8MetalX_Facilities_Guide_2.4 | June 25, 2020

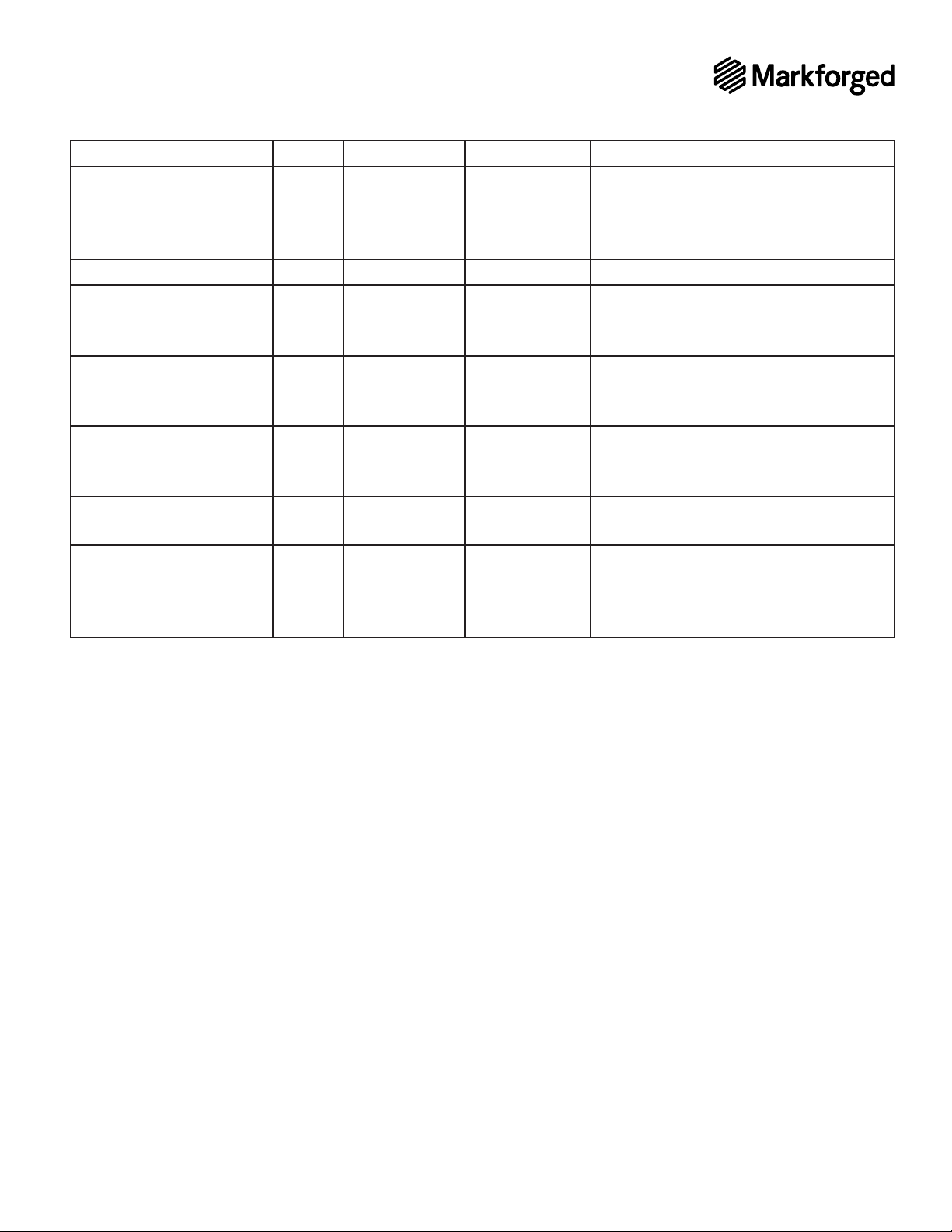

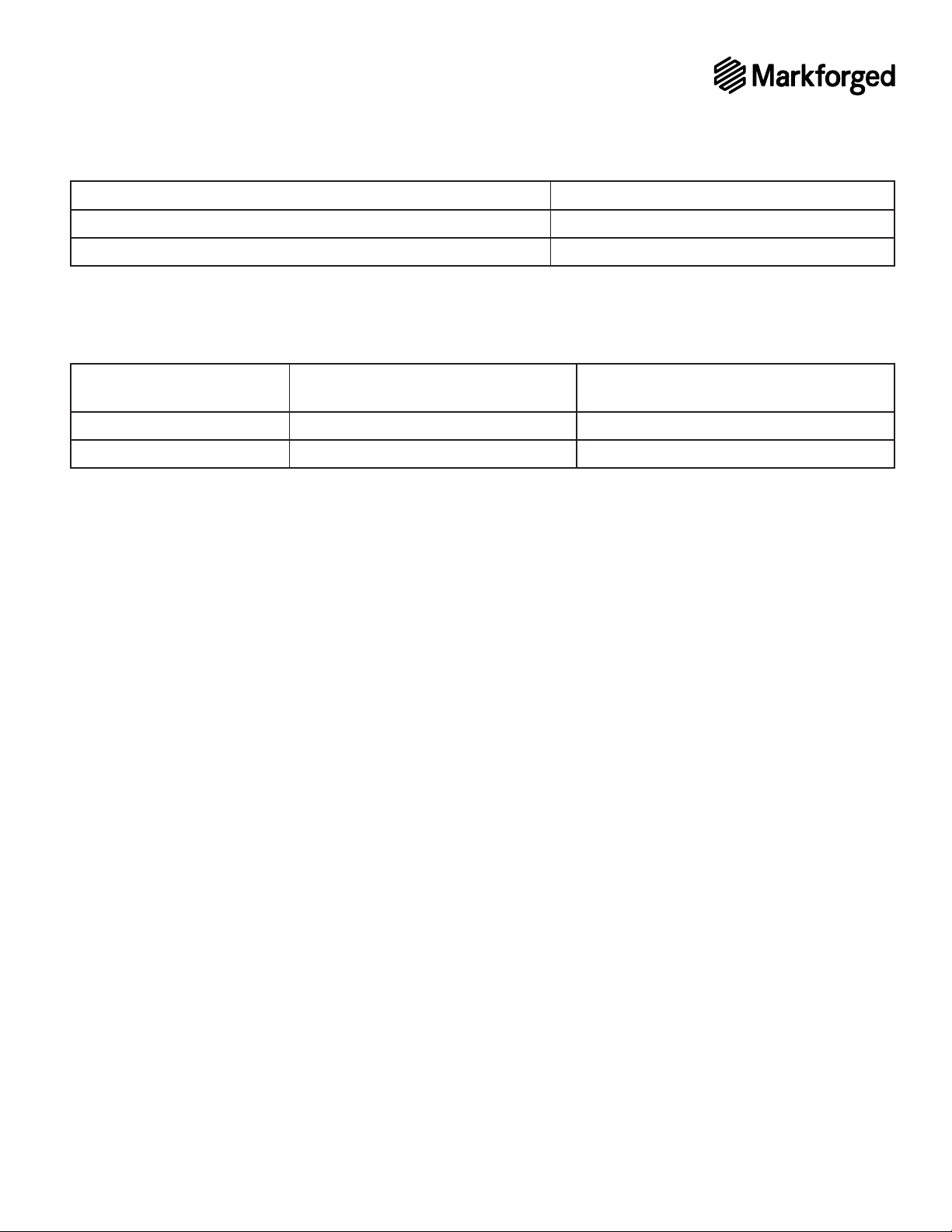

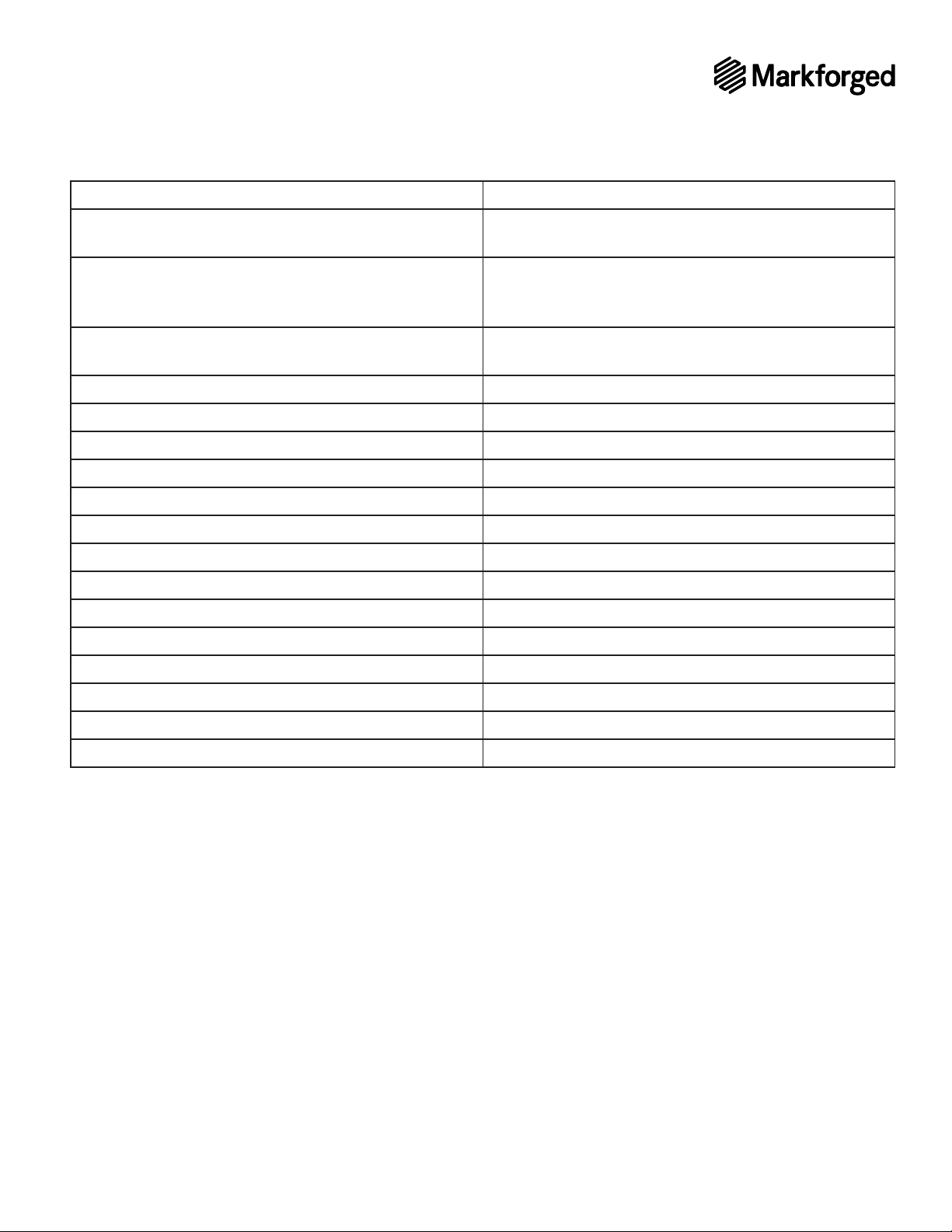

HOSTNAME PORT PROTOCOL REQUIRED? REASON

s3.amazonaws.com

mfeiger-production.

s3.amazonaws.com

TCP yes Downloading MFP part

cdn.eiger.io TCP yes Device operation

www.eiger.io TCP yes Connecting to Eiger (required to

view device status, queue print

*.pool.ntp.org 123 UDP yes Time synchronization via NTP is

required for devices to connect

80 TCP no Network connection status

check (primarily used for

data.logentries.com TCP no Remote logging of device events

and errors

data.logentries.com 10000 TCP no Legacy setting for remote

logging, only required if

software version is older than

Most of these services are cloud-based and geographically distributed, meaning

that the underlying IP address ranges are fairly broad and can change over time,

while the hostnames remain the same. This exibility allows Eiger to maintain a

higher level of availability and performance, and this mechanism is common for

many cloud-based applications you already use and trust.

DEVICE TIME SYNCHRONIZATION

Markforged products require accurate system time for securing HTTPS connections

to Eiger and other services; the SSL certicates used to ensure the authenticity

of these services have time-limited validity, and the device’s time must fall within

this window. Currently, NTP — Network Time Protocol, on UDP port 123 — is the

only supported mechanism for time synchronization, and Markforged devices will

attempt to connect to four dierent servers within the global public NTP server

pool, determined by querying hostnames ending in “.pool.ntp.org”.

