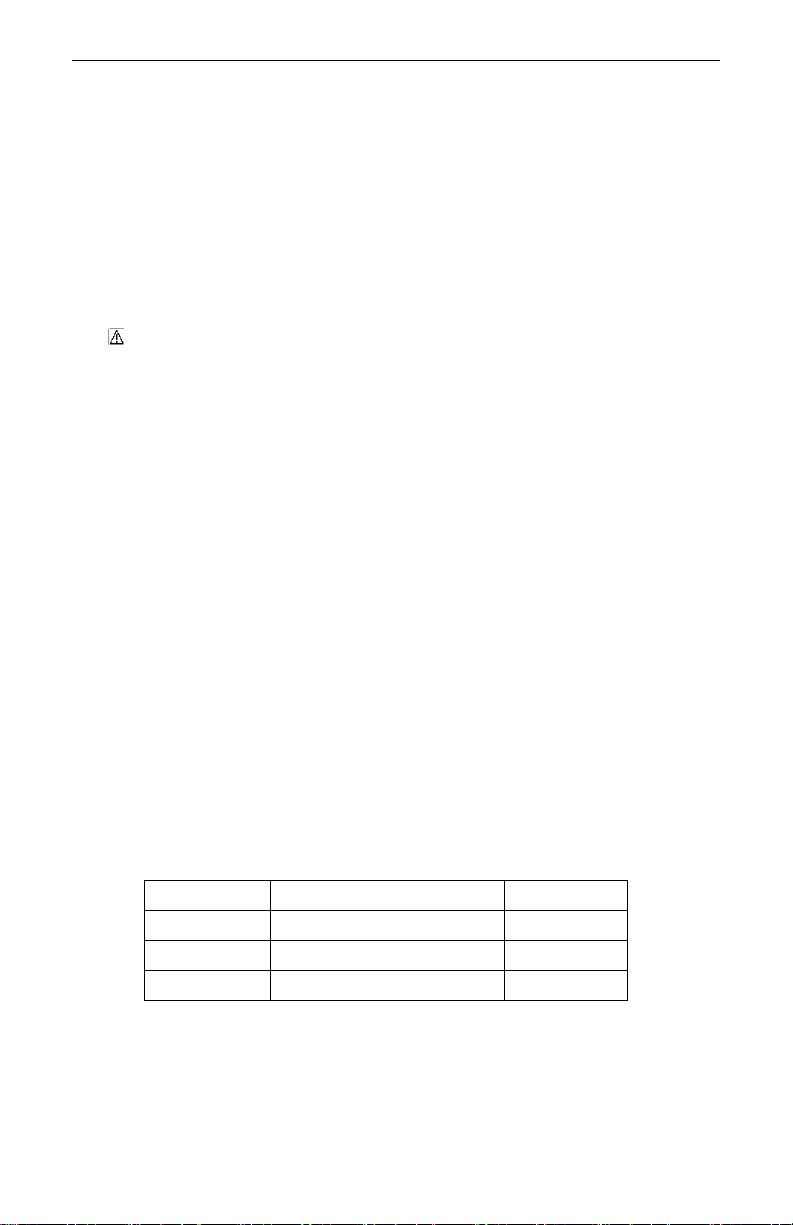

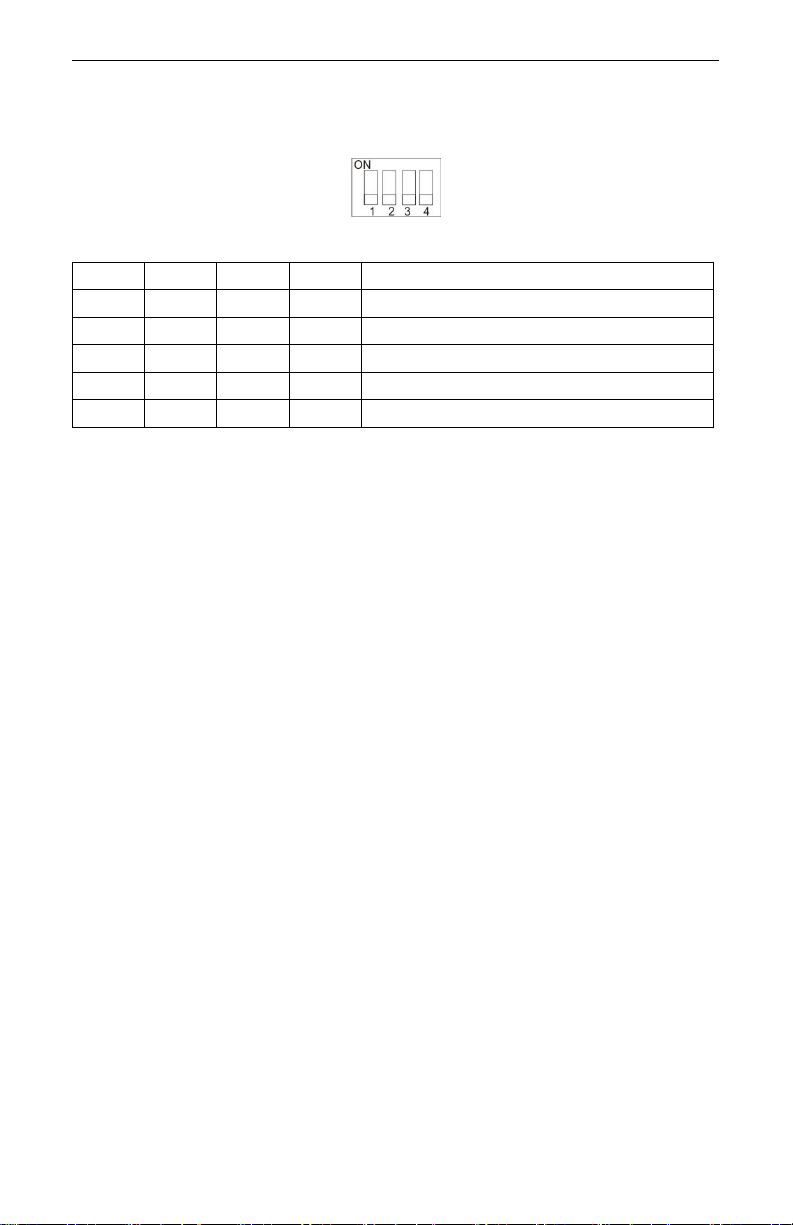

DIP switch positions (not on all models)

DIP switches shown in the off position.

SW1

SW2

SW3

SW4

Mode

ON

OFF

OFF

OFF

Touchscreen Calibration mode

OFF

ON

OFF

OFF

Hide System Toolbar

OFF

OFF

ON

OFF

Boot Loader mode

OFF

OFF

OFF

ON

Reserved

OFF

OFF

OFF

OFF

Normal operation

Note:HMI Power must be cycled to enable the DIP switch mode.

Touchscreen Calibration mode: This mode allows calibration of the

touchscreen.

Hide System Toolbar: Hides the arrow in the bottom-right corner of the

screen that accesses the System Toolbar (same as “Hide System

Toolbar” in System Parameters and LB9020).

Boot Loader mode: This mode forces the HMI to not execute the

project. This mode is used when replacing or reinstalling the operating

system. All units have an Upgrade OS button in the system menus.

Contact Maple Systems for more information.

Fusing Requirements

If the display does not come on within two seconds of power up, remove

power. An internal fuse (except HMI5043L and HMI5043LB) will prevent

damage if the polarity of the DC power is incorrect. Check wiring to

ensure proper connections and try to power up again.

12 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

USB Stick Clamp (not on all models)

The USB Stick Clamp prevents a USB stick from disconnecting from the

HMI due to vibration.

Steps:

1. Insert the USB stick connector into the clamp and secure with the

included zip tie.

