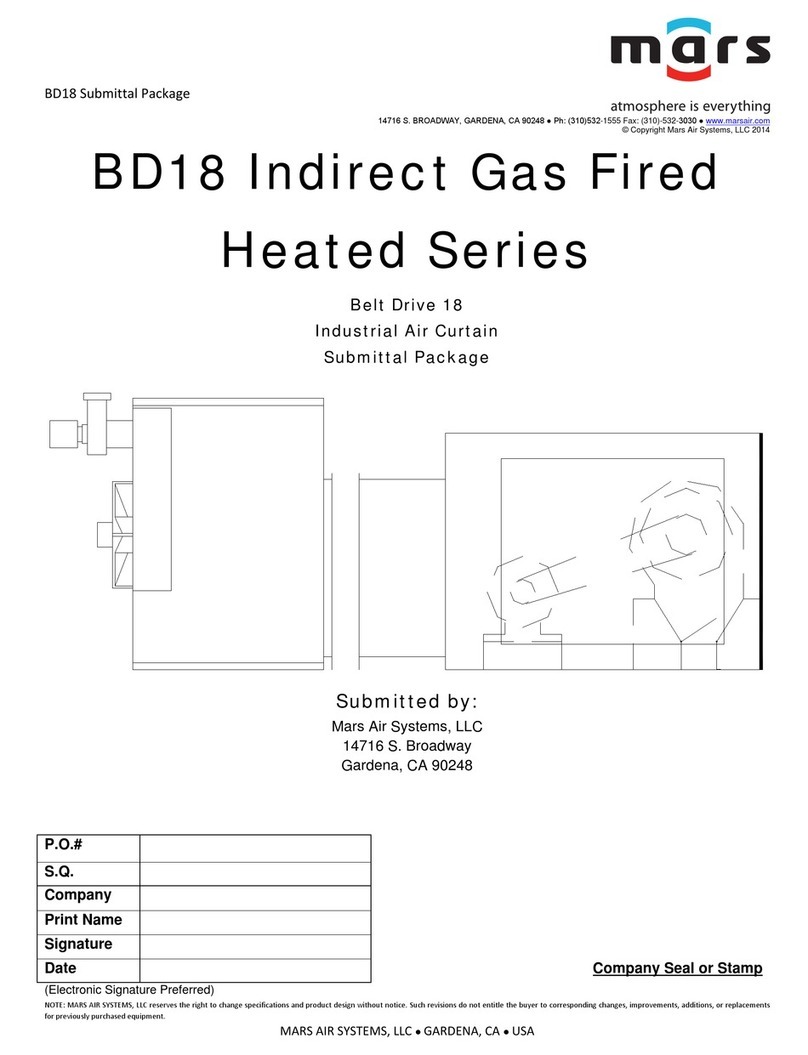

BD18 (Belt Drive 18) Series

Indirect Gas Fired

Model Lengths 96” – 192”

14716 S. BROADWAY, GARDENA, CA 90248 ● Ph: (310) 532-1555 Fax: (310) 532-3030 ● www.marsair.com

© Copyright Mars Air Systems, LLC 2014

NOTE: MARS AIR SYSTEMS, LLC reserves the right to change specifications and product design without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions, or replacements

for previously purchased equipment.

MARS AIR SYSTEMS, LLC ● GARDENA, CA ● USA AR, 8/3/21

BD18

Series: BELT DRIVE 18

144 1 I H TS

LENGTH OF UNIT

# OF MOTORS

VOLTAGE CODE

COLOR

EXAMPLE

BD1896-1I*-TS 2250 415 28 5" Rnd 1/2"

BD18120-1I*-TS 2400 664 36 6" Rnd 3/4"

BD18144-1I*-TS 2400 664 30 6" Rnd 3/4"

BD18168-1I*-TS 3400 996 38 6" Rnd 3/4"

BD18192-1I*-TS 3400 996 33 6" Rnd 3/4"

* - Use corresponding letters in"Electrical Data" columns to complete the model numbers.