Markforged devices also support customer-specied NTP servers. When a device

receives NTP server IP addresses via DHCP (using DHCP option 042), these addresses

will also be used for time synchronization (connecting to UDP port 123).

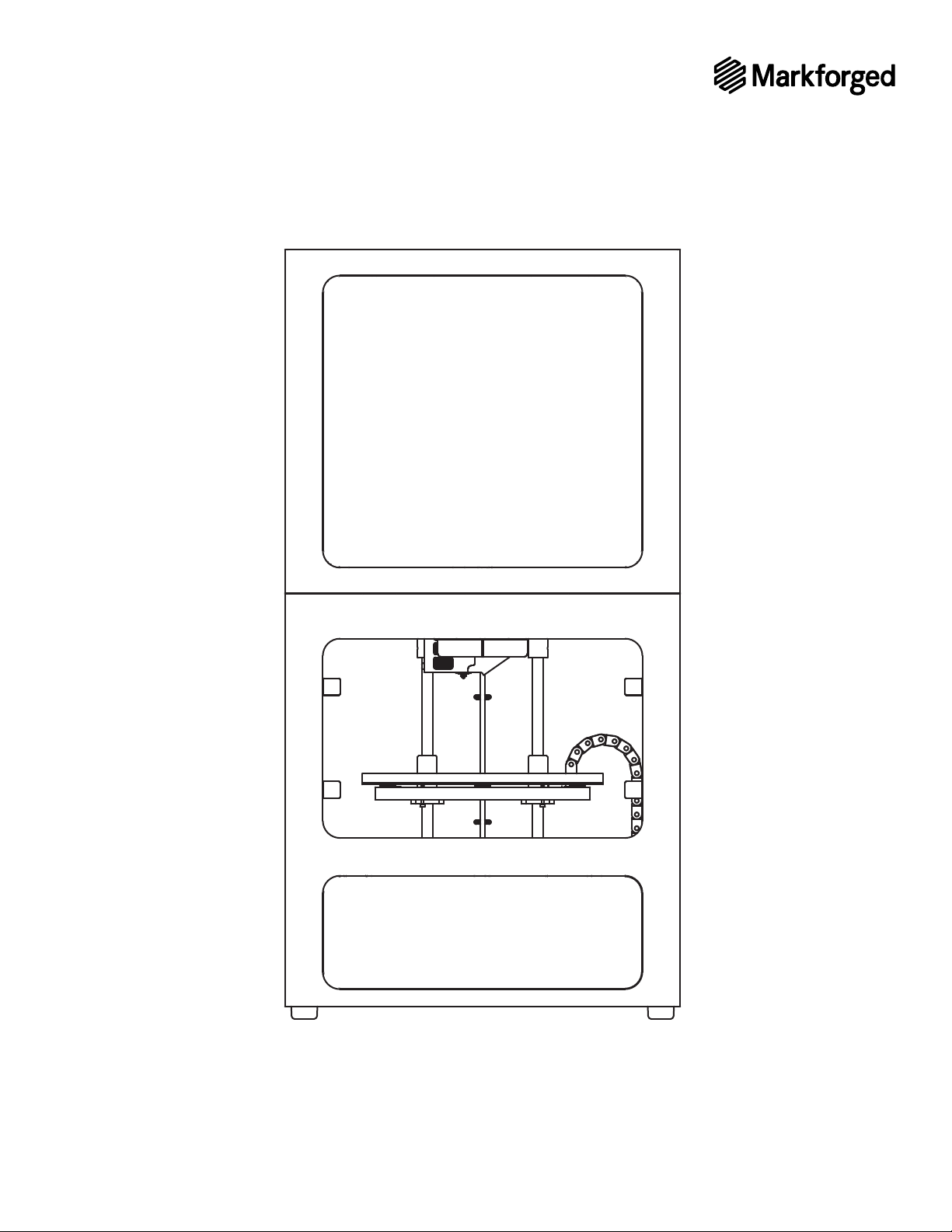

METAL X SYSTEM FACILITIES GUIDE

SOFTWARE