2. Press the spring and insert the USB stick into the USB port.

Note: The USB Host port is designed for data storage only. If

connecting a USB hard drive, power the drive with its own power

supply. Do not charge any device from the USB port.

HMI5000L Installation Guide 13

1010-1018 Rev 06 www.maplesystems.com

Serial Port Connections

The following diagrams indicate the proper pin connections for the serial

ports of the HMI5000L Series.

Serial Port Pinouts

Pin# COM1

[RS-232] COM1

[RS-485 4 wire] COM1

[RS-485 2 wire] COM3

[RS-485 2 wire]

1 RX- TX/RX-

2 RX+ TX/RX+

3 TX-

4 TX+

5GND

6 TXD

7 TX/RX-

8 TX/RX+

9 RXD

DE9P

HMI5043L, HMI5043LB

HMI5121XL

HMI5150XL

DE9S DE9P

Pin# COM1

[RS-485 2 wire]

COM1

[RS-485 4 wire]

COM3

[RS-485 2 wire]

1 TX/RX- RX-

2 TX/RX+ RX+

3 TX-

4 TX+

5 GND(COM1)

6

7 TX/RX-

8 TX/RX+

9 GND(COM3)

Pin# COM1

[RS-232]

1

2 RXD

3 TXD

4

5 GND

6

7RTS

8CTS

9

HMI5100L

HMI5070L, HMI5070LB

14 HMI5000L Installation Guide

1010-1018 Rev 06 www.maplesystems.com

Serial Port Pinouts (cont.)

Pin# COM2

[RS-485 2 wire]

COM2

[RS-485 4 wire]

COM3

[RS-485 2 wire]

CANBus

(HMI5097XL only)

1 TX/RX- RX-

2 TX/RX+ RX+

3 TX-

4 TX+

5 GND

6 TX/RX-

7 CAN_L

8 CAN_H

9 TX/RX+

Pin# COM1

[RS-232]

1

2 RXD

3 TXD

4

5 GND

6

7RTS

8CTS

9

HMI5070NL

HMI5097XL, HMI5097NXL

DE9S DE9P

HMI5000L Installation Guide 15

1010-1018 Rev 06 www.maplesystems.com

© 2015 Maple Systems Inc. All rights reserved.

Maple Systems Inc.

