PH12 (Phantom 12) Series

Electric Heated

Model Lengths 36” – 144”

14716 S. BROADWAY, GARDENA, CA 90248 ● Ph: (310)532-1555 Fax: (310)532-3030 ● www.marsair.com

© Copyright Mars Air Systems, LLC 2014

NOTE: MARS AIR SYSTEMS, LLC reserves the right to change specifications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions, or replacements

for previously purchased equipment.

MARS AIR SYSTEMS, LLC ● GARDENA, CA ● USA VM, 10/02/20

MARS Air Systems, LLC certifies that the Air Curtains shown on this data

sheet are licensed to bear the AMCA seal. The ratings shown are based on

tests and procedures performed in accordance with AMCA Publication 211

and comply with the requirements of the AMCA Certified Ratings Program.

The AMCA Certified Ratings Seal applies to airflow rate, average outlet

velocity, outlet velocity uniformity, velocity projection and power rating at

free delivery only.

NOTE: Models PH1260-1 & PH12120-2 are not AMCA Certified.

Electric Heated Data Sheet

Applications: Environmental Separation: Max Height 16’ /Insect Control: Max Height 14’

Features:

Air Curtain

1 HP Continuous Duty TEAO Motors

Recessed mounted in ceiling for invisible coverage

ETL Certified to conform to UL 2021 (US) and CSA 22.2 (Canada) Standards

(4) 3/8” top mounting holes provided

Utilized in premium design concepts

Durable aluminum construction

Cabinet has sufficient strength for fastening to wall on both ends without

intermediate support. (Tandem mounted units longer than 72” require center

support)

Cleanable polyester filters included as standard

Adjustable air directional vanes with 40° sweep front to back

Standard color is Pearl White

Rust preventative electrostatic polyurethane powder coating

18-month parts warranty

Freight Included (FOB Continental USA)

Proudly Made in the USA

Electric Heater Coil and Wiring

Coils are an open type for rapid temperature rise to be located in the air curtain's intake directly in

the air stream

Manual reset thermal overload protection provided

Controls internally mounted, prewired ready for power connection and accessible through the

bottom intake or top access panels

A heat/off/fan switch is unit mounted at the bottom and the control voltage is 24 volts

A wall mounted 24-volt thermostat is included (field wired and installed by others)

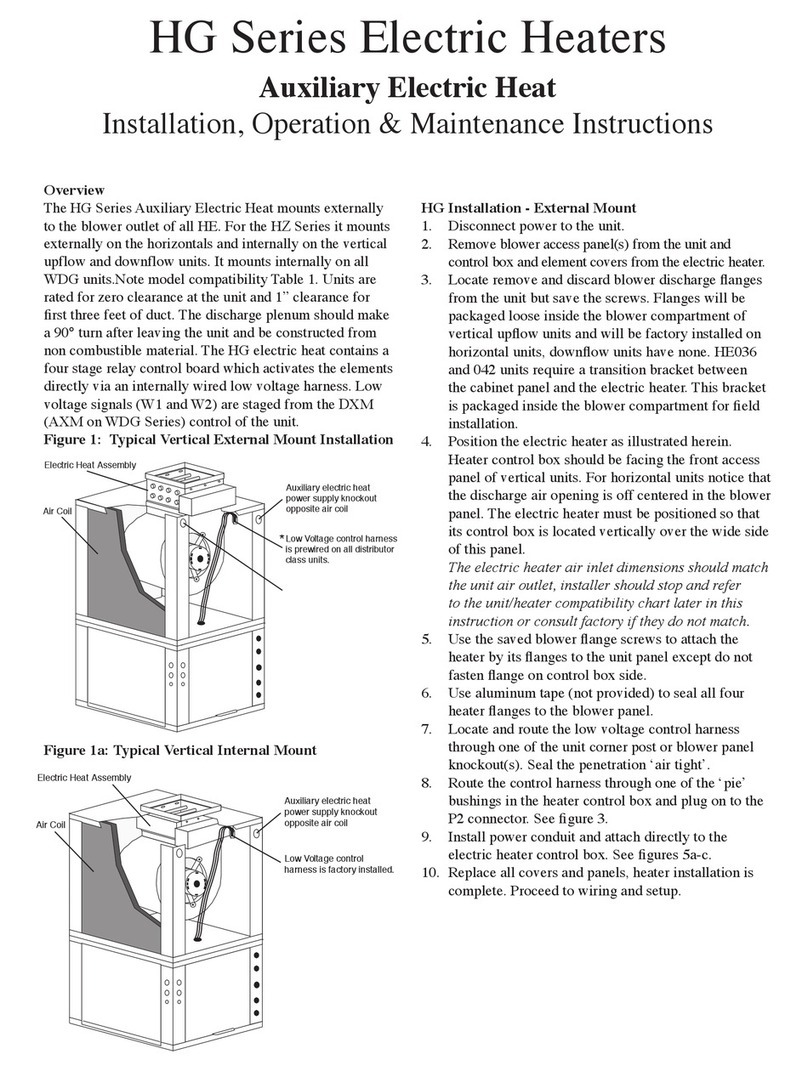

Mars Recommended Accessories (See Submittals for additional details):

