Document No: LP2-IOM

Date: 08/21/20

LOW PROFILE (LPV2) VARIABLE SPEED AND LOW PROFILE

(LPN2) ETL SANITATION CERTIFIED COMMERCIAL SERIES

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate, or maintain

the product described. Protect yourself and others by observing all safety information. Failure to comply with these

instructions could result in personal injury and/or property damage. Retain these instructions for future reference.

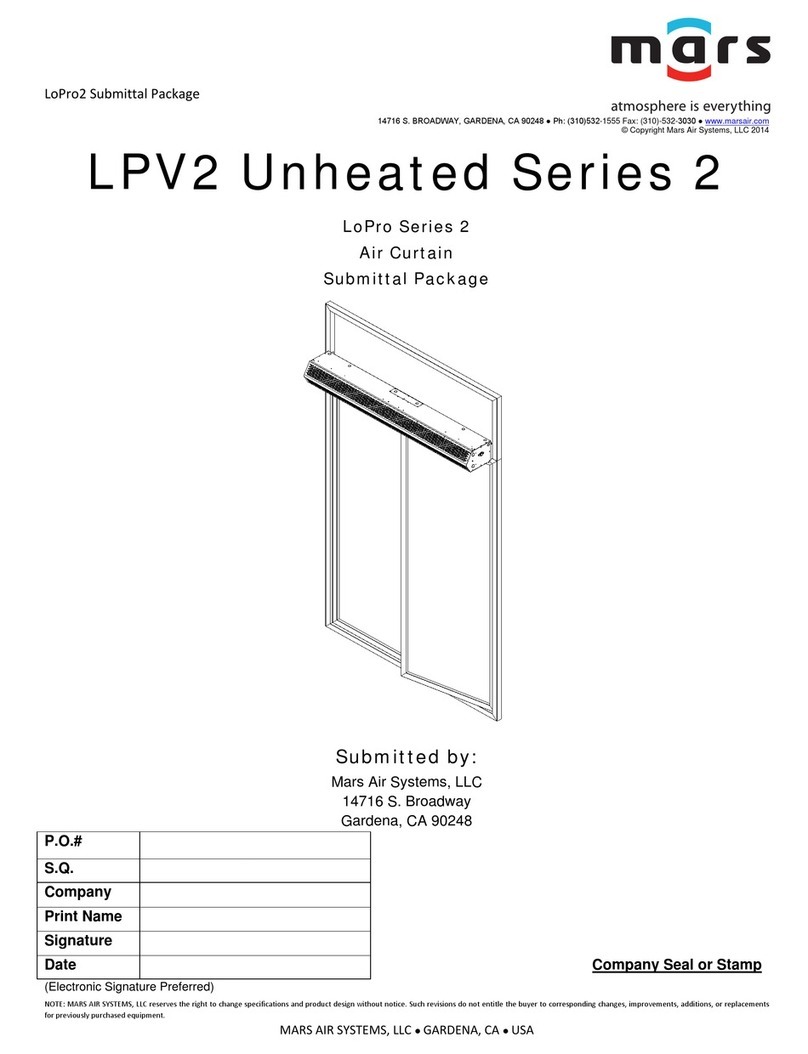

OVERVIEW

Mars Air Curtains are

designed to cover

door openings,

providing both

temperature

control/environmental

separation and flying

insect control, when

the building’s doors

are opened. Typical

installation heights

are: LoPro Series; LPV2 (Variable Speed) models

(Environmental up to 8’), LPN2 (ETL Sanitation for

Customer Entrances) models (Flying Insect Control up to

7’) and LPN2-F (ETL Sanitation for Counter Top/Pass

Through Windows) models (Flying Insect Control up to 4’

from Counter Top) All ETL Sanitation Certified Models

should be mounted at the Flying Insect Control heights

referenced above. The units are typically wall mounted

horizontally above the door opening. They can also be

suspended from the ceiling. The units are ETL Listed,

Canada and US, for either an inside or outside mount and

ETL Sanitation Certified. Heated units must be mounted

on the inside or the protected side of the opening. The

motors used in all LoPro Series are 1/6HP.

The LoPro Series come standard with a stamped air

intake screen(s). The LPV2 models can be configured

with an aluminum mesh filter(s) as an option. The LPN2

models 25” and all LPN-F models come standard with an

aluminum mesh air intake filter(s) in conjunction with the

punched air intake screen(s).

GENERAL SAFETY

INFORMATION

Use this product only in

the manner intended

by the manufacturer. If

you have any

questions, contact the

manufacturer. Only

qualified personnel

should install this

product. Installing

personnel should have

a clear understanding

of these instructions and should be aware of general

safety precautions. Improper installation can result in

electric shock, possible injury due to coming in contact

with moving parts, as well as other potential hazards.

WARNING

To reduce the risk of fire, electric shock, or injury to

persons, observe the following.

A. Always disconnect, lock and tag power source before

installing or servicing product.

B. Installation work or electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

C. The combustion airflow needed for safe operation of

fuel burning equipment in the area may be affected by

the product’s operation. Follow the heating equipment

manufacturer’s guideline and safety standards, such as

those published by the National Fire Protection Agency

(NFPA), the American Society of Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) and local

code authorities.

D. When cutting or drilling into a wall or ceiling, be careful

not to damage elec

trical wiring and other hidden

utilities.

When servicing the product, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.