1. Legal information

1.1 Declaration of compliance

The manufacturer, MARK Save A Life GmbH, Gleinkerau

23, 4582 Spital am Pyhrn, Austria, hereby declares that the

product described below, “MARK Secure 2”, complies with

the requirements formulated in EN 795:2012 anchor point

type A, which is also the subject of the inspection report

number ZP/B141/17-R1.

Type approval testing by: DEKRA Exam GmbH,

Dinnendahlstraße 9, 44809 Bochum, Germany.

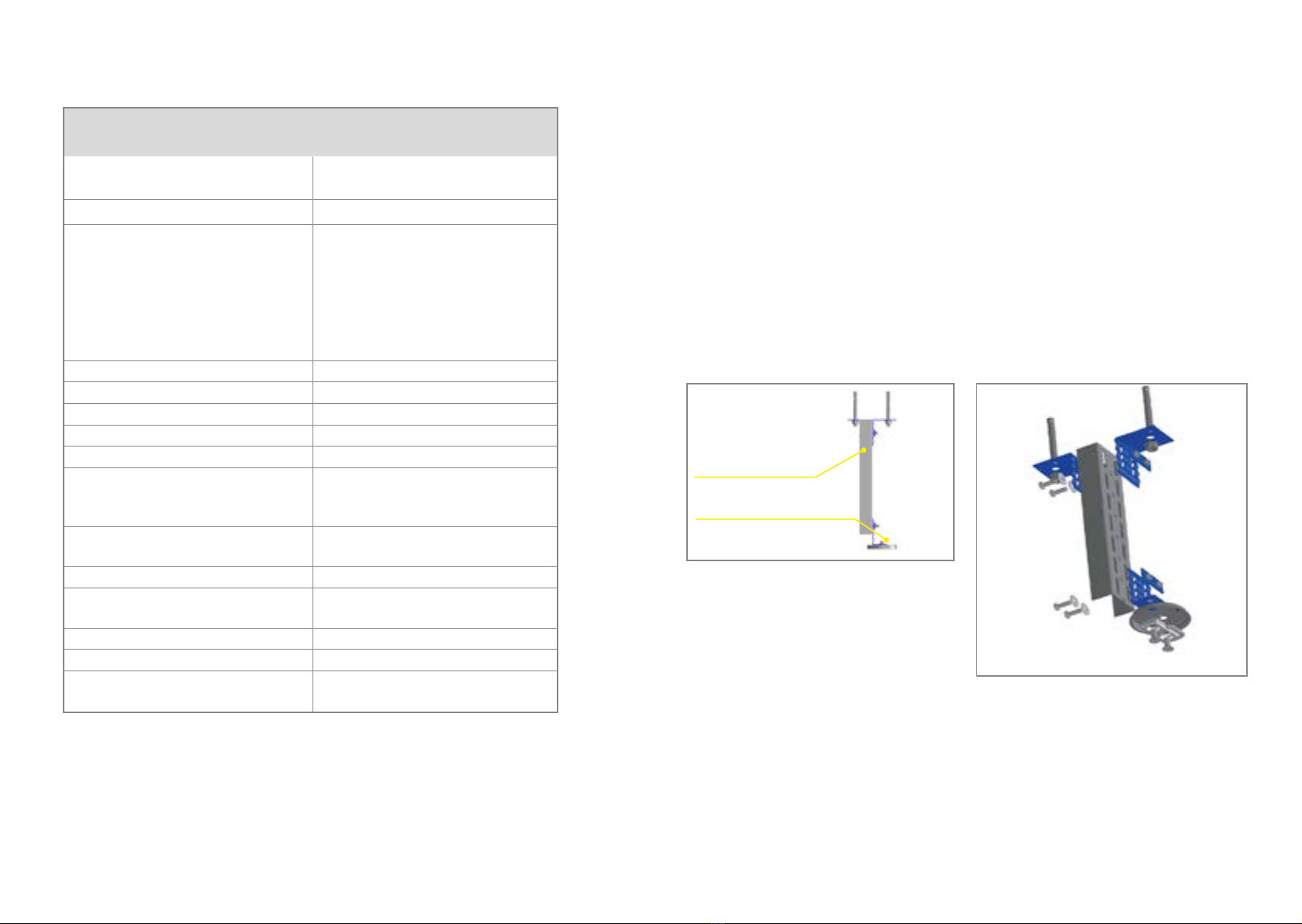

1.2 Labelling

Your product is labelled with a batch number.

