2M4033ESA-06/20

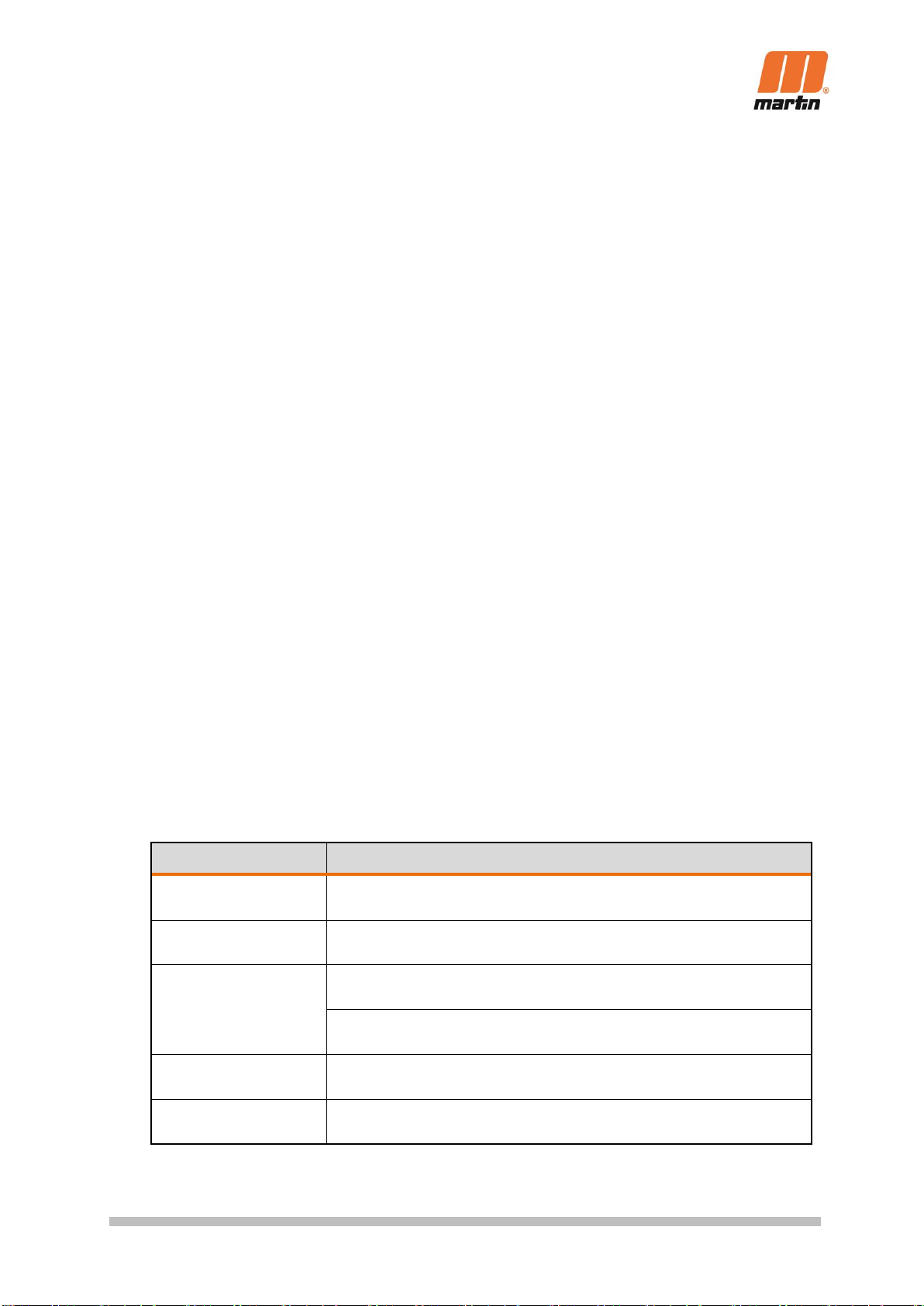

Table of Contents

1General.................................................................................................................. 3

