cod. F07011720

2 - EN

Technical specification

Technical specification.................................. 4

Technical specification - Hitch...................... 8

Safety signs

Safety-Alert symbol ...................................... 9

Machine identification................................... 9

Serial no label............................................... 9

Machine safety labels................................... 9

Labels and positions

Machine safety labels and positions............. 10

Machine labels and positions....................... 11

Preparing the vehicle

Preparing the tractor..................................... 12

Park vehicle safety........................................ 12

Stay clear of rotating drivelines .................... 12

Installing

Installing tiller on tractor................................ 12

PTO shaft ..................................................... 14

PTO shaft with clutch ................................... 15

Torque Table / Torque Setting........................ 15

Quick Coupler (optional)............................... 16

Park vehicle safety........................................ 16

Stay clear of rotating drivelines .................... 16

Removing

Removing tiller.............................................. 17

Removing tiller with Quick Coupler............... 17

Operating

Operate safely.............................................. 18

Wear appropriate clothing ............................ 19

Stay clear of rotating drivelines .................... 19

Raising parking stand................................... 19

Lowering parking stand ................................ 19

Levelling attachments (side-to-side)............. 20

Levelling tiller (front-to-rear).......................... 20

Adjusting skid shoes .................................... 20

TABLE OF CONTENTS