Assign your product an inventory number and enter it in the

installation report.

Do not remove any labels from your product!

Manufacturer

Product standard

Personal authorisation

Type designation

Year of manufacture

1.3 Exclusion of product liability

We accept no liability for direct, indirect or accidental

consequences, nor any type of damage arising from the

use of this product or from incorrect information provided

by the competent inspector or installation engineer on the

installation report or the inspection report.

1.4 Copyright notice

The layout, graphics, pictograms and photographs, as well

as all other text and image content found in this instruction

manual are protected by copyright.

2. Use

Activities that require use of this product can often be

dangerous. Therefore observe the safety notices. Please

contact our customer service if you have any doubts or nd

the information difcult to understand. Ensure that the fall

space is calculated so that in the event of a fall you do not

hit an obstacle or impact on the oor.

Protect the product from sharp-edged objects,

welding sparks, sources of re, chemicals, oils,

acids, etc.

Draw up a rescue plan that includes the sequence

and the execution of rescue measures.

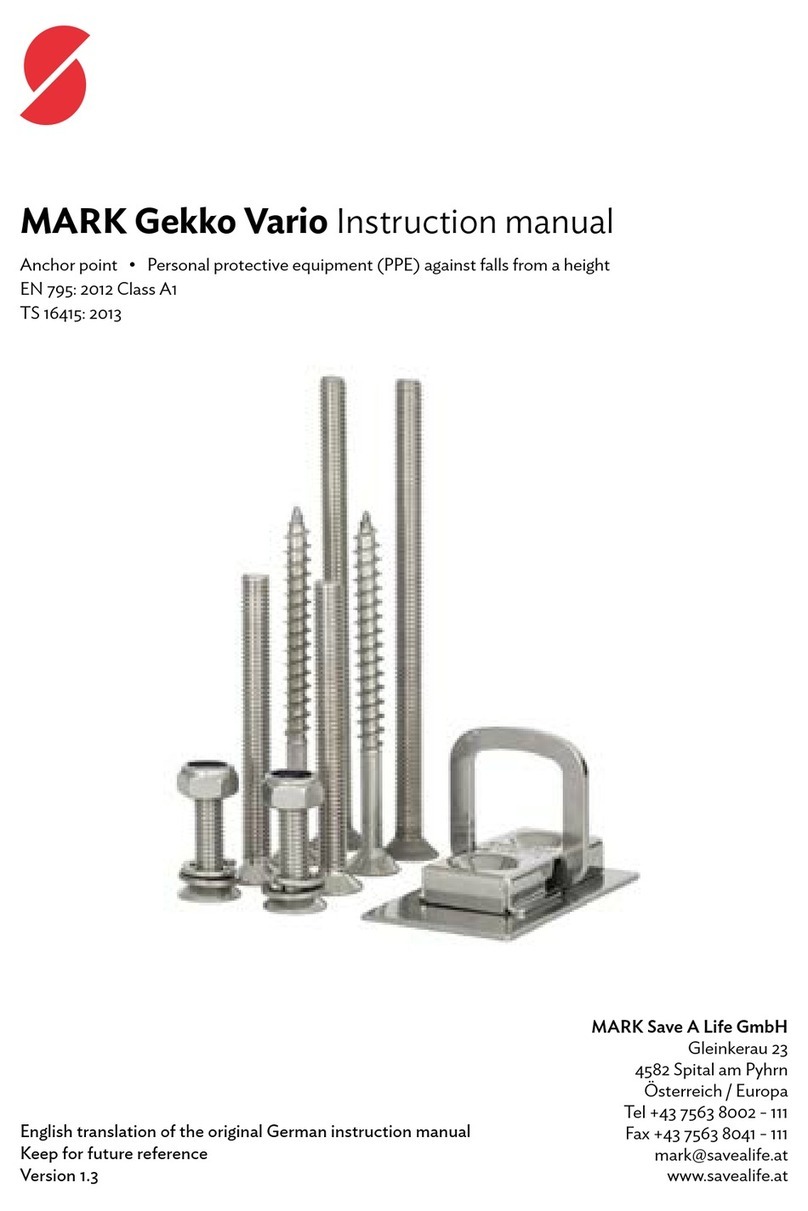

2.1 Intended use

This product may only be used for the purpose described

in this instruction manual (see Point 2.1.1) and only in

conjunction with tested and approved components. It must

not be combined with other components, as this could put

your safety at risk. MARK Secure 2 must be used with

Knauf system components or with similar products with the

same properties.

You may only use this product if you are physically and

mentally capable of doing so, i.e., for example, not if you

are under the inuence of drugs or alcohol, are suffering

from mental strain or have other mental or physical

impairments. In any case, the intended use as protection

against a fall from height requires full physical and mental

aptitude.

