10 42900 Rev. 09-30-2008

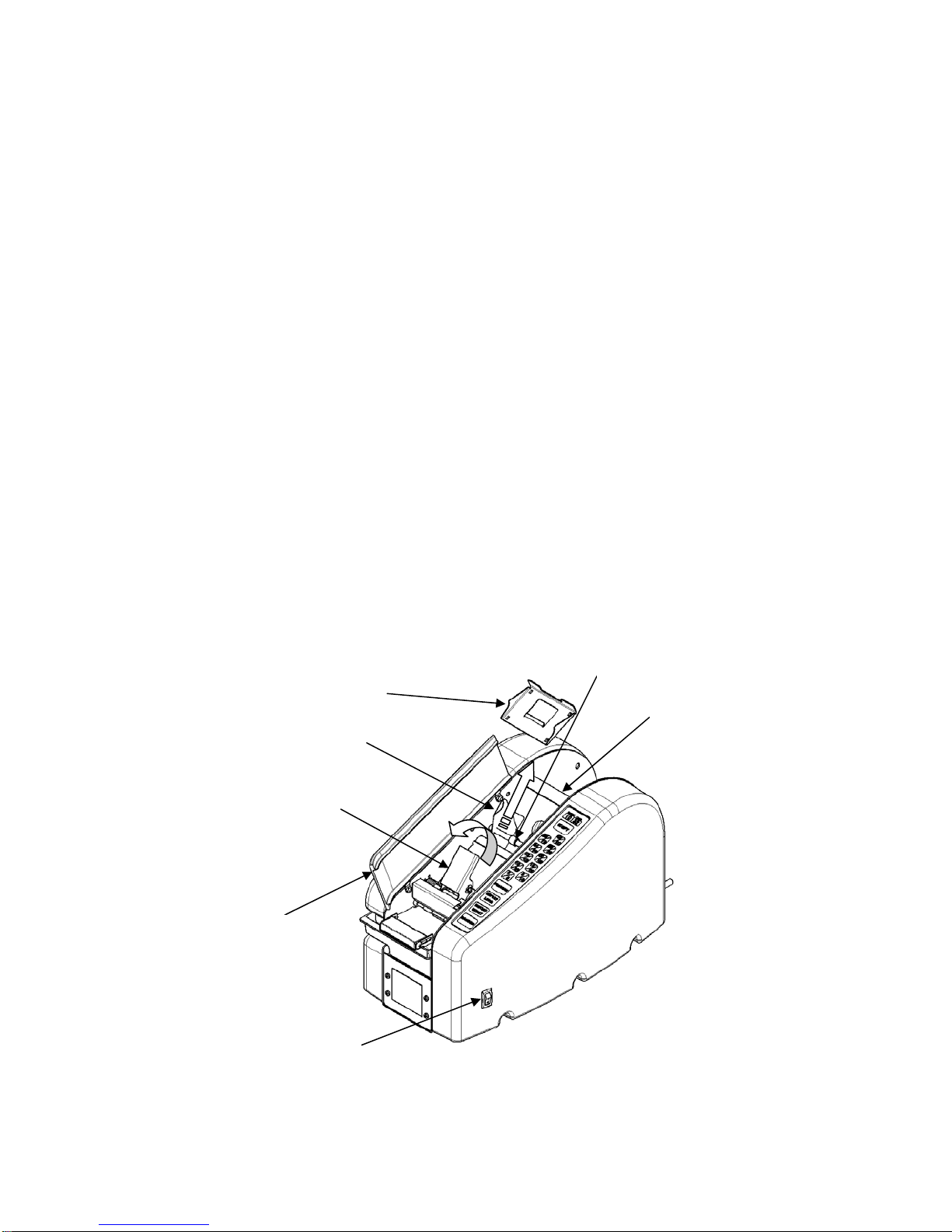

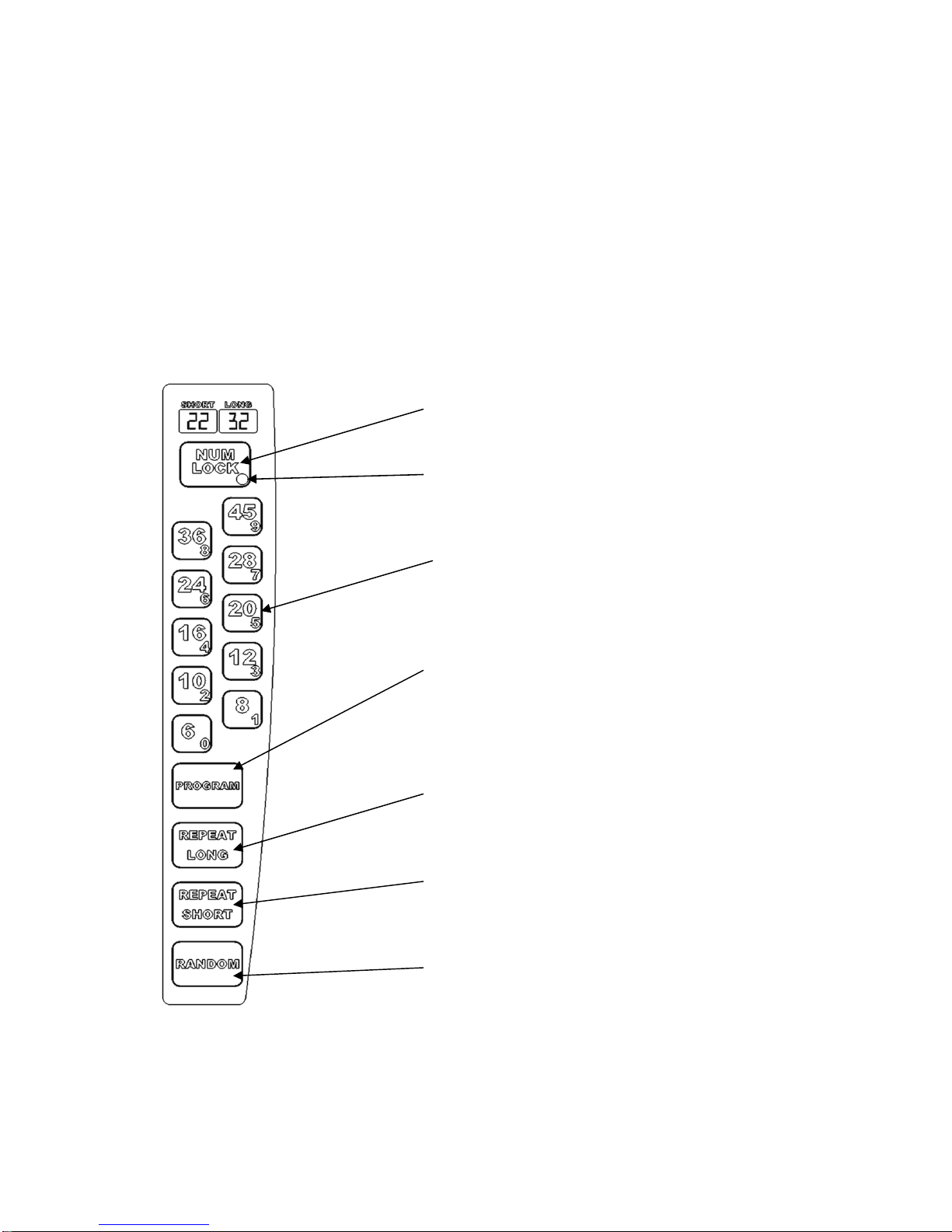

TD2100 PREMIUM Keypad

The PREMIUM keypad offers all the same function as the STANDARD keypad plus it is

possible for you to dispense any length of tape from 5” to 99” in 1” increments. The exception

from the STANDARD keypad is there are 10 preset lengths versus 20. There are two versions of

the PREMIUM keypad, Short and Long. The Long version has longer pre-programmed lengths

than the Short.

To dispense a length of tape 5” to 99” press the NUM LOCK key. The NUM LOCK light is lit

and the 0-9 keys are activated. Just press any two keys to get the desired length. For example,

press 07 for 7” piece of tape or 77 for a 77” piece of tape. These “custom” lengths can be

programmed in the REPEAT SHORT or REPEAT LONG keys by turning on the NUM LOCK,

press PROGRAM, press two keys of desired length and then desired REPEAT key to store

value. You must turn off the NUM LOCK mode to verify the length is stored and displayed.

Num Lock Key: When pressed this key will activate

the red number on the keypad.

Num Lock Key Indicator: When lit, the NUM

LOCK is activated and the red numbers are used.

When not lit, the black numbers are used.

Number Keys: When pressed will dispense the

length of tape in black, when num lock is on will give

the red numbers for dispensing or programming,

requires 2 key strokes for custom lengths.

Program Key: When pressed will begin the

programming sequence, follow by pressing the

desired length and the location to store it, press the

num lock followed by the corresponding red numbers

to achieve a custom length.

Repeat Long Key: When pressed, this key will

repeat the length that is stored in the long display.

You will use this button during programming.

Repeat Short Key: When pressed, this key will

repeat the length that is stored in the short display.

You will use this button during programming.

Random Key: When pressed will dispense tape until

released.

Figure 7 – Premium Short Keypad