1

1

3

4

5

2

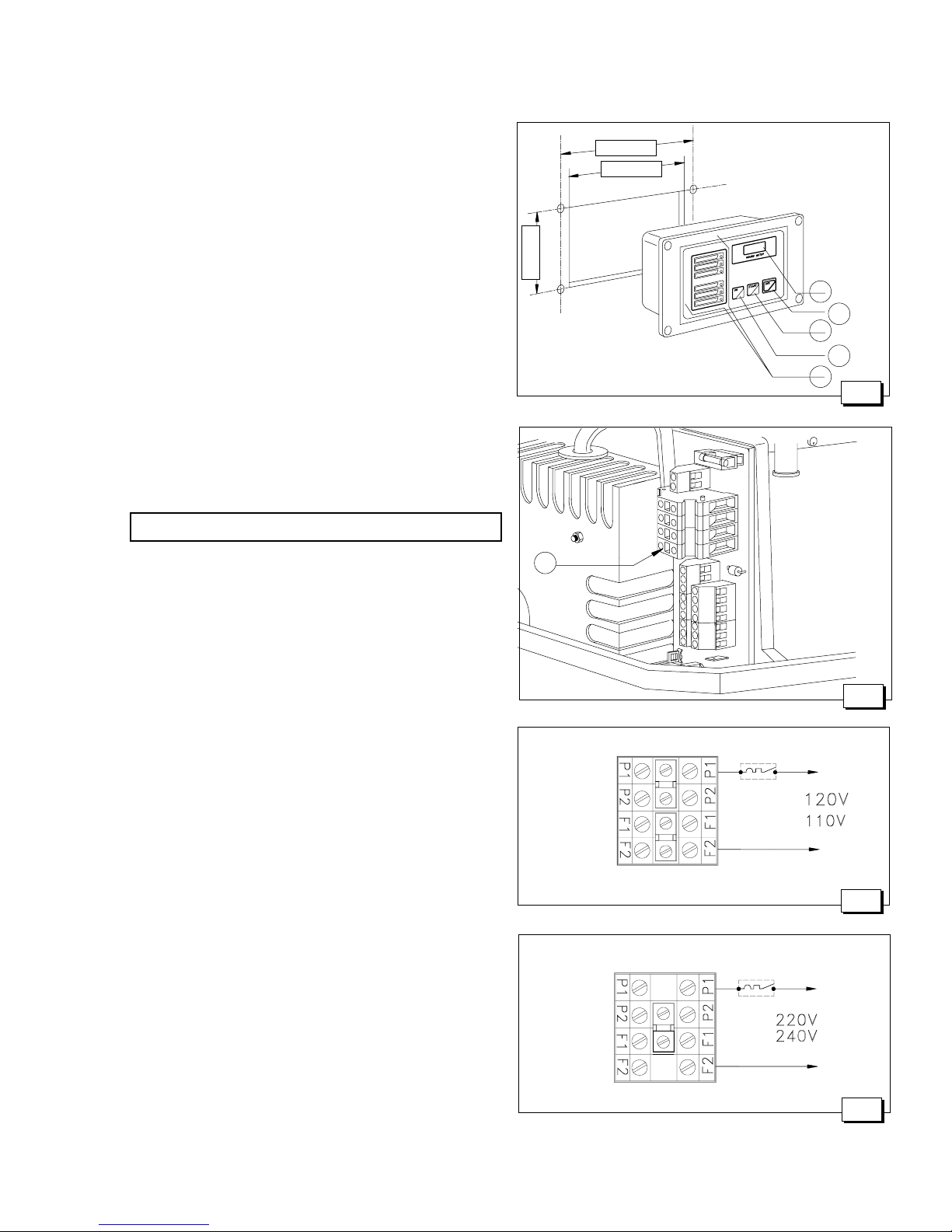

Fig.14

Fig.15

Fig.17

Fig.16

4.0. ELECTRICAL CONNECTIONS

4.1. Battery connection

To start the genset, an independent 12V battery, 18 - 30

capacity Ah min is needed.

It should be connected to the generator as shown in fig.

11 with cables up to 16'. For longer distances, follow the

sequence of operations described below:

- First connect the positive pole (+) of the battery to the

terminal marked with the symbol (+) on the generator,

(the starter).

- Then connect the negative pole (-) of the battery to the

terminal marked with the symbol (-) on the generator.

- Apply non-conductive grease to the connections to

protect against oxidation and corrosion.

- The generator has a built-in 10A charging circuit to

automatically recharge the start-up battery, giving

10 A, at a voltage of 12 V, when fully charged.

IMPORTANT

Install the battery in a well-ventilated area, away

from the generator and from any device which might

produce heat or sparks.

Periodically check the state of the connections of

the terminals and the water level of the battery. If the

cables need to be disconnected, follow the

instructions for connection in reverse order.

Do not invert the poles of the connecting cables

since serious damage might be caused to the

generator and the battery.

Do not connect other loads to the battery.

In order to minimize galvanic currents, the (-) of the

battery of the electric generator should not be connected

to the (-) of the other batteries on board.

4.2. Control panel connection

This connection can be made with the terminal strips (fig.

12, ref. 1) using the cables already connected to the

control panel. The terminals to be used are those marked

1 to 9 for the control cables. The ground should be

connected to the push-on terminal (fig. 12, ref. 3) insulating

them carefully and using a pre-insulated female push-on

connection. In making the connections it is important to

follow the diagram and the colours codes as indicate (fig.

13). Fasten the cable with the provided plastic support on

the bail (fig. 12, ref. 3).

The control panel contains 5 LEDs for operation and

alarm (fig. 14, ref. 1), an hour counter (fig. 14, ref. 2) and

the start and stop buttons (fig. 14, ref. 3/4/5).

For fixing the control panel is necessary to perforate as

shown in fig.14.

9

5-1/32"

4-3/4"

3-3/8"