Note: Gas pressure required min/max in (“wc)(kPa): Natural Gas (3.5/14)(0.9/3.5) and LP (10/14)(2.5/3.5)

Indirect Gas Fired Data Sheet

Applications: Environmental Separation: Max Height 20’ / Insect Control: Max Height 18’

Features:

Air Curtain and Transition

7 ½ to 15 HP continuous duty premium efficiency industrial TEFC

motors

Air curtain is a self-contained one-piece heavy gauge corrosion proof

paint lock metal design

Top mounting holes provided (3/4”)

Cabinet has sufficient strength for fastening from overhead on both

ends without intermediate support

Adjustable air directional nozzle with 40° sweep front to back

Transition is shipped fully assembled and fastened to unit (overhead

support required)

Standard color is Titanium Silver

Rust preventative electrostatic polyurethane powder coating

12-month parts warranty

Freight Not Included (FOB Factory)

Proudly Made in the USA

Indirect Gas Fired Furnaces

ETL verified to be 83% efficient

In-shot burner technology

Aluminized tubular heat exchanger (20 gauge)

Positive pressure 120V impellers (separate 120V, 1Ø power required)

Power vented exhaust

Single stage gas valve

Standard direct spark ignition

Certified for Category I and III Venting

Natural gas

Factory test fired

Overhead mounting hardware provided (2 per furnace)

Mars Recommended Accessories (see submittals for additional details):

Door limit switches

o99-125, Industrial surface-mounted door limit switch

Controllers

oMCP*-†I‡, Motor Control Panel, 24V control voltage (* = HP Code, † = # of Motors, ‡ = Voltage Code)

Note: possible HP Codes = G (7½ HP), H (10 HP), I (15 HP)

MCP-TD, Adjustable time delay, 1sec-100hr (panel required)

IDF-2STG, Two-stage heat exchanger

IDF-SS, 409 stainless steel heat exchanger

IDF-MOD-RS, Room sensor for modulating gas valves (0-10VDC/4-20mA control voltage by others)

Sound Levels: (measured at 10’ in an open field)

7 ½ HP Motor Unit = 74 dBA, 10 HP Motor Unit = 75 dBA, 15 HP Motor Unit = 76 dBA

Length

(in)

Depth

(in)

Height

(in)

Motor

(hp)

BD1896-1I*-TS

96 107 82 1/2 33 7 1/2 1148 2 @ 211 5100 13800

BD18120-1I*-TS

120 131 82 1/2 33 7 1/2 1513 2 @ 335 5100 17255

BD18144-1I*-TS

144 155 82 1/2 33 10 1630 2 @ 335 5100 20700

BD18168-1I*-TS

168 179 82 1/2 33 10 2082 3 @ 335 5100 24100

BD18192-1I*-TS

192 203 82 1/2 33 15 2199 3 @ 335 5100 27600

* - Use corresponding letters in "Electrical Data" columns to complete the model numbers. Note: Data above is for 60 Hz, 17% reduction in the performance data with 50 Hz.

** - Total Weight includes air curtain, transition, and furnace weights.

208/230v

(G)

460v

(H)

575v

(I) 115V

BD1896-1I*-TS

21.6/20.0 10.0 8.9 16.0

BD18120-1I*-TS

21.6/20.0 10.0 8.9 27.0

BD18144-1I*-TS

28.0/26.0 13.0 10.3 27.0

BD18168-1I*-TS

28.0/26.0 13.0 10.3 40.5

BD18192-1I*-TS

42.0/40.0 20.0 15.6 40.5

* - Use corresponding letters in"Electrical Data" columns to complete the model numbers.

Alternate voltage codes with FLA (Full Load Amp) data:

380-415V/3Ø/50Hz (W) - 8.3A per motor (7½HP), 11.5A per motor (10HP), 15.5A per motor (15HP)

Note: For ampacity, multiply FLA X 1.25

Unit Voltage

(Voltage Code)