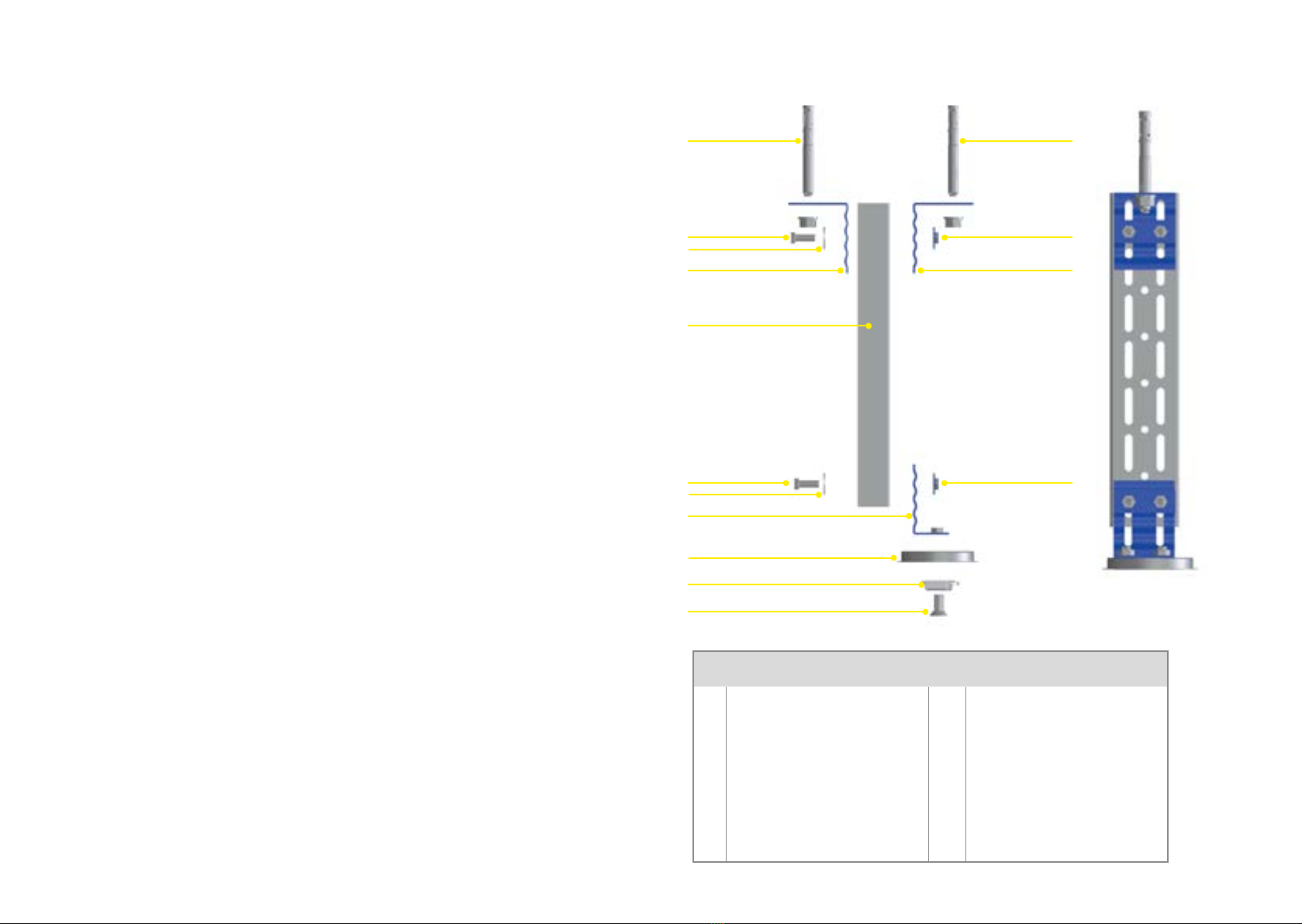

2.1.1 Purpose of the product as an anchor device

according to EN 795:2012 type A

The product may be used within the intended use conditions

on the specied wall and attachment shell systems from

Knauf Gesellschaft m.b.H., or similar products with the

same properties, for the intended purpose as protection

against a fall from height.

Note:

This product is an anchor device, the purpose of which

is to protect the user from a fall from height, either by

preventing a fall (restraint system) or by arresting a

free fall (fall arrest system).

The MARK Secure 2 anchor point is intended for use as

an anchor device in conjunction with personal protective

equipment (PPE) recommended by MARK Save A Life

GmbH (retractable fall arrest blocks, safety overalls and

connectors from MARK Save A Life).

