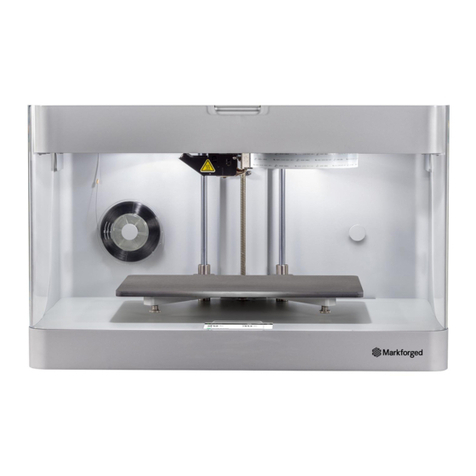

DESKTOP PRINTER SERVICE MANUAL

6

CHECKING ELECTRONICS CONNECTIONS

QService Notes (p.4).

Note: Take care not to discard any hardware you remove during this procedure, as you may need it

during the reinstallation.

PREPARE YOUR PRINTER FOR INSPECTION

secure. Before you can start checking connections, your printer must be properly prepared.

1. Unload all print material.

2.

3.

4. Disconnect the feed tube from the plastic extruder. Remove it from the printer and set it aside.

5.

6. Tape the lid and visor of the printer closed to prevent them from accidentally opening.

7. Carefully turn the printer upside down so that the bottom is facing up.

8. Remove and set aside the 10 screws that hold the bottom panel in place.

Note: The color of the metal BeagleBone cover may vary; the boards themselves are identical.

9. Remove and set aside the bottom panel.

VERIFY CONNECTIONS TO BEAGLEBONE AND MOTHERBOARD

1. Disconnect all of the cables on the left and right sides of the BeagleBone with the exception of the

grey cable. Disconnect the grey cable from the green motherboard but leave it connected to the

BeagleBone.

2. Pull up on the BeagleBone case to remove it from the touchscreen. Note that this connection is very high

Note: You should be left with only the touchscreen attached to the printer frame.

3. Turn the BeagleBone over and inspect the connection between the grey wire and the BeagleBone. Ensure

that it is properly secured.

4. If the grey wire is connected properly, replace the BeagleBone back on the board and secure it to the

prongs on the touchscreen.

Note: Ensure that the USB port on the BeagleBone faces toward the USB hub.

5. Reattach all of the cables to the BeagleBone including the grey wire to the motherboard. Verify that all

motherboard connections are tight and secure.