808 134th Street SW, Suite 120

Everett, WA 98204-7333

Phone: (425) 745-3229

Web: www.maplesystems.com

Table of contents

Other Maple Systems Recording Equipment manuals

Maple Systems

Maple Systems HMI5043L User manual

Maple Systems

Maple Systems cMT3071 series User manual

Maple Systems

Maple Systems HMC4043A-M Series User manual

Maple Systems

Maple Systems RMI5001 User manual

Maple Systems

Maple Systems HMI5000P Series User manual

Maple Systems

Maple Systems HMI5000B Series User manual

Maple Systems

Maple Systems HMI5043Lv2 User manual

Popular Recording Equipment manuals by other brands

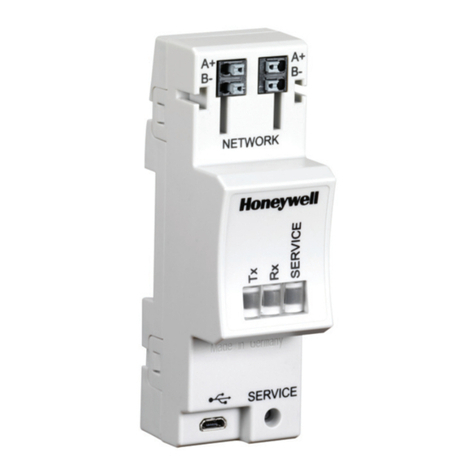

Honeywell

Honeywell IF-LON2 Product Manual and Mounting Instructions

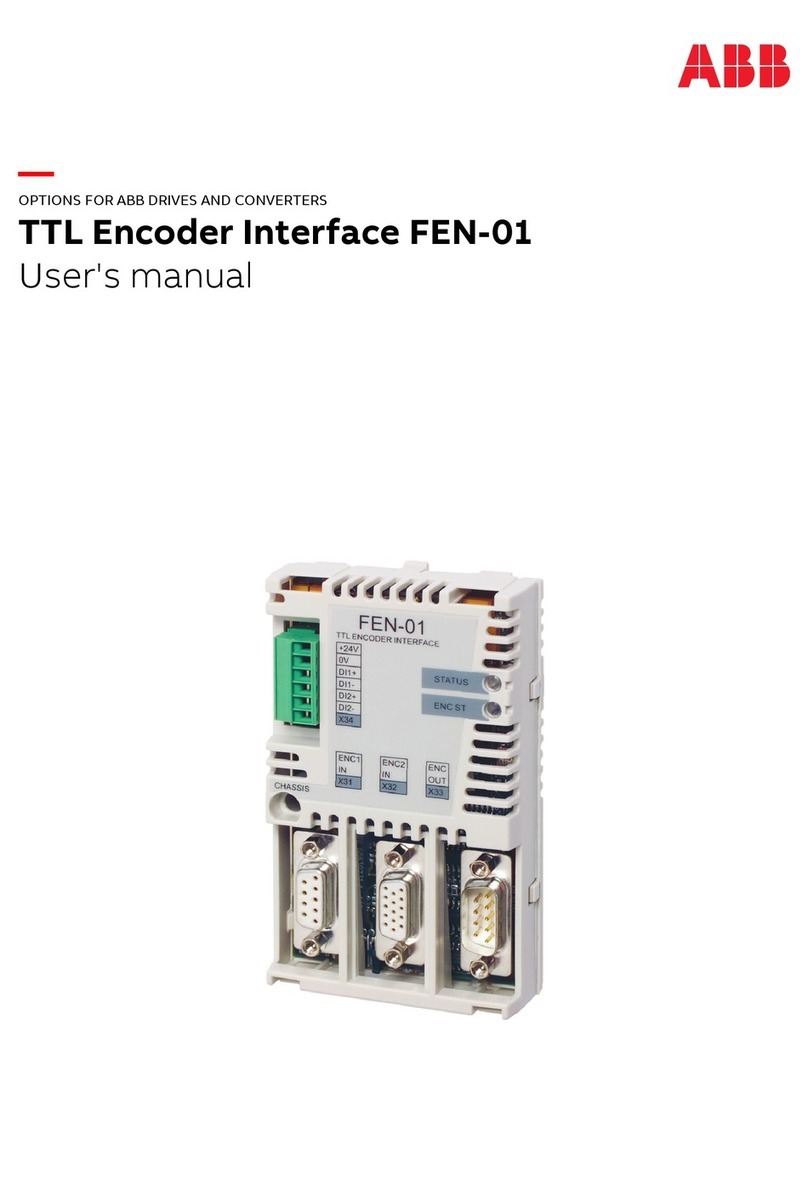

ABB

