Contents

1 Safety Information ......................................................................................................................................................................................................1

1.1

Symbols.........................................................................................................................................................................................................................1

1.2

Safety Instructions....................................................................................................................................................................................................2

1.2.1

General Safety Precautions......................................................................................................................................... 2

1.2.2

Battery Handling guide............................................................................................................................................... 2

1.2.3

Response to Emergency Situations............................................................................................................................. 3

1.3

Qualified Personnel..................................................................................................................................................................................................3

2 Product Introduction .................................................................................................................................................................................................4

2.1

General Information ................................................................................................................................................................................................4

2.2

Product Features.......................................................................................................................................................................................................4

2.3

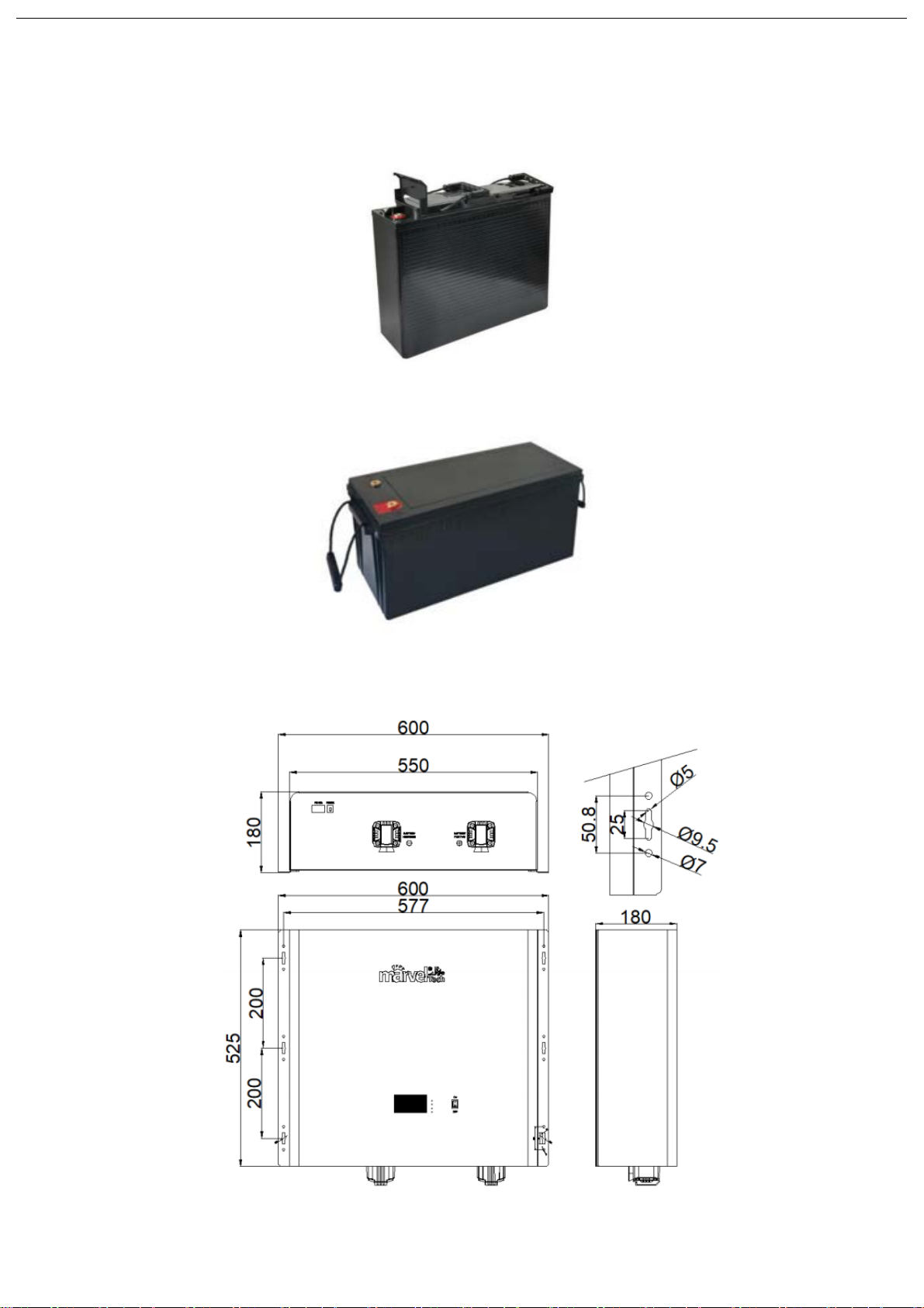

Appernce and Mechanical Drawing ..................................................................................................................................................................5

2.4

Electrical Performance ...........................................................................................................................................................................................7

2.4.1

Battery Pack Parameters ...................................................................................................................................................................................7

2.4.2

BMS and Display....................................................................................................................................................................................................7

2.4.3

Bluetooth & App Function.................................................................................................................................................................................9

2.5

Transportation and Storage .................................................................................................................................................................................9

2.5.1Transportation .......................................................................................................................................................................................................9

2.5.2 Storage......................................................................................................................................................................................................................9

3 Installation .................................................................................................................................................................................................................. 10

3.1

Install Location........................................................................................................................................................................................................ 10

3.2

Tools/Safety Gears Required............................................................................................................................................................................ 10

3.2.1Tools ........................................................................................................................................................................................................................ 10

3.2.2Safety Gears For Personal Protection........................................................................................................................................................ 10

3.3

DC Cable Prepared................................................................................................................................................................................................. 11

3.3.1Choose DC Cable ................................................................................................................................................................................................. 11

3.3.2Fabrication of DC Cable ................................................................................................................................................................................... 11

3.4

Battery Pack Installation .................................................................................................................................................................................... 13

3.4.1Battery Installation............................................................................................................................................................................................ 13

3.4.2Battery Parallel Installation Guide..........................................................................................................................................................................15

3.4.3System Installation Guide............................................................................................................................................................................................15

4 Commissioning and operation ........................................................................................................................................................................................16

4.1

Operating Conditions ........................................................................................................................................................................................... 16

4.2

Battery Commissioning Steps........................................................................................................................................................................... 16

4.3

Communication Protocol Setting .................................................................................................................................................................... 17

4.3.1Setting By Battery LCD..................................................................................................................................................................................... 17

4.3.2Setting By BMS Host Software(PC)............................................................................................................................................................. 18

4.4

Communication with INVERTER or MPPT................................................................................................................................................. 20

4.4.1Master/RS485/CAN Ports Introduction .................................................................................................................................................. 20

4.4.2Dial switch setting ............................................................................................................................................................................................. 21

5 Troubleshooting........................................................................................................................................................................................................ 21

6 Liability Limitation .................................................................................................................................................................................................. 22