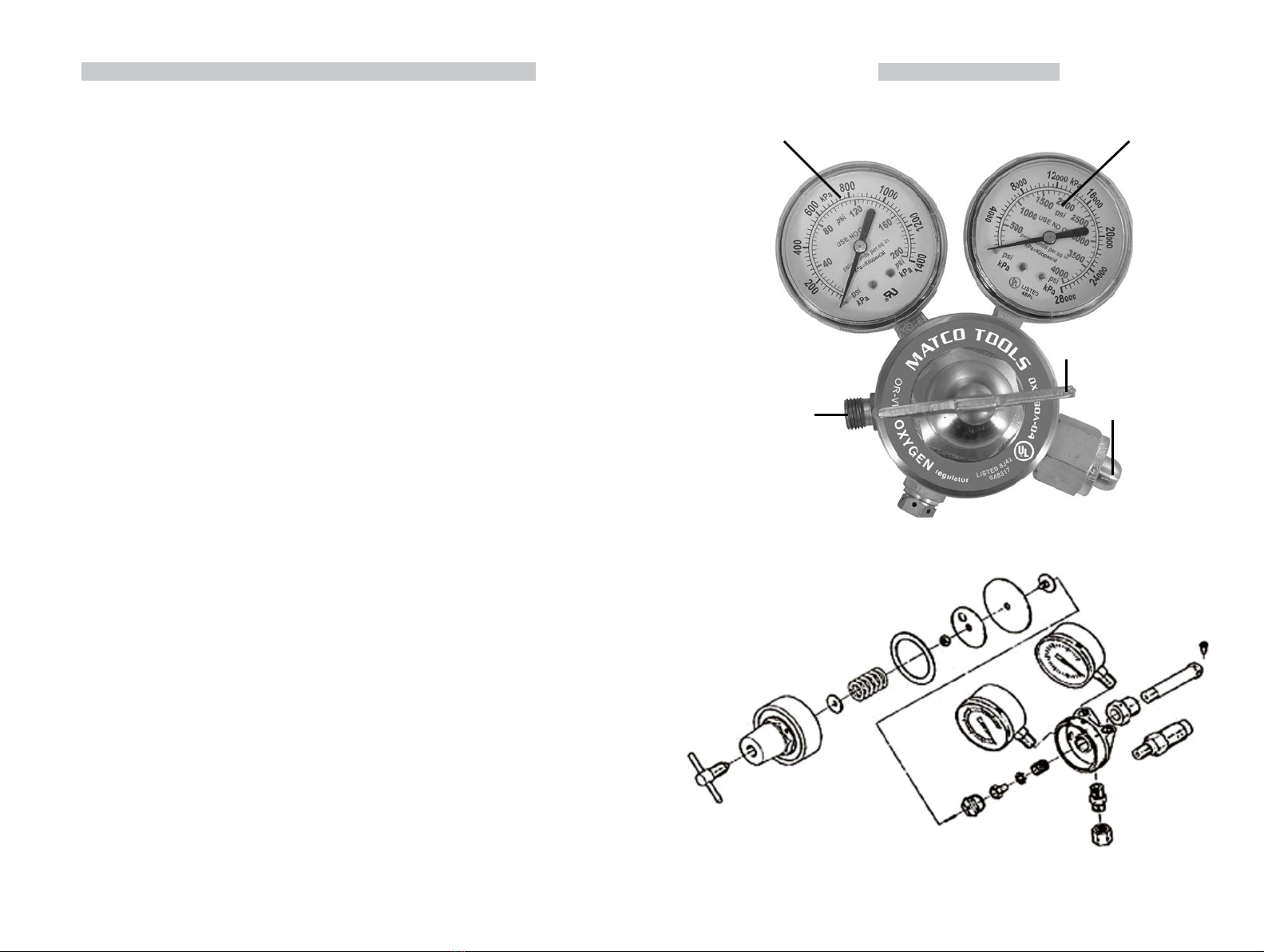

There must

be 2 O-rings

on the cone end. The absence of

either O-ring can lead to ashback

within the torch handle or cutting

attachment.

For cutting attachment, inspect the

tampered seating surfaces on tip

and in torch head. Have a qualied

technician resurface the seat area if it

has dents, burrs or is burned. A poor

seating surface may result in backre

of ashback.

The following

instructions are

for acetylene gas use only. Contact

your gas supplier for instructions on

the use of other fuel gases.

17

WARNING

NOTICE

WARNING

16

Safety Guidelines BACKFIRE AND FLASHBACK

When the ame goes out with a loud

pop, it is called a backre. Backre

can be caused by

(1) Operating the torch at lower

pressures than required for

the tip used,

(2) Touching the tip against the work,

(3) Overheating tip or,

(4) An obstruction in the tip.

If backre occurs, shut off the

torch handle valves (oxygen

rst) and after remedying the

cause relight the torch.

A ashback is a condition that

results when the ame ashes back

into the torch and burns inside with

a shrill hissing or squealing noise.

If ashback occurs, turn off the

torch handle valves (oxygen rst)

IMMEDIATELY. Flashback generally

indicates a problem that should

be xed. A clogged tip, improper

functioning of the valves, or incorrect

acetylene / oxygen pressure could

lead to ashback. Be certain to nd

the cause before relighting the torch.

WARNING

DANGER

CAUTION

NOTICE

WARNING

WARNING

Flying sparks and

hot metal can cause

injury. Take necessary

precautions to reduce

the possibility of injury from ying

sparks and hot metal.