1.1 About these operating instructions ................................................................. 3

1.2 General information on cleaners..................................................................... 4

1.3 Intended usage............................................................................................... 4

1.4 Use in hazardous areas according to the ATEX directive............................... 5

1.5 Personnel qualification.................................................................................... 6

1.6 Technical data ................................................................................................ 6

1.7 Requirements for the usage site..................................................................... 7

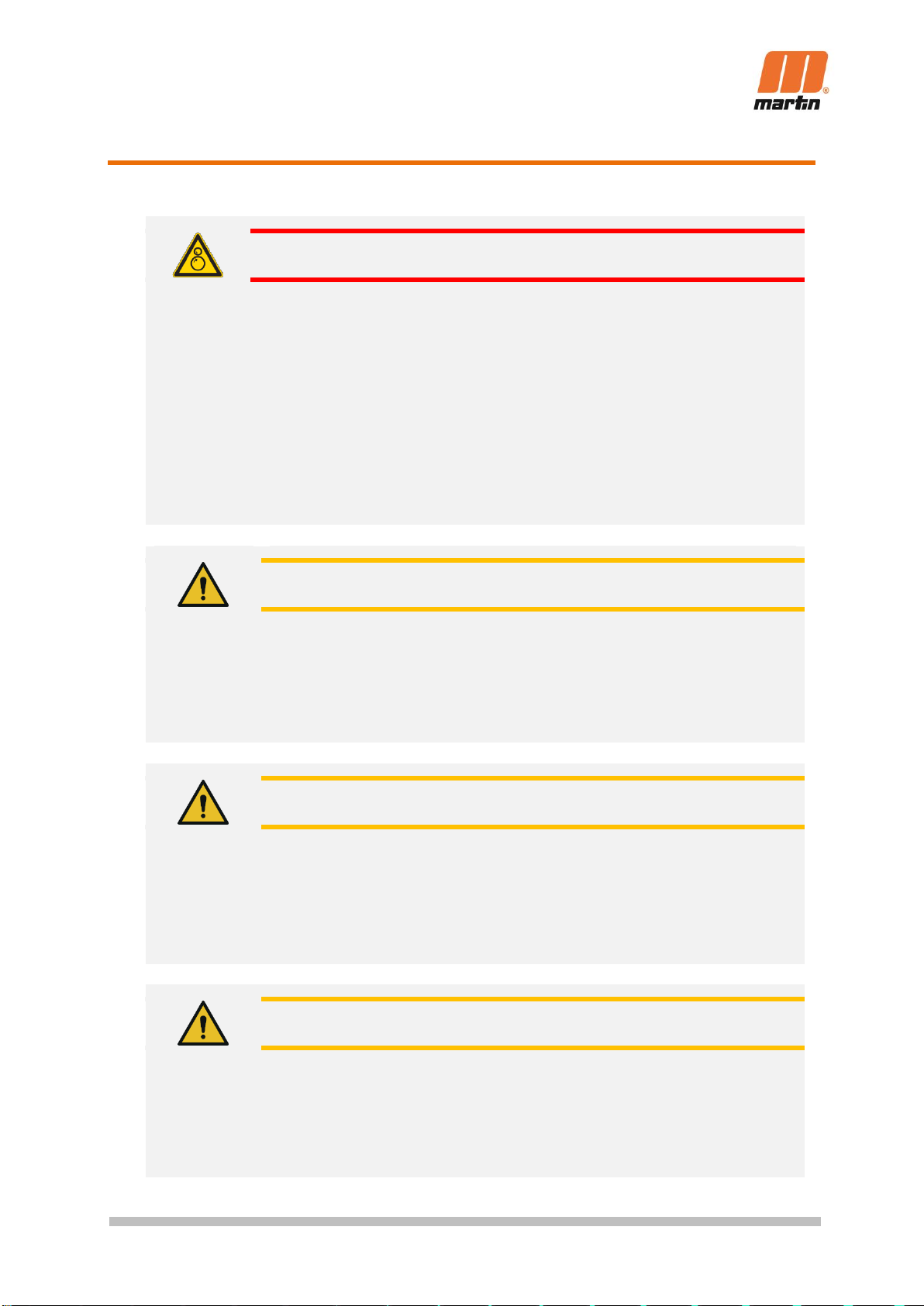

2Safety..................................................................................................................... 8