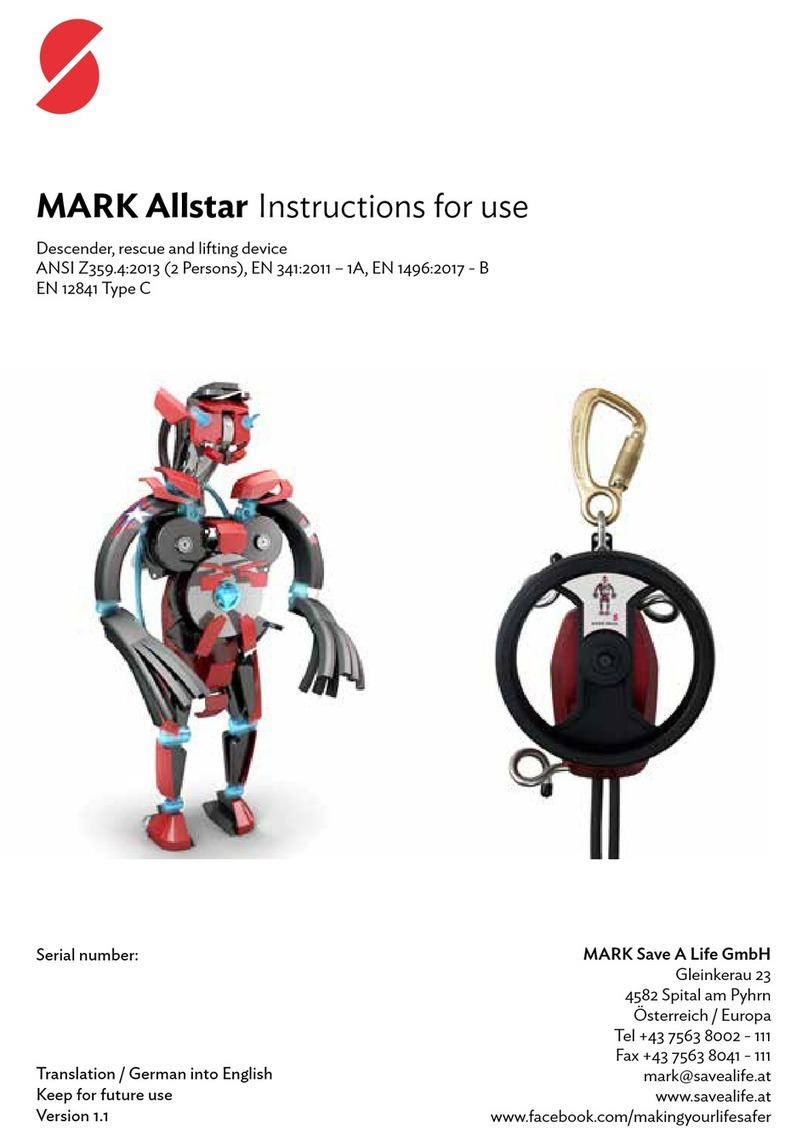

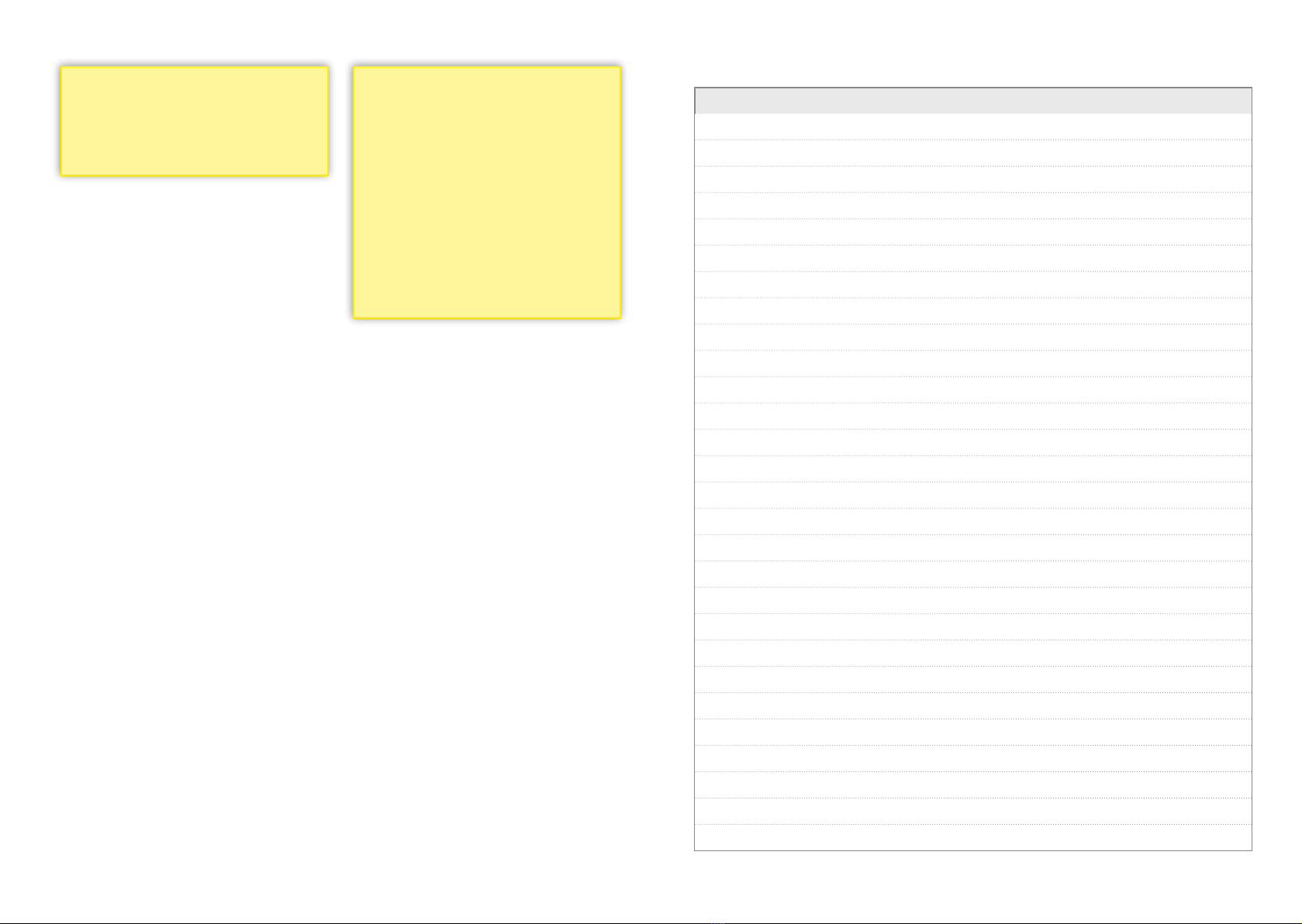

Classed as tested accessories: Test standard

Descender and rescue devices

Lifting devices

Retractable fall arrest blocks

Guided-type fall arresters on

flexible anchor lines

Energy absorbers

Carabiners

Safety harnesses

Safety nets

EN 341

EN 1496

EN 360

EN 353-2

EN 355

EN 362

EN 361

EN 1263

If it seems unsafe to continue using this product, (see Point

8.1) you must not use it again under any circumstances.