Door Limit Switches

o99-018, Commercial surface mounted magnetic switch, 24v

Controllers

oSK-EU, SimpleLink, 208V-575V, (460-575V, 3PH needs additional 115-230V, 1PH power), Integral

Control, Nema1

Factory Mounted Options

oINS-TD, Adjustable time delay (1 sec to 17 min)

oINS-HD, Heat on demand

oINS-2S, Unit mounted 2 speed switch (460-575V, 3PH needs additional 115-230V, 1PH power)

oBMS-300, BMS for monitor and control

Note: Dry contact provided in panel for monitoring motor and heater. 24Vac signal provided from panel for

controlling motor and heater.

Disconnects

o99-122 & 99-123, Non-Fused Disconnect, remote mounted,

600V, 32A & 80A respectively, 3 Pole, IP65

o99-***-**, Fused Disconnect, remote mounted, 240V-600V,

30A-100A, 3 Pole, Nema3R (See disconnect submittals for

complete part numbers)

Sound Levels: (measured at 10’ in an open field)

1 Motor Unit = 70 dBA; 2 Motor Unit = 73 dBA; 3 & 4 Motor Unit

= 75 dBA

Max Core

Velocity at

Nozzle (fpm)

PH1248-1E**-PW 48 48 26 17 1100 5203 3164 2373 91 1190

PH1260-1E**-PW 60 60 26 17 1105 5055 3539 2654 90 1290

PH1272-2E**-PW 72 72 26 17 Two 1 170 5500 2789 4184 80 2180

PH1284-2E**-PW 84 84 26 17 Two 1 190 5250 3089 4634 89 2190

PH1296-2E**-PW 96 96 26 17 Two 1 195 5203 3164 4746 91 2380

PH12120-2E**-PW 120 120 26 17 Two 1 210 5055 3539 5308 90 2580

PH12144-4E**-PW 144 144 26 17 Four 1 340 5500 2789 8368 91 4360

Note: Data above for 1725 RPM at 60 Hz. 50 Hz is 1425 RPM with a 17% reduction in

the performance data.

* - Use corresponding letters in "Electrical Data" & "Heater Wattage Data" columns to complete the model

numbers.

1. The AMCA Certified Ratings Seal applies to airflow rate, average outlet velocity, outlet velocity uniformity, velocity projection and power rating at free delivery only.

2. Rated data shown are only for

electric heated units, as shown.

PH1248-1E**-PW 37 34 17 14

12 - - 15

PH1260-1E**-PW 37 34 17 14

12 - - 14

PH1272-2E**-PW 74 67 34 27

-24 -16

PH1284-2E**-PW 74 67 34 27

-24 -15

PH1296-2E**-PW 74 67 34 27

-24 -15

PH12120-2E**-PW 74 67 34 27

-24 -14

PH12144-4E**-PW 147 134 67 54

- - 48 16

*- Usecorresponding letters in "Voltage Code" and "Wattage

Code" to complete themodelnumbers.

Three Phase

Electrical Data

(FLA)

For ampacity, multiply FLA X 1.25

Motor amps per motor: 9A@115v; 5A@ 208v/230v/1Ø; 3.3A@208v/3Ø; 3.2A@230v/3Ø; 1.6A@ 460v; 1.3A@ 575v/3Ø

Unit Voltage

(Voltage Code)

Amperage

Heater Kilowatts

(Wattage Code)

kW

PH1248-1E**-PW 34 32 6- - 7

PH1260-1E**-PW 34 32 6- - 7

PH1272-2E**-PW 68 63 -12 - 8

PH1284-2E**-PW 68 63 -12 - 8

PH1296-2E**-PW 68 63 -12 - 7

PH12120-2E**-PW 68 63 -12 - 7

PH12144-4E**-PW 136 125 - - 24 8

For ampacity, multiply FLA X 1.25

*- Usecorresponding letters in "Voltage Code" and

"WattageCode" to completethe model numbers.

Single Phase

Electrical Data

(FLA)

Heater kilowatts

(Wattage Code)

kW

Unit Voltage

(Voltage Code)

Amperage

Motor amps per motor: 5A @ 208/230v/1Ø

Distance

from nozzle

(in)

40 1494

80 1053

120 986

160 953

200 948