© Martin Engineering GmbH 1 M3682UK-09/17

Table of Contents

1Table of Contents

1 Table of Contents ............................................................. 1

2 Introduction ...................................................................... 3

2.1 About these installation instructions................................... 3

2.1.1 Scope ............................................................................ 3

2.1.2 Copyright ....................................................................... 3

2.1.3 Exclusion of liability ....................................................... 3

2.1.4 Reference to additional documents ............................... 4

2.1.5 Classification of the hazards.......................................... 5

2.2 Intended usage .................................................................. 6

2.2.1 Conveyor systems with open transfer systems ............. 6

2.2.2 Usage in explosion-protected areas .............................. 6

2.2.3 Restrictions on the use of the product ........................... 6

2.3 Occupational safety............................................................ 7

2.3.1 Safety information, occupational safety ......................... 7

2.3.2 Duties of the owner-operator ......................................... 7

2.3.3 Authorised personnel ..................................................... 7

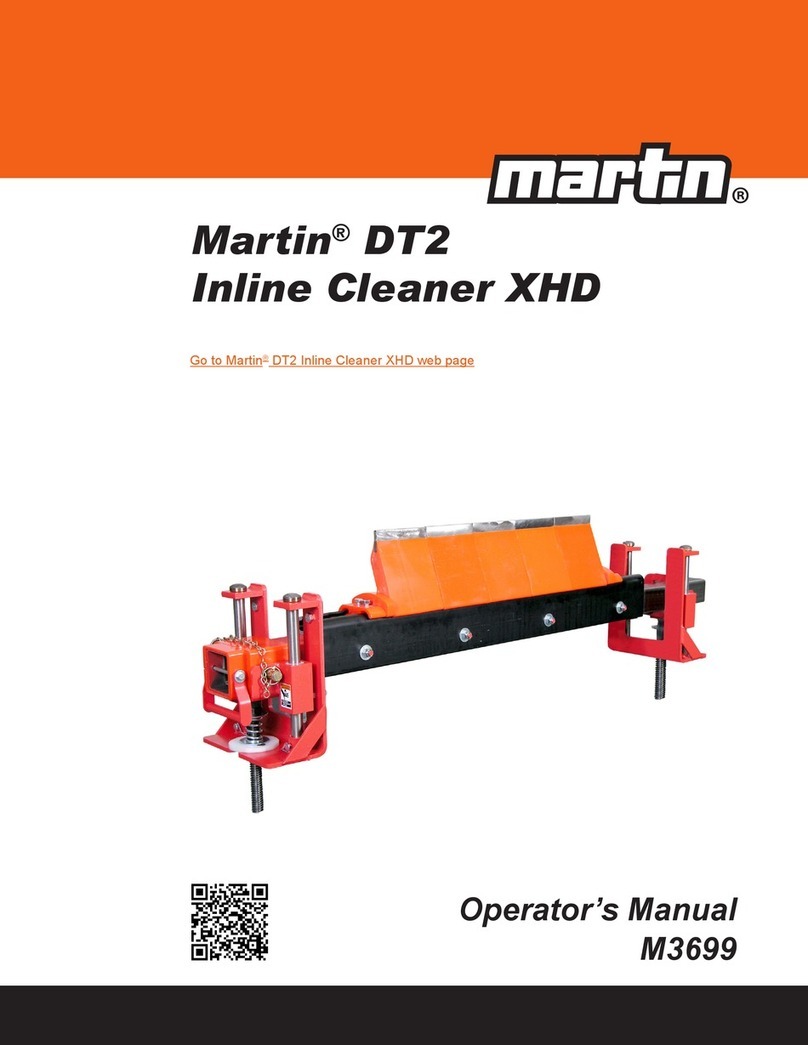

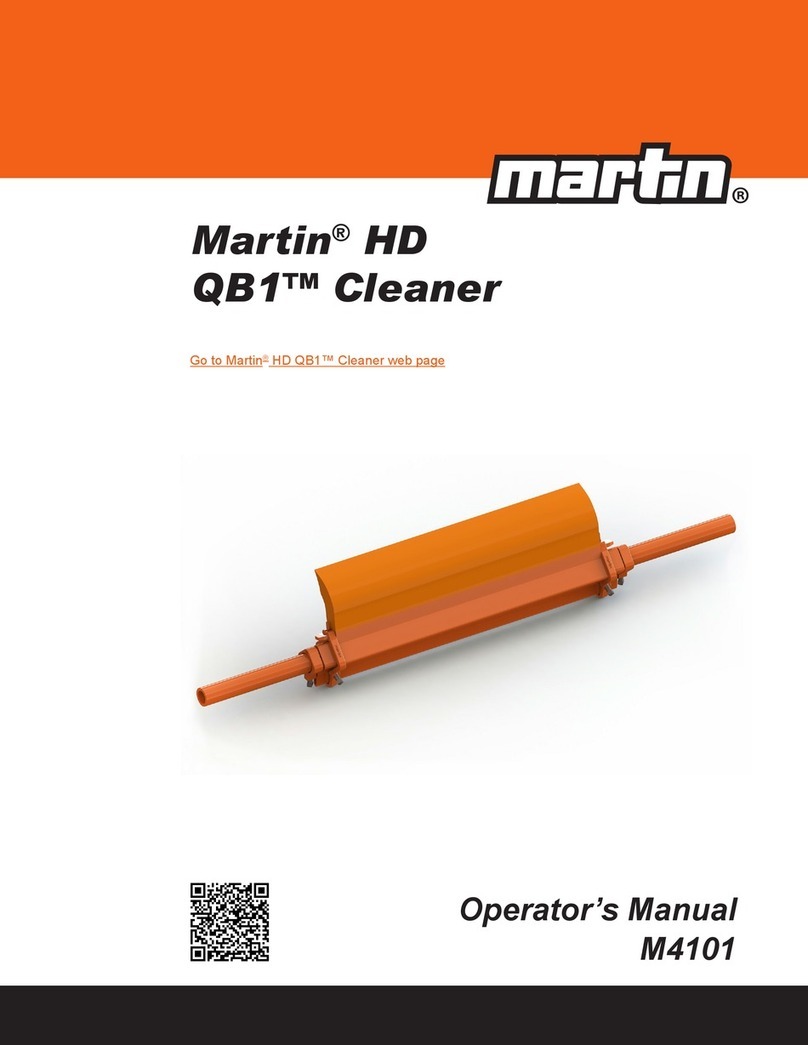

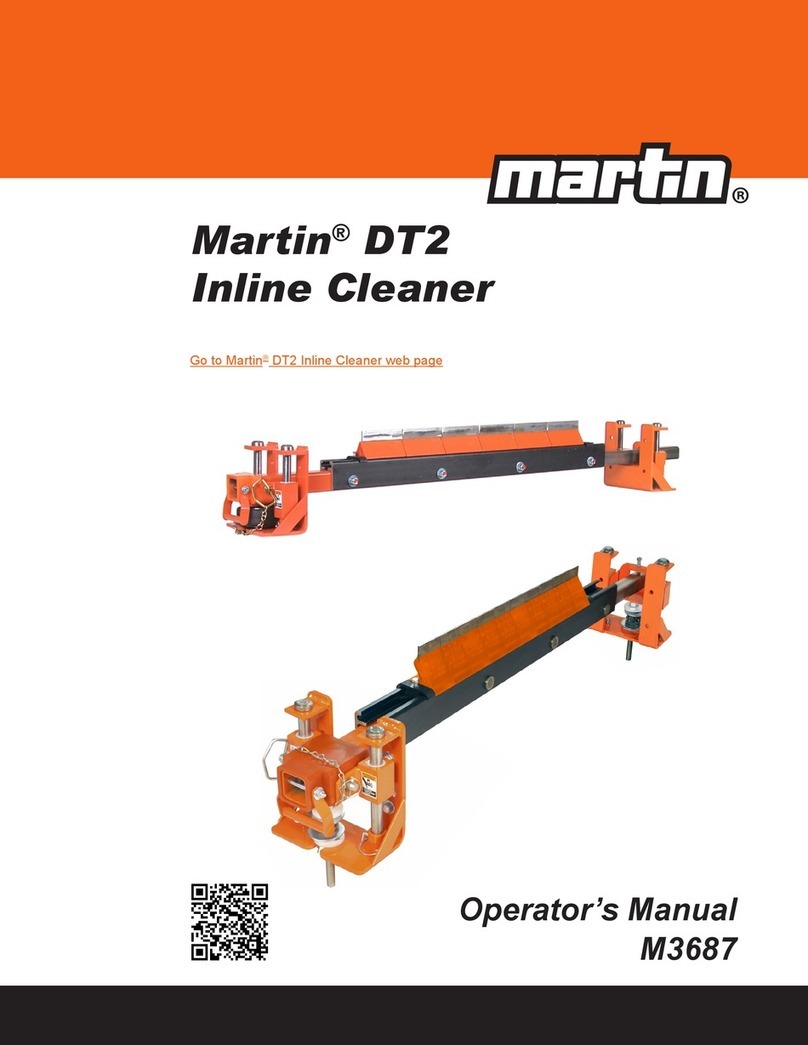

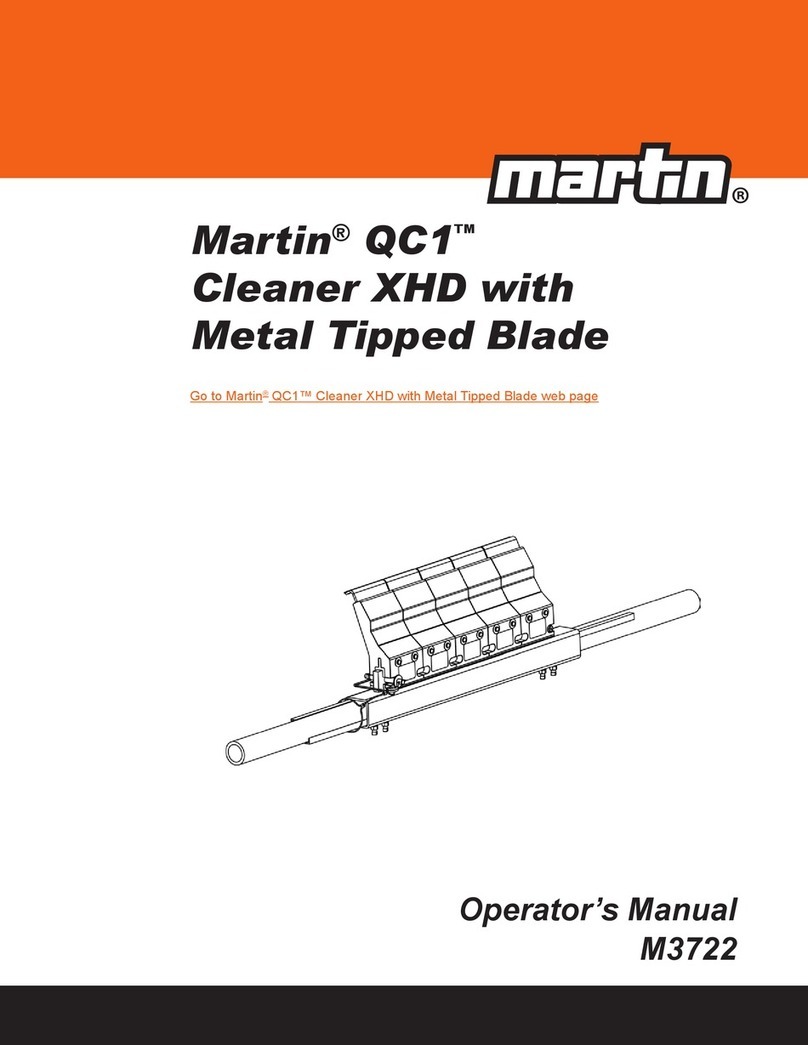

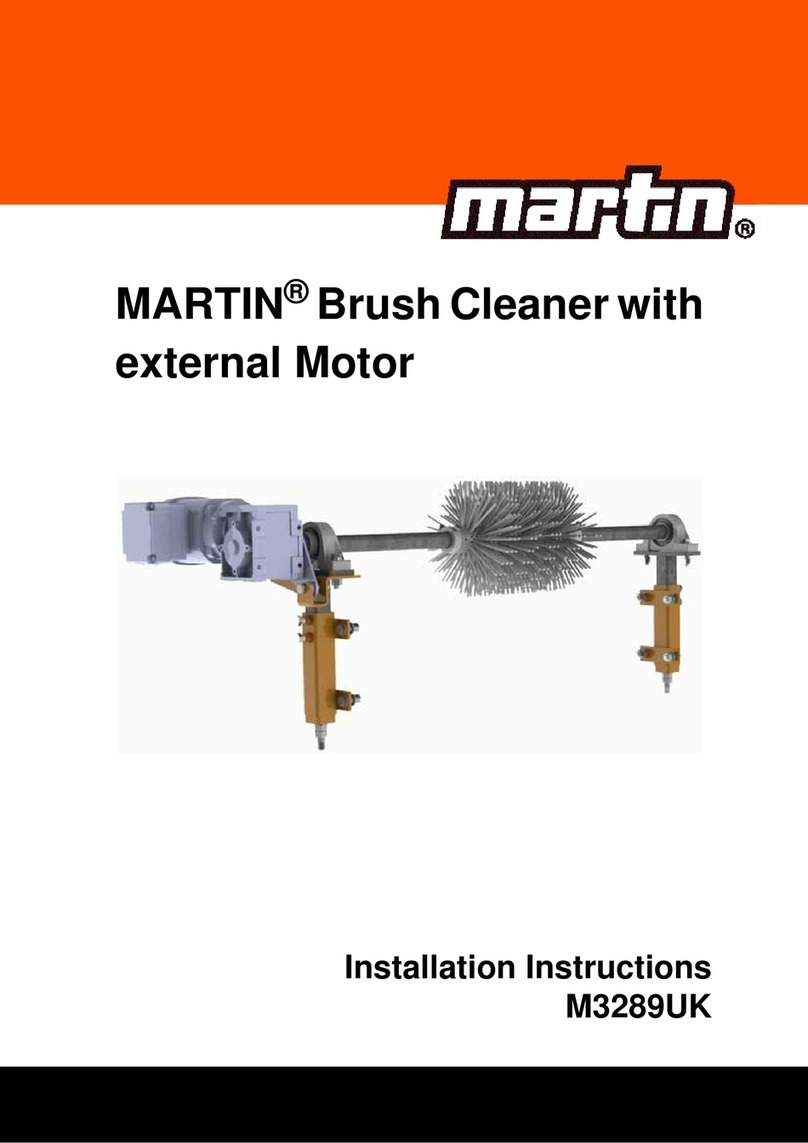

3 Description of the product .............................................. 8

3.1 Design and function ........................................................... 8

3.2 Tensioners ......................................................................... 8

3.3 Type designation................................................................ 8

4 Preparing for the installation .......................................... 9

4.1 Before the installation......................................................... 9

4.1.1 Required materials and tools ......................................... 9

4.1.2 Preparatory measures ................................................... 9

4.1.3 Removal of the tensioner ............................................. 10

5 Installation ...................................................................... 12

5.1 Safety information ............................................................ 12

5.2 Installation process .......................................................... 13

5.2.1 Determination of the installation position ..................... 13

5.2.2 Installing the tensioner................................................. 18

5.2.3 Installing the cleaner.................................................... 20

5.2.4 Centring the mainframe beneath the conveyor belt..... 26

5.2.5 Aligning the mainframe parallel to the conveyor belt ... 27

5.2.6 Aligning the mainframe horizontally ............................. 28

5.2.7 Attaching the secondary cleaner ................................. 29

5.2.8 Tensioning the secondary cleaner............................... 30

5.3 Test run ............................................................................ 32

5.4 Placement of the warning labels and warning tags.......... 34

6 Maintenance ................................................................... 35

6.1 Safety information ............................................................ 35

6.2 Weekly maintenance........................................................ 35

6.3 Replacing the blades........................................................ 37

6.3.1 Replacing the blade cartridge...................................... 38

6.3.2 Replacing a single blade ............................................. 41