Before every use of the product, the user must carry out

a visual inspection according to Point 7 of this manual to

ensure that the product is in serviceable condition.

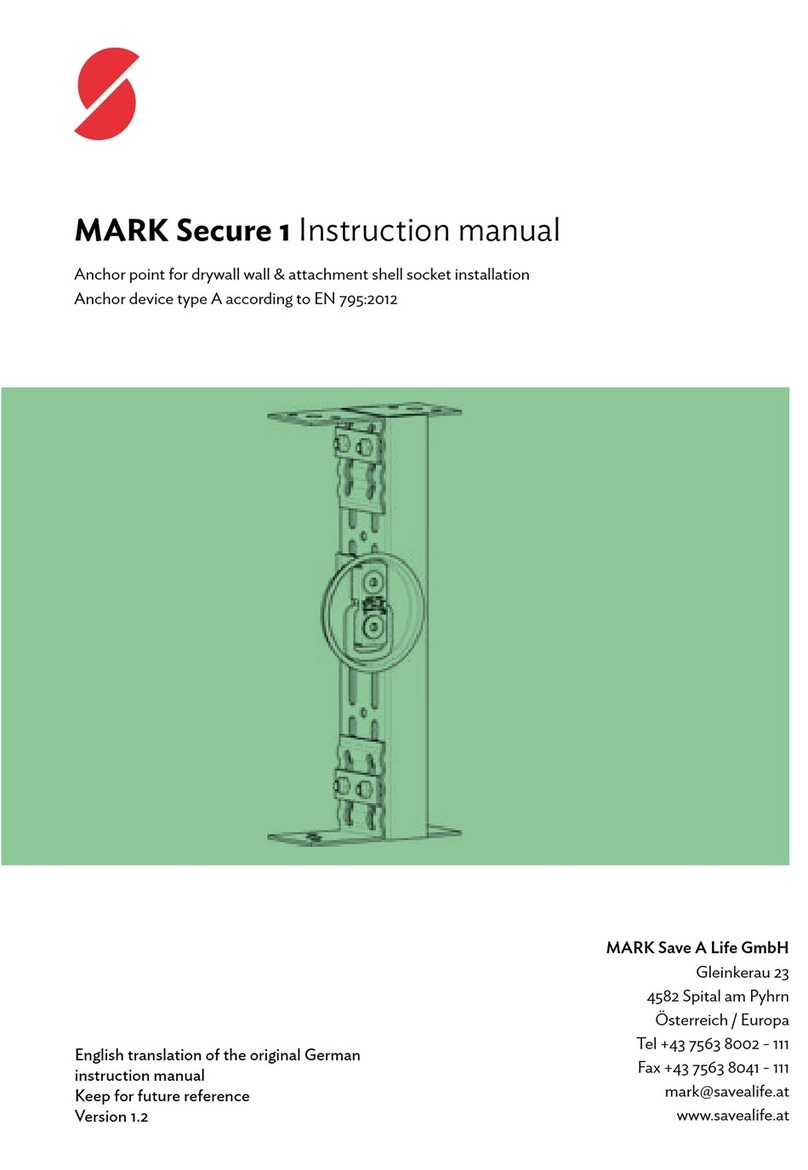

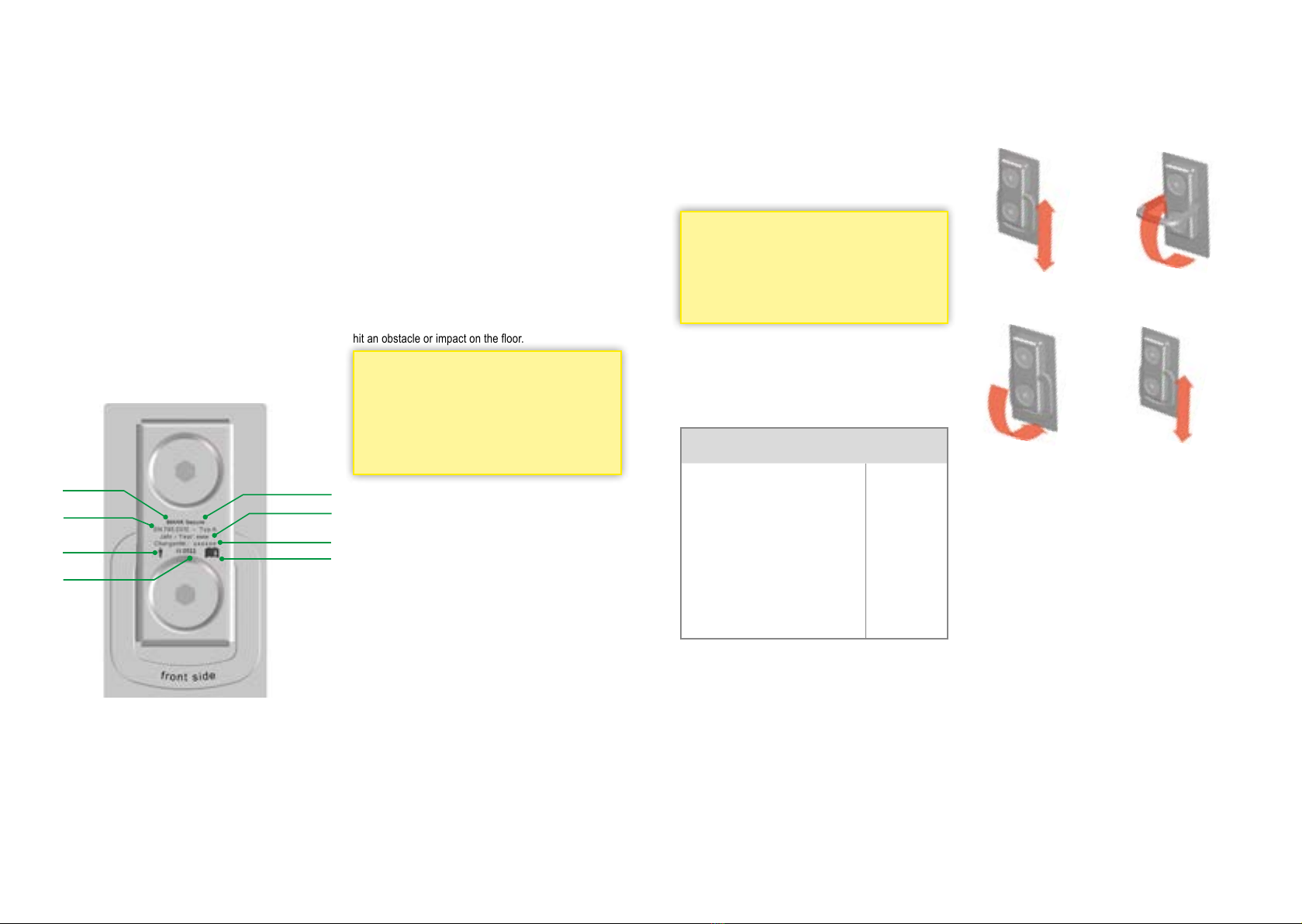

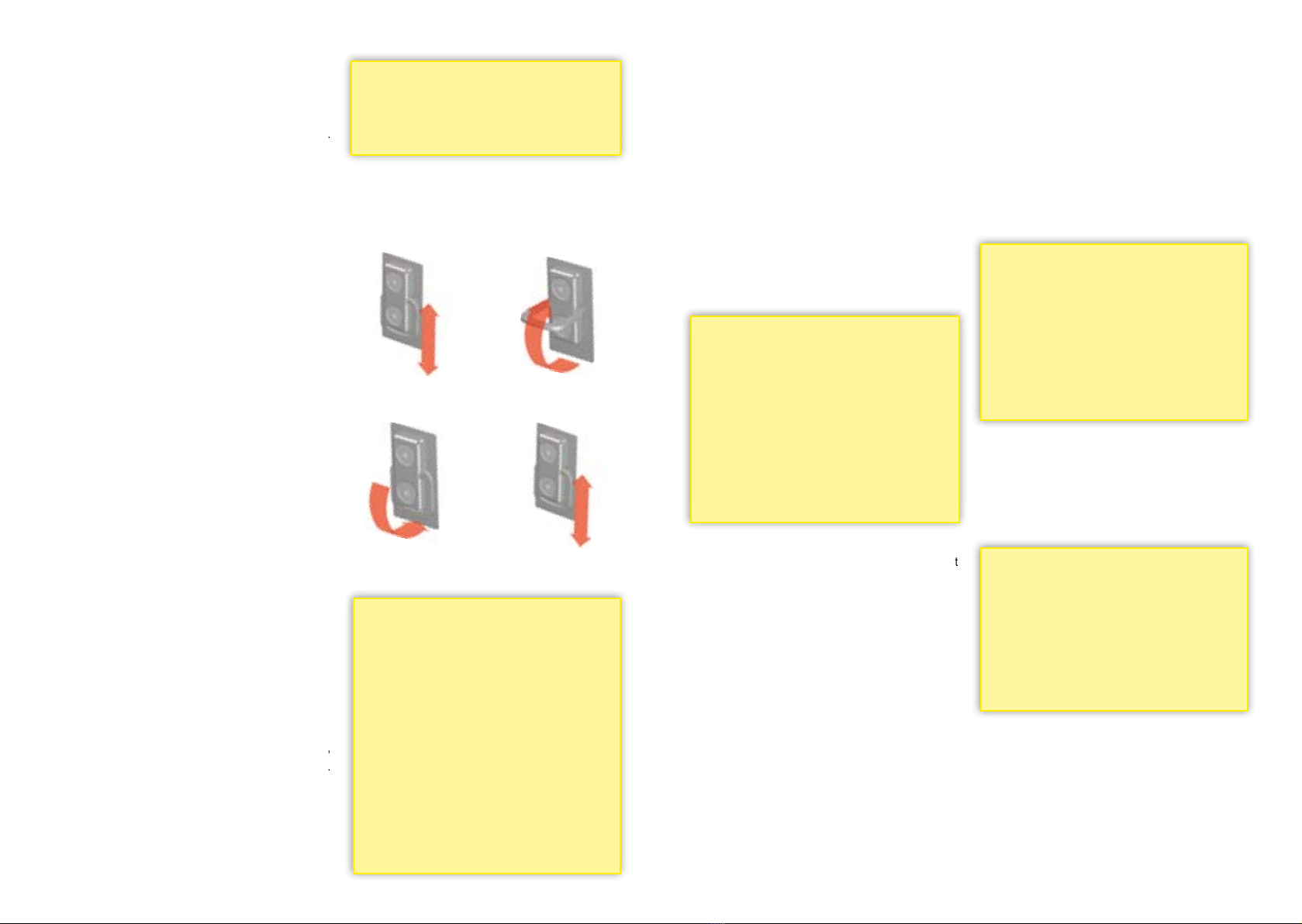

2.1.2 Use of the anchor point

In order to use the anchor point, the buckle is released

from the lock and folded up. The connector of the PPE can

be suspended.

In principle, the load from a fall from height may be in any

direction protruding from the wall surface or parallel to the

wall.

The total position change of the anchor point to be

expected in the event of a fall from height (consisting of

the deformation of the metal stud partition or attachment

shell and the anchor point itself) is a maximum of 15 cm

in the event of a vertical load direction parallel to the wall

surface.

If there is a fall-related load when a person falls vertically

to the wall surface (e.g. in the event of an unintentional

redirection of the load), it must be anticipated that there will

be a total position change of the anchor point (consisting

of the deformation of the metal stud partition or attachment

shell and the anchor point itself) of a maximum of 15% of

the respective wall height.

In principle, the product may be installed at any position

of the specied Knauf or similar metal stud partitions and

attachment shells that is selected as being sensible for the

intended use.

2. Fold up buckle

Working position

3. Fold buckle down

after use

4. Move buckle into lock

1. Move buckle out of lock

45

Read instruction manual

Batch number

CE marking