2.1 General safety instructions............................................................................. 8

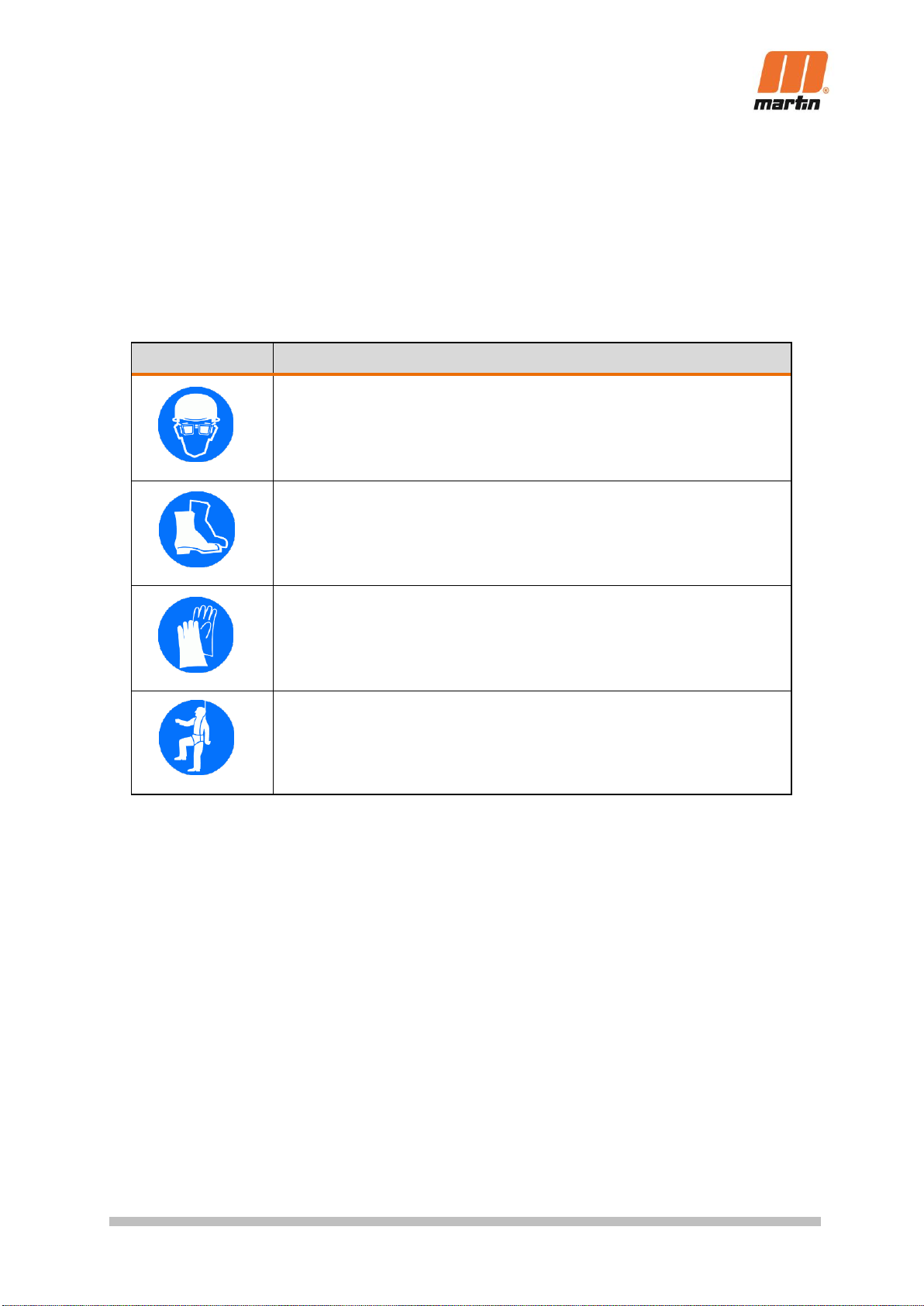

2.2 Personal protective equipment....................................................................... 9

2.3 Safety markings on the system....................................................................... 9

2.4 Special safety instructions for usage in ATEX areas .................................... 10

3Preparations before installation........................................................................ 11

3.1 Required maximum of tools and materials.................................................... 11

3.2 Checking the operating conditions................................................................ 12

3.3 Unpacking/transportation.............................................................................. 12

3.4 Identification of the correct installation position ............................................ 13

4Before Installation Belt Cleaner ........................................................................ 18

4.1 Installing chains............................................................................................ 19

5Installing Belt Cleaner & Tensioners................................................................ 20

5.1 Locating belt cleaner..................................................................................... 21

6After Installing Belt Cleaner .............................................................................. 29

7Maintenance / Servicing / Repair ...................................................................... 31

7.1 Replacing Breakaway Link ........................................................................... 33

8Troubleshooting................................................................................................. 35

9Disassembly / Recycling / Disposal.................................................................. 38

10Part Numbers...................................................................................................... 39

11Appendix............................................................................................................. 45