Mars BD1896-1IG-TS User manual

Other Mars Heater manuals

Mars

Mars BELT DRIVE INDUSTRIAL Series User manual

Mars

Mars WMI Series User manual

Mars

Mars High Velocity 2 Series User manual

Mars

Mars WMH Unheated Series User manual

Mars

Mars BD2296-1E TS Series User manual

Mars

Mars QP10 Series User manual

Mars

Mars BD18 Series User manual

Mars

Mars BD22 Series User manual

Mars

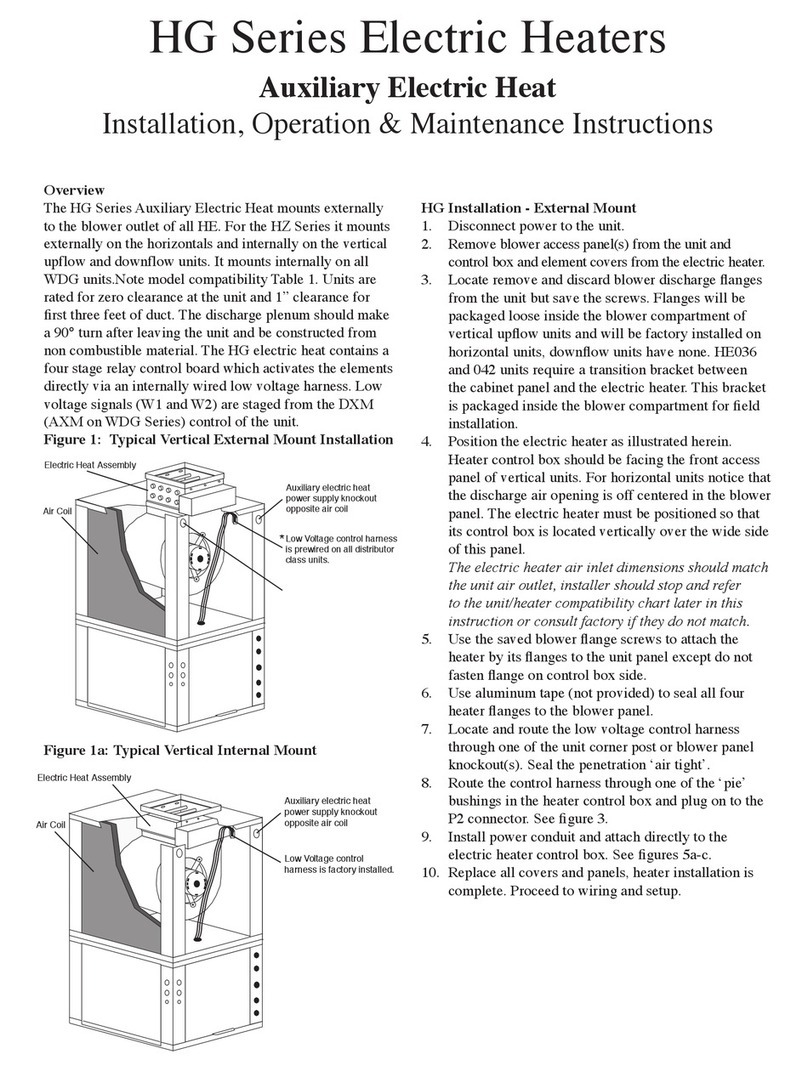

Mars Comfort-Aire Century HG Series Guide

Mars

Mars BD3096-1 TS Series User manual

Mars

Mars QP10 Series User manual

Mars

Mars Wind Stopping 16 Series User manual

Mars

Mars STD2 Unheated 2 Series User manual

Mars

Mars LPV2 2 Series User manual

Mars

Mars LPV2 Series User manual

Mars

Mars BD2296 1I TS Series User manual

Mars

Mars LoPro Series User manual

Mars

Mars BD14 Series User manual

Mars

Mars BD1896-1EH-TS User manual

Mars

Mars LVP2 2 Series User manual

Popular Heater manuals by other brands

oventrop

oventrop Regucor Series quick start guide

Blaze King

Blaze King CLARITY CL2118.IPI.1 Operation & installation manual

ELMEKO

ELMEKO ML 150 Installation and operating manual

BN Thermic

BN Thermic 830T instructions

KING

KING K Series Installation, operation & maintenance instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-5 Installation instructions and owner's manual

Well Straler

Well Straler RC-16B user guide

EUROM

EUROM 333299 instruction manual

Heylo

Heylo K 170 operating instructions

Eterna

Eterna TR70W installation instructions

Clarke

Clarke GRH15 Operation & maintenance instructions

Empire Heating Systems

Empire Heating Systems WCC65 Installation and owner's instructions