Tiller depth adjustment................................. 21

Adjusting levelling board............................... 21

Tilling tips..................................................... 22

During tilling ................................................. 22

Replacement parts ....................................... 22

Service Machine Safely

Practice safe maintenance........................... 23

Wear appropriate clothing ............................ 23

Stay clear of rotating drivelines .................... 23

Service lubrication

Service lubrication........................................ 24

Every 8 work hours / After every use............ 24

Every 50 work hours / ~Every week ............. 24

Every 400 work hours / ~8 weeks................. 24

Lubricant points............................................ 25

Lubricants..................................................... 25

Screw tightening torques.............................. 25

Service

Service intervals........................................... 26

Replacing tines............................................. 26

Tines............................................................. 26

Troubleshooting

Using troubleshooting chart ......................... 27

Storing machine

Storing tiller .................................................. 28

Removing tiller from storage......................... 28

Assembly / Spare parts

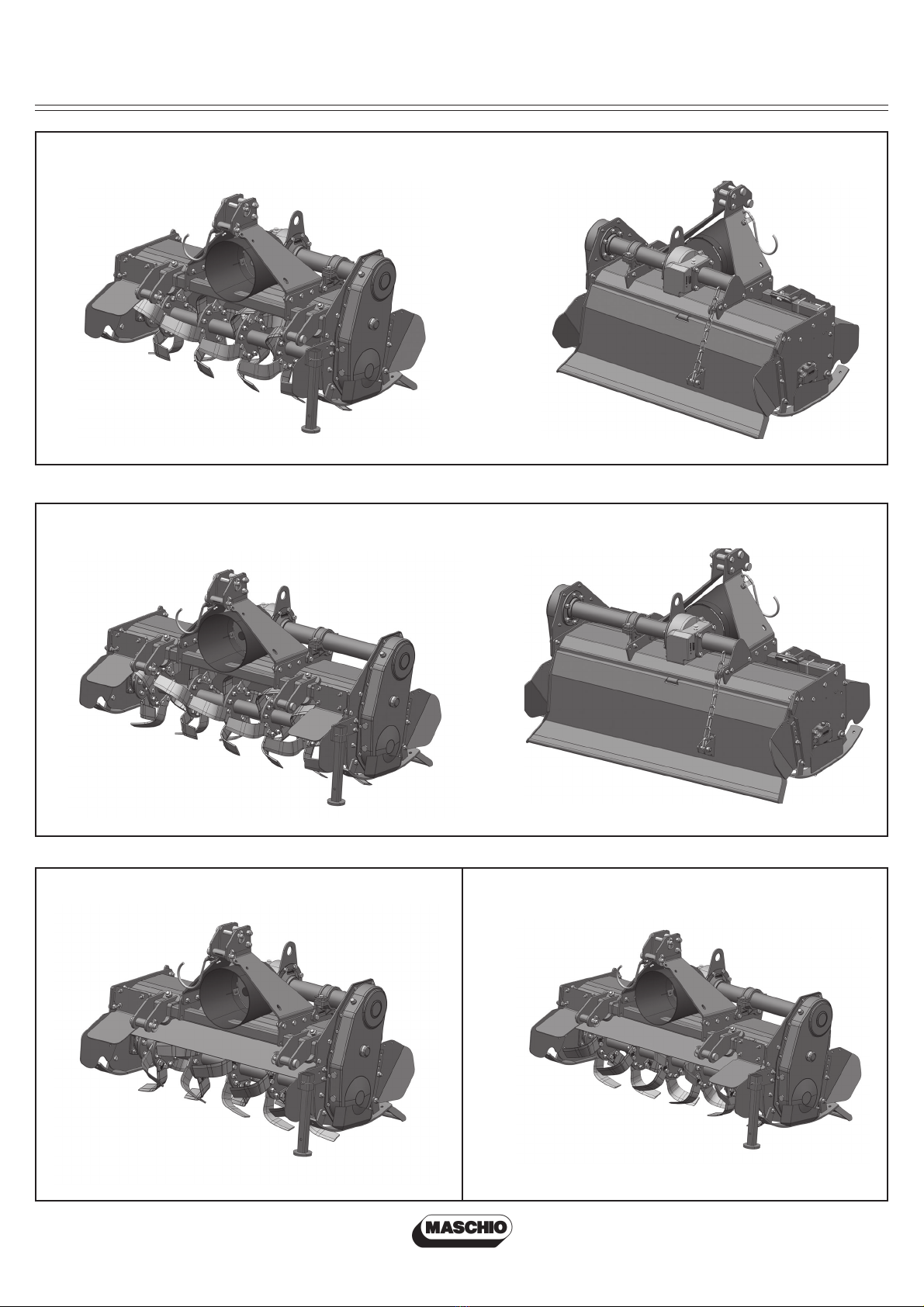

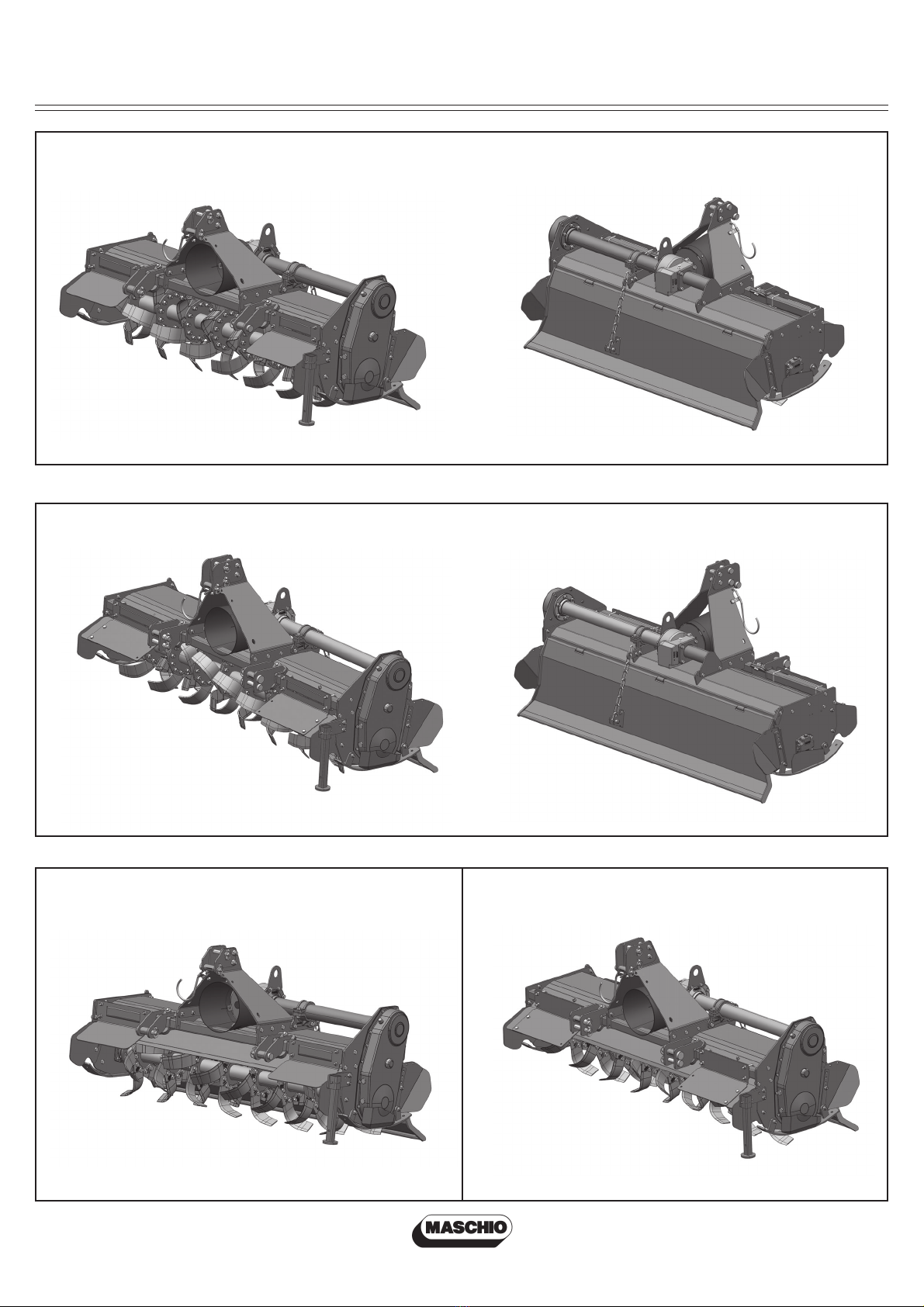

WW 6042-6042R-6049-6049R-6062-6062R

.....30

WW 6073-6073R...........................................34

Installing safety guards................................. 38

Installing reverse shield................................ 42

Lift hook assembly procedure ...................... 44

Installing driveline on tiller ............................ 44

Spare parts................................................... 44