WARNING

WARNING

Oxy-fuel perations

cause sparks

and heat metal to

temperatures that

can cause severe

burns! Use protective gloves and

clothing when performing any metal

working operation. Take necessary

precautions to reduce the possibility

of skin and clothing burns.

• Keep all clothing and protective

equipment free of oil and

grease.These substances can

ignite and will burn violently in

the presence of pure oxygen.

Always keep an

approved re

extinguisher

accessible while

performing oxy-fuel operations.

Danger means a

hazard that will

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It may also mean

a hazard that will only cause damage

to property.

Notice means

any additional

information pertaining to the product

or its proper usage.

Oxy-fuel

operations

produce intense light and heat and

ultraviolet (UV) rays. The intense

light and UV rays can cause injury

to eyes and skin. Take all

precautions described in the

manual to reduce the possibility of

injury to eyes and skin.

• All person operating this equipment

or in the area while equipment is in

use must wear protective welding

gear including: welding goggles

with a minimum shade 5, ame

resistant clothing, leather welding

gloves, and full foot protection.

• Make sure that all persons in the

welding area are protected from

heat, sparks, and ultraviolet rays.

Use ame resistant barriers

as needed.

• Never touch work pieces until

completely cooled.

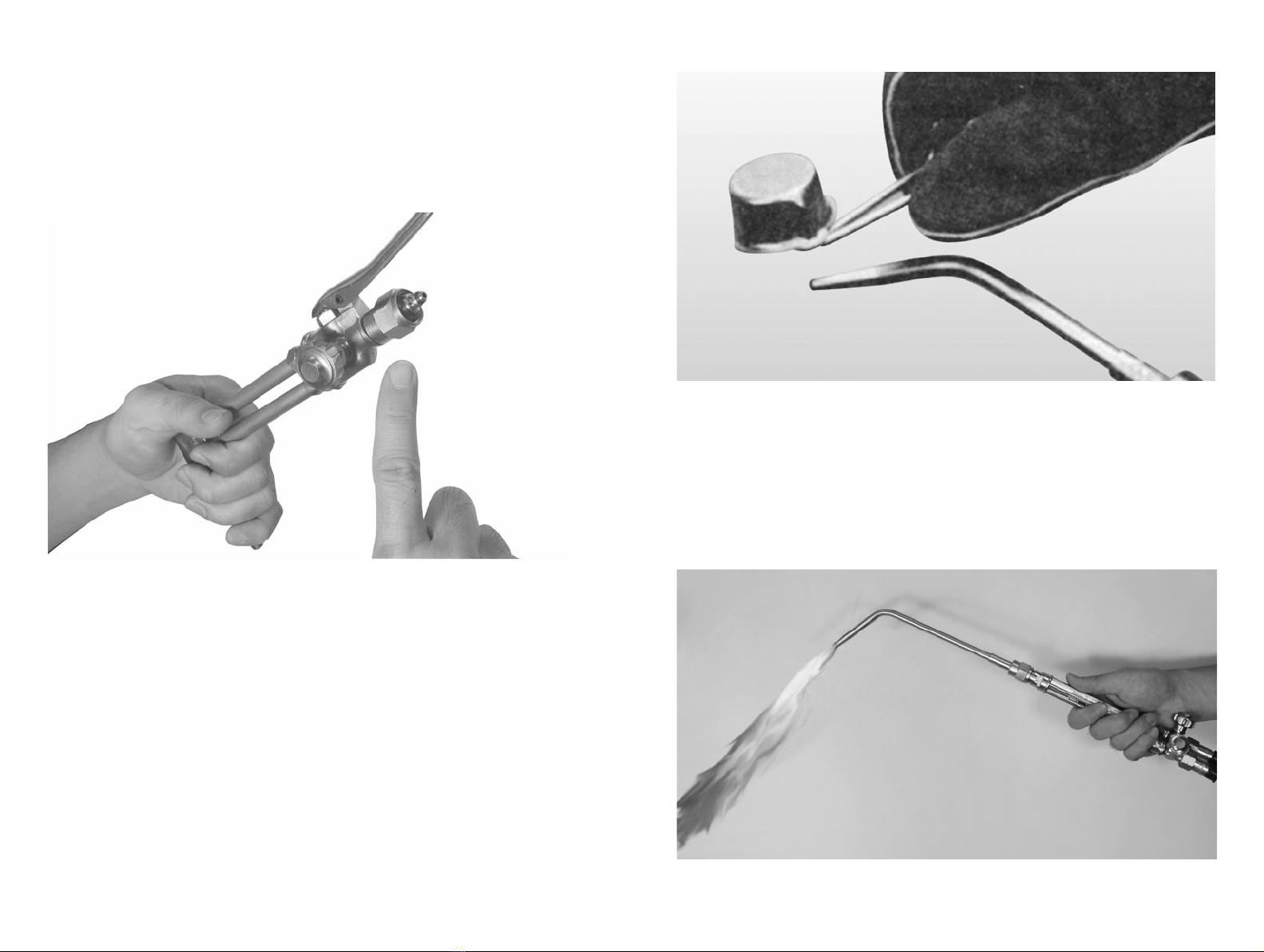

Lighting Torch

Before lighting

the torch, follow

all personal and equipment safety

regulation. Wear ltered protective

eyewear (shade 5 minimum) to

protect the eyes from heat, sparks

and hazardous rays of light produced

by the ame. Keep work area well

ventilated.

• Wear ANSI approved face shield

or safety glasses with side shield

protection when chipping

or grinding metal parts.

• Wear ear plugs when welding

overhead to prevent spatter or

slag from falling into ears.

General Safety Operation