ABB FEN-01 user manual

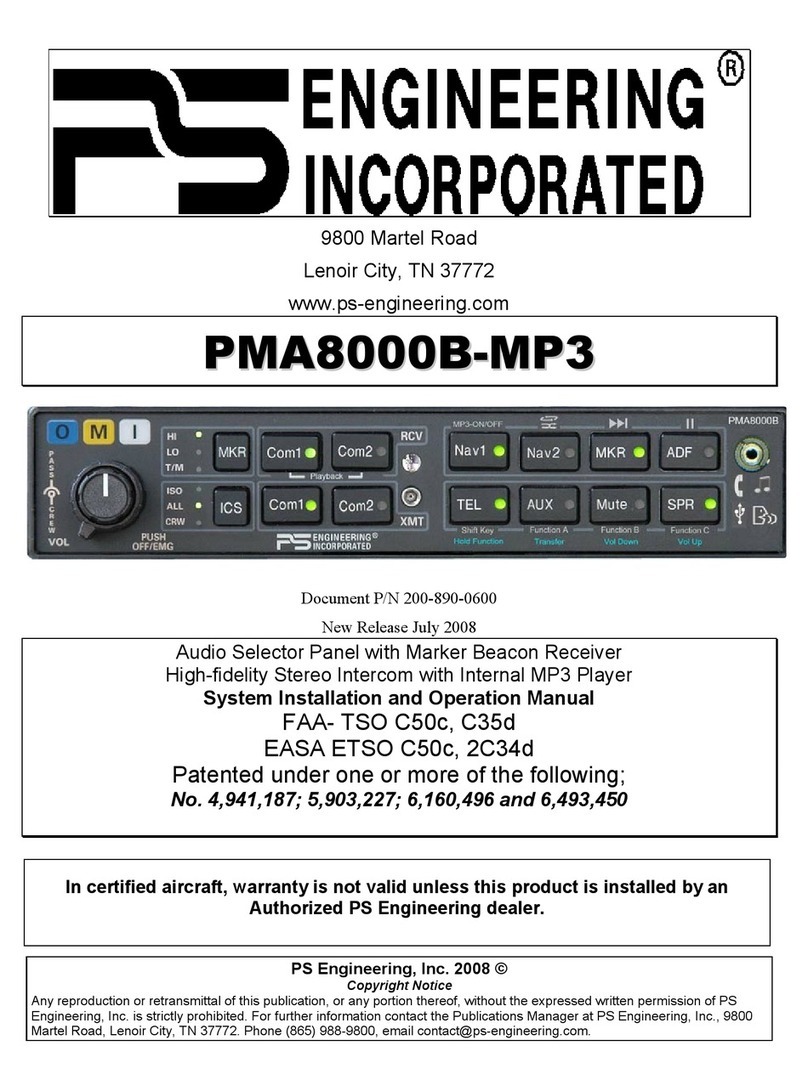

PS Engineering

PS Engineering PMA8000B--MP3 Installation and operation manual

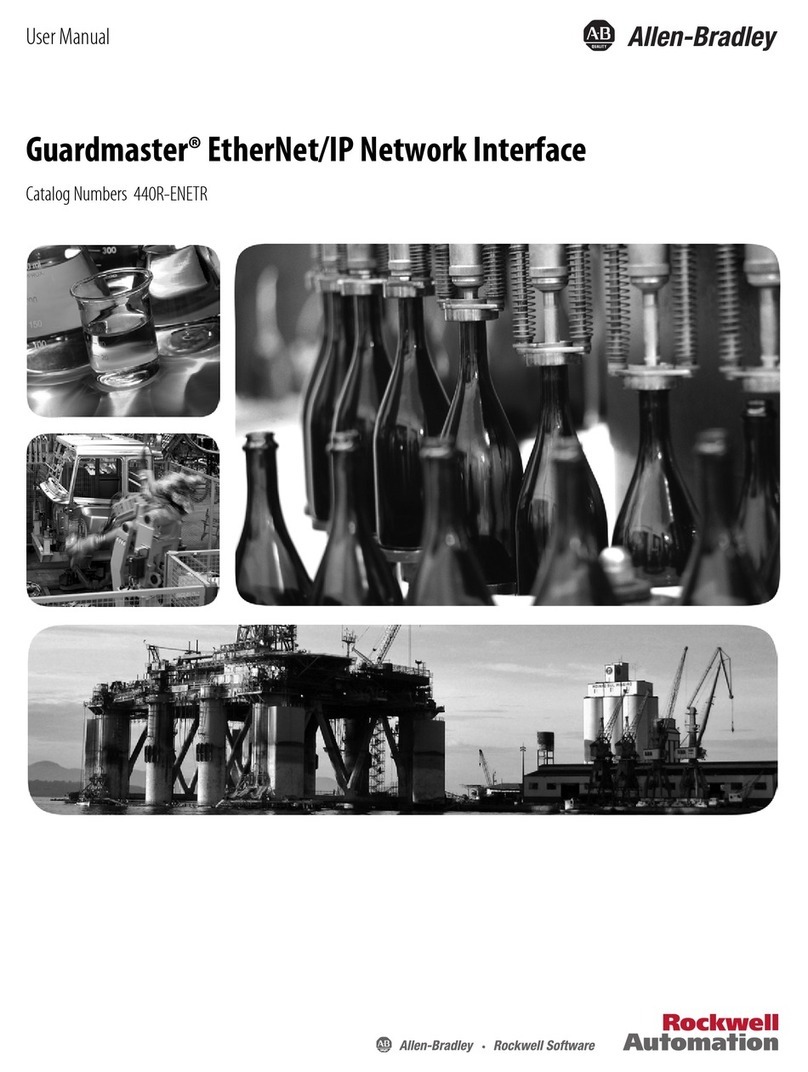

Rockwell Automation

Rockwell Automation Guardmaster 440R-ENETR user manual

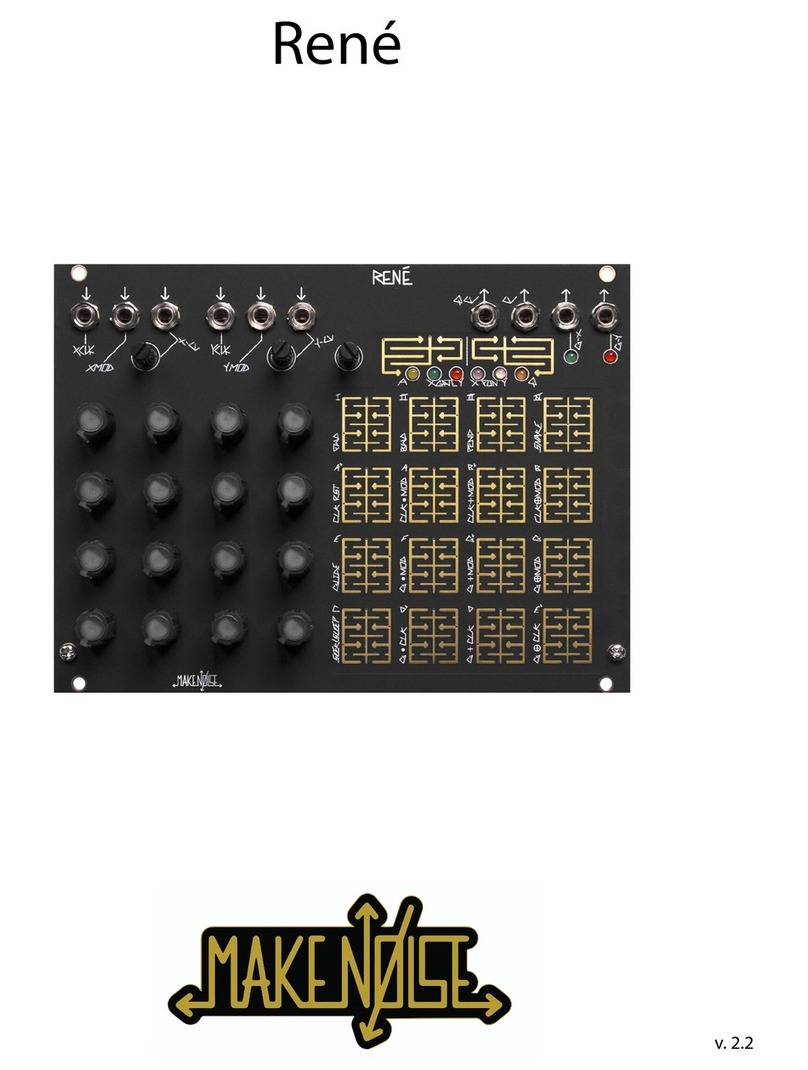

Make Noise

Make Noise Rene user manual

Cochlear

Cochlear Nucleus CP910 manual