6

OCCLUSION ADJUSTMENT

(on 77201-60, -62 models only)

Adjust occlusion setting near top of pump head. (Figure #5.)

“4” for nominal performance;

“5” for increased pressure/vacuum

with reduced tubing life;

“2” or “3” for longer life with less

pressure and vacuum.

NOTE: For optimum performance,

turn knob to “1” after loading. Start

drive and adjust knob until pump primes

and fluid begins to flow.

NOTE: Occlusion usually does not need

to be readjusted when changing tubing.

MULTI-CHANNEL MOUNTING

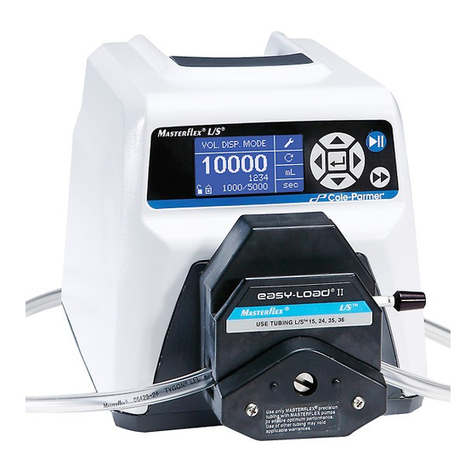

L/S EASY-LOAD II Pump Heads can be mounted in tandem (up to four), depending

on the torque capabilities of the drive. (See Figure #6.)

Special mounting hardware is required.

See REPLACEMENT PARTS AND ACCESSORIES for mounting hardware.

Figure #6. Multi-channel Mounting

CAUTION: DO NOT OVER-TIGHTEN SCREWS ORWING NUTS.

NOTE: The L/S EASY-LOAD II Pump Head can be used in any combination with

other L/S EASY-LOAD Pump Heads. The longer L/S EASY-LOAD II mounting

hardware is required (not supplied).

NOTE: The tubing on the inside L/S EASY-LOAD II Pump Head(s) can be changed.

OCCLUSION SETTING

INDICATOR WINDOW

OCCLUSION

ADJUSTMENT

KNOB

TUBING

LOADING

LEVER

Figure #5. Adjust Occlusion

SPECIFICATIONS

Pump Head Number Pump Material Occlusion Shaft Length L/S®Tubing

77200-50 PPS/CRS Fixed Short L/S®13,14,16,25,17,18

77202-50 PPS/CRS Fixed Short L/S®13,14,16,25

77200-52 PPS/CRS Fixed Short L/S®15,24,35,36

77200-60 PPS/SS Fixed Short L/S®13,14,16,25,17,18

77202-60 PPS/SS Fixed Short L/S®13,14,16,25

77200-62 PPS/SS Fixed Short L/S®15,24,35,36

77200-70 PPS/CRS Fixed Long L/S®13,14,16,25,17,18

77200-72 PPS/CRS Fixed Long L/S®15,24,35,36

77200-80 PPS/SS Fixed Long L/S®13,14,16,25,17,18

77200-82 PPS/SS Fixed Long L/S®15,24,35,36

77201-60 PPS/SS Adjustable Short L/S®13,14,16,25,17,18

77201-62 PPS/SS Adjustable Short L/S®15,24,35,36

Typical Flow, Pressure and Vacuum Data

L/S®Flow rate Max. Discharge Pressure* Vacuum* Suction Lift*

Tubing @1 rpm @ 600 rpm psig (bar) @600 rpm @600 rpm

mL/Rev mL/min in (mm) Hg ft (m) H20

L/S®13 0.06 36 40 (2.7) 26 (660) 29 (8.8)

L/S®14 0.22 130 40 (2.7) 26 (660) 29 (8.8)

L/S®16 0.80 480 40 (2.7) 26 (660) 29 (8.8)

L/S®25 1.7 1000 35 (2.4) 26 (660) 29 (8.8)

L/S®17 2.8 1700 20 (1.4) 20 (510) 22 (6.7)

L/S®18 3.8 2300 5 (1.0) 20 (510) 22 (6.7)

L/S®15 1.7 1000 40 (2.7) 26 (660) 29 (8.8)

L/S®24 2.8 1700 40 (2.7) 26 (660) 29 (8.8)

L/S®35 3.8 2300 35 (2.4) 26 (660) 29 (8.8)

L/S®36 4.8 2900 20 (1.4) 24 (610) 27 (8.3)

Number of rollers: 4

Maximum pump speed (rpm): 600

Nominal torque load—Running: up to 90 oz-in (6.5 kg•cm)

Housing materials: Polyphenylene sulde (PPS), acetal, nylon

Roller materials: Cold-Rolled Steel (CRS) / Stainless Steel (SS)

Bearing materials: Cold-Rolled Steel (CRS) / Sealed Stainless Steel

Rotor materials: Stainless Steel (SS)

Operating Temperature‡:32°F to 104°F (0°C to 40°C)

Storage Temperature: –49°F to 149°F (–45°C to 65°C)

Humidity: 0% to 90% (non-condensing)

Dimensions (W xH xD):

Operating: 4 in x 4-3/4 in x 2-3/4 in (102 mm x 121 mm x 70 mm)

Open: 4 in x 5-1/2 in x 2-3/4 in (102 mm x 140 mm x 70 mm)

Weight: 1.4 lb (0.6 kg)

Noise level: <70 dBA @ 1 meter

Compliance (for CE mark): EN809 (EU Machinery Directive)

*As tested with NORPRENE®, PHARMED®BPT, and TYGON®tubing.

Values will be less with silicone and C-FLEX®.

‡ Use in this temperature range for continuous duty operation with no decrease in performance or

product life. Pump heads will work outside this range with some possible reductions in performance

or product life.

3